Cast film slurry of ultrathin lamination flaky inductor and manufacturing method for cast film of ultrathin lamination flaky inductor

An ultra-thin laminated sheet type and production method technology, which is applied in the production field of casting film slurry and casting film, can solve the problem of increasing the density of the green sheet of the film, low viscosity of the casting slurry, and increase of the viscosity of the slurry, etc. problems, to achieve the effect of enhanced ductility, uniform and stable slurry, and reduced viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

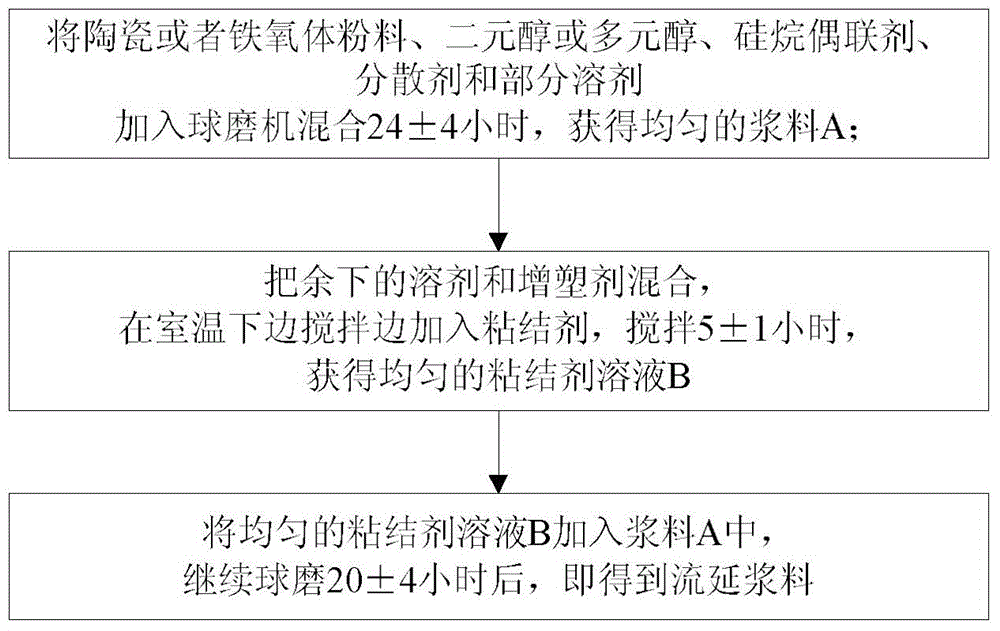

Method used

Image

Examples

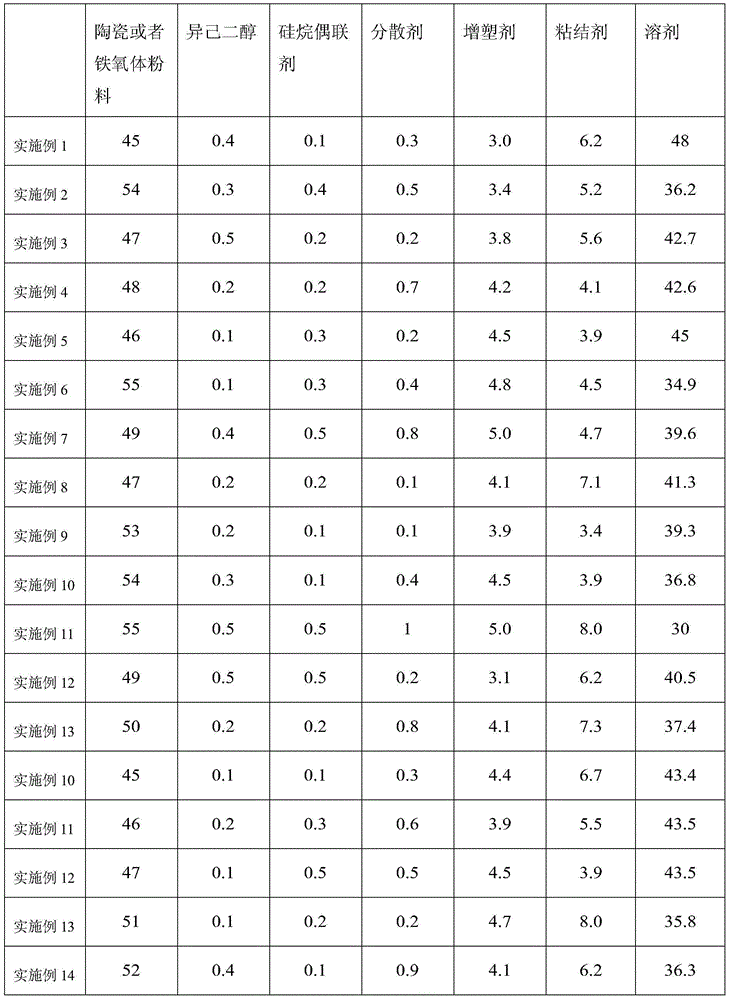

Embodiment 1

[0049] The ratio of raw materials is: ceramic powder 50%, isohexanediol 0.2%, silane coupling agent 0.2%, castor oil (dispersant) 0.2%, polyethylmethacrylate (binder) 7%, triglyceride Alcohol diisocaprylate (plasticizer) 5%, solvent 37.4%.

[0050] Proceed as follows:

[0051] A. After weighing 50kg of ceramic powder, 0.2kg of castor oil (dispersant), 9.5kg of ethanol, 9.2kg of methyl ethyl ketone, 0.2kg of isohexanediol and 0.2kg of silane coupling agent, add them into a ball mill and mix for 24±4 hours , to obtain a uniform slurry; the particle size D50 of the ceramic powder is 0.6 μm; the solvent composed of ethanol and butanone accounts for 50% of the total solvent mass;

[0052] B. After weighing 11.22kg of ethanol, 7.48kg of methyl ethyl ketone, 7kg of polyethyl methacrylate (binder), and 5kg of triethylene glycol diisocaprylate (plasticizer), the solvent (ethanol, butyl Ketone) and plasticizer are mixed, then add binding agent while stirring at room temperature, stir ...

Embodiment 2

[0057] The ratio of raw materials is: 53% of ferrite powder, 0.4% of isohexanediol, 0.1% of silane coupling agent, 0.4% of tributyl phosphate (dispersant), 5.3% of polyvinyl butyral (binder) %, triethylene glycol diisocaprylate (plasticizer) 4.5%, solvent 36.3%.

[0058] Proceed as follows:

[0059] A. Weigh 53kg of ferrite powder, 0.4kg of tributyl phosphate (dispersant), 14.52kg of ethyl acetate, 3.63kg of butanol, 0.4kg of isohexanediol and 0.1kg of silane coupling agent, and add them together The ball mill was mixed for 26 hours to obtain a uniform slurry; the particle size D50 of the ceramic powder was 0.4 μm; the solvent composed of ethyl acetate and butanol accounted for 50% of the total solvent mass;

[0060] B. After weighing 12.1kg of ethyl acetate, 6.05kg of butanol, 7kg of polyvinyl butyral (binder) and 5kg of dibutyl phthalate (plasticizer), the solvent (ethyl acetate) ester, butanol) and a plasticizer, then add the binder while stirring at room temperature, and...

Embodiment 3

[0065] The ratio of raw materials is: 50% of ferrite powder, 0.2% of pentaerythritol, 0.2% of silane coupling agent, 0.8% of polyethylene glycol octyl phenyl ether (dispersant), polyethyl methacrylate (bonding agent) Agent) 5.0%, butyl benzyl phthalate (plasticizer) 4.7%, solvent 39.6%.

[0066] Proceed as follows:

[0067] A. Weigh 50kg of ferrite powder, 0.8kg of polyethylene glycol octylphenyl ether (dispersant), 12.6kg of propyl acetate, 3.24kg of butanol, 0.2kg of pentaerythritol and 0.2kg of silane coupling agent , added together into a ball mill and mixed for 26 hours to obtain a uniform slurry; the particle size D50 of the ceramic powder is 0.5 μm; the solvent composed of propyl acetate and butanol accounts for 40% of the total solvent mass;

[0068] B. After weighing 19.21kg of propyl acetate, 4.55kg of butanol, 5kg of polyethyl methacrylate (binder), and 4.7kg of butyl benzyl phthalate (plasticizer), the solvent (acetic acid Propyl ester, butanol) and plasticizer a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com