High voltage direct current contactor with magnetic coil arc quenching

A high-voltage DC, contactor technology, applied in electromagnetic relays, electromagnetic relay details, relays, etc., can solve problems such as high operating voltage requirements, burning of main contacts, inability to pull off, etc., to enhance the induction magnetic field, safety The effect of reliable contact and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Suppose the rated working current is 250A, and its working voltage is 1500V~2000V.

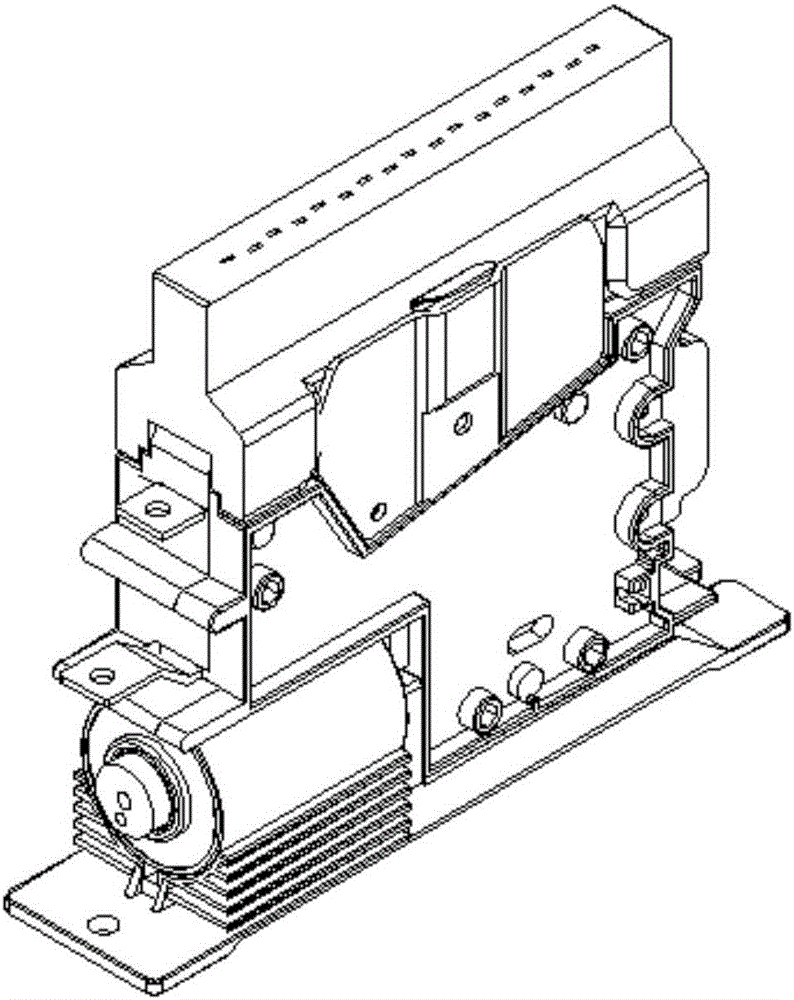

[0057] Such as Figure 7 As shown, the realization principle of this technical solution:

[0058] Current flow direction of the product: the positive pole of the power supply is connected to the moving contact 8; the moving contact 8 is connected to the moving contact 2 9 and the arc reed B12; the static contact 1509 is connected to the load.

[0059] When the active contact A11 and the static contact three 1511 are in conduction and are connected stably, the current flows from the moving contact one 8 to the moving contact two 9, through the active contact A11 and the static contact three 1511, and the static contact one 1509 Through, forming a current loop with the load.

[0060] At the moment when the auxiliary moving contact A902 and the static contact piece 1512 are turned on and off, the contact between the moving contact A902 and the static contact piece 1512 generates an arc due to hig...

Embodiment 2

[0066] In addition, the contact material no longer uses AgCu, AgNi and other materials, but adopts the addition of trace rare metal elements in the AgSnO2 alloy. This material has high thermal stability, welding resistance and low material transfer characteristics. SnO2 particles In silver melting, the viscosity of molten metal can be increased and arc erosion can be reduced. After repeated arc action, the SnO2 component can still be retained on the contact surface, and the arc erosion resistance and fusion welding resistance of the contact will not be significantly reduced, so it has a high service life, so AgSnO2 has excellent arc erosion resistance and wear resistance Damage and improve the ablation resistance of the product.

Embodiment 3

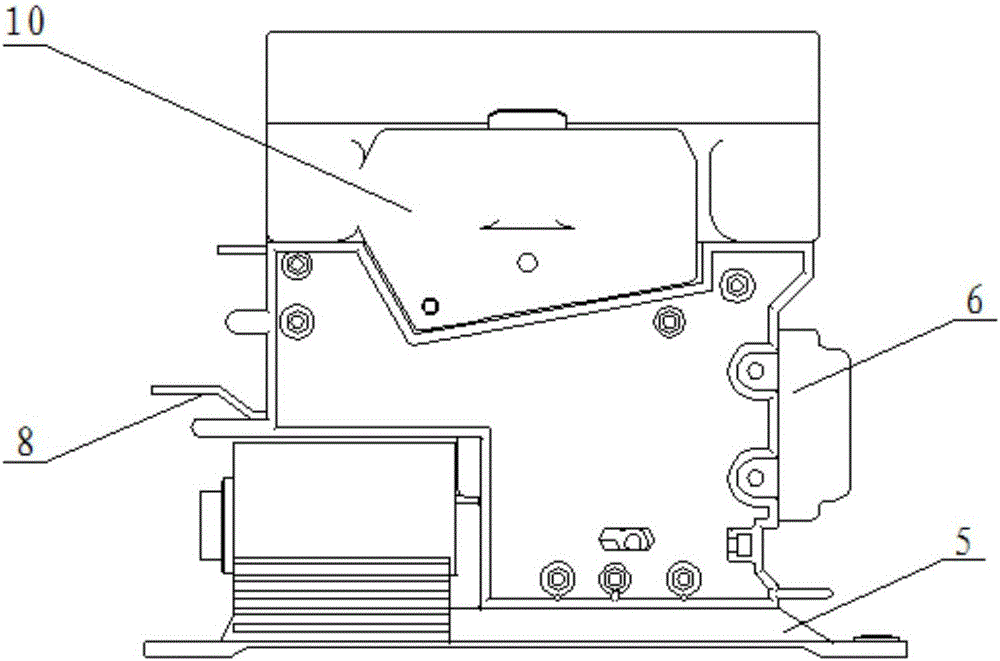

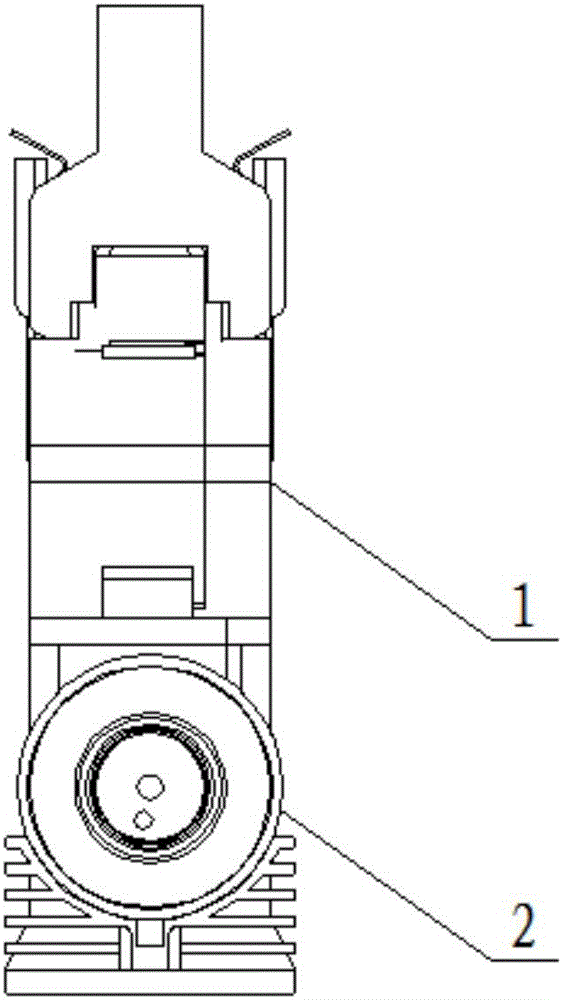

[0068] When the 110V power supply voltage is applied to the coil of the electromagnet assembly 2, the electromagnet assembly 2 starts to move under the action of the magnetic force, driving the push rod 18 to move, and the pushing rod 18 pushes the reed 14, which is attached to the micro switch 6, so that The micro switch 6 is turned on to realize the control signal output.

[0069] At the same time, the push rod 18 drives one end of the pendulum rod 13 to swing around its hinge point to a certain extent, and the movable contact piece 9 rotates counterclockwise accordingly. The auxiliary moving contact A902 first contacts the static contact piece 1502. At the moment of contact, the current flows through Movable connecting piece 8, moving connecting piece 9, auxiliary moving contact A902, static connecting piece 1512, adjusting screw 1501, magnetic ring coil 1506, embedded nut B1504, static connecting piece 1 1509 to the load, forming an instantaneous loop, An arc is generated bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com