A kind of shell-core structure mxene@max composite contact reinforcement phase material and preparation method thereof

A composite contact, shell-core structure technology, applied in electrical components, circuits, electrical switches, etc., can solve the problems of inability to enhance the effect of Ag matrix, not Ag/CdO, and not finding electrical contact materials, and achieve resistance to arc erosion. Excellent performance, simple preparation process, good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

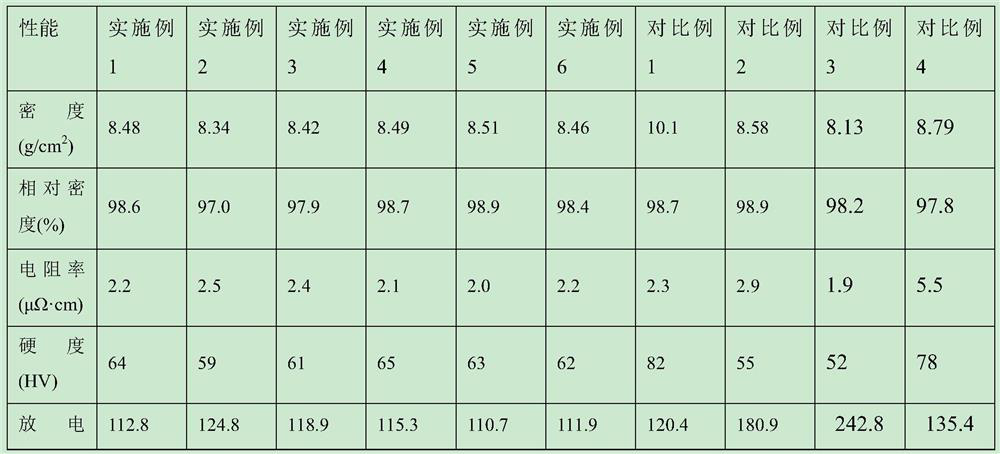

Examples

Embodiment 1

[0039] 10g Ti 3 SiC 2 The powder is added into the HF acid solution with a concentration of 20wt% according to the mass ratio of liquid: solid = 20:1, and stirred at a speed of 50rpm in a magnetic stirrer at a temperature of 30°C for 1 hour; the mixed solution is poured into a centrifuge tube with a size of 10mL In the centrifuge, it was centrifuged at a set speed of 1000rpm for 1 hour, and the centrifuged mixture was placed in a freeze dryer for 1 hour to freeze-dry to obtain Ti with a core-shell structure. 3 SiC 2 @Ti 3 C 2 Powder; will account for 5% Ti of the overall material mass fraction 3 SiC 2 @Ti 3 C 2 Powder and the Ag powder of massfraction 95% were wet-mixed 0.5 hour (ball: alcohol: powder material=2:1:1) in the ball mill tank that medium is housed, then dried 2 hours to obtain mixed powder; The press was pressed with a pressure of 800MPa and kept for 10 minutes; the block sample was placed in a sintering furnace, and the temperature was raised to 600°C at ...

Embodiment 2

[0041] 25g Ti 3 SiC 2 The powder is added into the HF+FLi acid solution with a concentration of 25wt% according to the mass ratio of liquid: solid=30:1, and stirred at a speed of 78rpm in a magnetic stirrer for 1.8 hours at a temperature of 38°C; the mixed solution is poured into a 25mL container In a centrifuge tube, centrifuge at a set speed of 1800rpm for 1.5 hours in a centrifuge, and the centrifuged mixture is placed in a freeze dryer for 1.5 hours to freeze-dry to obtain Ti with a core-shell structure. 3 SiC 2 @Ti 3 C 2 Powder; will account for 8% Ti of the overall material mass fraction 3 SiC 2 @Ti 3 C 2 Powder and the Ag powder of massfraction 92% were wet-mixed 1 hour (ball: alcohol: powder material=2.5:1.5:1) in the ball mill tank that medium is housed, then dried 3 hours to obtain mixed powder; Compress molding with a pressure of 750MPa in a press for 9 minutes; place the block sample in a sintering furnace, N 2 Under atmosphere protection, the temperature ...

Embodiment 3

[0043] 48g Ti 3 SiC 2 The powder is added into the HF acid solution with a concentration of 28wt% according to the mass ratio of liquid:solid=38:1, and stirred at a speed of 90rpm in a magnetic stirrer for 2.5 hours at a temperature of 42°C; the mixed solution is poured into a centrifuge tube with a size of 50mL In the centrifuge, it was centrifuged at a set speed of 2000rpm for 2 hours, and the centrifuged mixture was placed in a freeze dryer for 2 hours to freeze-dry to obtain Ti with a core-shell structure. 3 SiC 2 @Ti 3 C 2 Powder; Ti will account for 10% of the overall material mass fraction 3 SiC 2 @Ti 3 C 2 Powder and the Ag powder of mass fraction 90% were wet-mixed 1.5 hours (ball: alcohol: powder material=2.8:2:1) in the ball mill tank that medium is housed, then dried 3.5 hours to obtain mixed powder; Compress molding with a pressure of 700MPa in a press and hold for 8 minutes; place the block sample in a sintering furnace, N 2 Under the protection of the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com