A preparation method of silver tin oxide electrical contact alloy with uniform structure

A technology of silver tin oxide with uniform structure, applied in the direction of circuits, electric switches, electrical components, etc., can solve the problems of high contact resistance, poor resistance to arc erosion, and uneven dispersion of electrical contact materials, and achieve good anti-welding performance, Good arc erosion resistance and uniform tissue distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

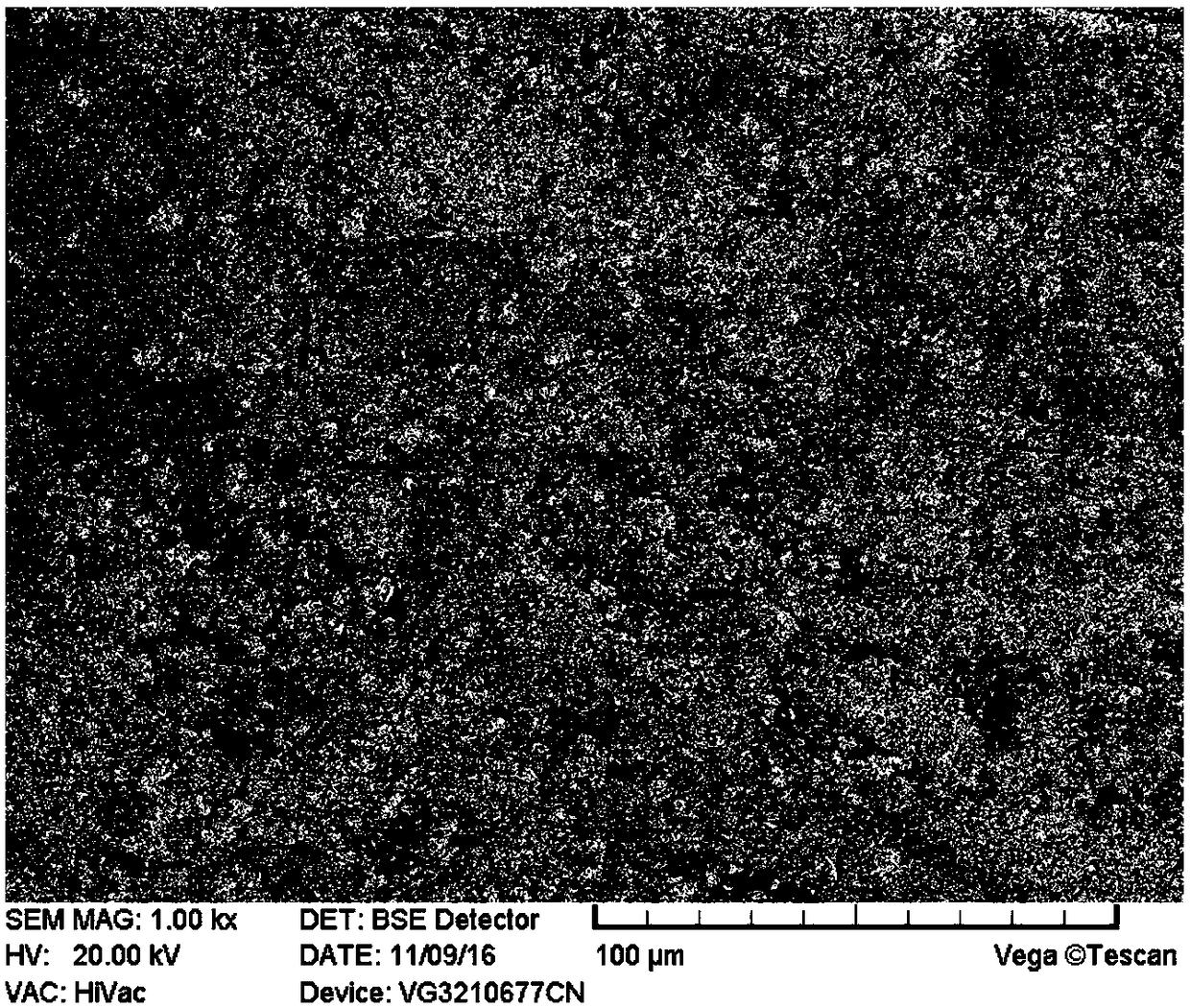

Image

Examples

preparation example Construction

[0029] The preparation of the soluble starch aqueous solution template is as follows: adding soluble starch to distilled water to obtain a soluble starch solution with a mass concentration of 5-10%, heating the soluble starch solution in a water bath, first preheating it in 40-50°C water, and using a temperature control Stir with a magnetic stirrer. As the solution is further heated until it reaches 80°C, the starch is in a gelatinized state, the starch gradually dissolves, and the solution turns from white turbidity to clear, keep warm for 15 minutes, and then cool to 55-65°C to obtain a soluble starch aqueous solution template.

[0030] Add the mixed solution prepared in step 2 into the soluble starch aqueous solution template, and perform magnetic stirring at 45-55° C. for 1-2 hours. The volume ratio of distilled water to the mixed solution prepared in step 2 is 1-1.5:2.

[0031] Step 4, preparing silver tin oxide composite powder:

[0032] Put the mixed solution obtained...

Embodiment 1

[0040] Step 1, preparing HNO for dissolving Sn powder 3 solution and AgNO 3 Mixture of solutions:

[0041] Add Sn powder to HNO with a mass fraction of 65% 3 Stir evenly in the solution to obtain a Sn powder suspension. Slowly add the prepared Sn powder suspension to 1mol / L AgNO 3 aqueous solution to obtain a mixed solution. Among them, Sn powder and HNO 3 The ratio of the amount of substance is 3:2, Sn powder and AgNO 3 The ratio of the amount of substances is 1:1.

[0042] Step 2, add citric acid solution dropwise to the mixed solution and stir well:

[0043] The mixed solution prepared in step 1 was magnetically stirred at 50° C. for 2 hours, and 3 mol / L citric acid solution was added dropwise during the first half hour of stirring. Wherein the amount of citric acid substance and AgNO 3 The ratio to the sum of the amount of Sn powder is 1:1.

[0044] Step 3, add to the soluble starch aqueous solution, and stir evenly:

[0045] The preparation of the soluble starc...

Embodiment 2

[0052] Step 1, preparing HNO for dissolving Sn powder 3 solution and AgNO 3 Mixture of solutions:

[0053] Add Sn powder to HNO with a mass fraction of 66% 3 Stir evenly in the solution to obtain a Sn powder suspension. Slowly add the prepared Sn powder suspension to 1.5mol / L AgNO 3 aqueous solution to obtain a mixed solution. Among them, Sn powder and HNO 3 The ratio of the amount of substance is 3:2, Sn powder and AgNO 3 The ratio of the amount of substances is 1:1.

[0054] Step 2, add citric acid solution dropwise to the mixed solution and stir well:

[0055] The mixed solution prepared in step 1 was magnetically stirred at 55° C. for 3 hours, and 4 mol / L citric acid solution was added dropwise during the first half hour of stirring. Wherein the amount of citric acid substance and AgNO 3 The ratio of the sum of the amount of the Sn powder and the amount of the substance is 2:1.

[0056] Step 3, add to the soluble starch aqueous solution, and stir evenly:

[0057...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com