MAX@MOm/AOn electrical contact reinforced phase material, composite electrical contact material and preparation method

An electrical contact material and reinforcing phase technology, applied in the field of composite electrical contact materials and preparation, MAX@MOm/AOn electrical contact reinforcing phase materials, can solve the problem of restricting the industrialization process and damaging the conductivity of Ag/MAX composite materials and other problems, to achieve the effect of remarkable silver saving effect, excellent arc erosion resistance and good processability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

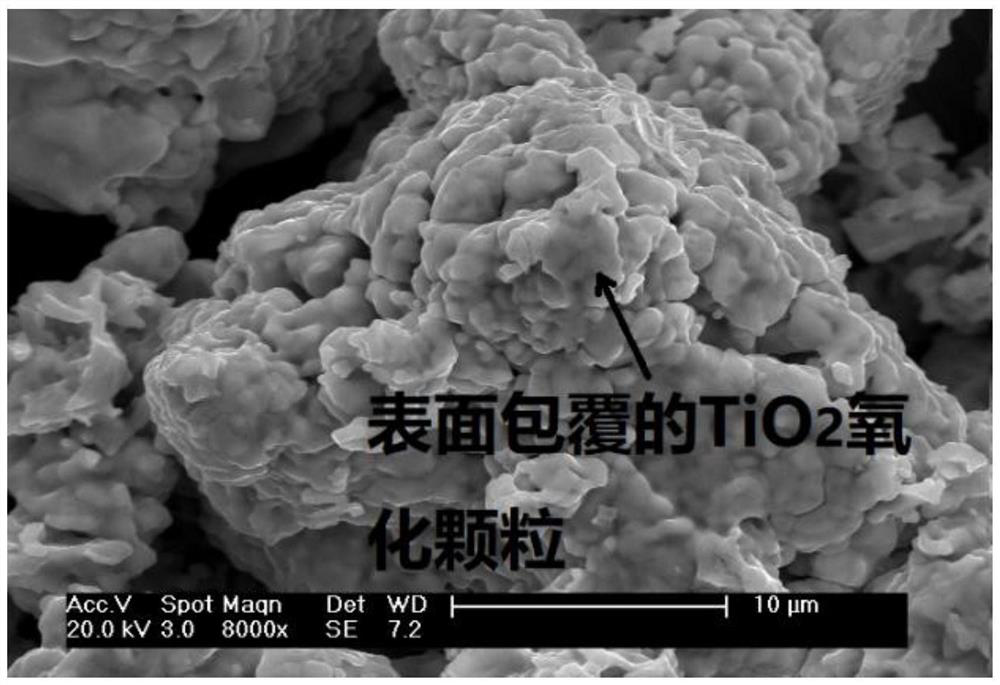

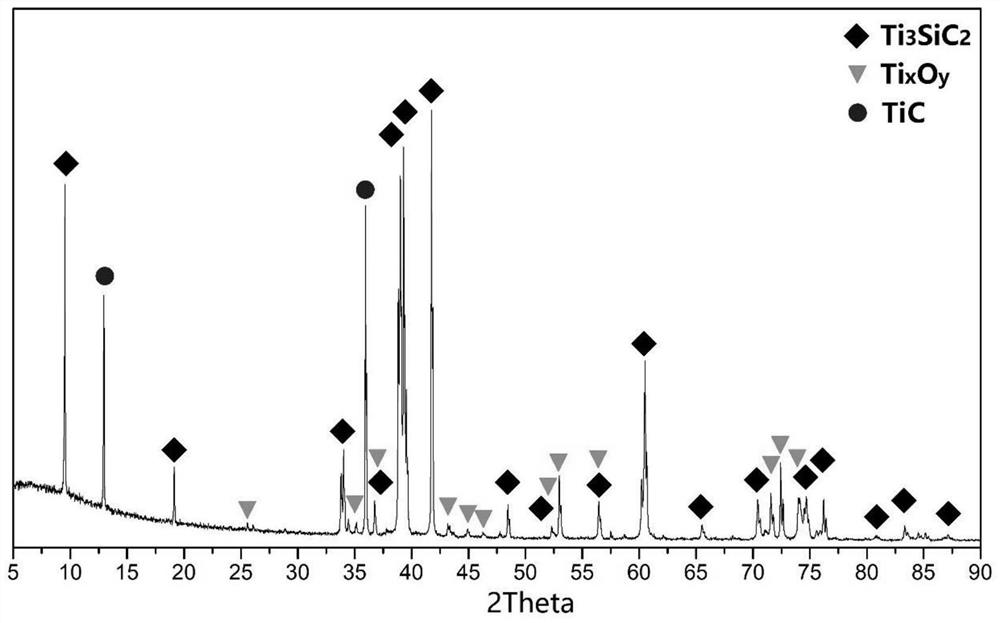

[0035] The preparation method of the enhanced phase material of the electric contact, specifically, the oxidation matrix MAX phase material is pre-oxidized in situ on its surface under a controlled atmosphere to generate oxide particles MO m 、AO n or composite oxide layer MO m / AO n , forming MAX@MO m / AO n .

[0036] In situ generation of oxide particles MO on the surface of the parent MAX material by pre-oxidation m 、AO n or composite oxide layer MO m / AO n , can be completed at a lower temperature, low equipment requirements, good repeatability, simple technology, low cost, obvious practical application value, and the shell MO m / AO n The integrated structure with the core MAX has stronger bonding force, strong barrier interface diffusion ability, and better performance of the overall composite material.

[0037] Specifically, the preparation method of the electrical contact reinforcement phase material includes the following steps:

[0038] S1: Weigh the MAX pha...

Embodiment 1

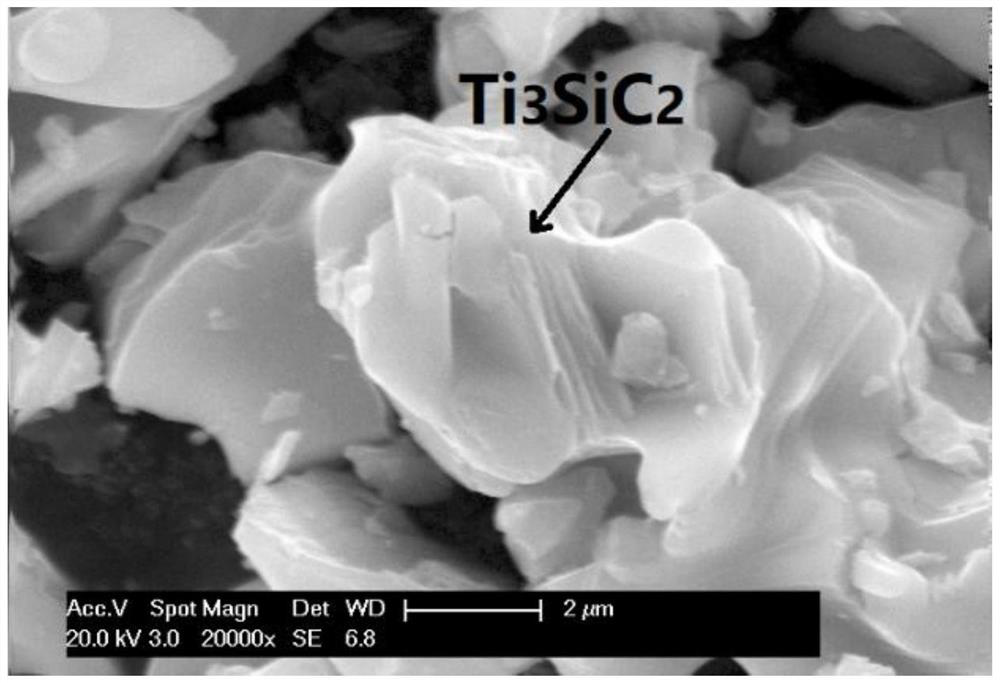

[0056] 10gTi 3 SiC 2 Put the powder into a high-temperature tube furnace, heat up to 1200°C at a heating rate of 10°C / min in an atmosphere of "oxygen + argon" with an oxygen content of 20vol%, keep it warm for 0.5 hours, and cool at a cooling rate of 10°C / min to room temperature, Ti with core-shell structure 3 SiC 2 @TiO 2 Powder; will account for 3% Ti of the overall material mass fraction 3 SiC 2 @TiO 2 Powder and Ag powder with a mass fraction of 97% were wet-mixed for 0.5 hours in a ball mill tank equipped with an ethanol medium (powder: ethanol: ball mass ratio was 1:1:2), and then dried for 1 hour to obtain a mixed powder; The powder was compacted in a cold press at a pressure of 900 MPa and kept for 15 minutes; the block sample was placed in a tube furnace, and the temperature was raised to 500 °C at a heating rate of 2 °C / min under the protection of Ar atmosphere, and kept for 8 hours. That is to get Ag / Ti 3 SiC 2 @TiO 2 Composite electrical contact materials...

Embodiment 2

[0059] 10gTi 3 AlC 2 Put the powder into a high-temperature tube furnace, heat up to 700°C at a heating rate of 2°C / min in an atmosphere of "oxygen + argon" with an oxygen content of 80vol%, keep it warm for 5 hours, and cool at a cooling rate of 5°C / min to room temperature, Ti with a core-shell structure 3 AlC 2 @TiO 2 / Al 2 o 3 Powder; Ti will account for 40% of the overall material mass fraction 3 AlC 2 @TiO 2 / Al 2 o 3 Powder and Ag powder with a mass fraction of 60% were wet-mixed in a ball mill tank equipped with ethanol medium for 8 hours (powder: ethanol: ball mass ratio was 1:3:6), and then dried for 5 hours to obtain a mixed powder; The powder was pressed into a cold press at a pressure of 50 MPa and kept for 1 minute; the block sample was placed in a tube furnace, and the temperature was raised to 900 °C at a heating rate of 16 °C / min under the protection of Ar atmosphere, and kept for 0.5 hours. That is to get Ag / Ti 3 AlC 2 @TiO 2 / Al 2 o 3 Composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com