Silver-borazon switching apparatus contact material and preparation method thereof

A technology for contact materials and switching electrical appliances, which is applied to contacts, electrical switches, circuits, etc., can solve the problems of complex processing technology, unreasonable microstructure, and difficult processing, and achieve simple preparation technology and good arc erosion resistance. , the effect of excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1. Boron nitride (powder particles) is 5% by weight, and the balance is silver (powder particles) ingredients. The average particle size of the above-mentioned powder particles is between 1-100 μm;

[0043] 2. Put boron nitride and silver powder into a ball mill and grind for 3 hours to make them fully mixed;

[0044] 3. Compress the evenly mixed boron nitride and silver powders under a pressure of 200Mpa;

[0045] 4. Sinter the compacted body at 900°C for 4 hours;

[0046] 5. Hot extruding the sintered material to obtain wire or strip. The extrusion ratio was 200.

Embodiment 2

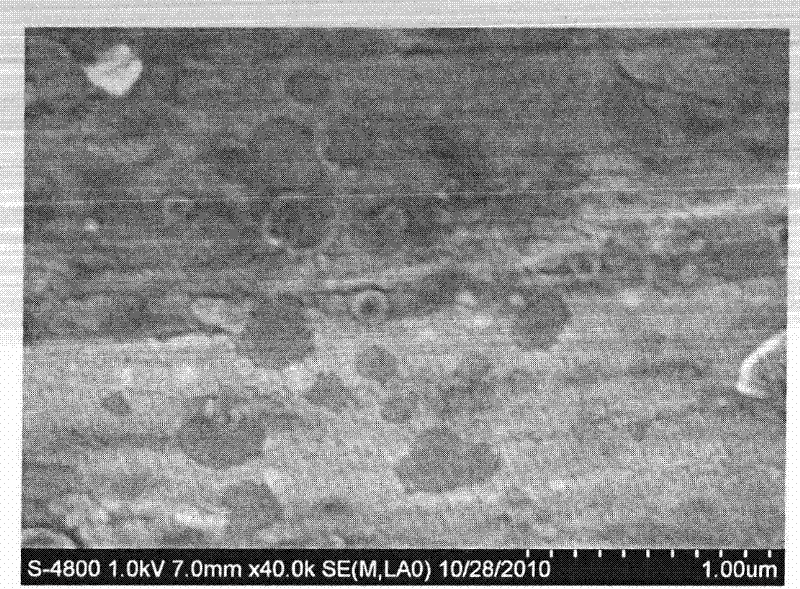

[0048] 1. Boron nitride (nano-spherical powder particles) is 4% by weight, and the balance is silver (powder particles) ingredients. The average particle size of silver powder particles is between 1-100 μm, and the boron nitride powder is spherical nano-boron nitride powder, with an average particle size between 0.03-1 μm;

[0049] 2. Put boron nitride and silver powder into a ball mill and grind for 3 hours to make them fully mixed;

[0050] 3. Compress the evenly mixed boron nitride and silver powders under a pressure of 800Mpa;

[0051] 4. Sinter the compacted body at 900°C for 3 hours;

[0052] 5. Hot extruding the sintered material to obtain wire or strip. The extrusion ratio was 200.

Embodiment 3

[0054] 1. Boron nitride (nano-spherical particles) is 1% by weight, and the balance is silver ingredients. The average particle size of spherical boron nitride powder particles is between 0.03-100 μm;

[0055] 2. Put the boron nitride powder particles into absolute ethanol, then add polyethylene glycol with a volume of 1% ml of absolute ethanol, use ultrasonic stirring for 2 hours, and then dry it for use;

[0056] 3. Melt the dispersed spherical boron nitride powder particles in silver at a melting temperature of 1000°C, mechanically stir for 10 minutes, and cool to shape;

[0057] 4. Drawing the smelted material to the final size wire or strip.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com