Tin oxide/tin/few-layer graphene composite material as well as preparation method and application thereof

A few-layer graphene, tin oxide technology, applied in nanotechnology for materials and surface science, electrochemical generators, electrical components, etc., can solve the problem of electrode material shedding, inability to obtain cycle performance, electrode material powder and other problems, to achieve the effect of low cost, excellent cycle performance and large powder output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation of the composite materials in each embodiment of the present invention adopts the dielectric barrier discharge plasma-assisted high-energy ball milling method.

[0026] The specific steps of the dielectric barrier discharge plasma-assisted high-energy ball milling method are:

[0027] (1) Install the front cover and the electrode rod of the ball mill, and connect the iron core inside the front cover and the electrode rod to the positive and negative poles of the plasma power supply respectively, wherein the iron core inside the electrode rod is connected to the plasma power supply The positive pole of the front cover is connected to the negative pole of the plasma power supply;

[0028] (2) Put the grinding balls and the mixed powder of tin powder and expanded graphite in the ball mill tank;

[0029] (3) Vacuum the ball mill tank through the vacuum valve, and then fill the discharge gas medium with oxygen or a mixture of oxygen and inert gas to make the...

Embodiment 1

[0035] Preparation of tin oxide / tin / few-layer graphene composites by dielectric barrier discharge plasma-assisted high-energy ball milling:

[0036] Put tin powder and expanded graphite raw material powder into a ball mill and mix them. The mass fraction of expanded graphite is 30%, and the mass ratio of ball powder to raw material is 50:1. Conduct dielectric barrier discharge plasma-assisted high-energy ball milling for 15 hours, discharge gas The medium is oxygen, and after discharge ball milling, a tin oxide / tin / few-layer graphene composite material is obtained.

[0037] The prepared composite material was made into a negative electrode sheet of a sodium ion battery and the battery was assembled, and then the charge and discharge test was carried out. SnO x The first reversible specific capacity of the / Sn / FLG composite is 255 mAh g -1 , after 250 cycles, the reversible specific capacity drops to 180mAh g -1 .

Embodiment 2

[0039] Same as Example 1, except that the discharge ball milling time is 20h.

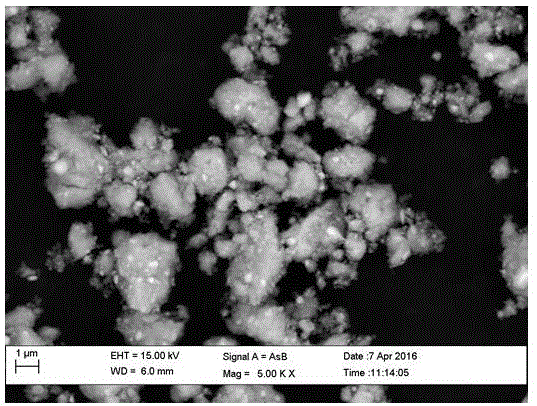

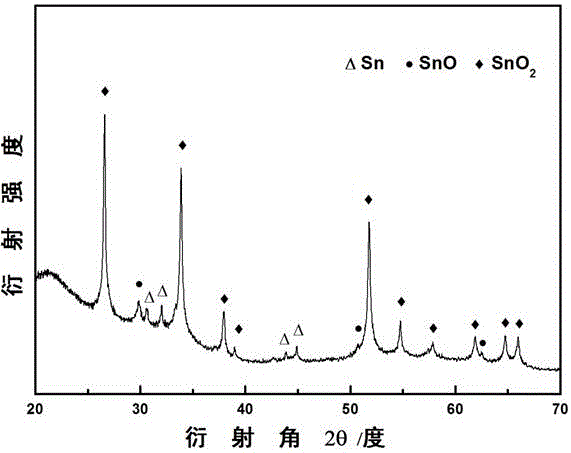

[0040] After discharge ball milling, such as figure 1 Shown is the prepared SnO x / Sn / FLG composite XRD patterns, by figure 1 It can be seen that the composite material components include tin and tin oxide;

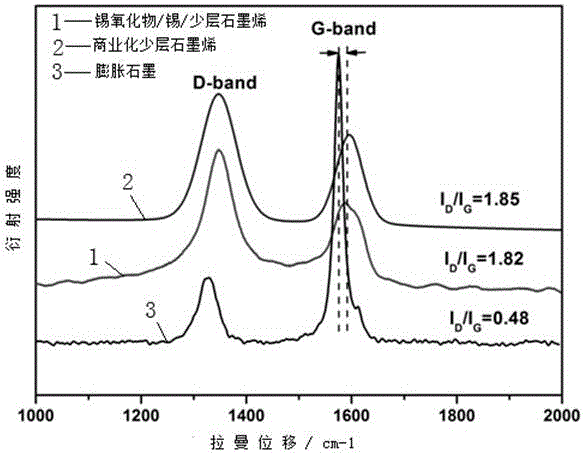

[0041] figure 2 are expanded graphite and the prepared SnO x / Sn / FLG composite material and the Raman diagram of commercial few-layer graphene, it can be seen from the figure that compared with expanded graphite, the D peak of the few-layer graphene corresponding to the carbon layer in the prepared composite material is weakened, and the G peak is enhanced. It shows the stripping of the carbon layer, and the shift of the G peak to the right indicates the thinning of the carbon layer; and compared with the commercial few-layer graphene, the Raman diagram of the few-layer graphene in the prepared composite is almost the same, indicating that After discharge ball milling, the expanded graph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inverse specific capacity | aaaaa | aaaaa |

| Inverse specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com