Rare earth-doped tin oxide as well as preparation method and application thereof

A rare earth doping and rare earth oxide technology, which is applied in the chemical industry and can solve the problems of low product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the rare earth doped tin oxide of one embodiment, comprises the following steps:

[0029] S110, preparing tin oxide.

[0030] Specifically, the steps of preparing tin oxide include S111~S113:

[0031] S111. Under the condition of 55°C-95°C, tin tetrachloride and alkali are mixed and reacted to obtain tin hydroxide, wherein the molar ratio of tin tetrachloride to alkali is 1:1.5-1:3.5. The base is selected from at least one of NaOH and KOH.

[0032] In one embodiment, the temperature for the mixed reaction of tin tetrachloride and NaOH is 65°C-95°C. Further, the temperature for the mixed reaction of tin tetrachloride and NaOH is 75°C-95°C. Furthermore, the temperature for the mixed reaction of tin tetrachloride and NaOH is 75°C, 95°C, 80°C or 85°C.

[0033] In one embodiment, the ratio of tin tetrachloride to alkali is 1:1.5, 1:2, 1:3, 1:2.5 or 1:3.5.

[0034] S113. Calcining tin hydroxide under the condition of 500° C. to 900° C. to obtain...

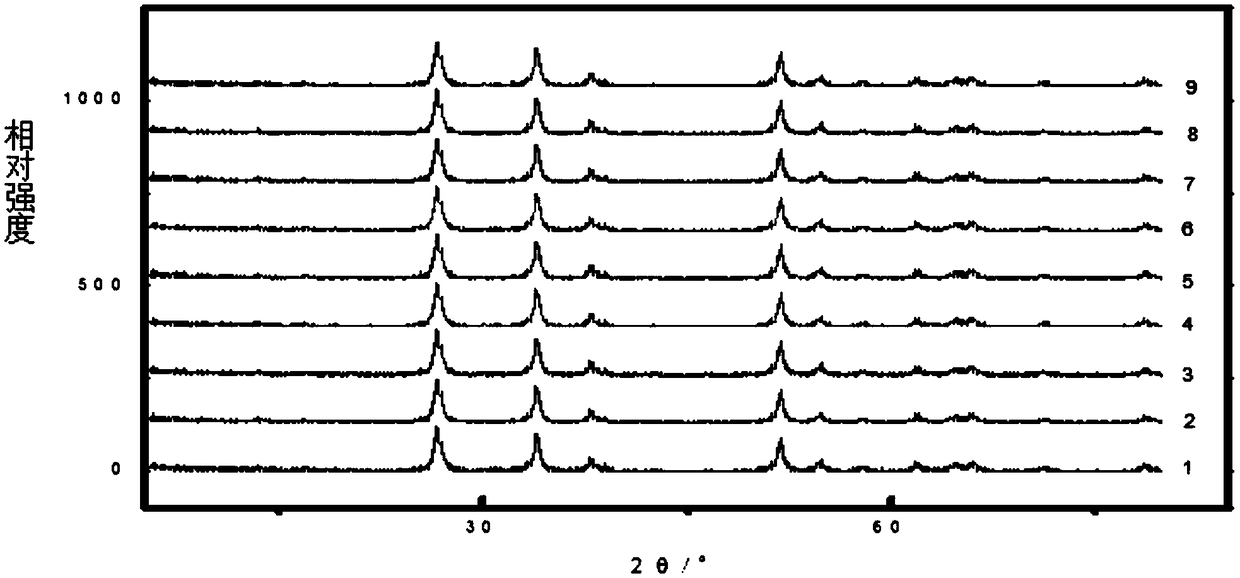

Embodiment 1~9

[0060] (1) Prepared as SnCl according to Table 1 4 ·5H 2 O solution and NaOH solution, SnCl in Table 1 4 ·5H 2 The ratio of O and NaOH is the ratio of the amount of substances. Slowly add the NaOH solution to the SnCl 4 ·5H 2 In the O solution, the reaction temperature and the reaction time of each embodiment are shown in Table 1 to obtain the reaction solution. Then the reaction solution was cooled to room temperature, and then centrifuged to obtain a crude product, which was washed with deionized water until the crude product was free of C1- (AgNO3 detection), and then dried without C1 - The crude product was obtained as tin hydroxide. Then tin hydroxide was ground and calcined for 4h to obtain the SnO 2 , the calcination temperature of each embodiment is shown in Table 1.

[0061] Table 1

[0062]

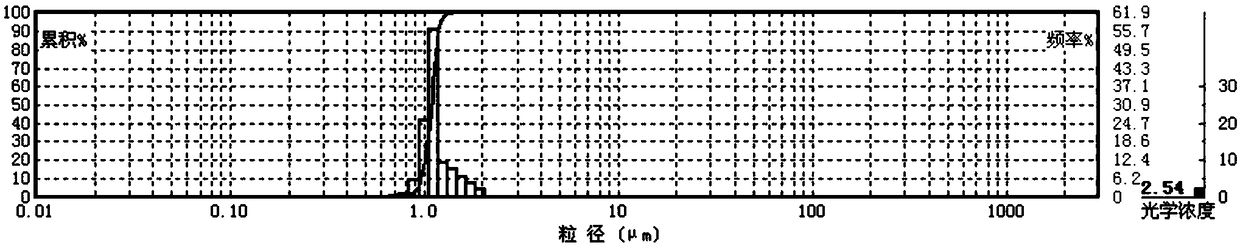

[0063] (2) adopt laser particle size analyzer to measure the SnO of each embodiment respectively 2 particle size and specific surface area. SnO of each example 2 ...

Embodiment 10~15

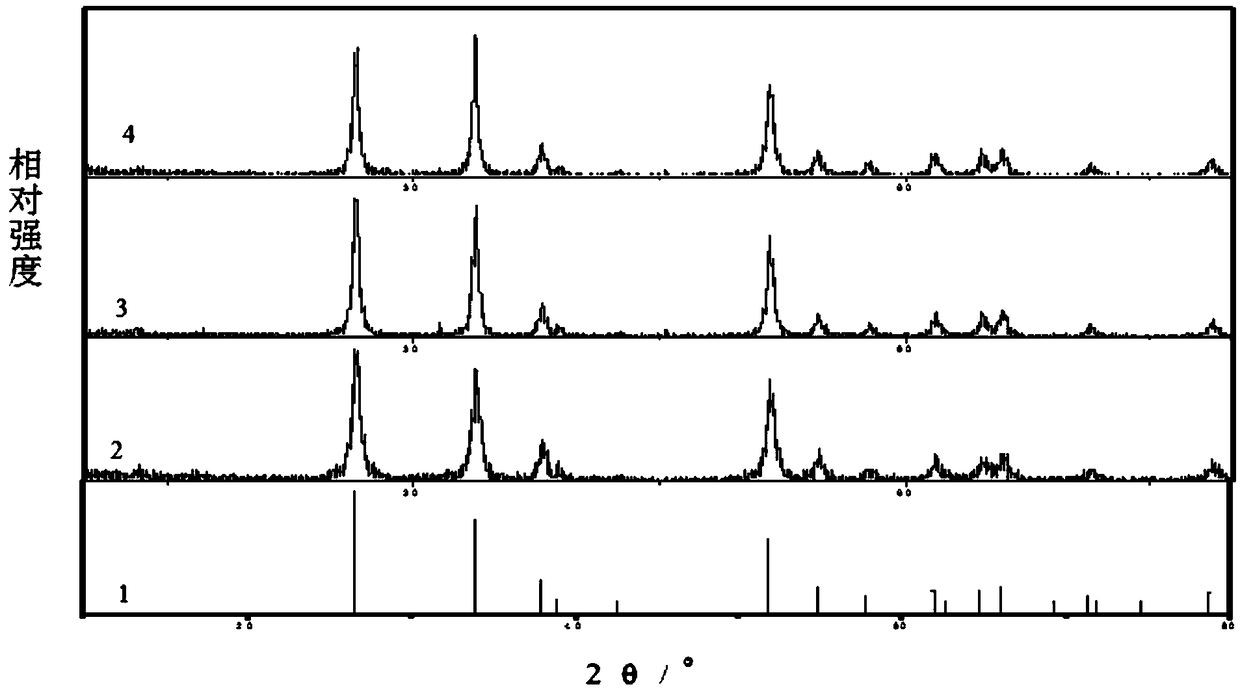

[0067] (1) Combine the rare earth salt solution with the SnO prepared in Example 7 respectively 2 Mix to get the mixed liquor of each embodiment, wherein, the mass percent of rare earth in the rare earth salt solution corresponding to each embodiment, the rare earth salt solution, the SnO corresponding to each embodiment 2 The dosage is shown in Table 3. Then, the mixtures of each example were mixed with ultrasound at a frequency of 80 Hz for 2 hours, then centrifuged and dried, and then calcined for 4 hours. The calcination temperature is shown in Table 3.

[0068] (2) The particle size of the doped tin oxide obtained in each embodiment is measured respectively by using a laser particle size analyzer method, and the specific surface area of the doped tin oxide obtained in each embodiment is calculated by a laser particle size analyzer method. The particle size and specific surface area of the doped tin oxide obtained in each embodiment are shown in Table 3. The X-ray di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com