Method for preparing carbon nano tube composite material loaded with nano indium-tin oxide

A carbon nanotube and composite material technology, applied in the fields of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of complex process and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

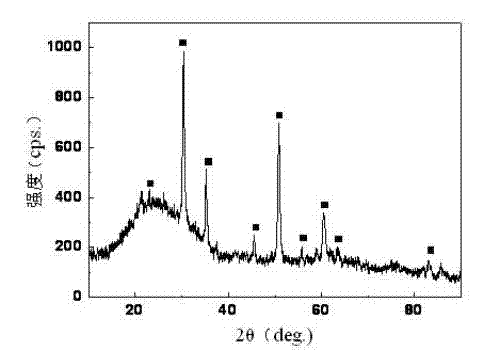

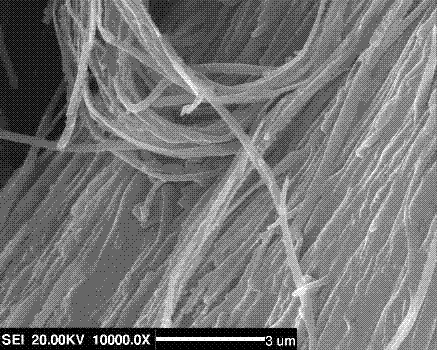

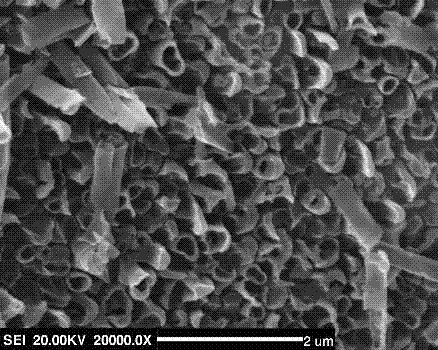

Image

Examples

specific Embodiment approach 1

[0007] Embodiment 1: The preparation method of the carbon nanotube composite material loaded with nano indium tin oxide in this embodiment is carried out according to the following steps: 1. Take indium nitrate, tin chloride and ethylene glycol methyl ether respectively, wherein indium nitrate : The molar ratio of tin chloride is 1: 0.1~0.125, the molar ratio of indium nitrate: ethylene glycol methyl ether is 1: 0.1~0.5, and indium nitrate, tin chloride and ethylene glycol methyl ether are added to the reactor reflux at 75°C to 85°C for 20h to 28h to obtain an organic phase solution; 2. Take resorcinol, formaldehyde, sodium carbonate and water respectively, wherein the molar ratio of resorcinol: formaldehyde is 100 : 45~55, resorcinol: the mol ratio of sodium carbonate is 100: 0.08~0.12, resorcinol: the mol ratio of water is 100: 15~20, and resorcinol, formaldehyde, sodium carbonate and Add water into the reactor and mix evenly, then use hydrochloric acid to adjust the pH valu...

specific Embodiment approach 2

[0009] Specific embodiment two: the difference between this embodiment and specific embodiment one is: in step one, the mol ratio of indium nitrate: tin chloride is 1: 0.11~0.12, the mol ratio of indium nitrate: ethylene glycol methyl ether is 1: 0.15~0.45. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: in step one, the mol ratio of indium nitrate: tin chloride is 1: 0.115, the mol ratio of indium nitrate: ethylene glycol methyl ether is 1: 0.25. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com