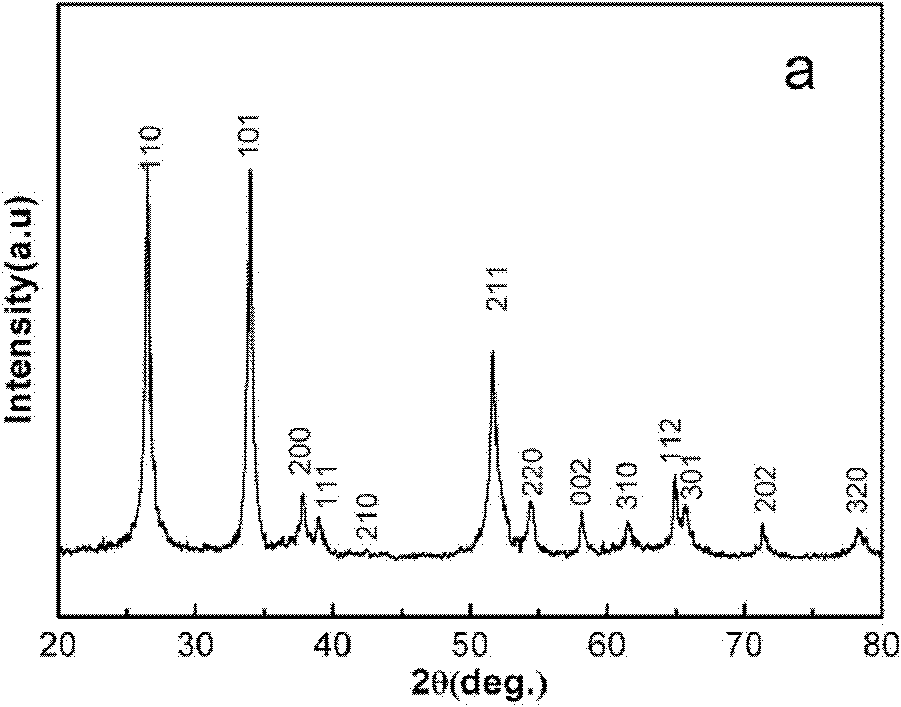

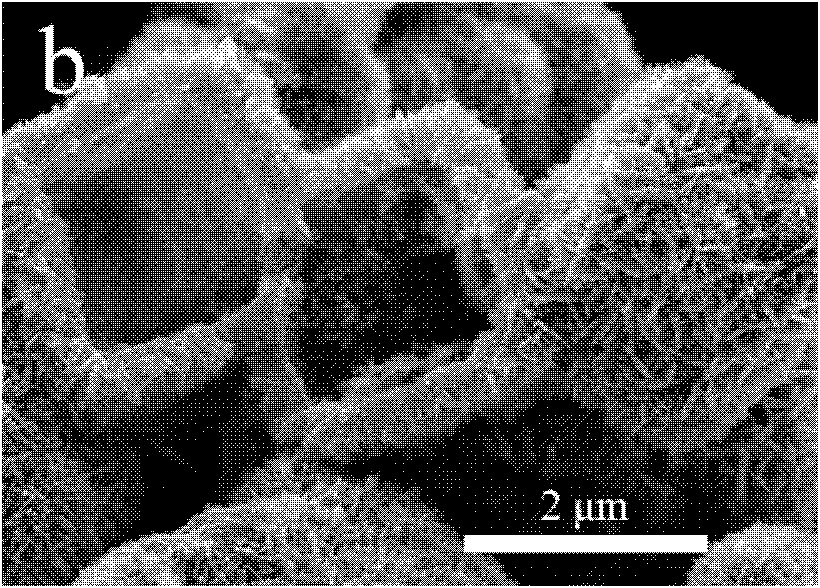

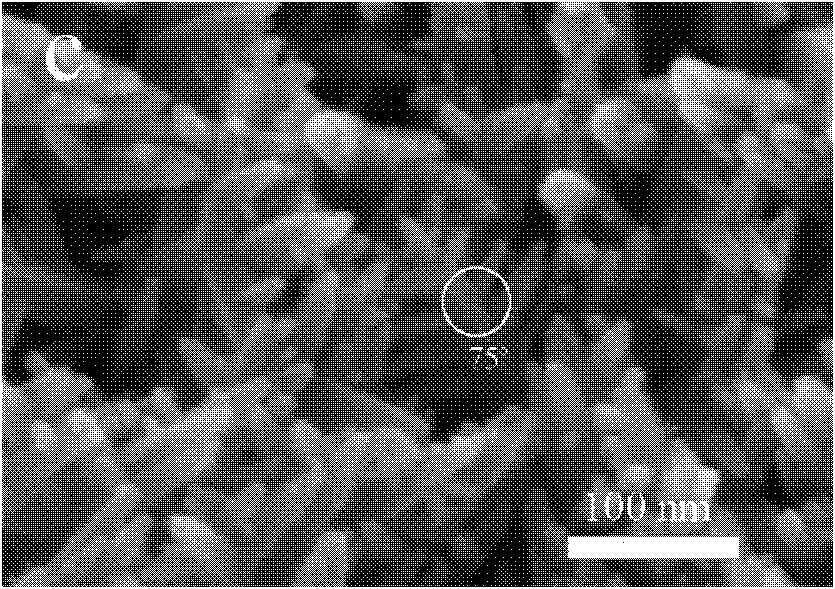

Hydrothermal synthesis method of zinc-doped tin oxide with hollow cubic structure

A cubic structure, hydrothermal synthesis technology, applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems that have not been reported in related reports, and achieve the effects of simple process, reduced agglomeration, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for hydrothermally synthesizing a zinc-doped tin oxide hollow cubic structure, comprising the steps of:

[0032] (1) Configure SnCl 4 ·5H 2 O and (Zn(NO 3 ) 2 ·6H 2 Mixed aqueous solution of O;

[0033] (2) The concentration of the configured substance is an aqueous NaOH solution of 2.5mol / L;

[0034] (3) the SnCl obtained in step (1) 4 and (Zn(NO 3 ) 2 The mixed aqueous solution of is added dropwise in the NaOH aqueous solution of step (2), SnCl 4 and (Zn(NO 3 ) 2 The volume ratio of the mixed solution and NaOH aqueous solution is 1:3, so that the SnCl 4 The concentration of the substance is 0.1094mol / L, (Zn(NO 3 ) 2 ·6H 2 The molar concentration of O is 0.0156mol / L, the molar concentration of NaOH is 1.875mol / L, the dropping rate is 2ml-3ml / min, and the precursor is obtained by stirring evenly;

[0035] (4) Transfer the precursor of step (3) to a hydrothermal reaction kettle so that its filling degree is 80%, and react at a constant temperature...

Embodiment 2

[0041] A method for hydrothermally synthesizing a zinc-doped tin oxide hollow cubic structure, comprising the steps of:

[0042] (1) Configure SnCl 4 ·5H 2 O and (Zn(NO 3 ) 2 mixed aqueous solution;

[0043] (2) The concentration of the configured substance is an aqueous NaOH solution of 2.25mol / L;

[0044] (3) step (1) to obtain SnCl 4 and (Zn(NO 3 ) 2 The mixed solution of is added dropwise in the NaOH aqueous solution of step (2), SnCl 4 and (Zn(NO 3 ) 2 The volume ratio of the mixed solution and NaOH aqueous solution is 1:5, and the rate of addition is 2ml~3ml / min, so that SnCl 4 The concentration of the substance is 0.1118mol / L, (Zn(NO 3 ) 2 ·6H 2 The molar concentration of O is 0.0131mol / L, and the molar concentration of NaOH is 1.875mol / L. Stir evenly to obtain the precursor;

[0045] (4) Transfer the precursor of step (3) to a hydrothermal reaction kettle so that its filling degree is 80%, and react at a constant temperature of 180° C. for at least 25 hou...

Embodiment 3

[0049] A method for hydrothermally synthesizing a zinc-doped tin oxide hollow cubic structure, comprising the steps of:

[0050] (1) Configure SnCl 4 and (Zn(NO 3 ) 2 mixed aqueous solution;

[0051] (2) The concentration of the configured substance is an aqueous NaOH solution of 2mol / L;

[0052] (3) the SnCl obtained in step (1) 4 and (Zn(NO 3 ) 2 The mixed aqueous solution of is added dropwise in the NaOH aqueous solution of step (2), SnCl 4 and (Zn(NO 3 ) 2 The volume ratio of the mixed solution and NaOH aqueous solution is 1: 15, and the dropping rate is 2ml~3ml / min, so that SnCl 4 The concentration of the substance is 0.1144mol / L, (Zn(NO 3 ) 2 ·6H 2 The molar concentration of O is 0.0106, and the molar concentration of NaOH is 1.875 mol / L. Stir evenly to obtain the precursor;

[0053] (4) Transfer the precursor of step (3) to a hydrothermal reaction kettle so that its filling degree is 80%, and react at a constant temperature of 190° C. for at least 25 hours ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com