Efficient low-warpage crystalline silicon solar cell conducive aluminium paste

A solar cell, low warpage technology, applied in conductive materials, circuits, electrical components, etc. dispersed in non-conductive inorganic materials, can solve the problems of poor conductivity of additives, difficult to disperse, affecting the electrical properties of cells, etc. High photoelectric conversion efficiency and warpage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

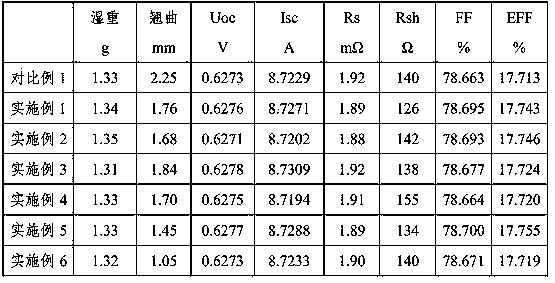

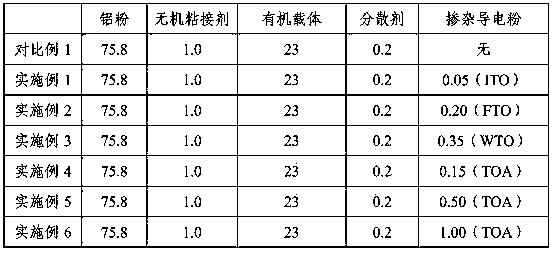

[0028] The specific ratio of aluminum paste is as follows:

[0029]

[0030] The components of the organic carrier are: 30 parts of terpineol, 30 parts of diethylene glycol butyl ether, 30 parts of lauryl alcohol ester, 6 parts of ethyl cellulose, and 4 parts of acrylate resin; the components of the inorganic adhesive It is: 55 parts of bismuth oxide, 10 parts of zinc oxide, 15 parts of antimony oxide, 10 parts of boron oxide, 2.5 parts of molybdenum oxide, 5 parts of aluminum oxide, and 2.5 parts of lithium oxide; the dispersant is monoglycerin stearate of aliphatic esters Esters; doped conductive powder ATO is 50nm, ITO is 150nm, FTO is 1.5μm, WTO is 2μm, TOA is 1.3μm.

[0031] The front silver used in the test is DuPont PV-18H, the back silver is Hongyuan SS-605, and the chip source is Jinko to provide 156mm×156mm polycrystalline silicon wafers. The sintering temperature is 550°C / 500°C / 560°C / 600°C / 720°C / 930°C, the sintering belt speed is 230IPM. The polycrystalline si...

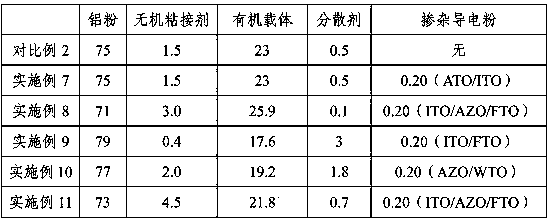

Embodiment 7-11

[0035] Doped conductive powder is mixed with each other in equal proportion by weight, and the specific proportion of aluminum paste is as follows:

[0036]

[0037] The components of the organic carrier are: 30 parts of ethylene glycol phenyl ether, 30 parts of diethylene glycol butyl ether acetate, 30 parts of dibutyl phthalate, 4 parts of phenolic resin, 4 parts of alkyd resin; The components of the adhesive are: 10 parts of calcium oxide, 35 parts of antimony oxide, 25 parts of boron oxide, 5 parts of zirconia, 10 parts of aluminum oxide, 10 parts of lead oxide, and 5 parts of cerium oxide; Ethylene glycol 400; doped conductive powder ATO 200nm, ITO 150nm, FTO 150nm, WTO 1μm, TOA 1.3μm.

[0038] The front silver used in the test is DuPont PV-18H, the back silver is Hongyuan SS-605, and the chip source is Jinko to provide 156mm×156mm polysilicon wafers. The sintering temperature is 550°C / 500°C / 560°C / 600°C / 720°C / 930°C, the sintering belt speed is 230IPM. The polycrysta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com