Carbon/tin oxide/graphene composite material and preparation method and application thereof

A composite material and graphene technology, applied in the field of electrochemistry, can solve problems such as high cost and poor electrochemical performance, and achieve the effects of low cost, improved dispersion, and shortened reaction sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

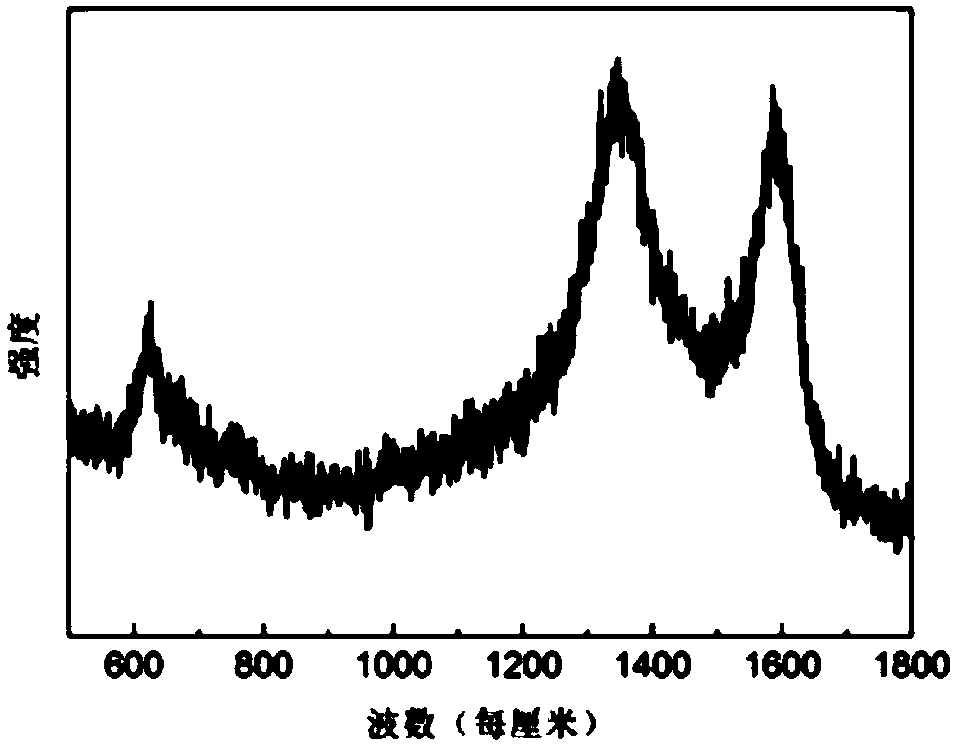

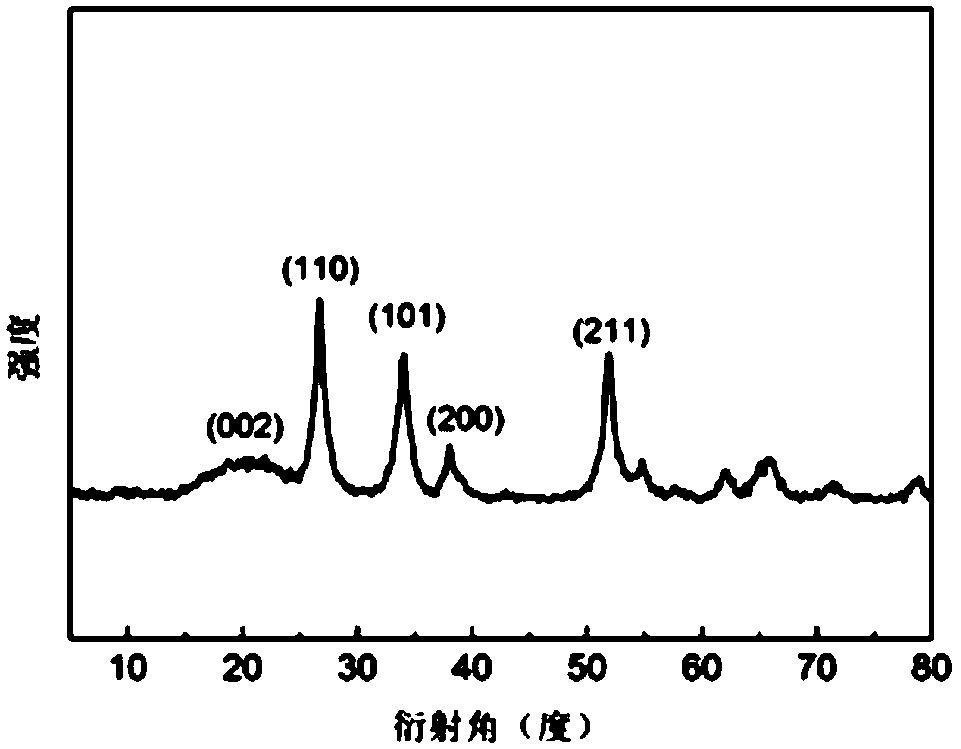

[0030] The preparation method of the carbon / tin oxide / graphene composite material of one embodiment, comprises the following preparation steps:

[0031] Step S110: Under the condition of 160° C. to 180° C., the rice husk is subjected to a hydrothermal reaction in an alkaline solution to obtain a first precipitate.

[0032] Wherein, the alkaline solution is selected from one of sodium hydroxide solution and potassium hydroxide solution. Further, the mass volume ratio of the rice husk to the alkali solution is 1g:15mL˜2g:15mL, and the concentration of the alkali solution is 2moL / L˜4moL / L.

[0033] Further, in the step of performing hydrothermal reaction on the rice husk in the alkali solution, the time of hydrothermal reaction is 12h-36h.

[0034] It should be noted that before the step of subjecting the rice husk to the alkali solution for hydrothermal reaction, a step of washing the rice husk and then drying it is also included. Further, the water used is deionized water; th...

Embodiment 1

[0056] The preparation steps of the carbon / tin oxide / graphene composite material of the present embodiment are as follows:

[0057] 1) Wash the rice husk with deionized water and dry it in an oven at a constant temperature of 60°C. Weigh 12 grams of dried rice husk and immerse it in 180mL sodium hydroxide solution with a concentration of 2moL / L at room temperature, and then transfer to the high pressure reaction The kettle was kept at a constant temperature of 180°C for 12 hours for hydrothermal reaction. After the reaction, the autoclave was cooled at room temperature to obtain the first precipitate;

[0058] 2) Wash the first precipitate with 200mL of 2moL / L hydrochloric acid, and then wash with deionized water until neutral, and finally obtain a carbon skeleton;

[0059] 3) Disperse 1.2 grams of carbon skeleton in 120 mL of deionized water, weigh 0.42 grams of stannous chloride dihydrate and dissolve it in a small amount of ethanol, and pour the dissolved stannous chloride ...

Embodiment 2

[0067] The preparation steps of the carbon / tin oxide / graphene composite material of the present embodiment are as follows:

[0068] 1) Wash the rice husk with deionized water and dry it in an oven at a constant temperature of 60°C. Weigh 12 grams of dried rice husk and immerse it in 180mL potassium hydroxide solution with a concentration of 3moL / L at room temperature, and then transfer to the high pressure reaction The kettle was kept at a constant temperature of 170°C for 24 hours for hydrothermal reaction. After the reaction, the autoclave was cooled at room temperature to obtain the first precipitate;

[0069] 2) Wash the first precipitate with 200mL of 2moL / L hydrochloric acid, and then wash with deionized water until neutral, and finally obtain a carbon skeleton;

[0070] 3) Disperse 1.2 grams of carbon skeleton in 120 mL of deionized water, weigh 0.42 grams of stannous chloride dihydrate and dissolve it in a small amount of ethanol, and pour the dissolved stannous chlori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com