Tin oxide and porous carbon composite lithium ion battery anode materials

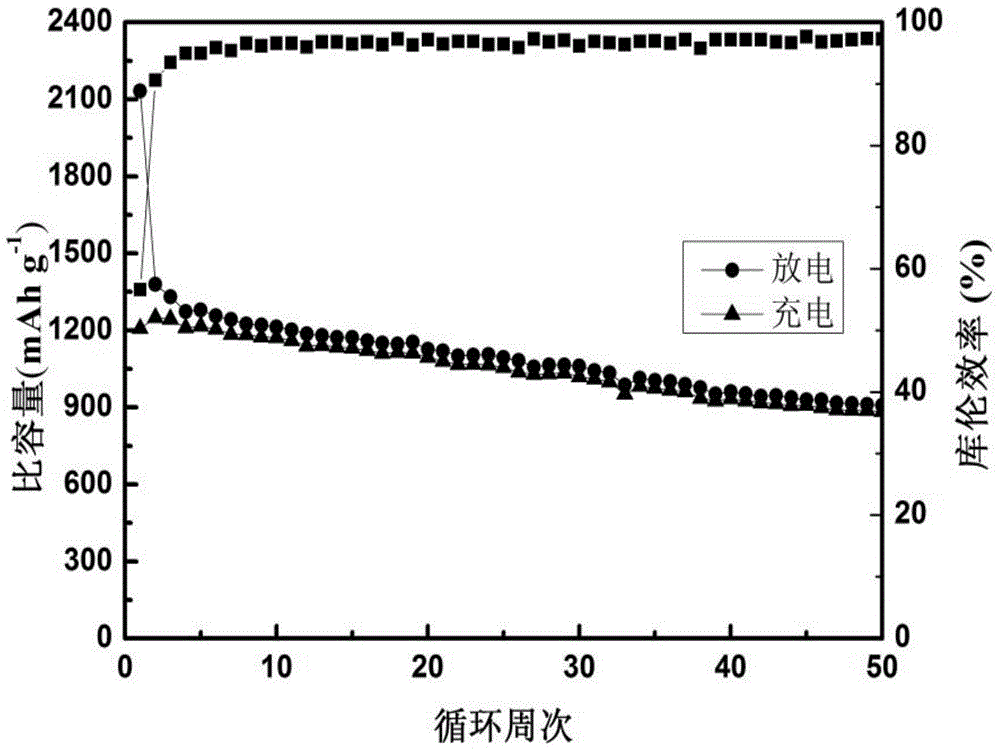

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of complicated preparation and unguaranteed performance, and achieve the effects of reducing production costs, uniform products, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

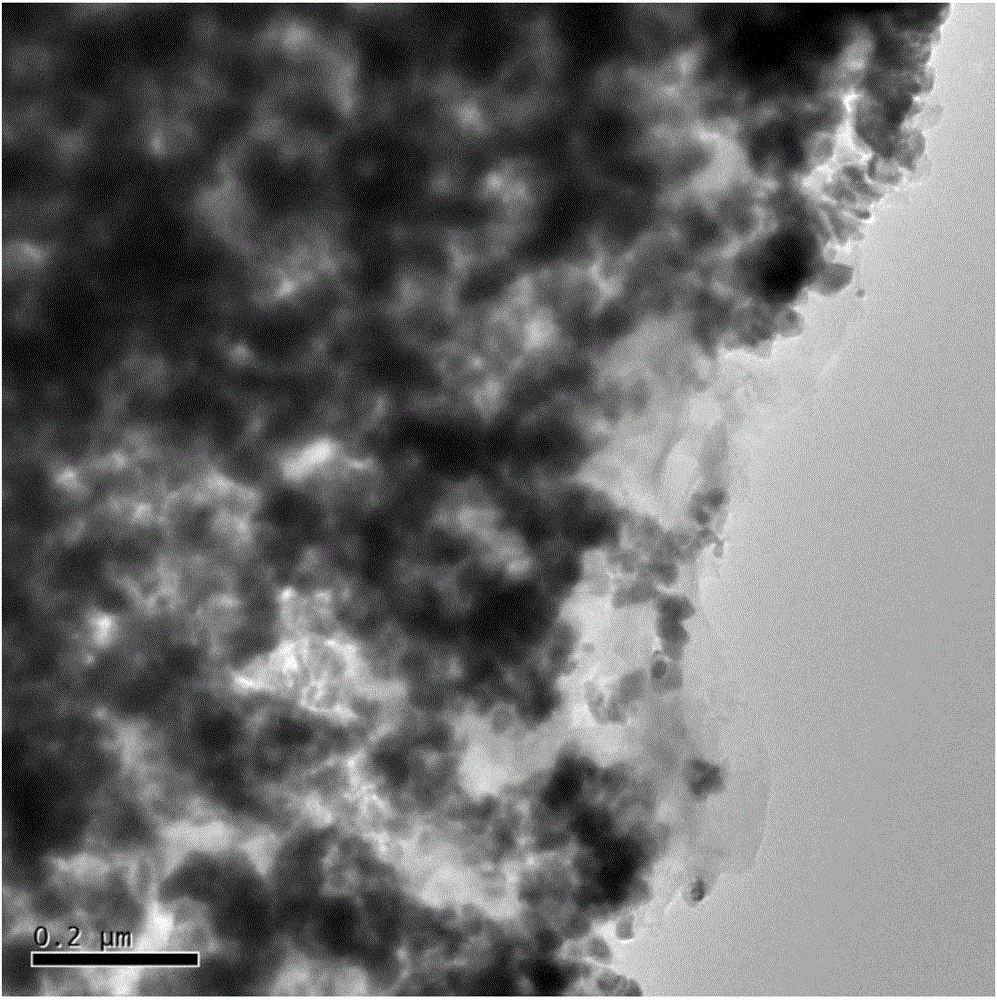

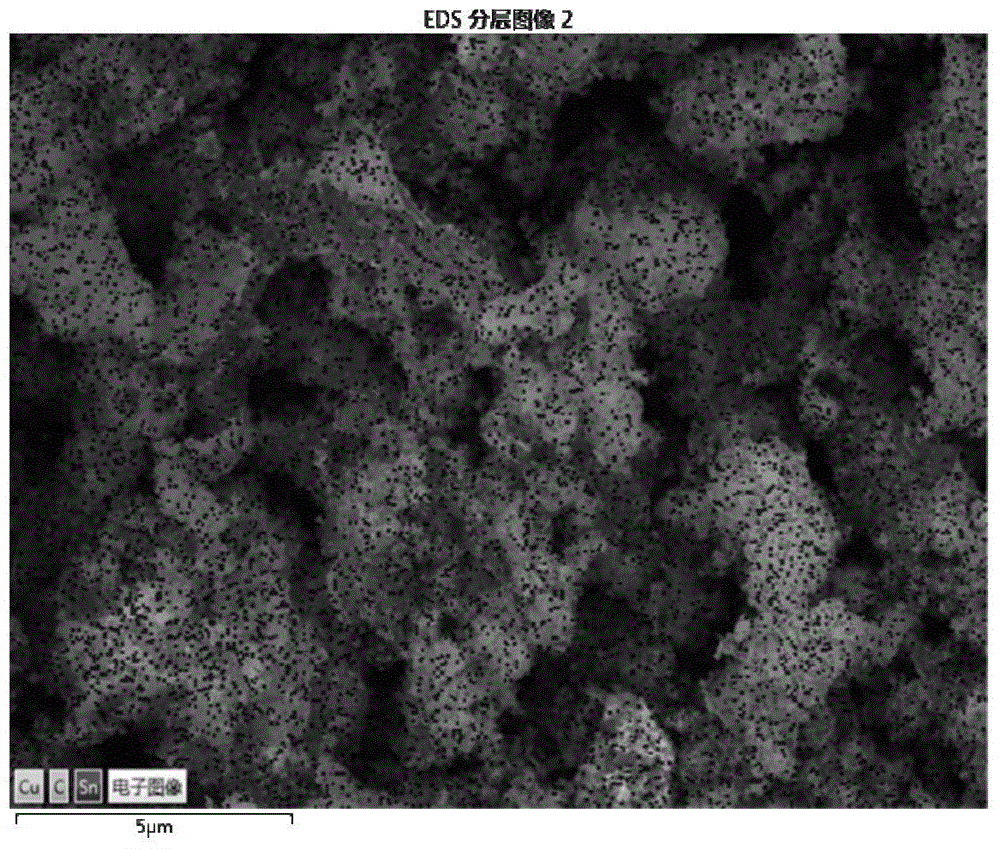

[0018] A preparation method of a tin dioxide / porous carbon composite lithium ion battery negative electrode material, the steps are as follows:

[0019] 1) In a standard 25mL polytetrafluoroethylene reaction kettle, mix copper nitrate trihydrate aqueous solution with trimesic acid-ethanol solution to obtain a mixed solution, heat it in an electric blast drying oven at 120°C for 12 hours, and then cool down naturally to room temperature, the filtered blue-green block crystals were dried at 65°C for 3 hours to obtain HKUST-1 (Hong Kong University of Science and Technology Metal Organic Framework No. 1); in the copper nitrate trihydrate aqueous solution, copper nitrate trihydrate and The dosage ratio of water is 0.3mmol: 1mL, the dosage ratio of trimesic acid and ethanol in the trimesic acid-ethanol solution is 1.0mmol: 6mL, and the molar ratio of copper nitrate trihydrate and trimesic acid in the mixed solution is 1.8 :1.0;

[0020] 2) Activate the prepared HKUST-1 at a vacuum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com