Water-cooled cathode head of plasma generator

A plasma generator and water-cooled cathode technology, which is applied to plasma, electrical components, etc., can solve the problems of short life, heavy maintenance and replacement work, and poor water-cooling effect at the cathode emitting end, so as to achieve convenient maintenance and replacement and improve cooling effect. , The effect of not easy to damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

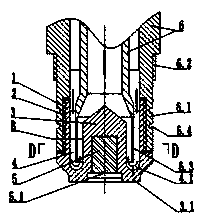

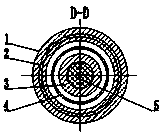

[0025] Example 1 see figure 1 , figure 2 , image 3

[0026] A water-cooled cathode head for a plasma generator, used in a non-transferred arc plasma generator, consisting of the following:

[0027] 1) see figure 1 , figure 2 , the upper end of which is a cylindrical central seat 3 with a pointed body; the outer periphery of the central seat 3 is provided with a cylindrical outer cold wall 1 at a certain annular distance B in the radial direction. The center seat 3 and the outer cold wall 1 are connected by the sealing ring bottom 3.1 at the bottom to form a heating unit, and the inner cavity of the sealing ring bottom forms an annular water return tank 4. The inner hole at the lower end of the center seat 3 is a planar emitter, and an alloy tungsten cylinder 5 is used. Except the alloy tungsten cylinder 5 in the center seat 3, all the components in the heating unit are made of red copper. That is, the center seat 3 , the sealing ring bottom 3.1 and the outer cold w...

Embodiment 2

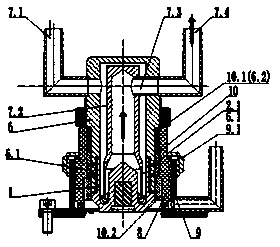

[0033] Embodiment 2: see Figure 4, Figure 5 , Figure 6 .

[0034] A water-cooled cathode head of a plasma generator, which can be used in a transferred arc generator, consists of the following:

[0035] 1) see Figure 4 , the upper end of which is a cylindrical central seat 3A with a pointed body; the outer periphery of the central seat 3A is provided with a cylindrical outer cold wall 1A at a certain annular distance Ba in the radial direction. The central seat 3A and the outer cold wall 1A are connected by a radial sealing ring bottom 3.1A at the bottom to form a heating unit, and the inner cavity of the sealing ring bottom forms an annular return water tank 4A. The inner hole emitter at the lower end of the center seat 3A adopts an alloy tungsten cylinder 5A. All components in the heating unit except the alloy tungsten cylinder 5A are made of red copper. That is, except for the alloy tungsten cylinder, the center seat 3A, the sealing ring bottom 3.1A and the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com