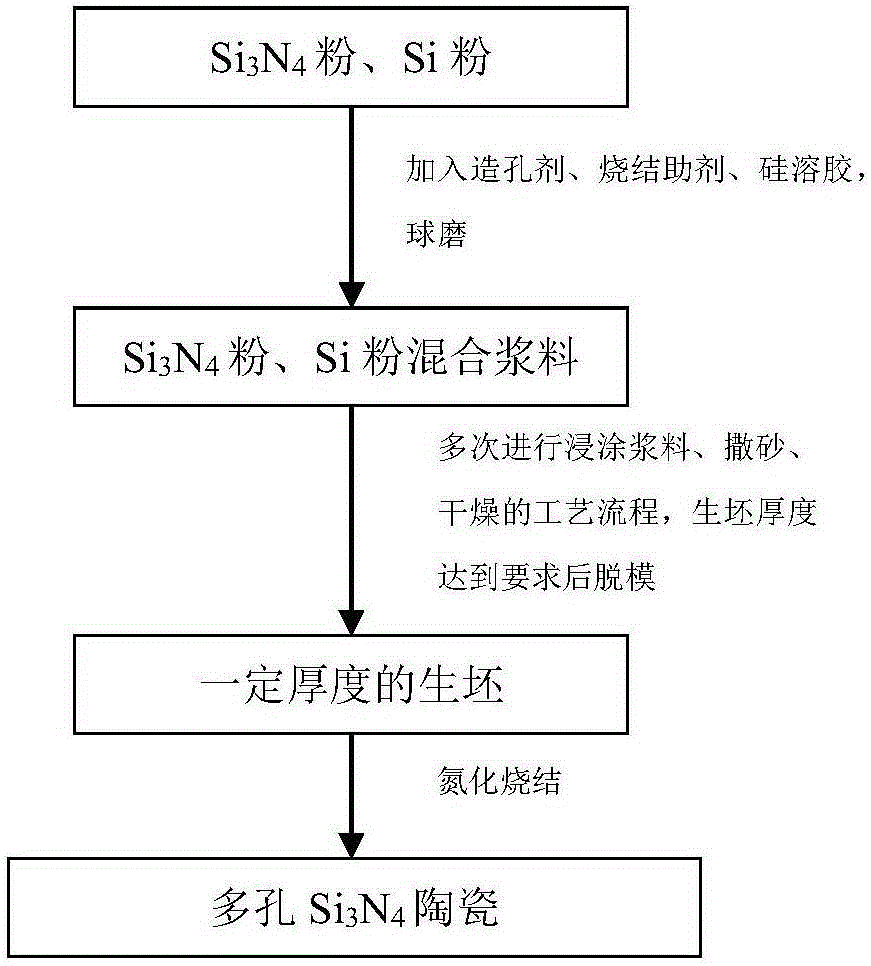

Method for producing complex-shaped porous silicon nitride ceramic product

A technology of silicon nitride ceramics and complex shapes, which is applied in the field of ceramic materials, can solve the problems such as the difficulty in preparing porous silicon nitride ceramic products with complex shapes, and achieve the effects of small size shrinkage, easy machining, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0028] Example 1: Select α-Si with a particle size of 0.4 μm 3 N 4 powder, Si powder with a particle size of 0.5 μm, and Lu powder with a particle size of 0.3 μm 2 o 3 powder and silica sol (in powder, α-Si 3 N 4 Powder, Si powder, Lu 2 o 3 The mass fraction of the powder is 70%, 25%, and 5%, respectively, and the mass ratio of the powder to the silica sol is 1:1), and the Si 3 N 4 Powder and Si powder mixed slurry. Put the slurry into a sealed tank, vacuumize and defoam for 30min. A radome-shaped metal mold (the maximum diameter of the mold is 60 mm and a height of 100 mm) coated with a layer of paraffin wax is immersed in the slurry, so that the surface of the mold is evenly coated with a layer of slurry with a thickness of about 0.5 mm. Take out the mold and spray α-Si with a particle size of 20 μm above the slurry on the surface of the mold 3 N 4 powder, so that the slurry is evenly and low-adhesively coated with a layer of Si 3 N 4 meal. Place the mold in a ...

example 2

[0029] Example 2: Select α-Si with a particle size of 0.4 μm 3 N 4 powder, Si powder with a particle size of 0.5 μm, and Lu powder with a particle size of 0.3 μm 2 o 3 powder and silica sol (in powder, α-Si 3 N 4 Powder, Si powder, Lu 2 o 3 The mass fraction of the powder is 55%, 40%, and 5%, respectively, and the mass ratio of the powder to the silica sol is 1:1), and the Si 3 N 4 Powder and Si powder mixed slurry. Put the slurry into a sealed tank, vacuumize and defoam for 30min. A radome-shaped metal mold (the maximum diameter of the mold is 60 mm and a height of 100 mm) coated with a layer of paraffin wax is immersed in the slurry, so that the surface of the mold is evenly coated with a layer of slurry with a thickness of about 0.5 mm. Take out the mold and spray α-Si with a particle size of 20 μm above the slurry on the surface of the mold 3 N 4 powder, so that the slurry is evenly and low-adhesively coated with a layer of Si 3 N 4 meal. Place the mold in a ...

example 3

[0030] Example 3: Select α-Si with a particle size of 1.2 μm 3 N 4 powder, Si powder with a particle size of 0.5 μm, and Lu powder with a particle size of 0.3 μm 2 o 3 powder and silica sol (in powder, α-Si 3 N 4 Powder, Si powder, Lu 2 o 3 The mass fraction of the powder is 70%, 25%, and 5%, respectively, and the mass ratio of the powder to the silica sol is 1:1), and the Si 3 N 4Powder and Si powder mixed slurry. Put the slurry into a sealed tank, vacuumize and defoam for 30min. A radome-shaped metal mold (the maximum diameter of the mold is 60 mm and a height of 100 mm) coated with a layer of paraffin wax is immersed in the slurry, so that the surface of the mold is evenly coated with a layer of slurry with a thickness of about 0.5 mm. Take out the mold and spray α-Si with a particle size of 20 μm above the slurry on the surface of the mold 3 N 4 powder, so that the slurry is evenly and low-adhesively coated with a layer of Si 3 N 4 meal. Place the mold in a v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com