Microwave sintering material placing device

A material holding device, microwave sintering technology, applied in crucible furnaces, furnaces, lighting and heating equipment, etc., can solve the problems of easy cracking of crucibles and uneven heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

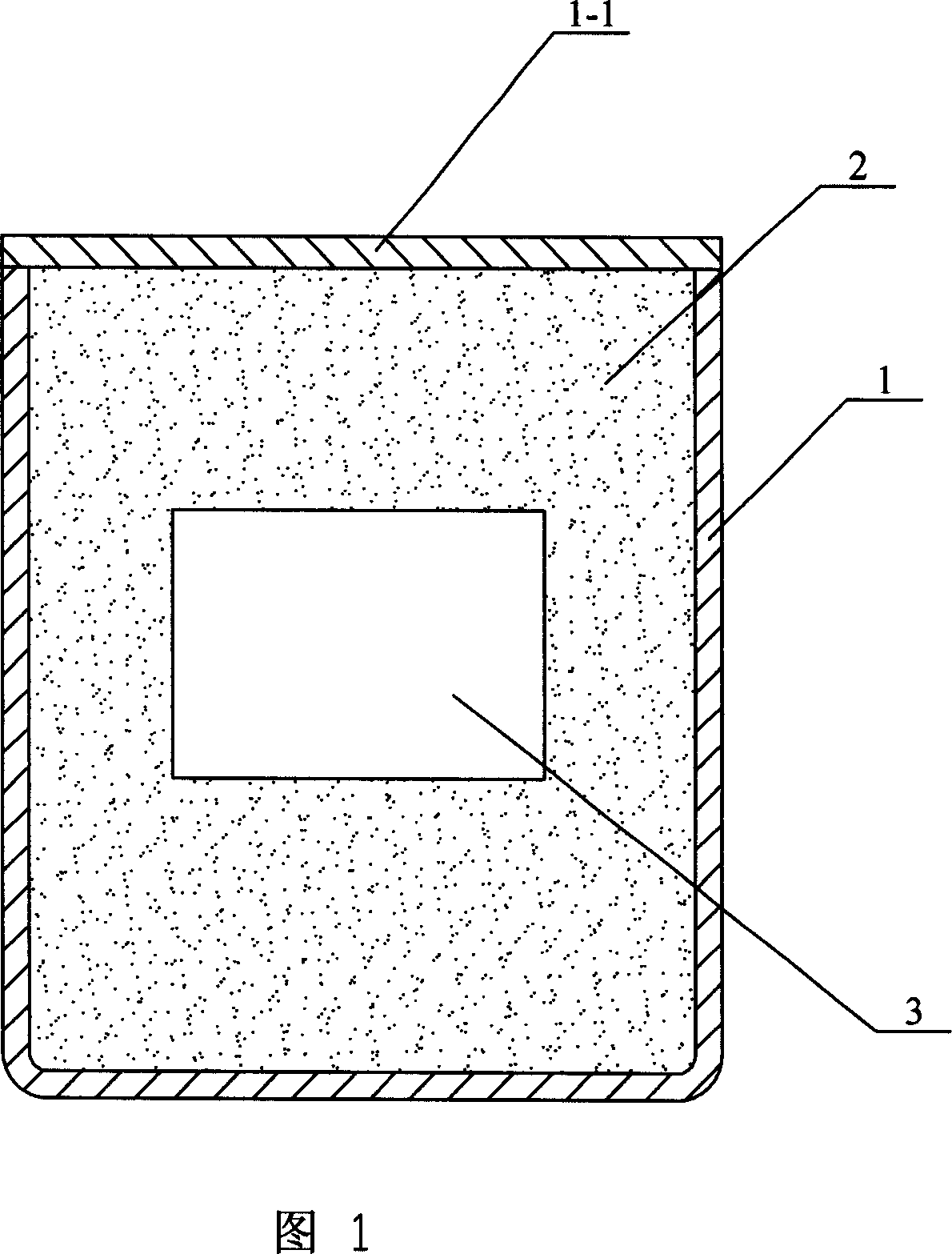

[0006] Specific Embodiment 1: This embodiment is described in conjunction with FIG. 1 . The microwave sintering material holding device of this embodiment is composed of a glass vessel 1 with a cover, a heat-resistant material 2 and a corundum crucible 3; wherein the glass vessel 1 is filled with resistant The thermal material 2, the corundum crucible 3 is embedded in the heat-resistant material 2, and the thickness of the heat-resistant material 2 between the corundum crucible 3 and the glass vessel 1 is not less than 2cm.

[0007] The microwave sintering charging device of this embodiment greatly prolongs the service life of the corundum crucible, and the corundum crucible can be used repeatedly for more than 20 times.

specific Embodiment approach 2

[0008] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the glass vessel 1 is a quartz glass vessel. Others are the same as the first embodiment.

[0009] The high temperature resistance of quartz glass is better than ordinary glass.

specific Embodiment approach 3

[0010] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the heat-resistant material 2 is mullite powder, corundum powder or zirconia powder. Others are the same as the first embodiment.

[0011] The heat-resistant material 2 of this embodiment has the advantages of high temperature resistance and good wave permeability. Even if the glassware 1 breaks due to other reasons, the heat-resistant material 2 of this embodiment will not burn, which ensures the sustainable progress of the reaction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com