Glass steel radar cover single element and forming method thereof

A molding method and glass fiber reinforced plastic technology, applied in the direction of radiation unit cover and other directions, can solve the problems of great influence on product wave transmission performance, discontinuous glass fiber reinforced plastic radome, poor product integrity, etc., and achieve environmental protection, product beauty, consistent thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

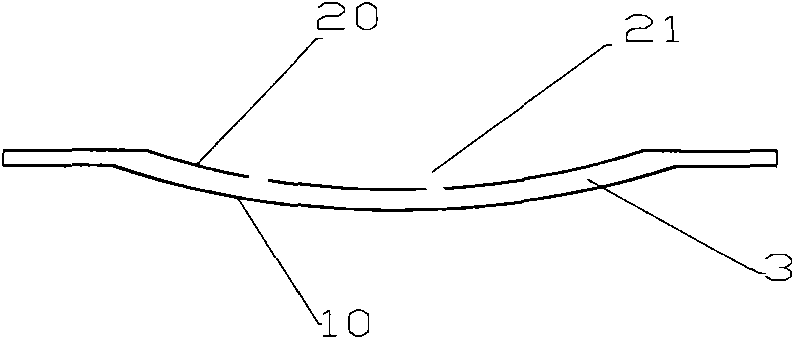

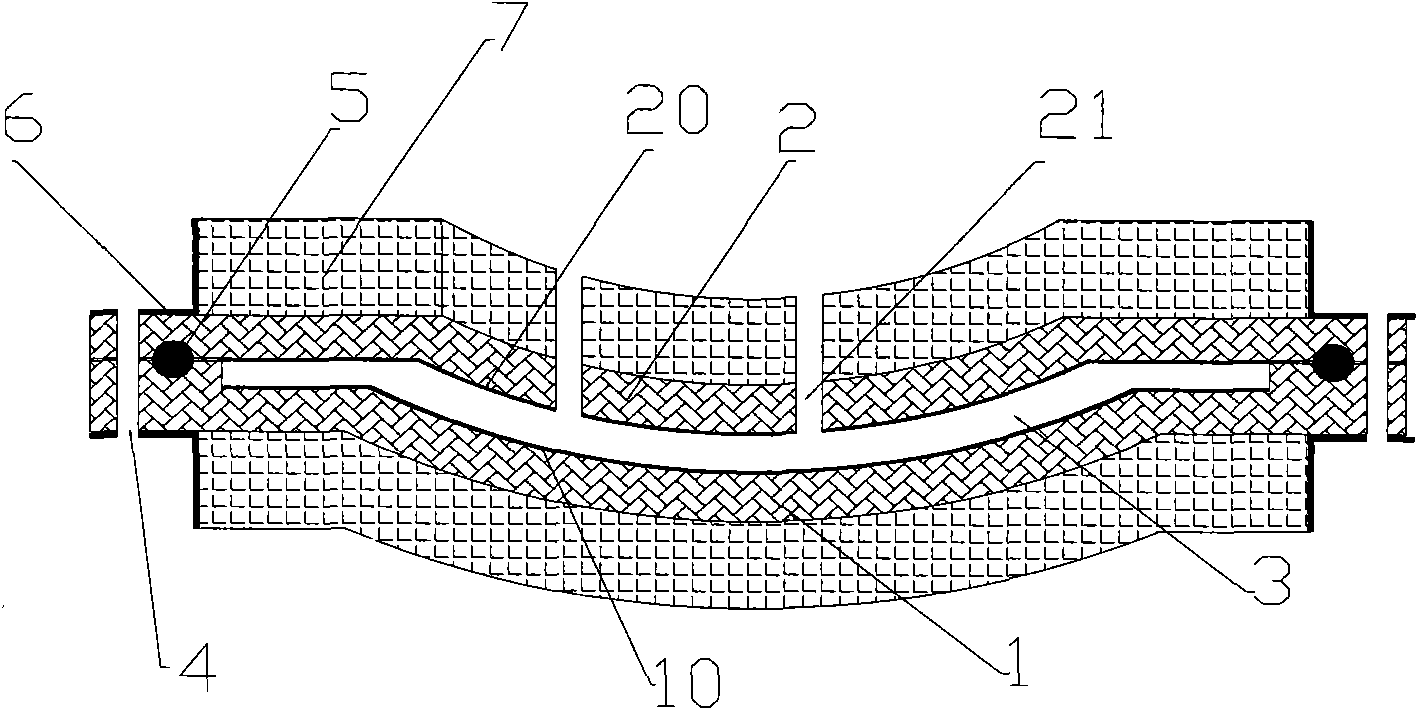

[0029] Such as figure 1 , Figure 4 Shown, the FRP radome unit element of the present invention is a spherical body 22 with a seam structure 23 on the periphery, and this spherical body 22 includes an inner chamber 3 made of a FRP outer skin 10 and a FRP inner skin 20; There are several through holes 21 on the inner skin 20, which connect the inner cavity with the outside; through the through holes 21, pour polyurethane foam into the inner cavity 3, fill the inner cavity 3 and solidify to form a foam sandwich layer; the radome After the single element is formed, the through hole 21 is sealed with putty, and the surface is trimmed and smoothed.

[0030] The diameter of the through hole 21 can be set to 10mm, and the distance between the through hole 21 and the adjacent through hole is 250-400mm.

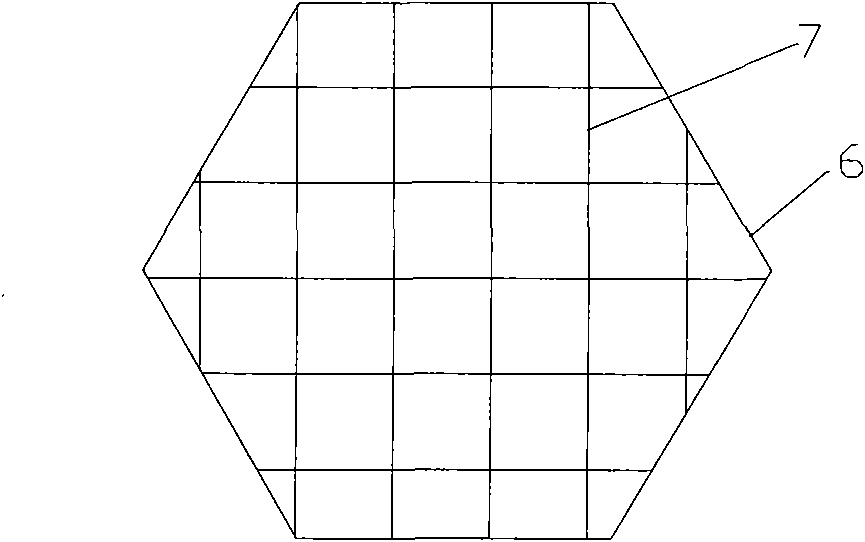

[0031] The seam structure 23 can be set as a pentagonal or hexagonal annular flat plate as required, with a plate width of 45-55 mm; the five-sided or hexagonal annular flat plate i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com