Method for preparing borosilazane ceramic fiber precursor

The technology of ceramic fiber and silaborazane is applied in the field of preparation of silaborazane ceramic fiber, which can solve the problems of limited research and application of wave-transmitting materials, and achieve the effects of excellent mechanical properties, high synthesis yield and simple preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

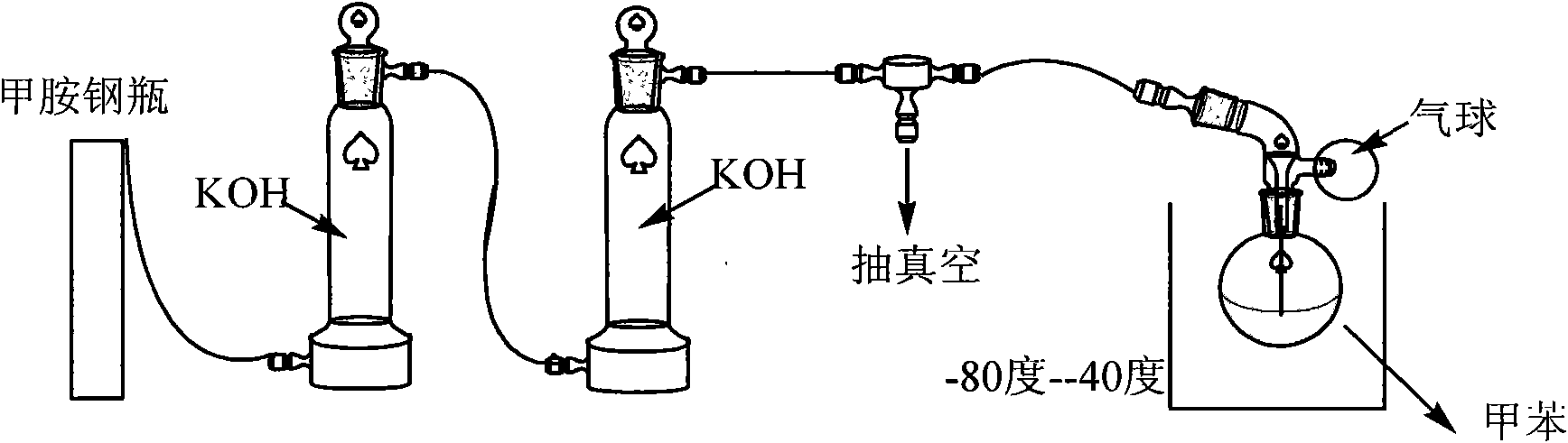

[0037](1) Set up the rectification device. The temperature rises above the boiling point of the toluene solvent, about 120°C. Solvent toluene flows in the solvent distillation head along airflow and reflux condenser, and the solvent toluene water content that distills out is about 5ppm; (2) as figure 1 As shown, take 200ml of distilled toluene, according to figure 1 Set up the device, vacuumize the whole device repeatedly, pass dry nitrogen three to four times, remove the air and moisture, and then place the single-necked flask in the cooling system to condense to -80 ° C ~ -40 ° C and keep it for 1 hour (3) Mix methylamine solution and toluene with a volume ratio of 1:1, and let stand for 1 hour; (4) Clamp one end of the three-way pipe connected to the methylamine steel cylinder with surgical forceps, and change this end to lead to boron trichloride (BCl 3 )gas. Then repeatedly evacuate the whole set of equipment and pass dry nitrogen three to four times to ensure that ...

Embodiment 2

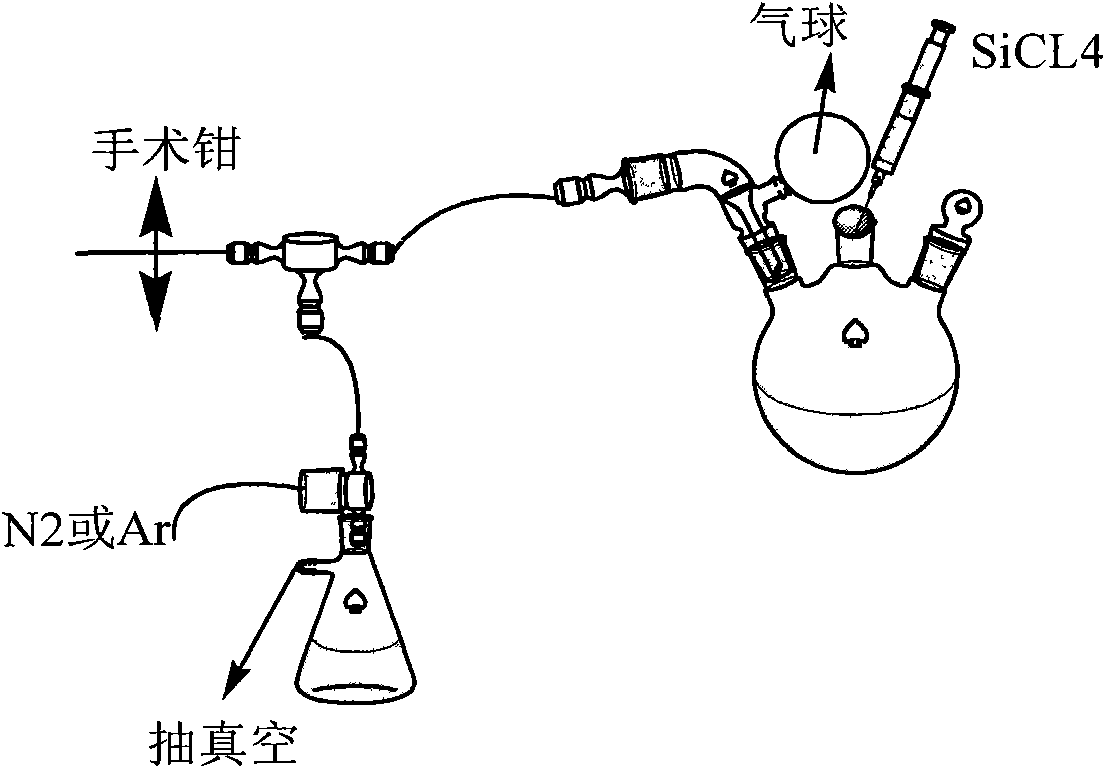

[0039] (1) the solvent toluene water content that distills out by embodiment 1 is about 5ppm; (2) as figure 2 As shown, take a certain amount of distilled toluene and put it into a three-necked flask, according to figure 2 Set up the device, vacuumize the whole device repeatedly, pass dry nitrogen three to four times, remove the air and moisture, and then place the single-necked flask in the cooling system to condense to -80 ° C ~ -40 ° C and keep it for 1 hour (3) Mix methylamine solution and toluene with a volume ratio of 1:1, and let stand for 1 hour; (4) Clamp the end of the three-way pipe connected to the methylamine cylinder with surgical forceps, then repeatedly vacuumize and dry the whole set of devices Nitrogen three to four times to ensure that the whole set of equipment is a vacuum environment; (5) take 48.7ml of SiCl with a syringe 4 The liquid (0.42mol) is injected into the mixed solution of methylamine and toluene, and white smoke is generated. At this time, i...

Embodiment 3

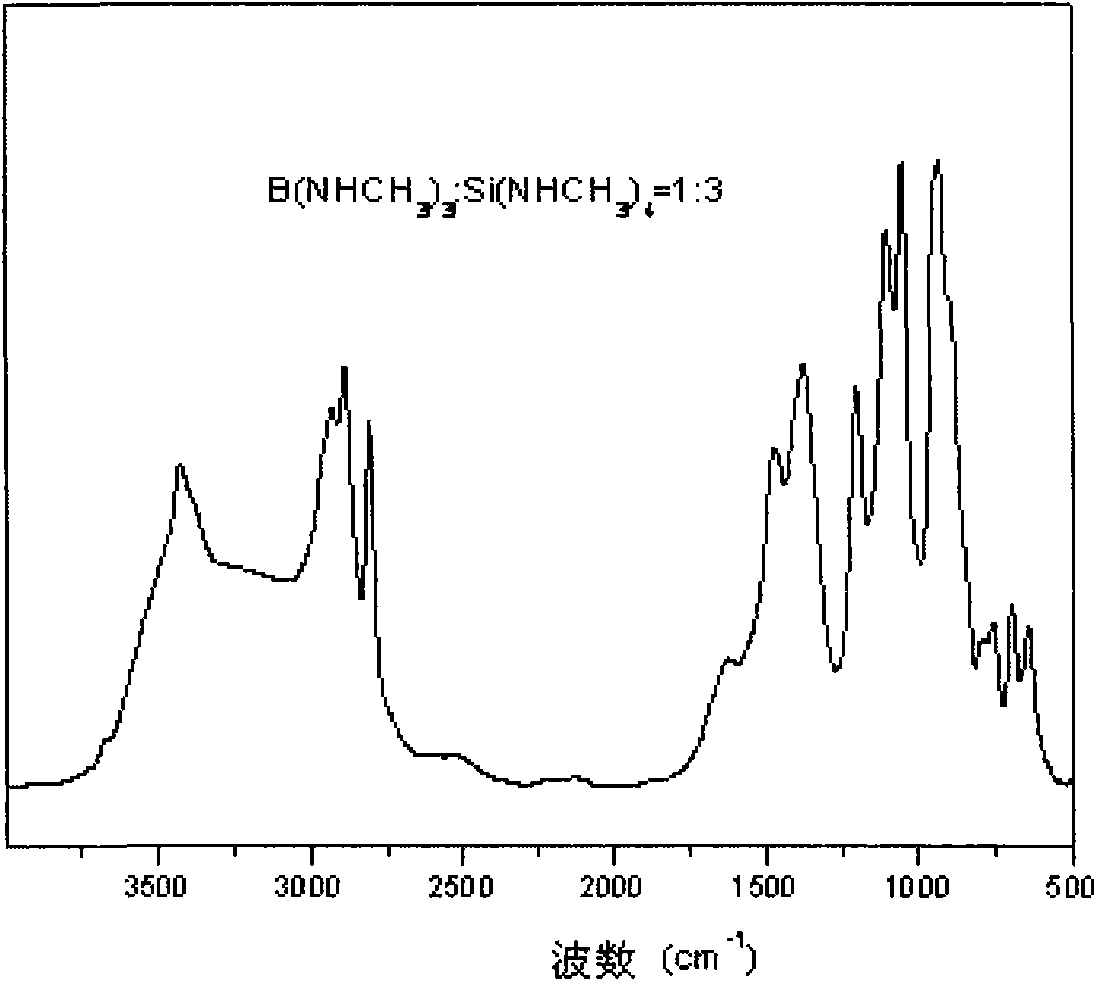

[0041] (1) Place the three-neck flask, hollow stopper, air guide plug, funnel, 50ml measuring cylinder, and electronic scale in the glove box to repeatedly vacuumize and replace with nitrogen gas for 2 to 3 times, according to the B(NHCH synthesized in Example 1) 3 ) 3 Small molecule 0.42mol, Si(NHCH synthesized in embodiment 2 3 ) 4 The small molecule is 1.26mol, and the two small molecules are mixed evenly and then transferred to a three-necked flask; (2) After setting up the co-condensation reaction device, use surgical forceps to clamp the wax-sealed end, repeat vacuuming, and Ar 2 After 2-3 replacements, start to rise from room temperature to 100°C at a rate of 10°C / min, and then keep it for 1 hour, then linearly raise the temperature to 120°C at the same rate, keep it for 2 hours, and stir vigorously. After the toluene is completely evaporated, Raise the temperature to 135-165°C; (3) After 12 hours of reaction, the solution begins to turn into a light yellow liquid wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com