High-quality aluminum nitride piezoelectric film and preparation method thereof

An aluminum nitride piezoelectric, high-quality technology, applied in chemical instruments and methods, manufacturing/assembly of piezoelectric/electrostrictive devices, nitrogen compounds, etc., can solve the problems of high sound speed and poor crystal quality, and achieve improved The effect of crystal quality, crystal quality improvement, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

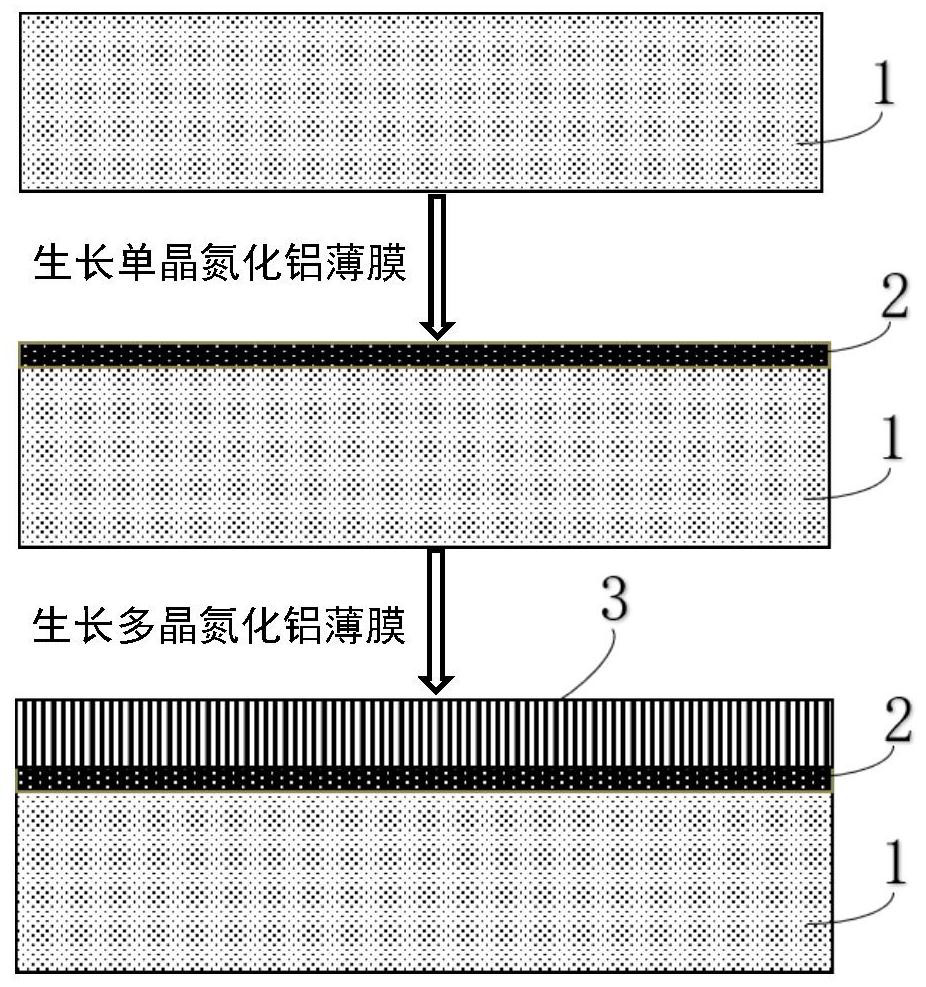

[0030] A kind of preparation method of high-quality aluminum nitride piezoelectric film, such as figure 1 shown, including:

[0031] (1) Take a substrate 1, wash and dry it, and grow a single crystal aluminum nitride film 2 on the substrate 1 by MOCVD equipment;

[0032] (2) Using PVD equipment to perform magnetron sputtering on the monocrystalline aluminum nitride thin film 2 obtained in step (1) to generate a polycrystalline aluminum nitride thin film 3 .

[0033] The above-mentioned substrate 1 is a silicon substrate, a sapphire substrate, a silicon carbide substrate, a gallium nitride substrate, an aluminum nitride substrate, an Al x Ga 1- x One or several composite substrates in N composite substrates.

[0034] The thickness ratio of the single crystal aluminum nitride film 2 to the polycrystalline aluminum nitride film 3 is 1: (3-10), wherein the thickness of the single crystal aluminum nitride film 2 is 10-500nm, and the thickness of the polycrystalline aluminum nit...

Embodiment 1

[0039] A method for preparing a high-quality aluminum nitride piezoelectric film, comprising the following steps:

[0040] (1) Get a sapphire substrate as an epitaxial growth substrate, and grow a 100nm single crystal aluminum nitride thin film 2 on the sapphire substrate by a conventional MOCVD method in the art;

[0041] (2) Put the structure prepared in step (1) into a PVD device, and continue to grow a polycrystalline aluminum nitride film 3 of 800nm on the single crystal aluminum nitride film 2 by the conventional magnetron sputtering method in this field.

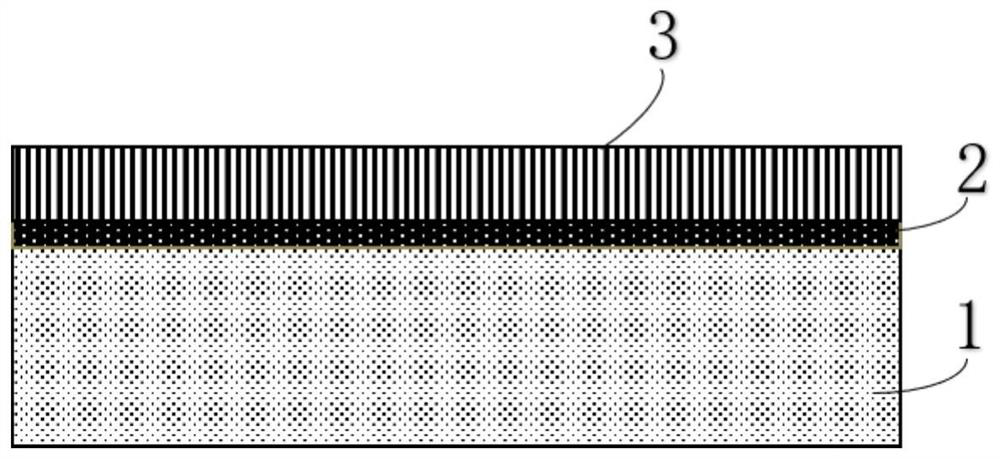

[0042] The high-quality aluminum nitride piezoelectric thin film prepared by the method of this embodiment includes, from bottom to top, a sapphire substrate, a single crystal aluminum nitride thin film 2 with a thickness of 100 nm, and a polycrystalline aluminum nitride thin film 3 with a thickness of 800 nm.

Embodiment 2

[0044] A method for preparing a high-quality aluminum nitride piezoelectric film, comprising the following steps:

[0045] (1) Get a silicon plate as an epitaxial growth substrate, and grow a 200nm single crystal aluminum nitride film 2 by MOCVD on the silicon plate;

[0046] (2) Put the structure obtained in step (1) into a PVD device, and continue to grow a 1 μm polycrystalline aluminum nitride thin film 3 on the single crystal aluminum nitride thin film 2 by magnetron sputtering.

[0047] The high-quality aluminum nitride piezoelectric thin film prepared by the method of this embodiment includes, from bottom to top, a silicon plate, a single crystal aluminum nitride thin film 2 with a thickness of 200 nm, and a polycrystalline aluminum nitride thin film 3 with a thickness of 1 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com