High polymer molecule modified waterproof and anticorrosive resin mortar and preparation method thereof

A technology of anti-corrosion resin and high polymer, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve the poor waterproof and anti-corrosion performance, impact resistance and crack resistance of epoxy cement Poor, prone to cracks and other problems, to achieve the best crack resistance, improve mechanical properties, prevent slump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

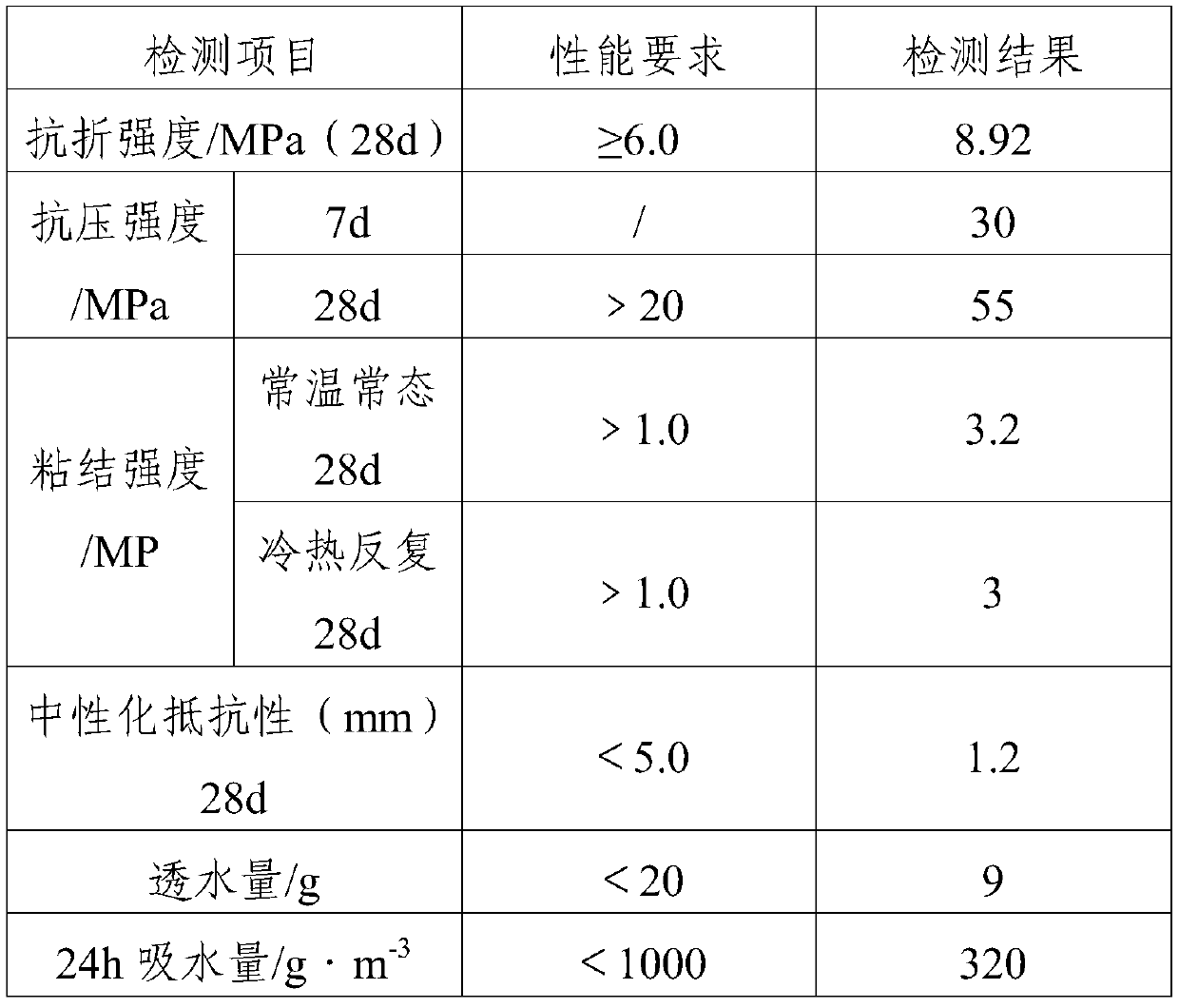

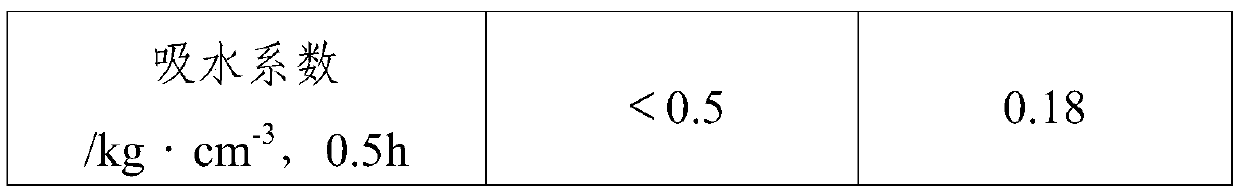

Examples

Embodiment 1

[0030] A polymer molecularly modified waterproof and anti-corrosion resin cement, comprising the following components in parts by weight:

[0031] 70 parts of POSS modified epoxy resin, 6 parts of liquid neoprene rubber, 8 parts of liquid polysulfide rubber, 5 parts of carboxyl-terminated polybutadiene, 12 parts of talcum powder, 15 parts of modified clay, 3 parts of N550 carbon black, expansion 6 parts of vitrified microbeads, 5 parts of expanded polyphenylene particles, 10 parts of polycrystalline alumina fiber, 2 parts of 2,4,6-tris(dimethylaminomethyl)phenol, 3 parts of polypropylene glycol diglycidyl ether, amino 0.5 parts of silane, 0.2 parts of vinyltriethoxysilane, 6 parts of polyethylene wax, 3 parts of hydroxyethyl cellulose, 3 parts of thixotropic agent compounded by organic bentonite and castor oil in a weight ratio of 1:1, 5 parts of binder compounded by polyvinyl alcohol and polyamide resin at a weight ratio of 5:1, 5 parts of diluent compounded by propylene oxid...

Embodiment 2

[0037] A polymer molecularly modified waterproof and anti-corrosion resin cement, comprising the following components in parts by weight:

[0038] 80 parts of POSS modified epoxy resin, 5 parts of liquid neoprene rubber, 10 parts of liquid polysulfide rubber, 5 parts of carboxyl-terminated polybutadiene, 12 parts of talcum powder, 10 parts of modified clay, 1 part of N550 carbon black, expansion 6 parts of vitrified microbeads, 4 parts of expanded polyphenylene particles, 5 parts of polycrystalline alumina fiber, 1 part of 2,4,6-tris(dimethylaminomethyl)phenol, 2 parts of polypropylene glycol diglycidyl ether, amino 0.1 part of silane, 0.2 part of vinyltriethoxysilane, 5 parts of polyethylene wax, 1 part of hydroxyethyl cellulose, 2 parts of thixotropic agent compounded by organic bentonite and castor oil at a weight ratio of 5:1, 8 parts of binder compounded by polyvinyl alcohol and polyamide resin in a weight ratio of 3:2, 5 parts of diluent compounded by propylene oxide butyl...

Embodiment 3

[0044] A polymer molecularly modified waterproof and anti-corrosion resin cement, comprising the following components in parts by weight:

[0045] 60 parts of POSS modified epoxy resin, 10 parts of liquid neoprene rubber, 5 parts of liquid polysulfide rubber, 5 parts of carboxyl-terminated polybutadiene, 14 parts of talcum powder, 15 parts of modified clay, 2 parts of N550 carbon black, expansion 6 parts of vitrified microbeads, 4 parts of expanded polyphenylene particles, 5 parts of polycrystalline alumina fiber, 3 parts of 2,4,6-tris(dimethylaminomethyl)phenol, 1 part of polypropylene glycol diglycidyl ether, amino 0.1 part of silane, 0.5 part of vinyltriethoxysilane, 5 parts of polyethylene wax, 1 part of hydroxyethyl cellulose, 1 part of thixotropic agent compounded by organic bentonite and castor oil at a weight ratio of 5:2, 5 parts of binder compounded by polyvinyl alcohol and polyamide resin at a weight ratio of 1:3, 8 parts of diluent compounded by propylene oxide but...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com