ASA-modified nylon PA66 particle material and preparation method and application thereof on automobile

A PA66, particle material technology, applied in the field of engineering plastics, can solve the problems of insufficient strength, toughness, corrosion resistance, unstable product quality, affecting automobile performance, etc., to achieve good fluidity, stable injection molding process, and stable product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

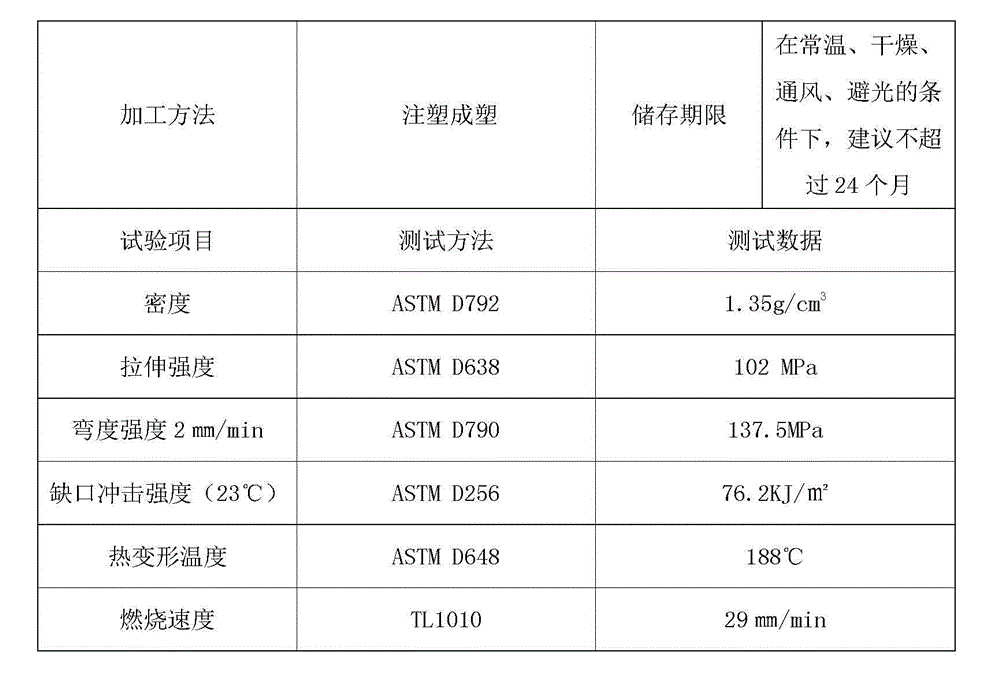

Image

Examples

Embodiment 1

[0031] Prepare ASA-modified nylon PA66 particle material, the specific steps are:

[0032] The first step: prepare material A (kg):

[0033] Weigh nylon PA66 50, ASA resin 15, polycarbonate 15, 3-aminopropyltrimethoxysilane 0.2, methyltriethoxysilane 0.4, antioxidant 1010 0.2, diphenylamine 0.3, polycaprolactone 2. Polyethylene wax 1.5, modified nano powder 6,

[0034] Among them, the modified nano powder is prepared by the following method: after mixing calcium carbonate, lapis lazuli powder, and potassium feldspar powder in equal proportions, burning at 600-700°C for 4-5 hours, then grinding into nano powder, mixing into Stir evenly with 3-5% bis(dioctyloxypyrophosphate) ethylene titanate by weight of the powder, dry and pulverize into powder,

[0035] Mix the weighed raw materials evenly, inhale into a drying barrel, and dry at 90-100°C for 4-6 hours;

[0036] When the water content of the mixture is less than 0.2%, the drying ends;

[0037] The dried mixed material is ...

Embodiment 2

[0046] With the nylon PA66 particle material of the ASA modification that embodiment 1 makes, prepare the connector blade type plug sheath DJ7115-3-11 on the automobile, comprise the following steps:

[0047] (1) After mixing 25kg of ASA-modified nylon PA66 particles and 1.5g of yellow-green powder evenly, add it to the dryer and dry it at 100-120°C for 5 hours.

[0048] (2) Set the temperature of the heating section of the injection molding machine: the first section is 285±5°C, the second section is 280±5°C, the third section is 270±5°C, the fourth section is 265±5°C, and the fifth section is 260±5°C ;

[0049] (3) Add the dried raw materials into the injection molding machine, and set the molding process parameters of the injection molding section:

[0050] a. The first section adopts medium and low pressure of 35-40 Mpa and medium speed injection of 45-55m / s, the injection time is 1.0-1.5 seconds, and the amount of glue injected is 78-80% of the product;

[0051]b. The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com