Electro-acoustic resonator device and method of manufacturing thereof

A resonator, electro-acoustic technology, applied in electrical components, impedance networks, etc., can solve problems such as changes in electro-acoustic behavior, affecting the electrical parameters and reliability of devices, and sticking of metal materials of electrodes, and achieves good thermal contact effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Both the foregoing general description and the following detailed description are exemplary only, and are intended to provide an overview or framework for understanding the nature and character of the claims.

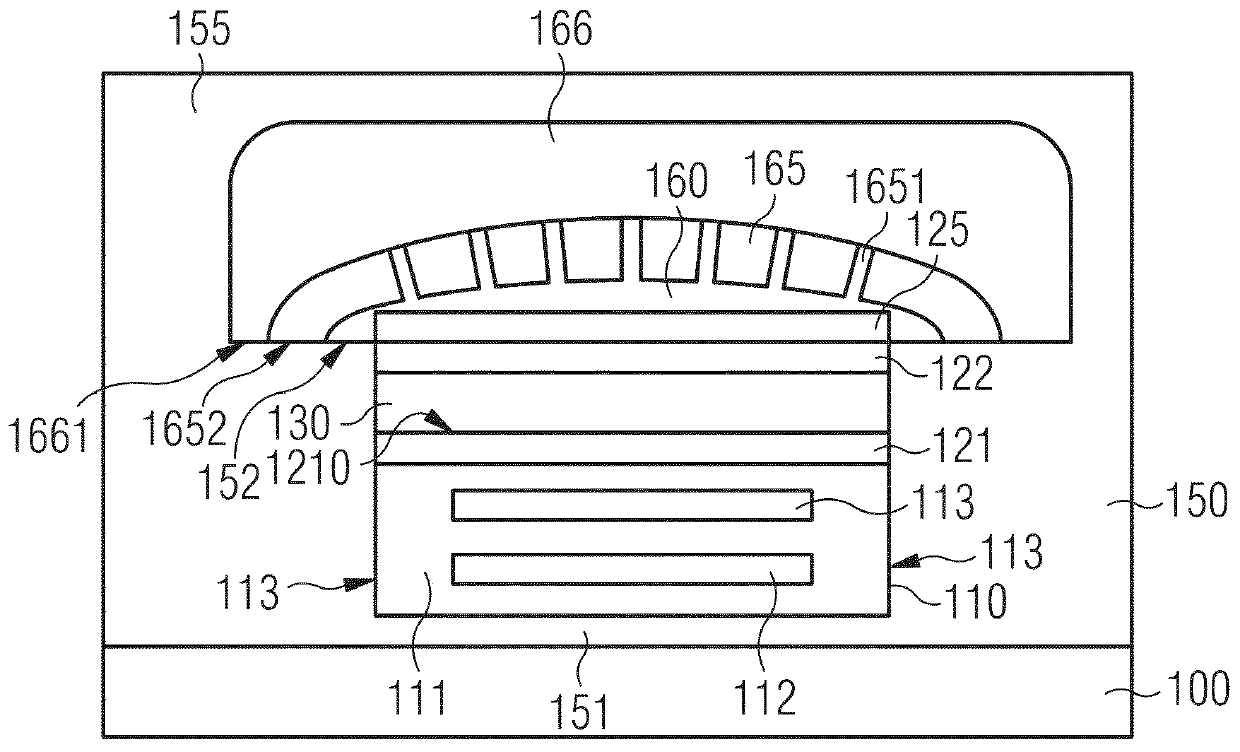

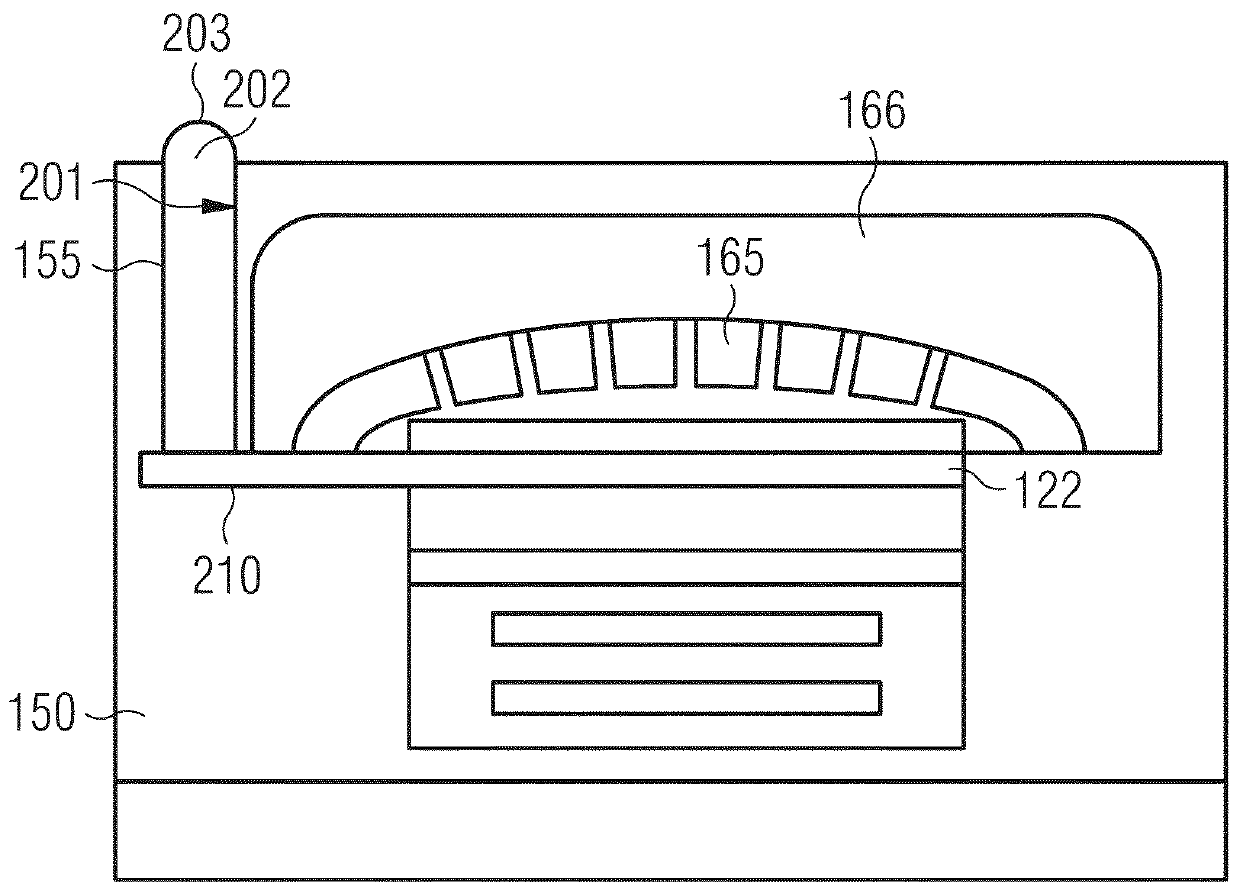

[0030] figure 1 The electroacoustic resonator device can be a solidly mounted resonator bulk acoustic wave device (BAW-SMR). The device is mounted on a substrate 100 as its underlying layer. Suitable substrates can be made from a variety of materials. In one embodiment, the substrate may be made of doped crystalline silicon. Doping makes silicon essentially non-conductive.

[0031] The BAW device includes an electroacoustic resonator including a bottom electrode 121 and a top electrode 122 with a piezoelectric layer 130 disposed therebetween. The top electrode and the bottom electrode may each be made of a metal layer. The metal layer may be made of tungsten (W) or a tungsten alloy. The piezoelectric layer 130 is made of a piezoelectric material. In this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com