Silicon nitride material and preparation method of heat insulating disc cover prepared from same

A technology of silicon nitride and nano-silicon nitride, which is applied in the field of heat insulation disk cover preparation, can solve the problems of large thermal expansion coefficient, impossibility of popularization and long delivery period, and achieve uniform density distribution, short diffusion distance and high quality Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

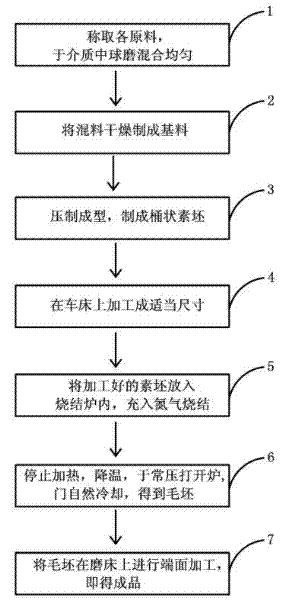

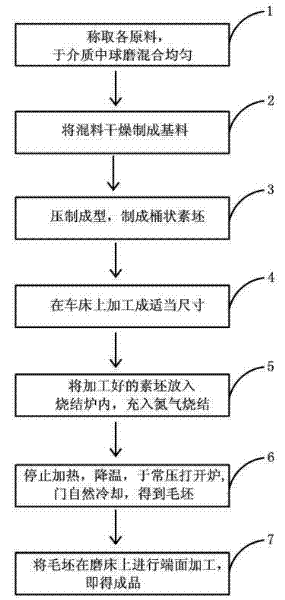

[0039] figure 1 The flow chart of the preparation method of the heat-insulating disc cover made of the silicon nitride material according to the present invention, such as figure 1 As shown, the preparation method of the heat-insulating disk cover made of the silicon nitride material described in the invention comprises the following steps:

[0040] 1) Weigh the raw materials according to the appropriate weight ratio, and mix them evenly by ball milling in the medium;

[0041] 2) drying the mixed material to make base material;

[0042] 3) After pressing and forming, a tubular green body is obtained;

[0043] 4) Processed to appropriate size on a lathe;

[0044] 5) Put the processed biscuit into the sintering furnace and fill it with nitrogen for sintering;

[0045] 6) Stop heating, cool down, open the furnace door under normal pressure to cool naturally, and get the blank;

[0046] 7) Process the blank on the grinding machine to obtain the finishe...

Embodiment 1

[0048] Weigh each raw material according to the following weight percentage: 87.5% of silicon nitride (average particle size of 0.1-5μm), 7% of nano-silicon nitride (average particle size of 2 o 3 (average particle size 2 o 3 6%, tungsten carbide (average particle size <5μm) is 0.5%, put it into a high-strength alumina ceramic container, add solvent high-purity ethanol, put silicon nitride grinding balls, roller ball mill for 30 hours, mix the materials into Dry it in an oven at a temperature of 120° C., sieve out impurities after drying, put it into a rubber mold for cold isostatic pressing at a molding pressure of 180 MPa, and obtain a green body. The biscuit is machined to precise dimensions on a lathe and then placed in a sintering furnace for sintering under nitrogen atmosphere with elevated temperature and pressure. The specific heating process is as follows: when the temperature rises to 1350°C, the pressure is increased to 0.4MPa and kept for 30 minutes; when the temp...

Embodiment 2

[0051] Weigh each raw material according to the following weight percentage: silicon nitride 65%, nano-silicon nitride 15%, sintering aid: Al 2 o 3 8%, La 2 o 3 (average particle size<5μm) 7%, tungsten carbide (average particle size<5μm) is 5%, add solvent high-purity ethanol, add abrasive polyethylene glycol with 1% of the total mass of raw materials, put alumina grinding balls, After roller milling for 40 hours, the mixed material was dried in an oven at a temperature of 80° C., and the sundries were sieved after drying. The base material is put into a polyurethane mold for cold isostatic pressing with a molding pressure of 200 MPa to obtain a green body. The biscuit is machined to precise dimensions on a lathe and then placed in a sintering furnace for sintering under nitrogen atmosphere with elevated temperature and pressure. The specific heating process is as follows: when the temperature rises to 1400°C, the pressure is increased to 1MPa and kept for 30 minutes; w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com