A kind of preparation method and application of porous mxene hydrogel based on electrogel process

A technology of electrogel and hydrogel, which is applied in the direction of electrolytic coating, electrophoretic plating, hybrid capacitor electrolyte, etc., can solve the problems of complex preparation, single shape, and the inability to realize the controllable modification of porous MXene hydrogel patterning, etc. achieve a universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

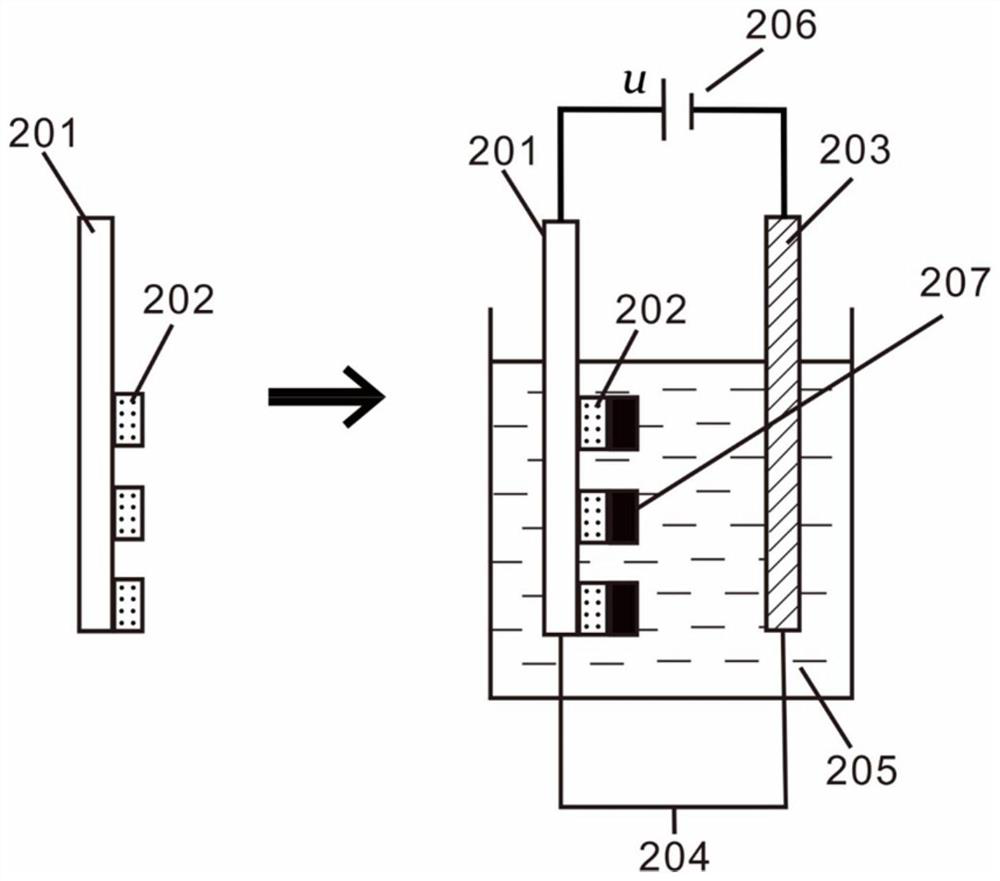

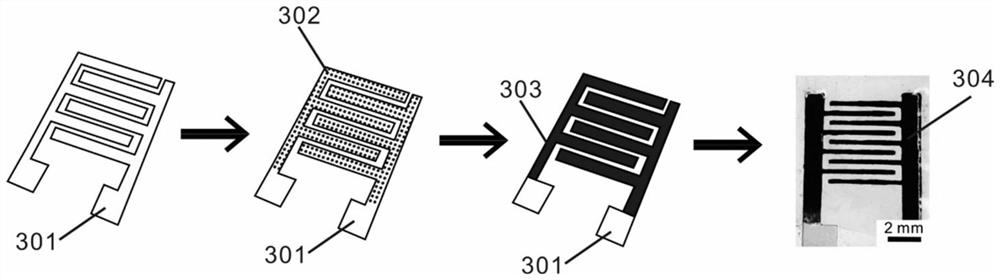

[0031] The present invention proposes a kind of porous MXene hydrogel preparation method based on electrogel process, and its preparation steps are:

[0032] S1: modifying the sacrificial metal layer on the target substrate;

[0033] S2: Use the target substrate modified with the sacrificial metal layer as the working electrode, and form an electrochemical system together with the standard electrode;

[0034] S3: The electrochemical system is immersed in the MXene dispersion, and an electrogel process is performed by applying an electric field, so that the MXene sheet in the dispersion forms a porous MXene hydrogel on the surface of the sacrificial metal layer.

[0035] Among them, the specific materials and process parameters in the above preparation method can adopt the following methods:

[0036] The electrogel process described above needs to apply a current or voltage bias to the electrochemical system. The method of modifying the sacrificial metal layer can be realized...

Embodiment 1

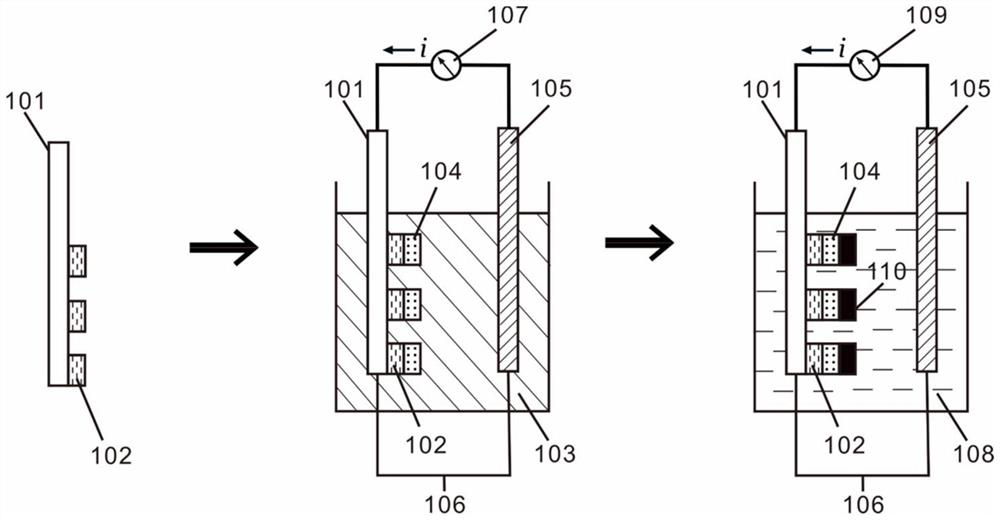

[0042] Such as figure 1 As shown, a method for preparing a porous MXene hydrogel based on an electrogel process is provided in this embodiment, which specifically includes the following steps:

[0043] 1) Form a gold-plated pad layer 102 with a certain pattern on the target substrate 101 by using a printed electronic circuit process.

[0044] 2) The above-mentioned target substrate 101 with the gold-plated pad layer 102 is immersed in the copper electrolyte 103 to implement a metal electroplating process, so that a copper sacrificial layer 104 is formed on the gold-plated pad layer 102, wherein the copper electrolyte is composed of 0.32g anhydrous copper sulfate, 4mL acetic acid, 45mL deionized water mixed. The electroplating process is to use the target substrate 101 as the working electrode and the standard electrode 105 to form an electrochemical system 106, and apply a constant current field 107 of -3mA to the electrochemical system 106.

[0045] 3) The electrochemical s...

Embodiment 2

[0048] Such as figure 1As shown, a method for preparing a porous MXene hydrogel based on an electrogel process is provided in this embodiment, which specifically includes the following steps:

[0049] 1) Form a gold-plated pad layer 102 with a certain pattern on the target substrate 101 by using a printed electronic circuit process.

[0050] 2) The above-mentioned target substrate 101 with the gold-plated pad layer 102 is immersed in the copper electrolyte 103 to implement a metal electroplating process, so that a copper sacrificial layer 104 is formed on the gold-plated pad layer 102, wherein the copper electrolyte is composed of 0.32g anhydrous copper sulfate, 4mL acetic acid, 45mL deionized water mixed. The electroplating process is to use the target substrate 101 as the working electrode and the standard electrode 105 to form an electrochemical system 106 , and apply a constant current field 107 of -1 mA to the electrochemical system 106 .

[0051] 3) Immerse the electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com