Iron lithium fluoride battery anode material prepared by nitrogen-doped silicon carbide-assisted solid phase one-step process and preparation method

A cathode material, lithium iron fluoride technology, used in iron halide, battery electrodes, circuits, etc., can solve the problems of unsuitable industrial application, poor reaction reversibility, and high reaction activation energy, to improve electrochemical performance, reduce Activation energy, the effect of increasing the reversible capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

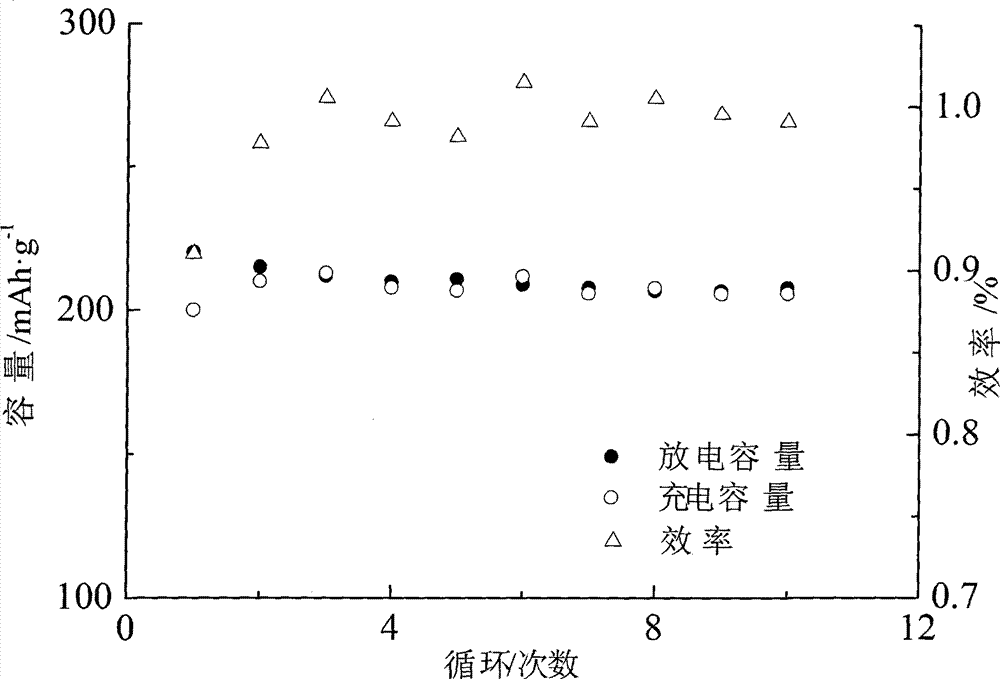

Image

Examples

Embodiment 1

[0020] Embodiment 1: Fe(NO 3 ) 3 9H 2 O and ammonium fluoride (molar ratio is 1.0: 3.0) mixture with 3% by weight of nitrogen-doped silicon carbide, 0.8% by weight of Tween-80 after ball milling at room temperature for 6 hours under the protection of high-purity nitrogen in a high-energy ball mill , take out the material, heat up to 320 degrees under the protection of a mixed gas of 5% hydrogen and 95% argon for 2 hours, and then cool down to obtain FeF that can be directly used for slurry coating 3 Cathode material.

Embodiment 2

[0021] Embodiment 2: FeCl 3 ·6H 2 O and ammonium fluoride (molar ratio is 1.0: 3.6) mixture with 12% by weight of nitrogen-doped silicon carbide, 2.8% by weight of tx-10 after ball milling at room temperature for 19 hours under the protection of high-purity argon in a high-energy ball mill , take out the material, heat up to 450 degrees under the protection of a mixed gas of 5% hydrogen and 95% argon for 9 hours, and then cool down to obtain FeF that can be directly used for slurry coating 3 Cathode material.

Embodiment 3

[0022] Embodiment 3: Fe 2 (SO 4 ) 3 .9H 2 O and ammonium fluoride (molar ratio is 1.0:3.3) mixture with 8% by weight of nitrogen-doped silicon carbide, 1.5% by weight of span-60 after ball milling at room temperature for 10 hours under the protection of high-purity argon in a high-energy ball mill , take out the material, heat up to 350 degrees under the protection of a mixed gas of 5% hydrogen and 95% argon for 6 hours, and then cool down to obtain FeF that can be directly used for slurry coating 3 Cathode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com