Iron fluoride/carbon composite positive electrode material, preparation method thereof and lithium ion battery

A technology of lithium ion battery and positive electrode material, which is applied in the direction of positive electrode, battery electrode, secondary battery, etc., can solve the problem that the reversible specific capacity and cycle performance of electrode material need to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

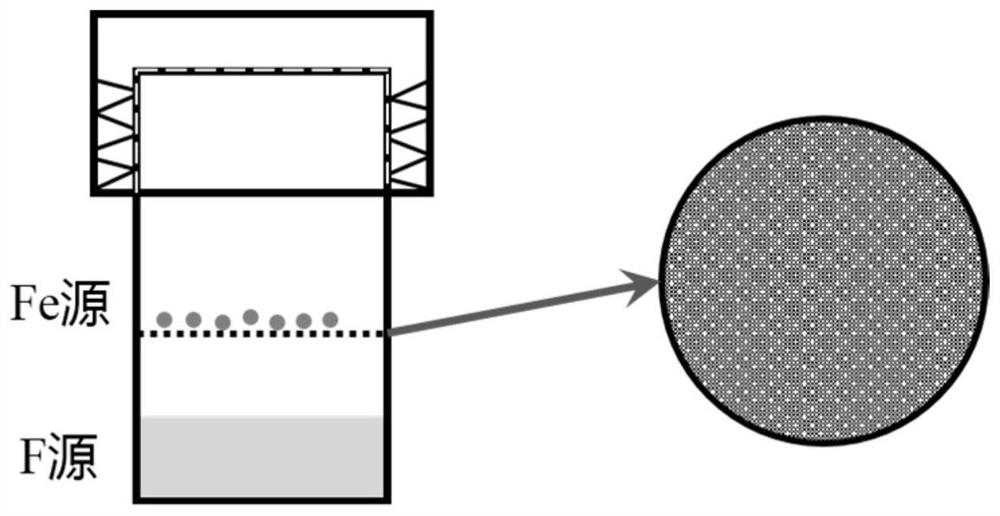

[0058] This embodiment provides a ferric fluoride / carbon composite positive electrode material and a preparation method thereof, and the preparation method specifically includes the following steps:

[0059] (1) ferrocene is placed on the upper strata of the airtight reactor, and the lower floor is hydrofluoric acid and toluene; wherein, the mol ratio of ferrocene and hydrofluoric acid is 1:3; the mol ratio of carbon in ferrocene and toluene is 1:0.5.

[0060] (2) Fill the closed reaction kettle with argon gas, heat treatment and reaction at 120°C for 10 hours, and collect the powder after the reaction;

[0061] (3) The obtained powder is heat-treated in an argon atmosphere, heated at a rate of 5°C / min to 250°C for 4 hours, and FeF is obtained after cooling. 3 / C cathode material.

[0062] The obtained positive electrode material was used as the lithium ion battery positive electrode material for electrochemical performance testing, and the ratio of the electrode sheet was p...

Embodiment 2

[0064] This embodiment provides a ferric fluoride / carbon composite positive electrode material and a preparation method thereof, and the preparation method specifically includes the following steps:

[0065] (1) Ferrocene is placed in the upper layer of the airtight reactor, and the lower floor is hydrofluoric acid and octafluorotoluene; wherein, the mol ratio of ferrocene to hydrofluoric acid is 1:0.5; the carbon in ferrocene and octafluorotoluene The molar ratio is 1:2.

[0066] (2) Fill the closed reaction kettle with nitrogen, heat treatment and reaction at 90°C for 15 hours, and collect the powder after the reaction;

[0067] (3) The obtained powder is heat-treated in a nitrogen atmosphere, heated at a rate of 1°C / min to 150°C for 10 hours, and FeF is obtained after cooling. 3 / C cathode material.

[0068] The obtained positive electrode material was used as the lithium ion battery positive electrode material for electrochemical performance testing, and the ratio of the...

Embodiment 3

[0070] This embodiment provides a ferric fluoride / carbon composite positive electrode material and a preparation method thereof, and the preparation method specifically includes the following steps:

[0071] (1) ferrocene is placed in the upper layer of the airtight reactor, and the lower layer is hydrofluoric acid and toluene; wherein, the molar ratio of ferrocene to hydrofluoric acid is 1:6; ferrocene and toluene and / or octafluorotoluene The molar ratio of middle carbon is 1:0.1.

[0072] (2) Fill the closed reaction kettle with helium, heat treatment and reaction at 150°C for 2 hours, and collect the powder after the reaction;

[0073] (3) The obtained powder is heat-treated in a helium atmosphere, heated at a rate of 30°C / min to 150°C for 1 hour, and FeF is obtained after cooling. 3 / C cathode material.

[0074] The obtained positive electrode material was used as the lithium ion battery positive electrode material for electrochemical performance testing, and the ratio o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com