Degradable environment-friendly membrane material as well as preparation method and production system thereof

A membrane material, an environmentally friendly technology, applied in chemical instruments and methods, sustainable manufacturing/processing, biological packaging, etc., can solve the problems of destroying the ecological balance of nature, PLA application restrictions, soil and water pollution, etc., and achieve excellent thermal stability , the effect of excellent service performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

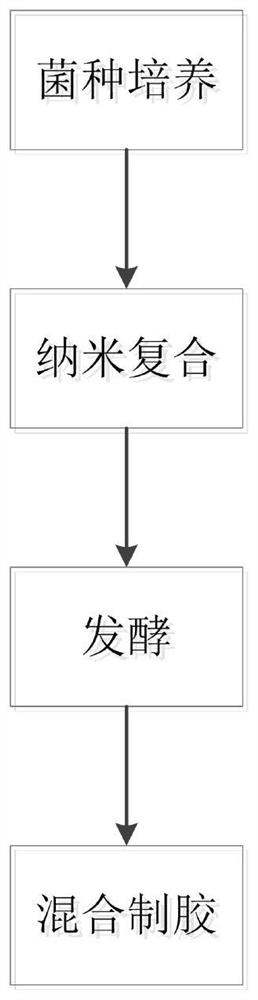

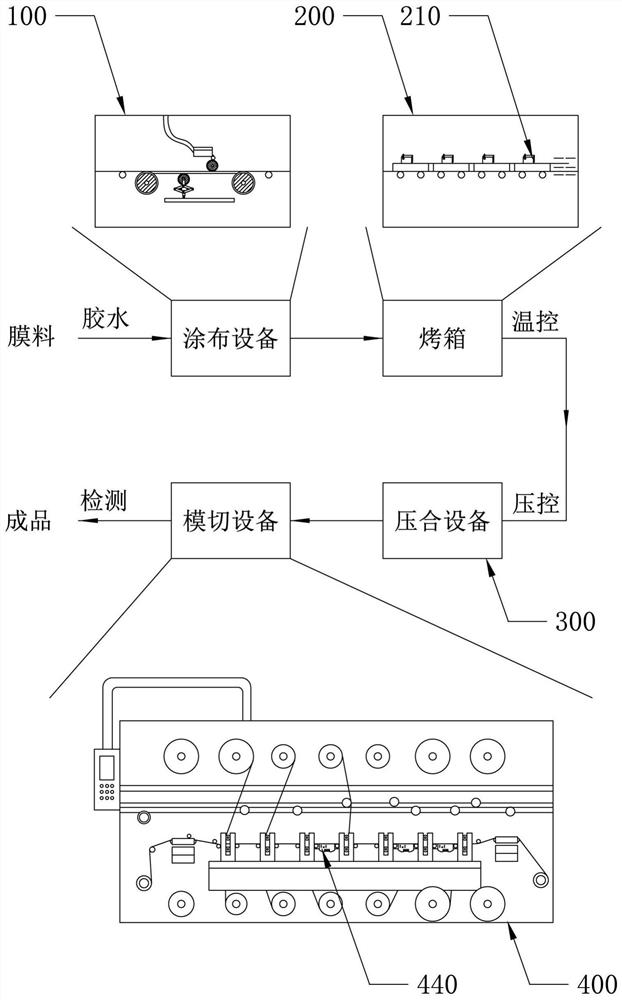

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1: the preparation of degradable environmental protection film material

[0052] A kind of degradable environment-friendly film material, comprises PLA layer, biological hydrogel layer and PLA layer successively; In biological hydrogel layer, by weight, comprises nanoclay sheet 2 parts, bacterial cellulose 6 parts and 1 part of carbon nanotubes, wherein nanoclay sheets and bacterial cellulose form a shell-like layered structure.

[0053] Nano-clay is prepared with sepiolite and attapulgite as the main components. It has good dispersion, suspension, adsorption, rheology and reinforcement properties, and has extremely strong ion exchange properties.

[0054] Bacterial cellulose refers to the general term for cellulose synthesized by certain microorganisms in the genus Acetobacter, Agrobacterium, Rhizobium and Sarcina under different conditions.

[0055] Carbon nanotubes, also known as bucky tubes, are one-dimensional quantum materials with a special structure ...

Embodiment 2

[0071] Embodiment 2: the preparation of degradable environmental protection film material

[0072] A kind of degradable environment-friendly film material, comprises PLA layer, biological hydrogel layer and PLA layer successively; In biological hydrogel layer, by weight, comprises nanoclay sheet 10 parts, bacterial cellulose 2 parts and carbon 0.1 parts of nanotubes, wherein nanoclay sheets and bacterial cellulose form a layered structure imitating shells.

[0073] The preparation process of the biohydrogel layer is the same as that of Example 1, and will not be repeated here.

[0074] The thickness of the PLA layer is 0.01mm; the thickness of the environmental film material is 0.03mm.

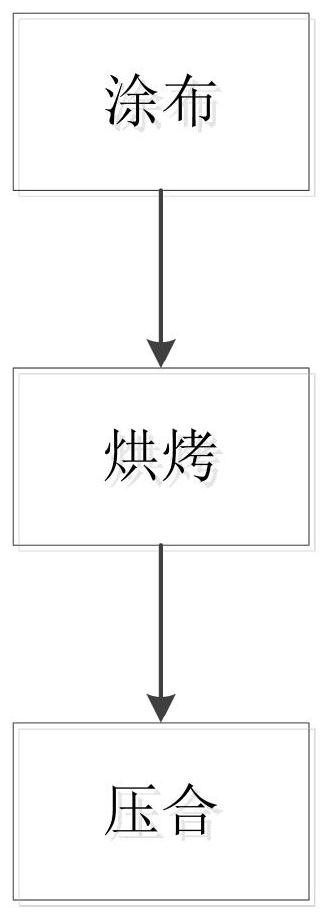

[0075] The preparation method of the above-mentioned degradable environmental protection membrane material comprises the following steps:

[0076] S1: Coating, coating the bio-hydrogel on the PLA film, the coating amount of the bio-hydrogel is 0.3g / cm2, when coating the above-mentioned bio-h...

Embodiment 3

[0079] Embodiment 3: the preparation of degradable environmental protection film material

[0080] A kind of degradable environment-friendly film material, comprises PLA layer, biological hydrogel layer and PLA layer successively; In biological hydrogel layer, by weight, comprises nanoclay sheet 6 parts, bacterial cellulose 4 parts and carbon 0.5 parts of nanotubes, wherein the nanoclay sheet and bacterial cellulose form a shell-like layered structure.

[0081] The preparation process of the biohydrogel layer is the same as that of Example 1, and will not be repeated here.

[0082] The thickness of the PLA layer is 0.01mm; the thickness of the environmental film material is 0.03mm.

[0083] The preparation method of the above-mentioned degradable environmental protection membrane material comprises the following steps:

[0084] S1: Coating, coating the bio-hydrogel on the PLA film, the coating amount of the bio-hydrogel is 0.5g / cm2, when coating the above-mentioned bio-hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com