Three-dimensional porous silicon/graphene composite negative electrode material, preparation method thereof and lithium ion battery

A graphene composite, negative electrode material technology, applied in batteries, battery electrodes, secondary batteries, etc., can solve the problems of silicon dispersion and agglomeration, limited stability, environmental pollution, etc. The effect of high current charge and discharge, reduce polarization, and improve cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

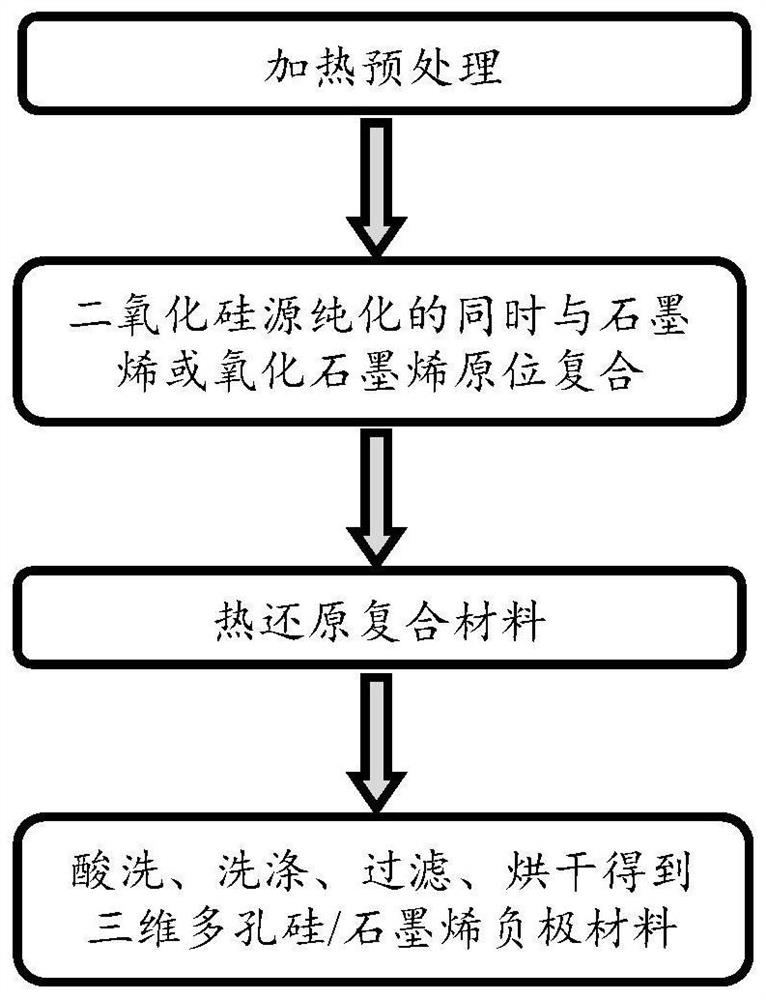

Method used

Image

Examples

Embodiment 1

[0042] Silicon dioxide with an average particle size of 0.2 μm was heated to 500° C. at a heating rate of 3° C. / min under atmospheric pressure and kept for 1 hour to remove organic impurities. Then add graphene or graphene oxide dispersed in 1mol / L sulfuric acid solution, stir and disperse with 100r / min magnetic force at room temperature for 1h, and finally filter, wash with deionized water, and dry at 50°C for 1h to obtain an intermediate product a.

[0043]The intermediate product A was reduced to obtain the intermediate product B by using 3 μm aluminum powder (Al) as a reducing agent at a reduction temperature of 650° C. and keeping it in a vacuum atmosphere for 1 hour.

[0044] Put the intermediate product B into 2.0mol / L hydrochloric acid for pickling for 0.5h, then wash with deionized water, filter, and dry at 50°C for 1h under argon atmosphere to obtain a three-dimensional porous silicon / graphene negative electrode material.

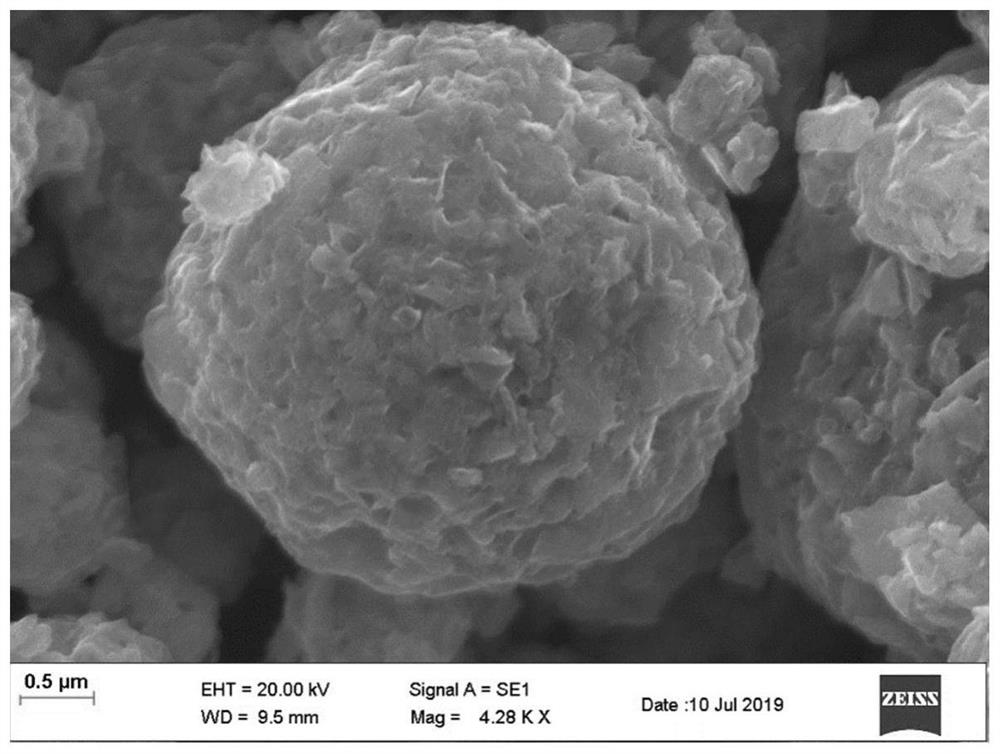

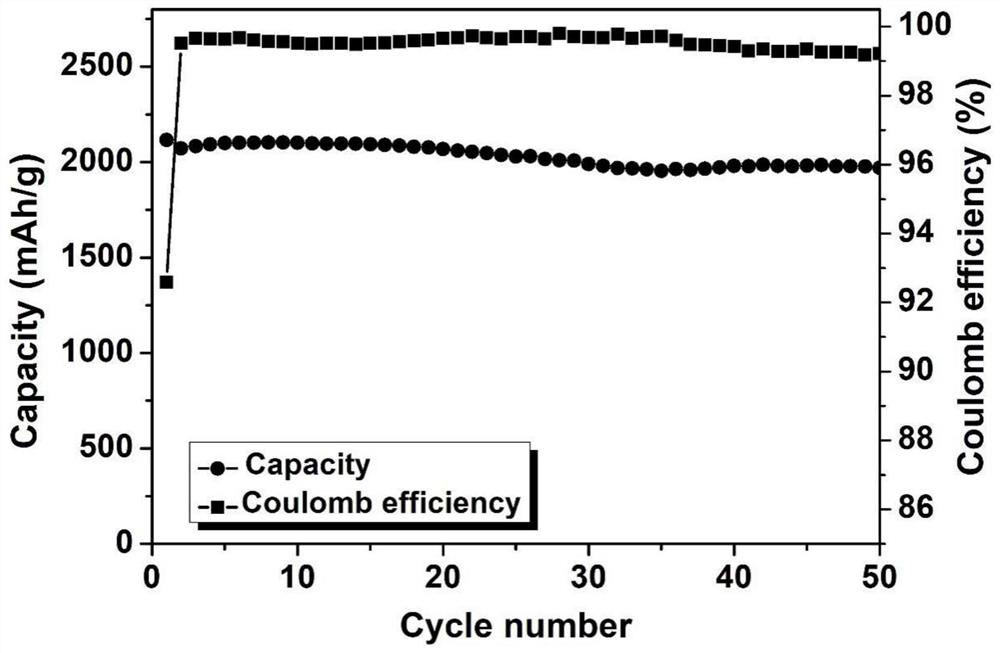

[0045] The obtained three-dimensional poro...

Embodiment 2

[0047] Porous silica with an average particle size of 3 μm was heated to 600° C. at a heating rate of 10° C. / min under atmospheric pressure and kept for 2 hours to remove organic impurities. Then add graphene or graphene oxide dispersed in a 3mol / L sulfuric acid solution, mechanically stir at 500r / min at room temperature to disperse and compound for 2h, and finally filter, wash with deionized water, and dry at 80°C for 1.5h to obtain an intermediate product a.

[0048] The intermediate product A was reduced to obtain the intermediate product B by using 3 μm aluminum powder (Al) as a reducing agent at a reduction temperature of 750° C. and keeping the temperature for 3 hours in a vacuum atmosphere.

[0049] Put the intermediate product B into 2.5 mol / L hydrochloric acid for pickling for 1 h, then wash with deionized water, filter, and dry at 50°C for 3 h under a nitrogen atmosphere to obtain a three-dimensional porous silicon / graphene negative electrode material.

[0050] fi...

Embodiment 3

[0053] Diatomite with an average particle size of 7 μm was heated to 550° C. at a heating rate of 20° C. / min under atmospheric pressure and kept for 2 hours to remove organic impurities. Then add graphene or graphene oxide dispersed in 1mol / L sulfuric acid solution, stir and disperse at room temperature at 800r / min for 1h, and finally filter, wash with deionized water, and dry at 80°C for 2h to obtain intermediate product A.

[0054] With 3μm aluminum powder (Al) and 10μm titanium hydride powder (TiH 2 ) are mixed at a mass ratio of 9:1 as a reducing agent, the reduction temperature is 650°C, and the intermediate product A is reduced to obtain the intermediate product B under a vacuum atmosphere for 5 hours.

[0055] Put the intermediate product B into 5.0 mol / L hydrochloric acid for pickling for 3 hours, then wash with deionized water, filter, and dry at 60°C for 1 hour in an argon atmosphere to obtain a three-dimensional porous silicon / graphene negative electrode material. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com