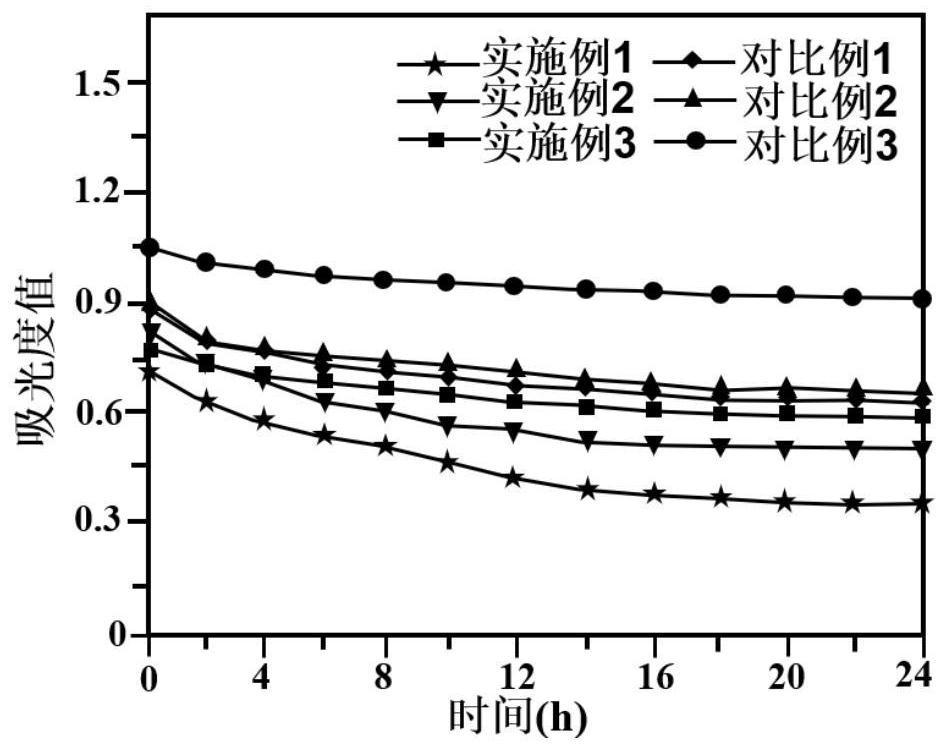

Preparation method of high-dispersity nano titanium dioxide/melamine resin for plastic products

A nano-titanium dioxide, melamine technology, applied in the direction of sustainable manufacturing/processing, chemical industry, climate sustainability, etc., can solve the problems such as the influence of the dispersibility of titanium dioxide, increase energy consumption, cost increase, etc., and achieve increased viscosity , Save production costs, improve the effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

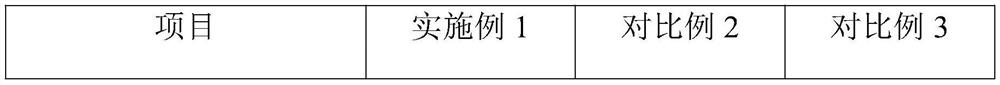

Embodiment 1

[0021] A kind of highly dispersed nano-titanium dioxide / melamine resin for plastic products prepared by the embodiment of the present invention 1, it specifically includes the following steps:

[0022] (1) Under magnetic stirring, mix 5mL glycerin and 6.3g melamine evenly, add 5mL polyethylene glycol and heat in water for 20min, then add 20mL isopropanol and stir evenly, then add 1mol / L hydrochloric acid to adjust the pH to 4 , then at 700rpm / min speed, add 5mL titanium tetrachloride dropwise, stir rapidly for 10min, until the test solution no longer flows, forming a gel-like titanium dioxide precursor;

[0023] (2) Centrifuge the titanium dioxide precursor prepared in step (1), then mix and grind the isolated solid product with 0.6% of its mass fraction of sodium stearate, then add 10mL of formaldehyde, and Ultrasonic dispersion for 1 hour, and during this process, triethanolamine was added to adjust the pH to 9 to maintain a stable polymerization reaction, and then the produ...

Embodiment 2

[0027] A kind of highly dispersed nano-titanium dioxide / melamine resin for plastic products prepared by the embodiment of the present invention 2, it specifically comprises the following steps:

[0028] (1) Under magnetic stirring, mix 10mL glycerin and 12.6.g melamine evenly, add 5mL polyethylene glycol and heat in water for 20min, then add 20mL isopropanol and stir evenly, then add 1mol / L hydrochloric acid to adjust the pH to 4. Then, at 700 rpm / min, add 5 mL of titanium tetrachloride dropwise, and stir rapidly for 10 minutes until the test solution no longer flows, forming a gel-like titanium dioxide precursor;

[0029] (2) Centrifuge the titanium dioxide precursor prepared in step (1), then mix and grind the isolated solid product with 0.3% sodium stearate accounting for its mass fraction, then add 20mL formaldehyde, and Ultrasonic dispersion for 1 hour, and during this process, triethanolamine was added to adjust the pH to 9 to maintain a stable polymerization reaction, a...

Embodiment 3

[0033] A kind of highly dispersed nano-titanium dioxide / melamine resin for plastic products prepared by the embodiment of the present invention 3, it specifically comprises the following steps:

[0034](1) Under magnetic stirring, mix 10mL glycerin and 12.6.g melamine evenly, add 5mL polyethylene glycol and heat in water for 20min, then add 20mL isopropanol and stir evenly, then add 1mol / L hydrochloric acid to adjust the pH to 4. Then, at 700rpm / min, add 2mL titanium tetrachloride dropwise, stir rapidly for 10min, until the test solution no longer flows, forming a gel-like titanium dioxide precursor;

[0035] (2) Centrifuge the titanium dioxide precursor prepared in step (1), then mix and grind the isolated solid product with 0.2% of its mass fraction of sodium stearate, then add 10mL of formaldehyde, and Ultrasonic dispersion for 1 hour, and during this process, triethanolamine was added to adjust the pH to 9 to maintain a stable polymerization reaction, and then the product ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com