a cu 2 o/n-c oxygen reduction catalyst and its preparation and application

A technology of catalyst and cuprous oxide, which is applied in the field of material chemistry, can solve the problems of poor stability of metal nitrogen carbon materials, damage to battery materials and devices, and shortage of metal platinum resources, so as to improve catalytic activity, reduce the generation of intermediate products, improve The effect of electrochemical performance

Active Publication Date: 2022-06-03

CENT SOUTH UNIV

View PDF13 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the development of aluminum-metal-air batteries is mainly limited by the oxygen reduction reaction of its cathode air. The oxygen reduction reaction is a process with slow kinetics. At present, the catalysts that are more commercially dependent are platinum-based catalysts, but metal platinum resources are in short supply. It is expensive, so it is one of the problems to be solved urgently to develop an efficient and cheap non-platinum oxygen reduction catalyst

[0003] In recent years, the non-platinum catalysts that have been widely studied are metal nitrogen carbon catalysts. [1-3] , the oxygen reduction active sites of metal nitrogen carbon materials are Me-N groups embedded in carbon, nitrogen-doped carbon-coated metal groups, nitrogen-doped carbon groups, etc. [4] , although the metal nitrogen carbon catalyst has excellent oxygen reduction performance, the study found that the stability of the metal nitrogen carbon material is poor. During the working process, the active substance will continue to dissolve and generate H 2 o 2 , damage battery materials and devices

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

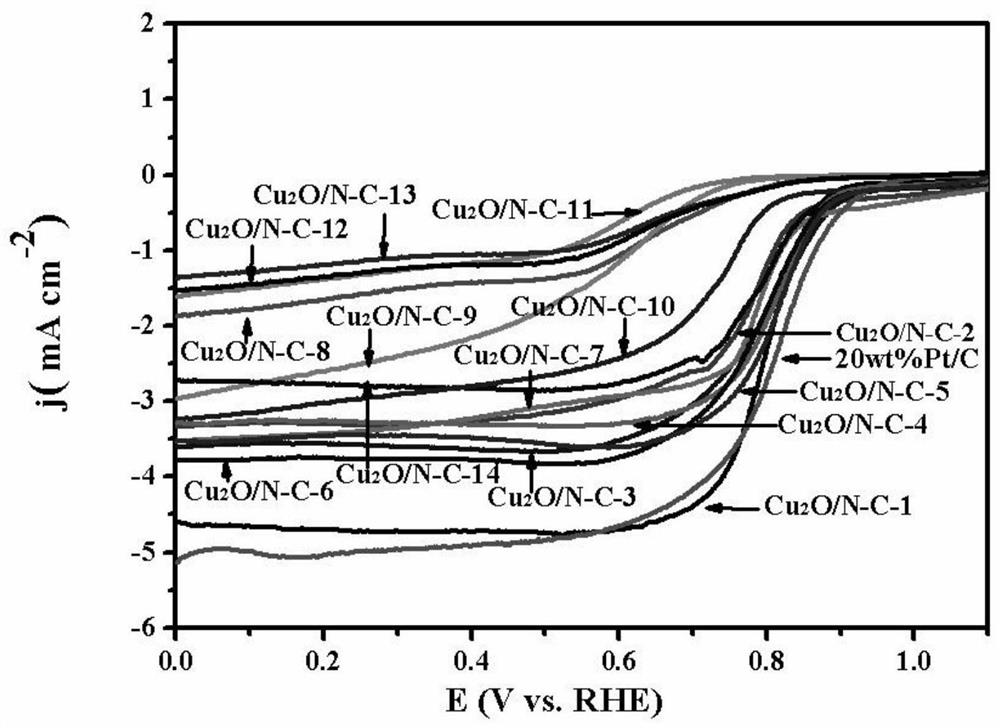

[0066] The limiting current density of the samples was tested in a three-electrode system by a rotating disk electrode (RDE) via an electrochemical workstation.

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Login to View More

Abstract

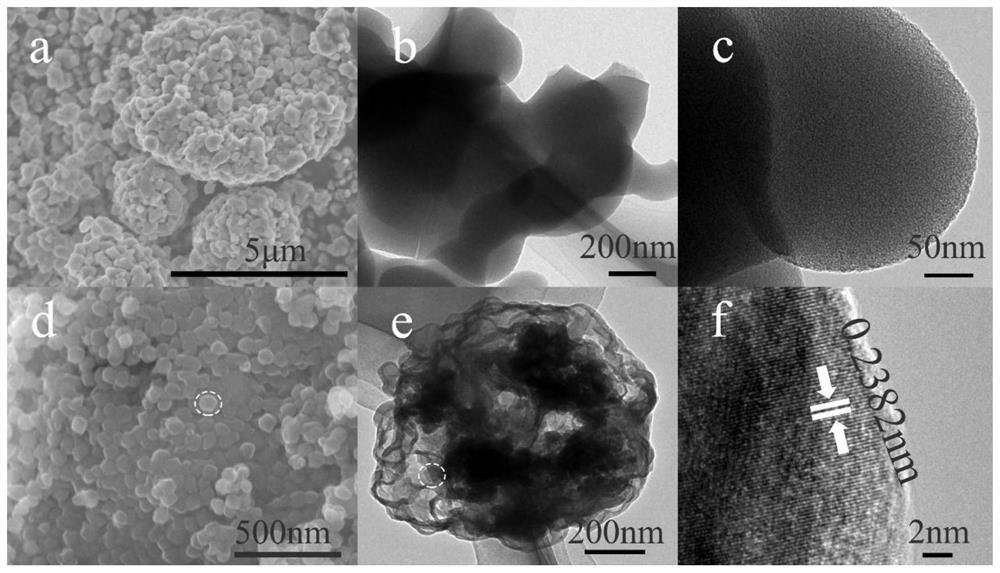

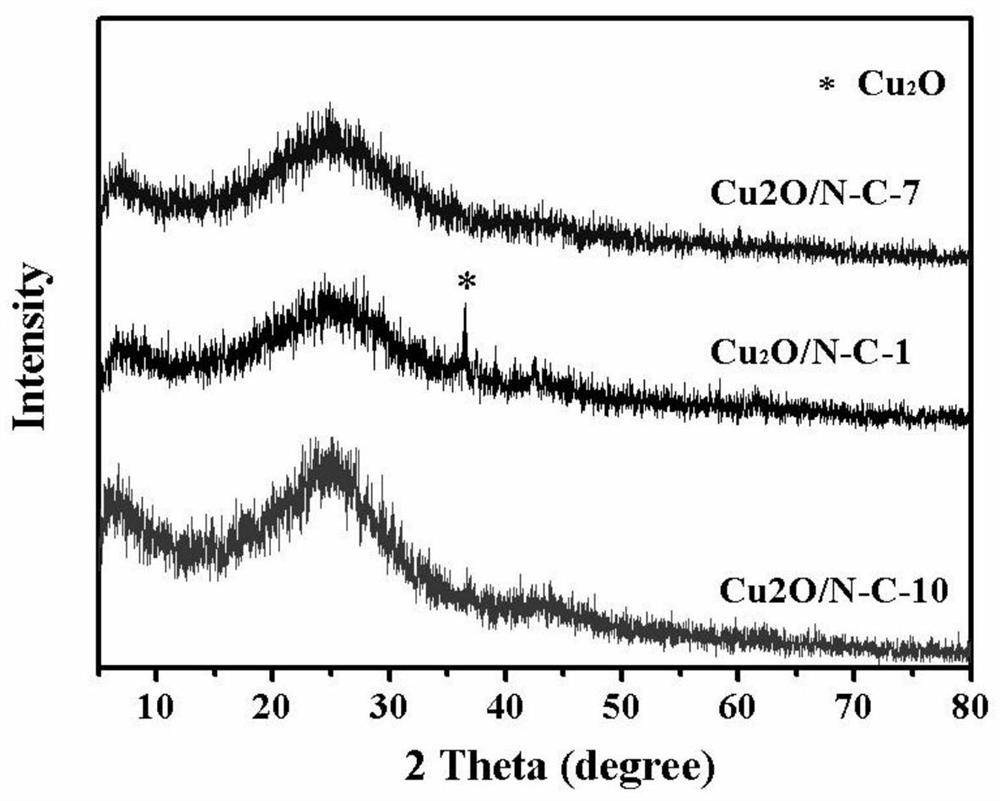

The invention discloses a Cu2O / N-C oxygen reduction catalyst as well as its preparation and application. The catalyst is prepared by dissolving a certain amount of zinc salt and carbon source in an organic solvent, adding a copper source, and obtaining Cu by pyrolysis. 2 O / N-C oxygen reduction catalyst, the experiment adjusts the amount of cuprous oxide generated by adjusting the amount of copper source added. The method is simple and repeatable. The catalyst is a composite material of cuprous oxide and nitrogen-doped carbon. Cuprous oxide is the active site of oxygen reduction catalysis. Nitrogen-doped carbon can improve the electrical conductivity of the material and make the material have a higher current density. The best material prepared is used as an oxygen reduction catalyst for aluminum-air batteries, its oxygen reduction half-wave potential is 0.8V, and its limiting current density is 4.6mA / cm 2 .

Description

a Cu 2 O / N‑C oxygen reduction catalyst and its preparation and application technical field The present invention relates to material chemistry field and electrocatalysis technical field, be specifically related to a kind of Cu 2 O / N‑C Oxygen Reduction Catalysis agent and preparation method and application thereof. Background technique With the deteriorating global environment and the increasing shortage of fossil energy, people are deeply aware of the development of new clean Energy is imminent, and aluminum-metal-air batteries have high energy density (theoretically up to ~8131Wh / kg Al and ~21, 954Wh / L Al ), abundant reserves, low cost, good safety and other advantages are considered to be a new generation of energy storage batteries with great potential. At present, the development of aluminum-metal-air batteries is mainly limited by the oxygen reduction reaction of its cathode air, which is an active The mechanical process is slow. At present, th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01M4/90H01M12/08B82Y30/00B82Y40/00

CPCH01M4/9016H01M4/9083H01M12/08B82Y30/00B82Y40/00Y02E60/50

Inventor 唐有根田敬王海燕李静莎刘德培

Owner CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com