Patents

Literature

40 results about "Rotating disk electrode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

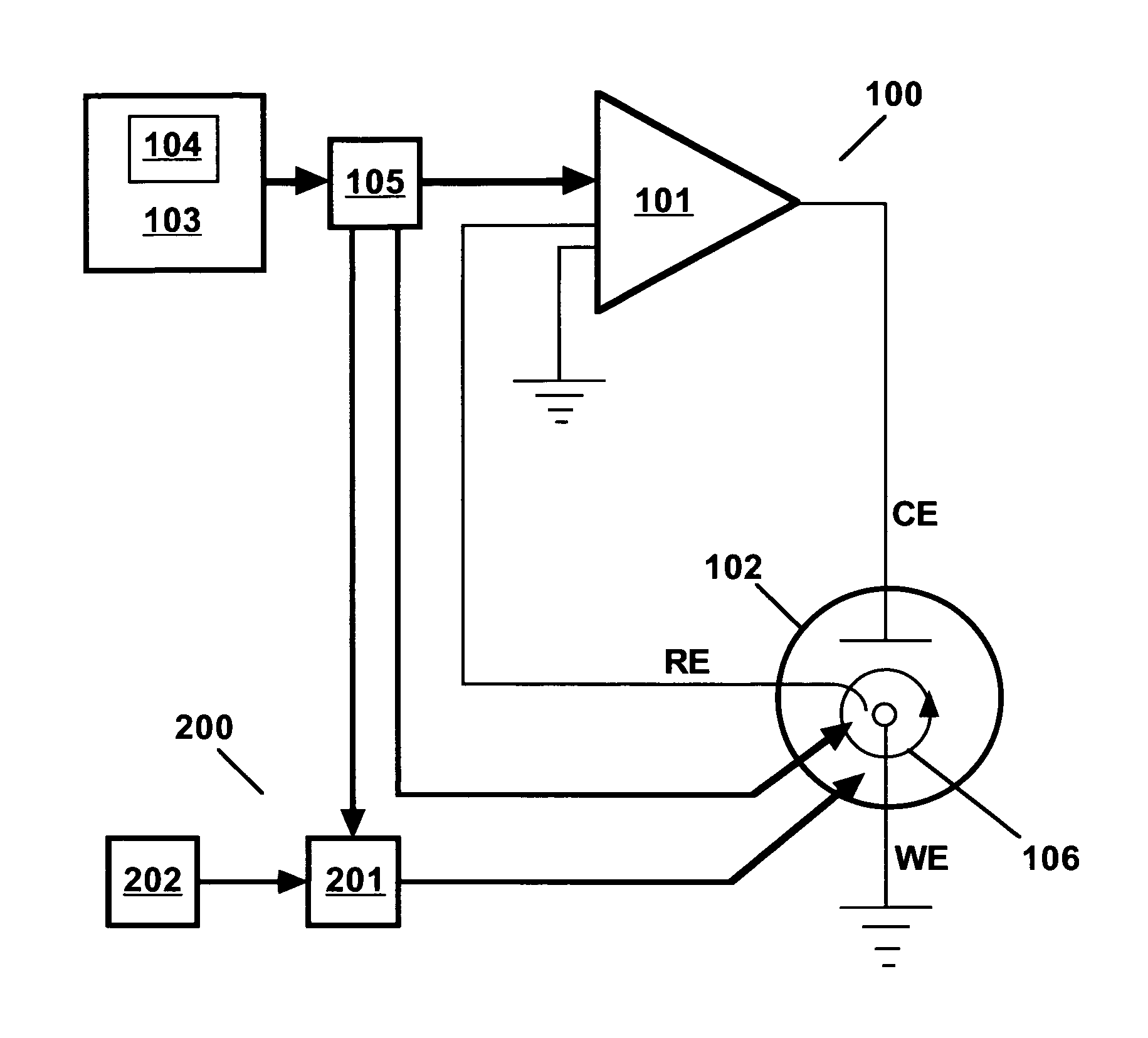

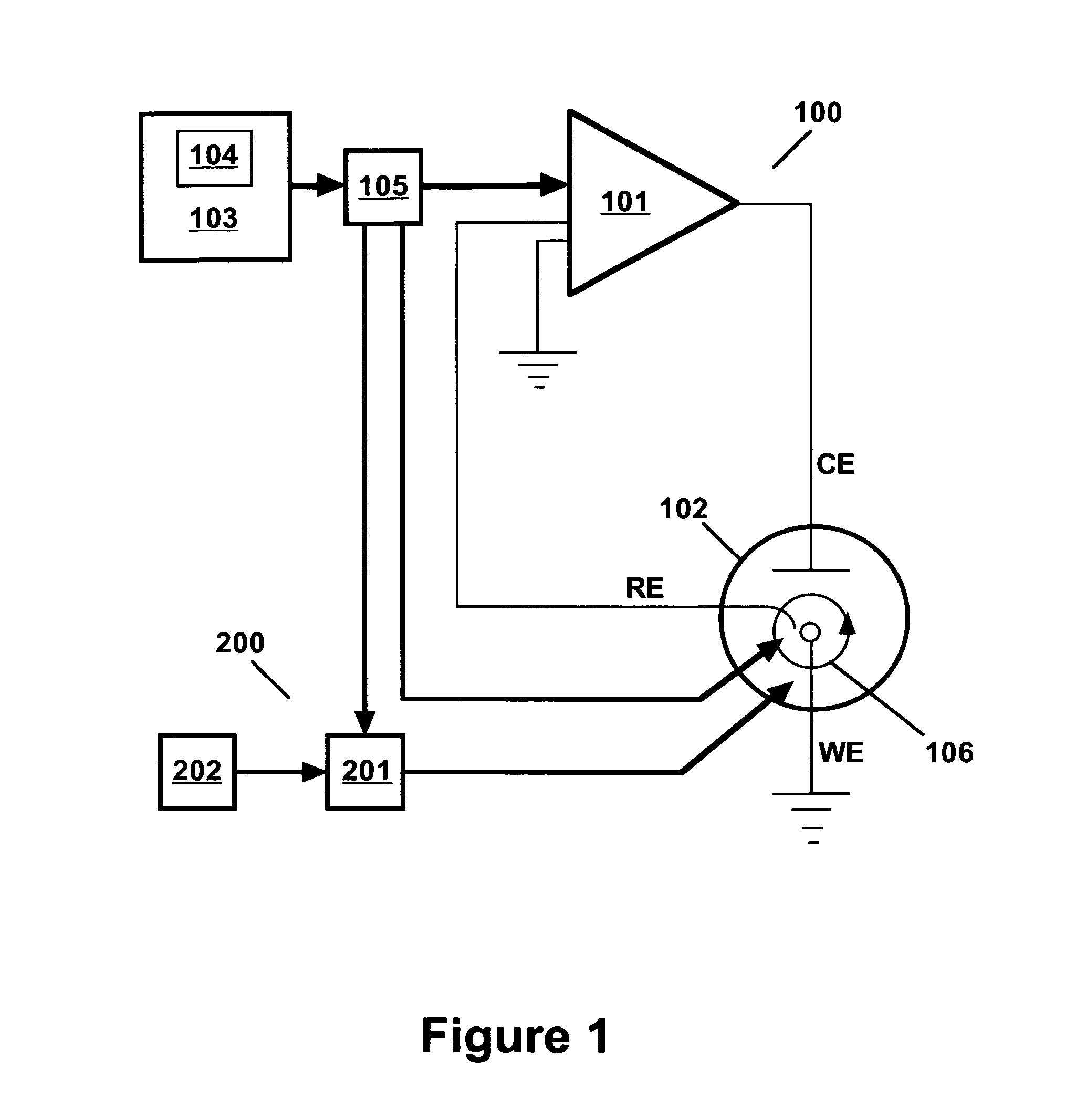

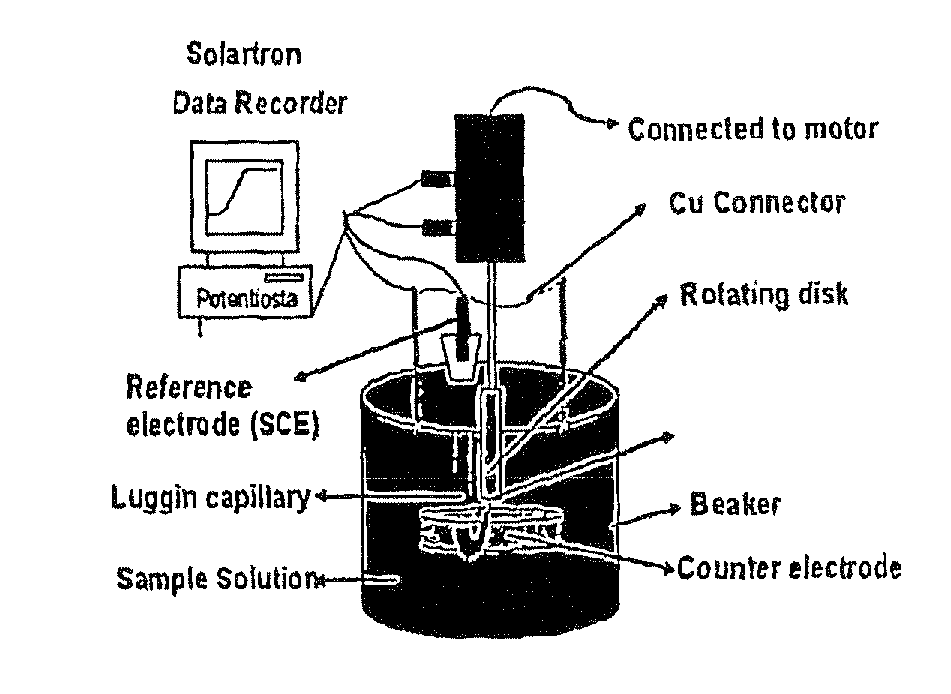

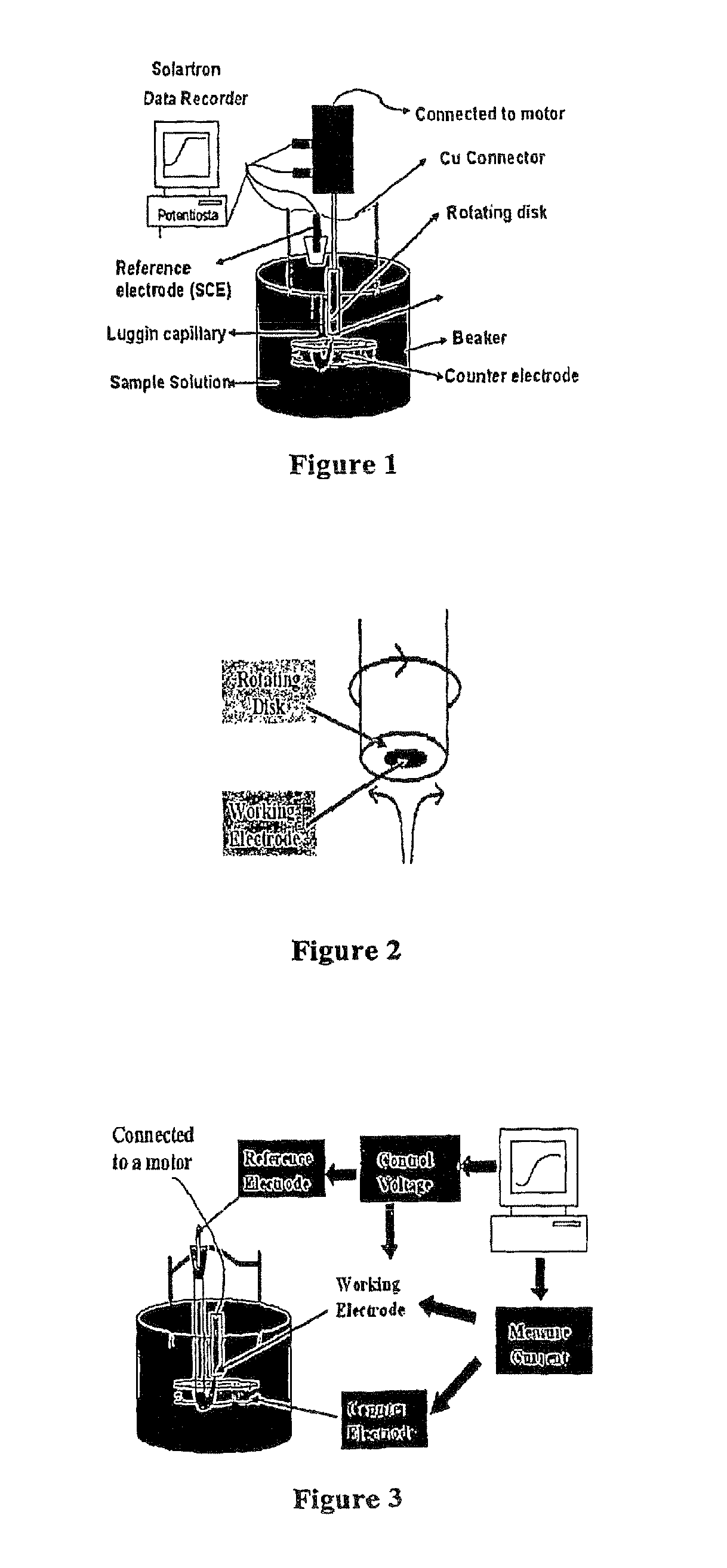

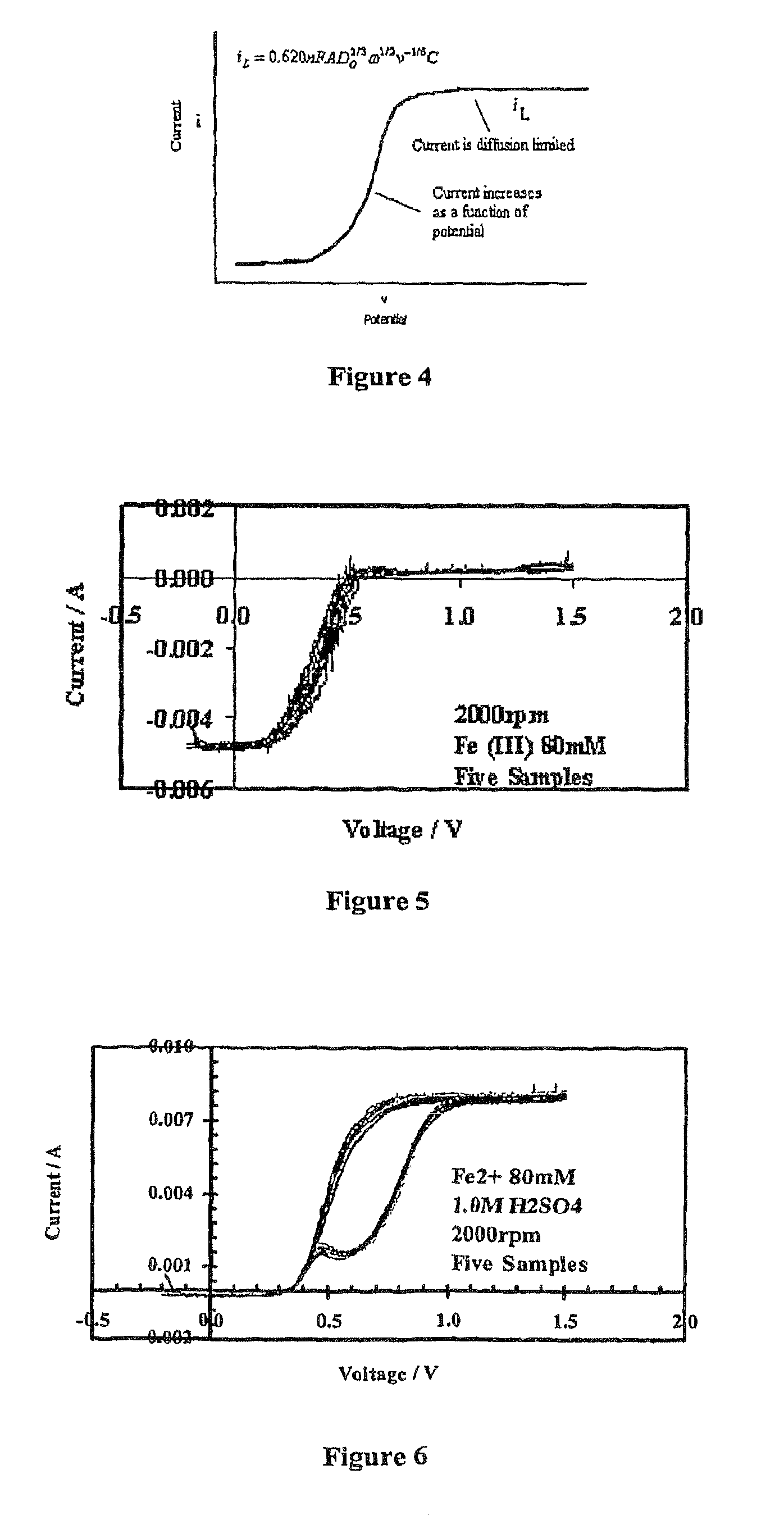

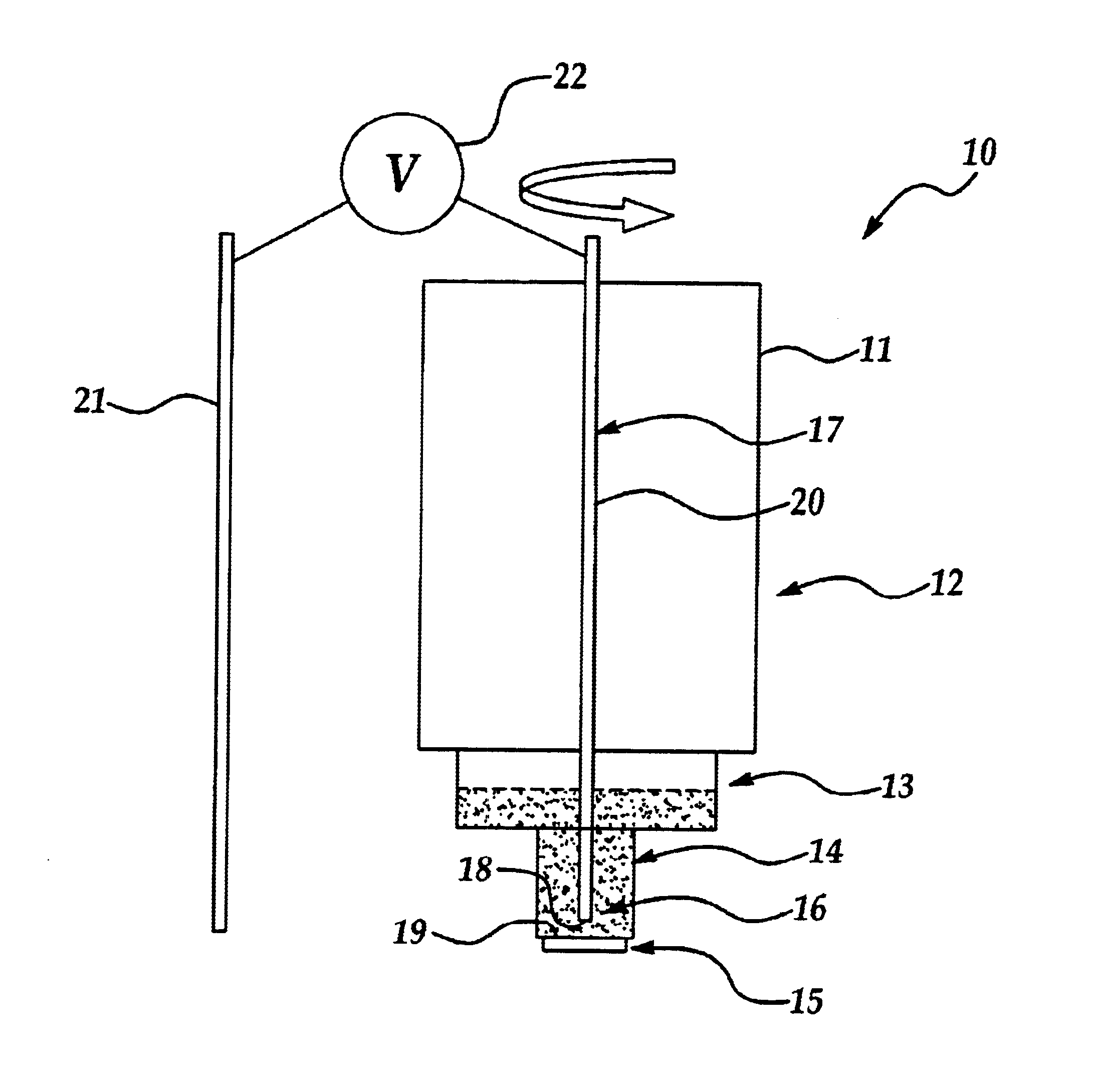

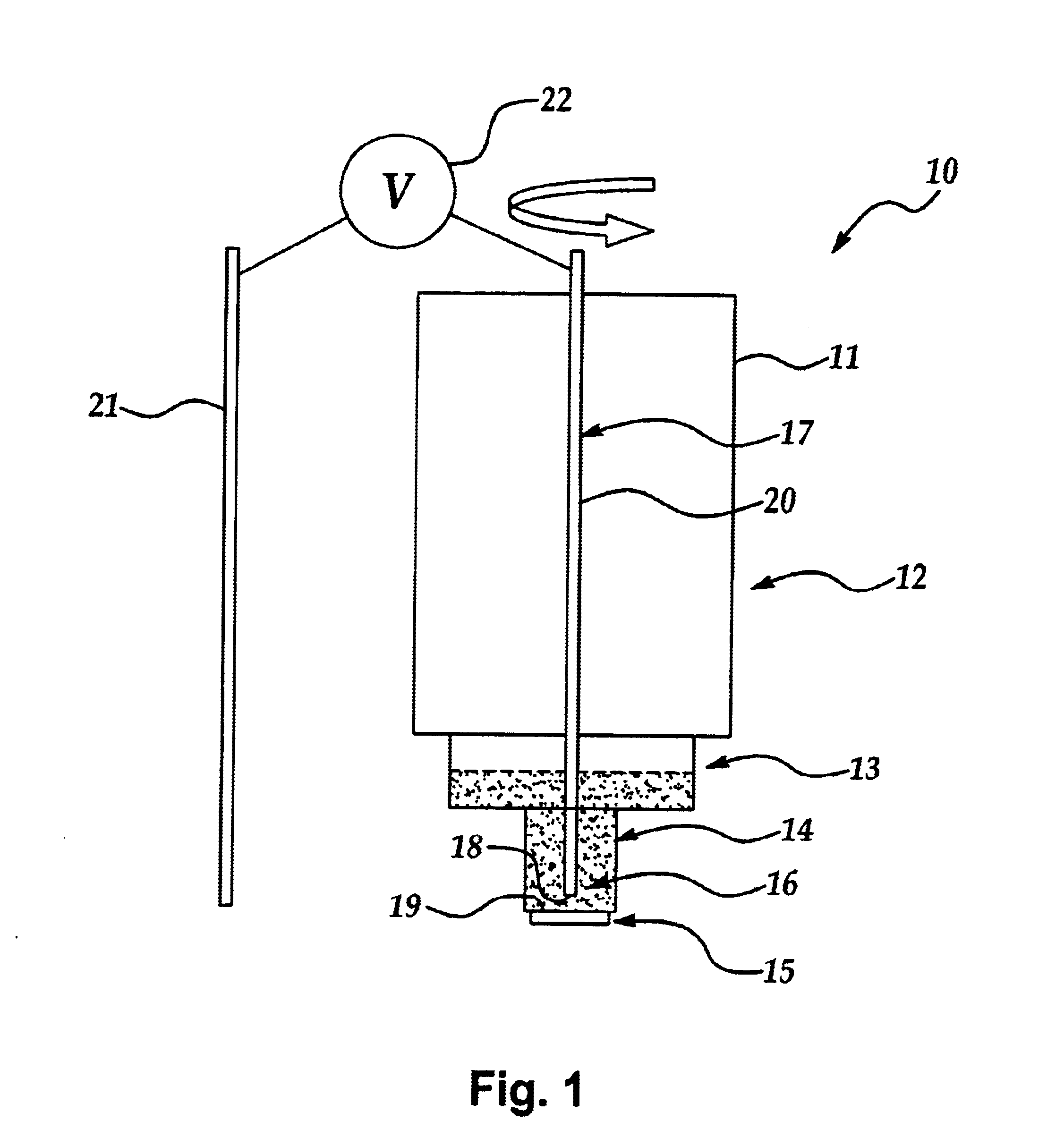

A rotating disk electrode (RDE) is a hydrodynamic working electrode used in a three electrode system. The electrode rotates during experiments inducing a flux of analyte to the electrode. These working electrodes are used in electrochemical studies when investigating reaction mechanisms related to redox chemistry, among other chemical phenomena. The more complex rotating ring-disk electrode can be used as a rotating disk electrode if the ring is left inactive during the experiment.

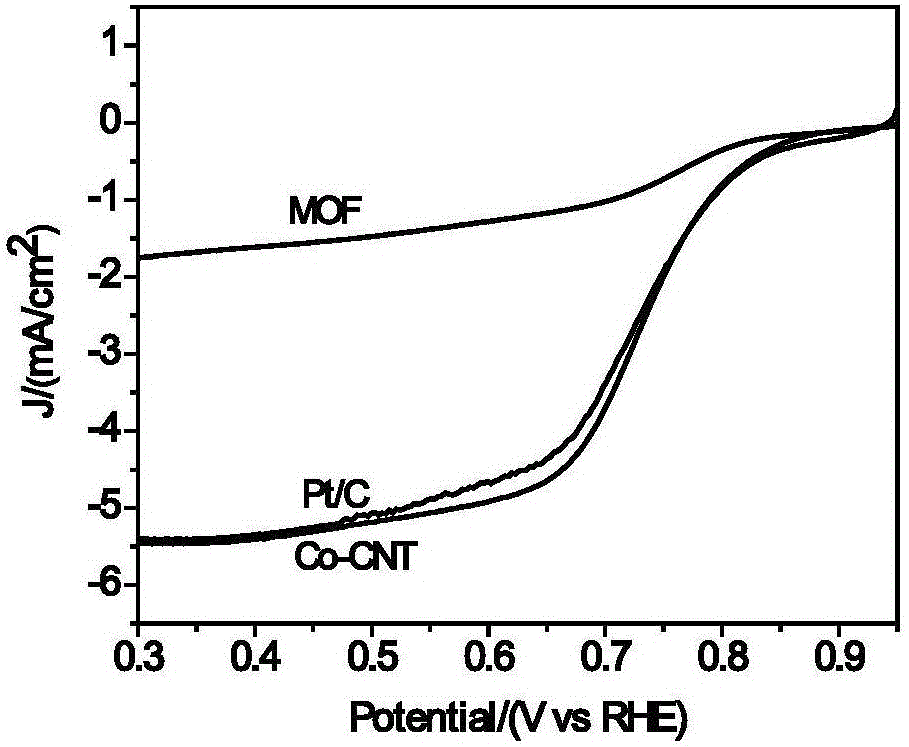

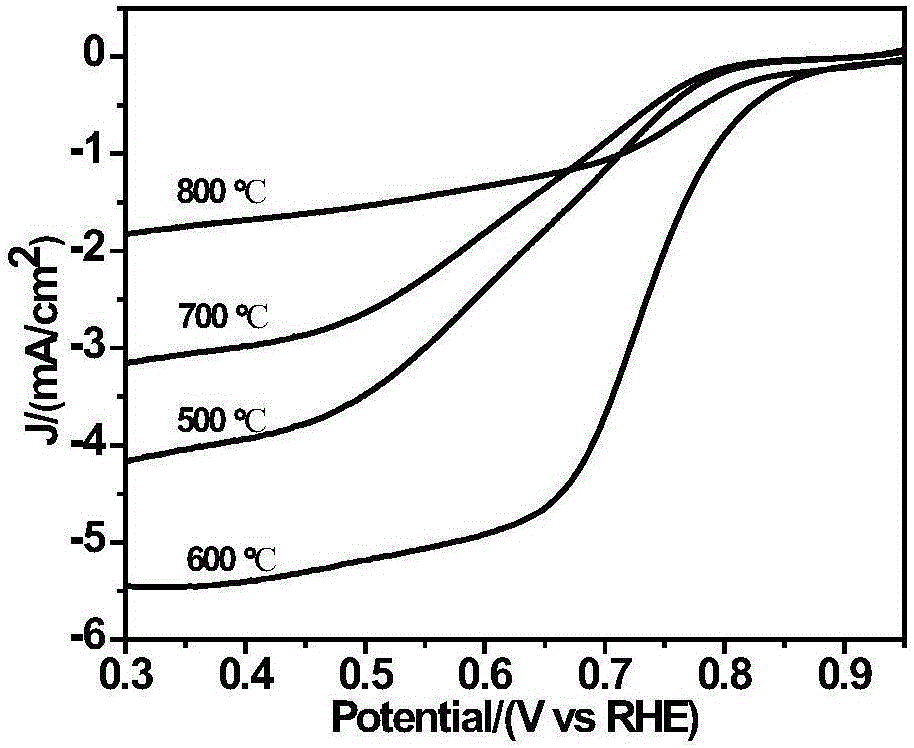

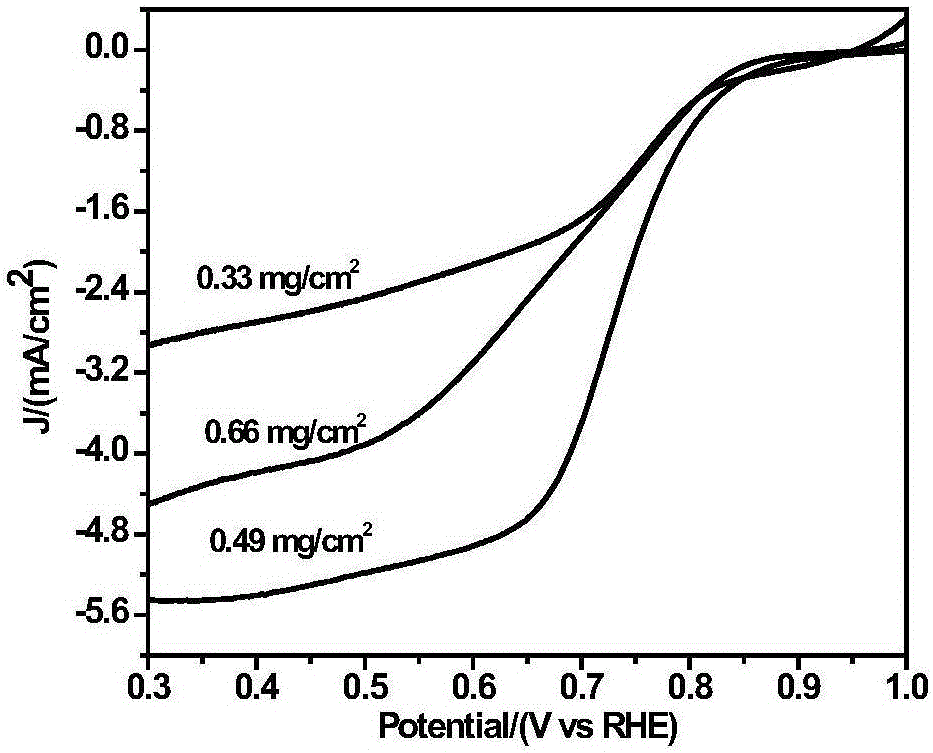

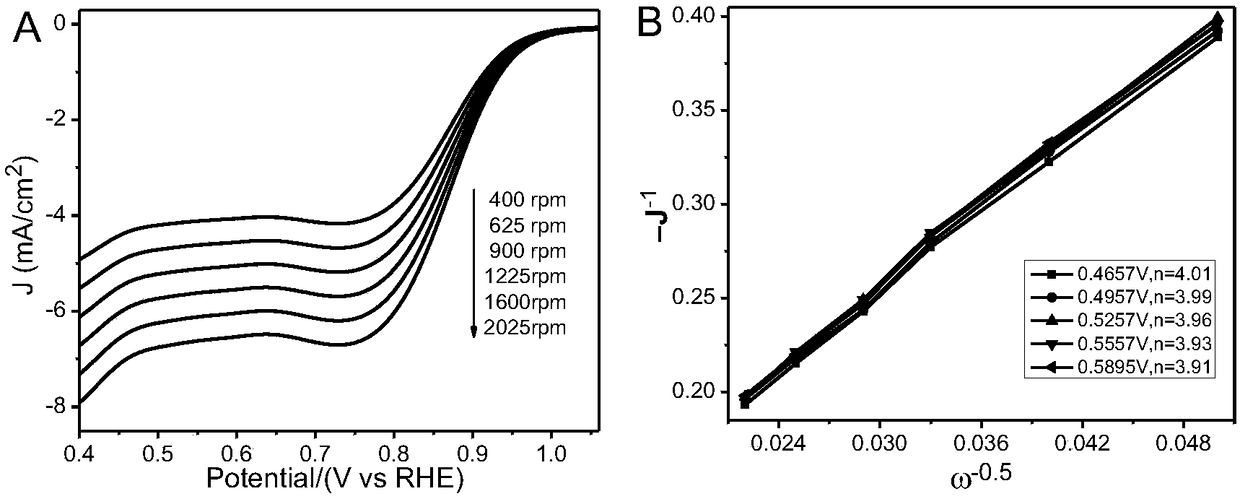

Cobalt-carbon porous nanocomposite oxygen reduction electrocatalyst and its preparation method and application

The invention discloses a metal organic skeleton compound-based cobalt-carbon porous nanocomposite oxygen reduction electrocatalyst and its preparation method and application. The cobalt-carbon porous nanocomposite oxygen reduction electrocatalyst is prepared from a metal organic skeleton compound [Co(O-BDC)(bbp)] as a precursor through high-temperature calcination. The carbon material has a porous structure. A cobalt element is uniformly supported on the carbon material. The oxygen reduction electrocatalyst has high electrical conductivity and a large specific surface area and effectively reduces the overpotential of oxygen reduction. Through a rotating disk electrode and a rotating ring electrode, it is proved that the oxygen reduction process is an ideal 4 electron oxygen reduction catalytic process. The electrocatalyst fully performs synergism of cobalt and a carbon material in electrocatalysis and has great theoretical and practical significance for the development of novel electrochemical catalysts and energy conversion and storage devices.

Owner:安徽伏碳科技有限公司

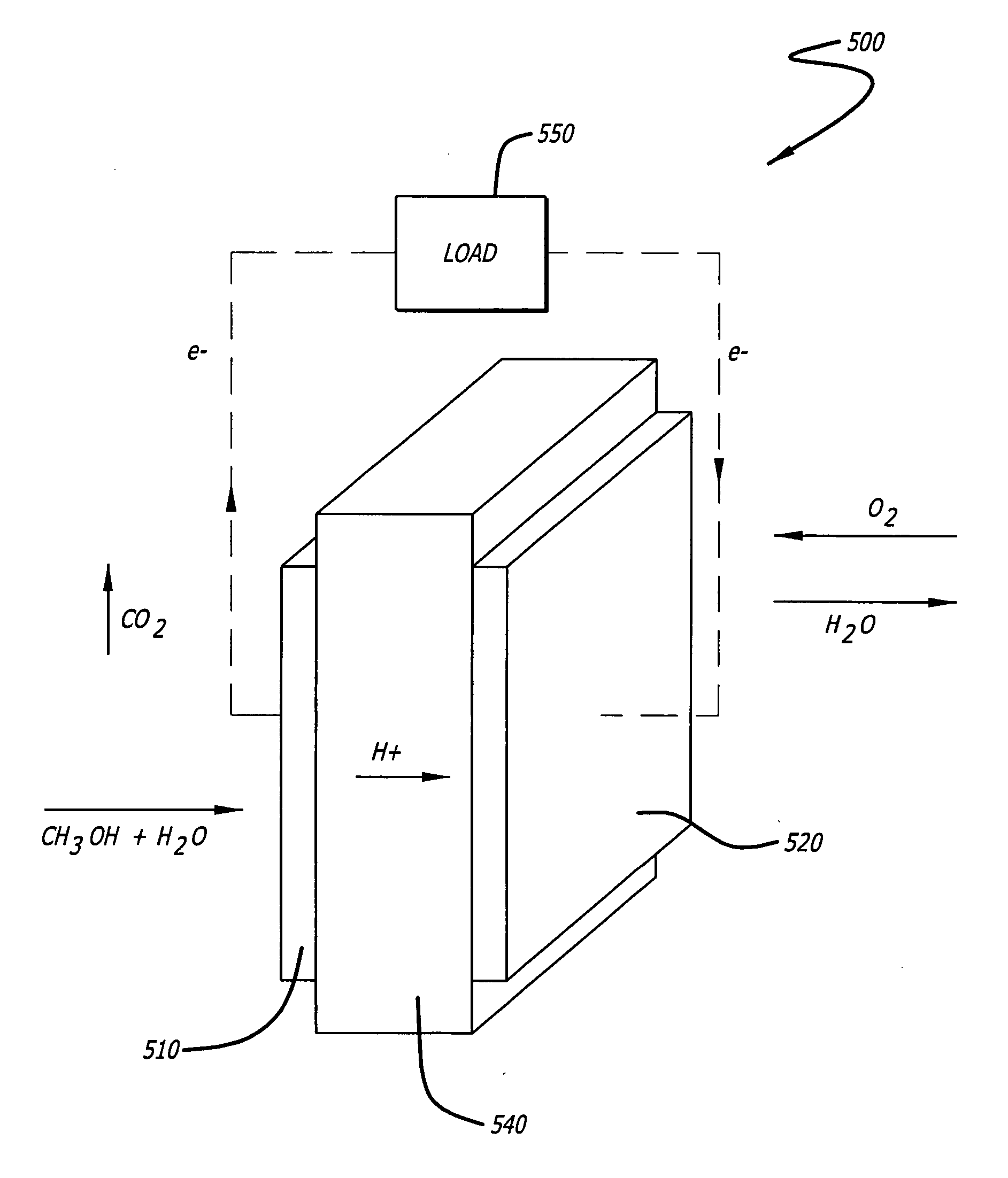

Methanol resistant cathodic catalyst for direct methanol fuel cells

InactiveUS20060088741A1Suppression of methanol oxidationHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsActive material electrodesOxygenPt element

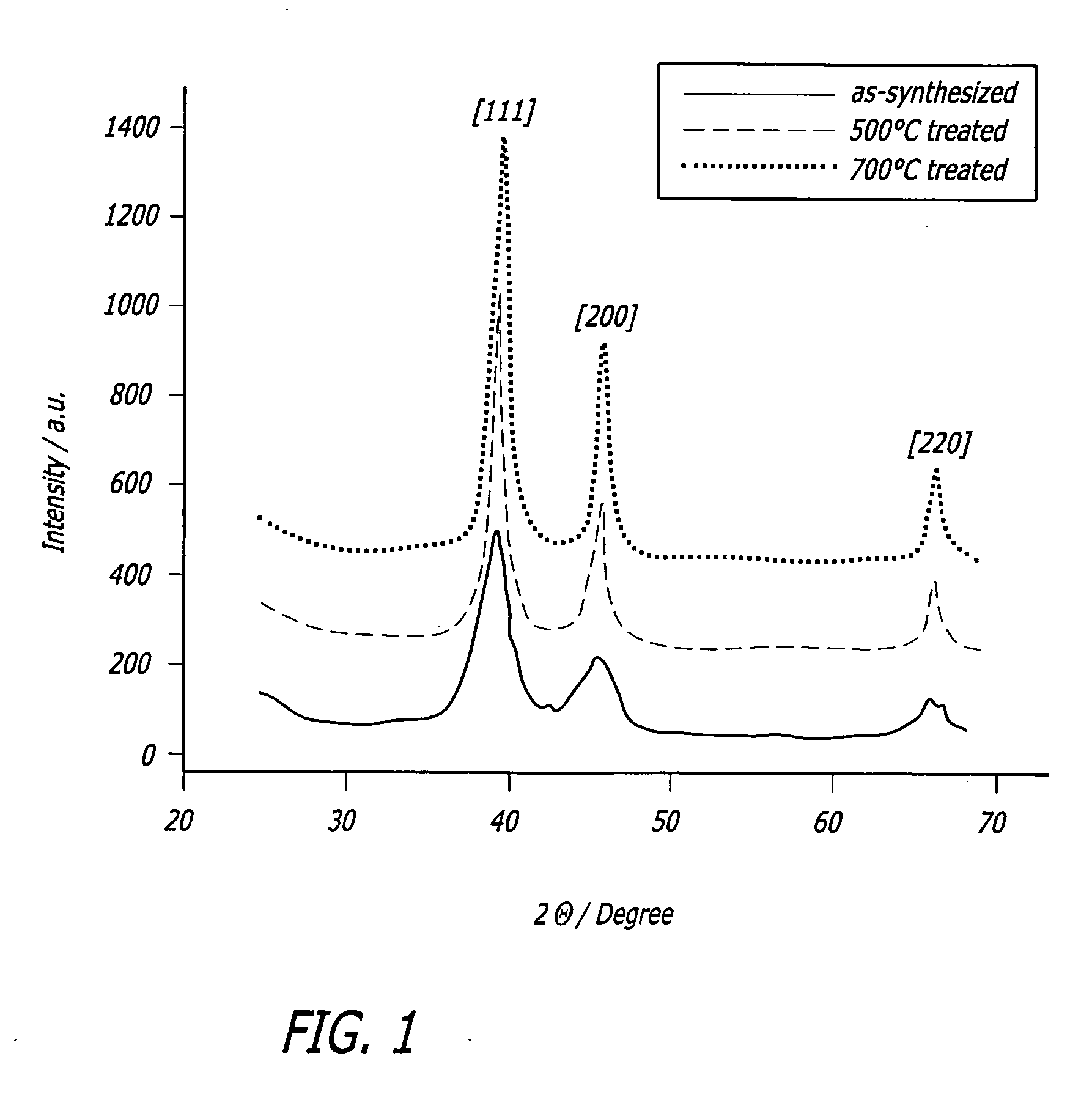

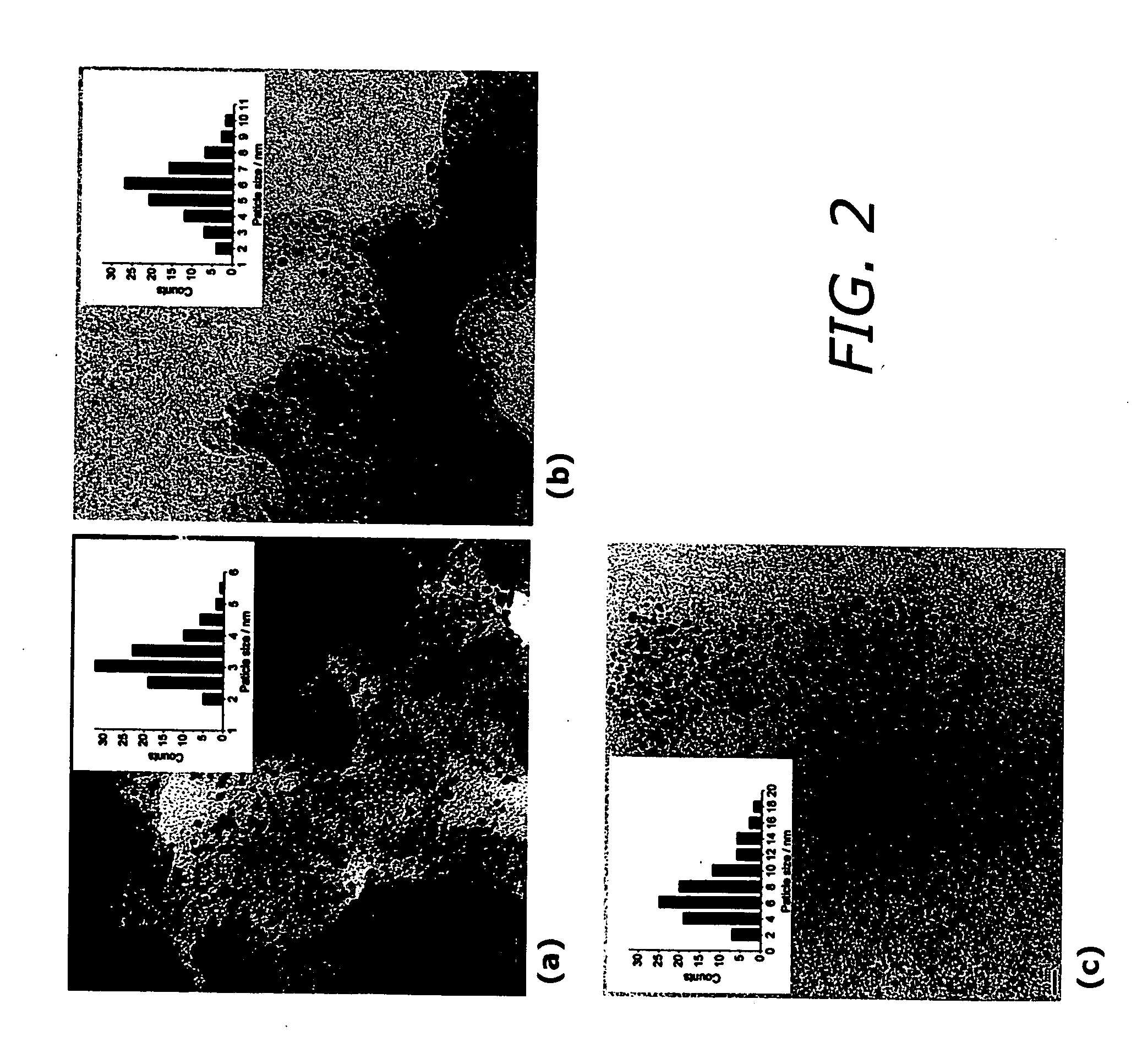

Methanol-tolerant cathodic catalysts were prepared by depositing platinum nanoparticles and iron macrocycles on a carbon substrate. The order of depositing the iron and platinum on the carbon substrate were varied to form a (Fe—Pt) / C catalyst and a (Pt—Fe) / C catalyst. Different sintering temperatures were investigated to determine the heating effect on methanol tolerance. Oxygen reduction with and without the presence of methanol on these new catalysts was evaluated by using a rotating disk electrode system.

Owner:PACIFIC FUEL CELL CORP

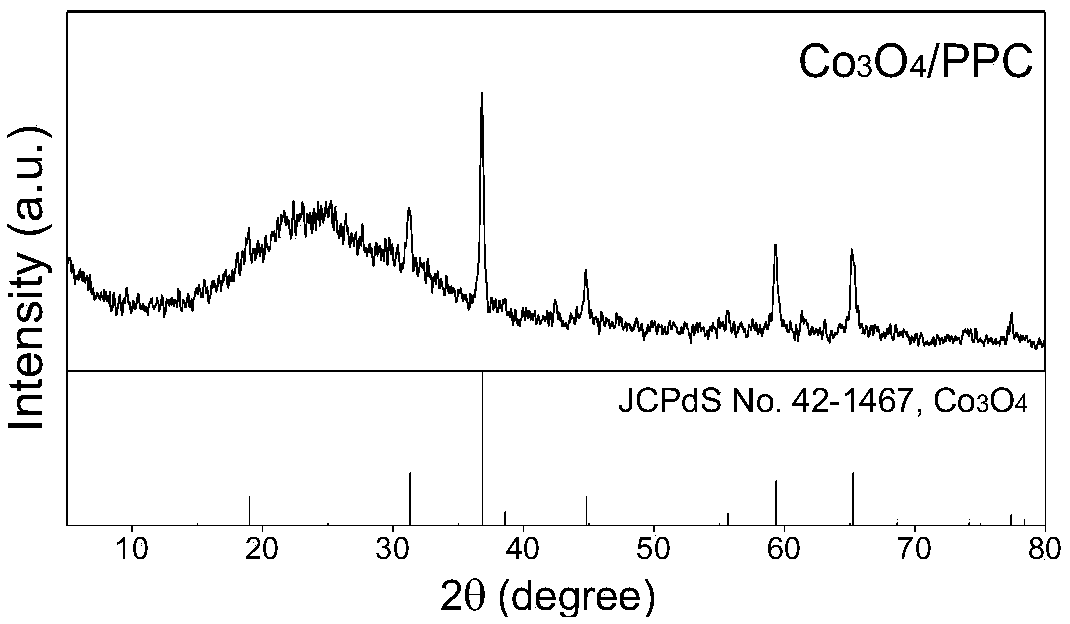

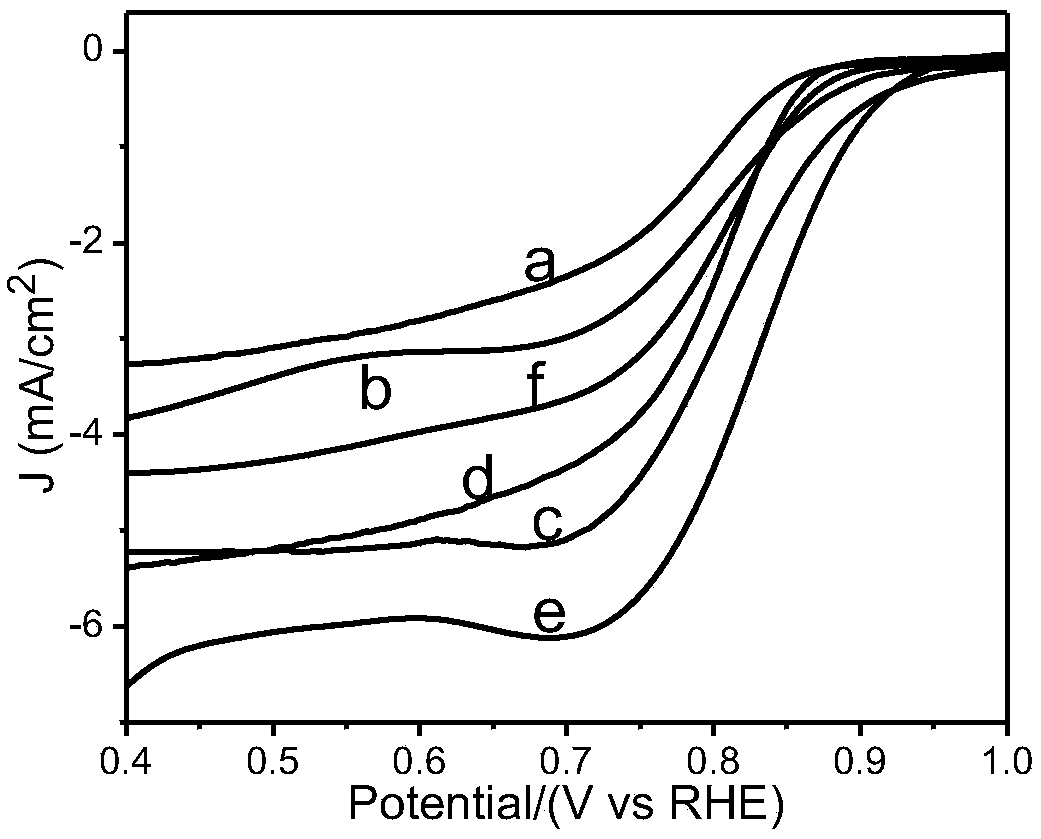

Phosphorus-doped porous carbon-coated cobalt tetroxide oxygen reduction catalyst and preparation method and application thereof

A phosphorus doped porous carbon coated cobalt tetroxide oxygen reduction catalyst, a preparation method and application thereof are provided. The invention adopts ZIF-67 as a template and precursors,uses phytic acid sodium as phosphorus source, A phosphorus doped porous carbon coated cobalt tetroxide oxygen reduction catalyst is prepared at high temperature calcination in an inert atmosphere, calcined carbon inherits the porous structure of ZIF, while the metal is oxidized to cobalt tetroxide, and uniformly supported on phosphorus-doped carbon materials, the oxygen reduction catalyst has high conductivity and specific surface area, which effectively reduces the overpotential of oxygen reduction. The rotating disk electrode and rotating ring disk electrode show that the oxygen reduction reaction is an ideal 4-electron mechanism, and has good stability and methanol tolerance. The electrocatalyst exerts the synergistic effect of cobalt tetroxide and phosphorus doped carbon materials inoxygen reduction catalysis and has potential application value in energy conversion and storage.

Owner:湖南麓邵技术服务有限公司

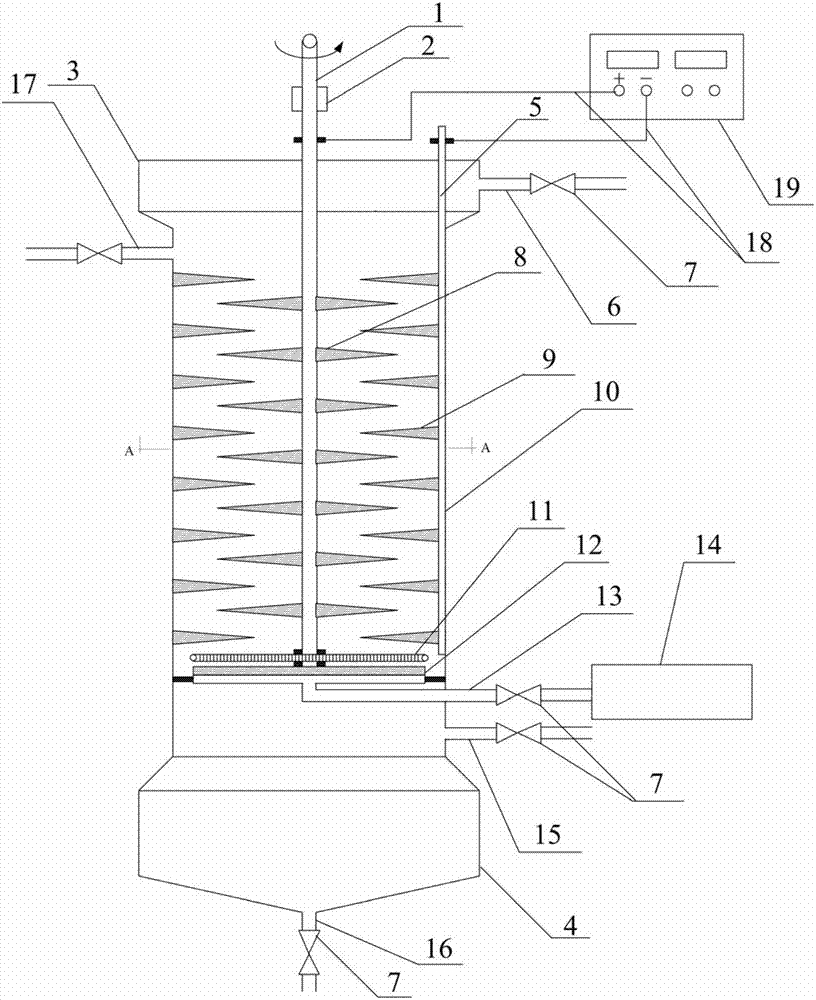

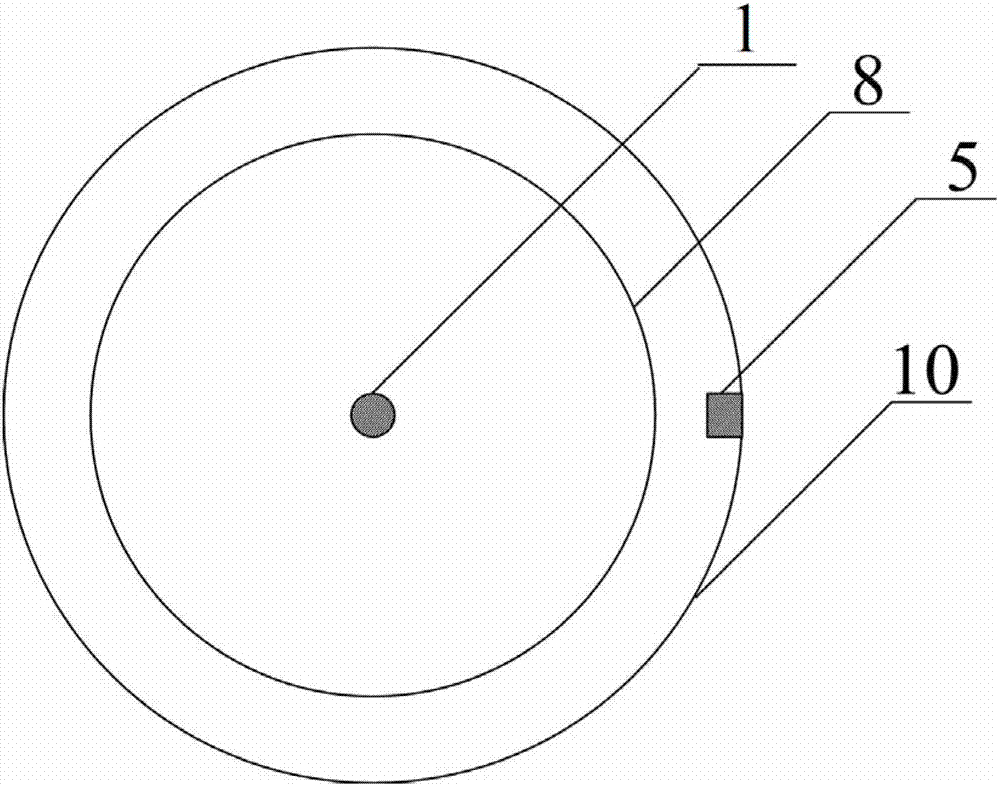

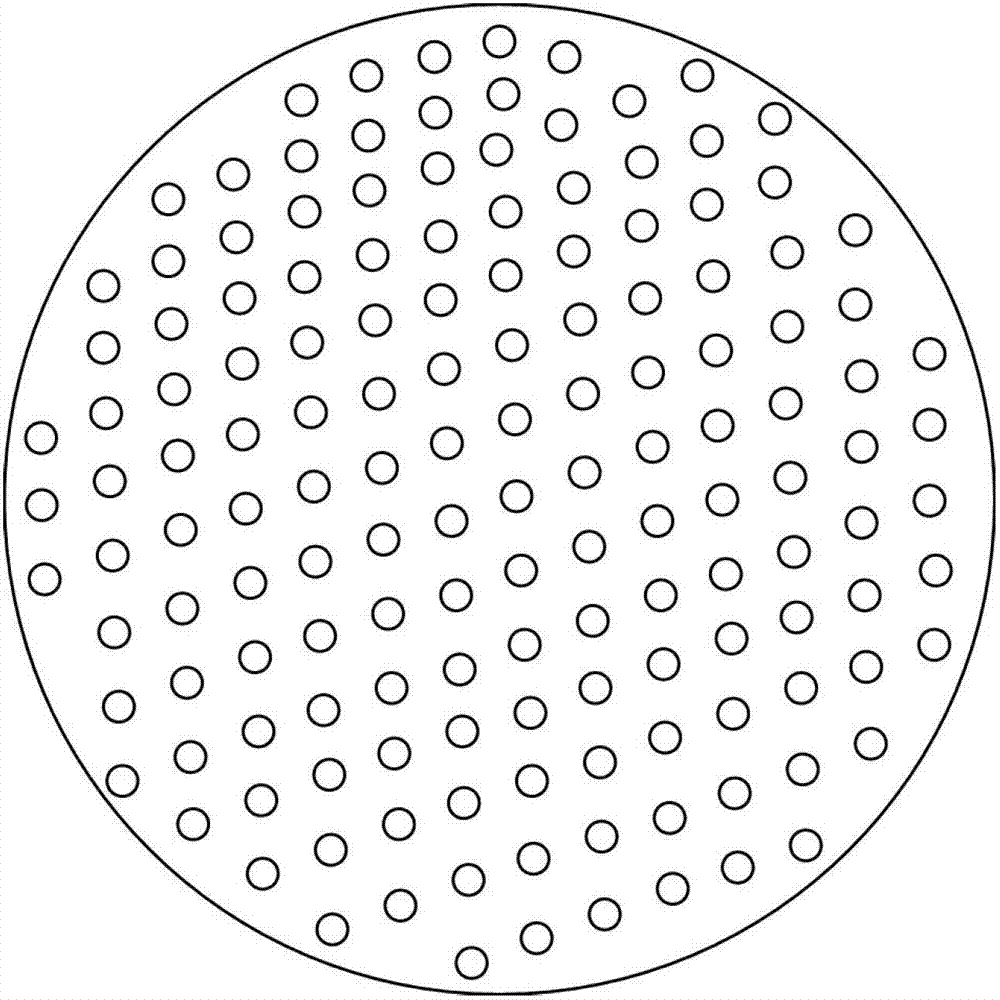

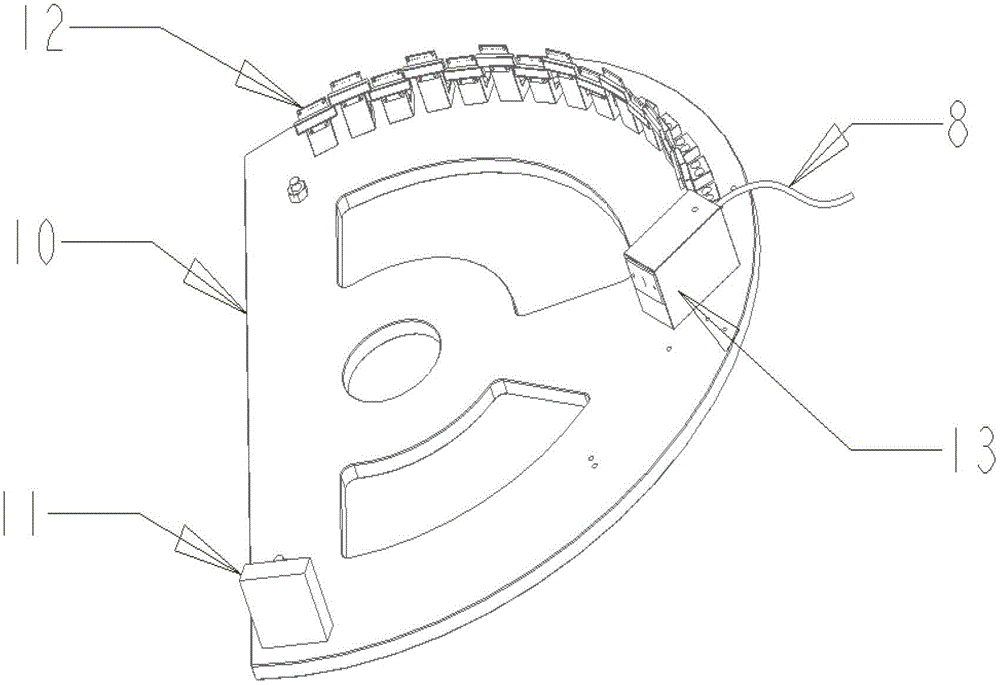

Electric flocculation device for separation and collection of industrial air-assisted microalgae water

ActiveCN103043755APrevent adsorption and precipitationImprove the efficiency of electrocoagulationWater/sewage treatment by flotationElectricityFlocculation

The invention relates to an electric flocculation device for the separation and collection of industrial air-assisted microalgae water, and a use method thereof. The device comprises a tower body, a main shaft, a lateral connecting rod, rotary table type electrode plates, ring-shaped electrode plates, a gas distributor, a gas feed device and auxiliary equipment, wherein the same-electrode rotary table type electrode plates fixed on the main shaft and the same-electrode ring-shaped electrode plates fixed on the lateral connecting rod on side of the tower body are distributed in a staggered manner; the main shaft and the rotary table type electrode plates rotate under the action of a mechanical rotation device; and the main shaft and the lateral connecting rod are mode of conductive metal and are respectively connected with the two poles of a direct-current power supply. According to the invention, as the pole plates have large superficial areas, the electric flocculation efficiency is high; a sieve plate is in a rotating state so as to effectively avoid adsorption precipitation of the microalgae on the surfaces of the electrodes; and the liquid in the tower body flows in the direction opposite to the precipitation direction of the microalgae, forming a cross flow which increases mass transfer and improves the electric flocculation efficiency. Therefore, the device is suitable for large scale industrial production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

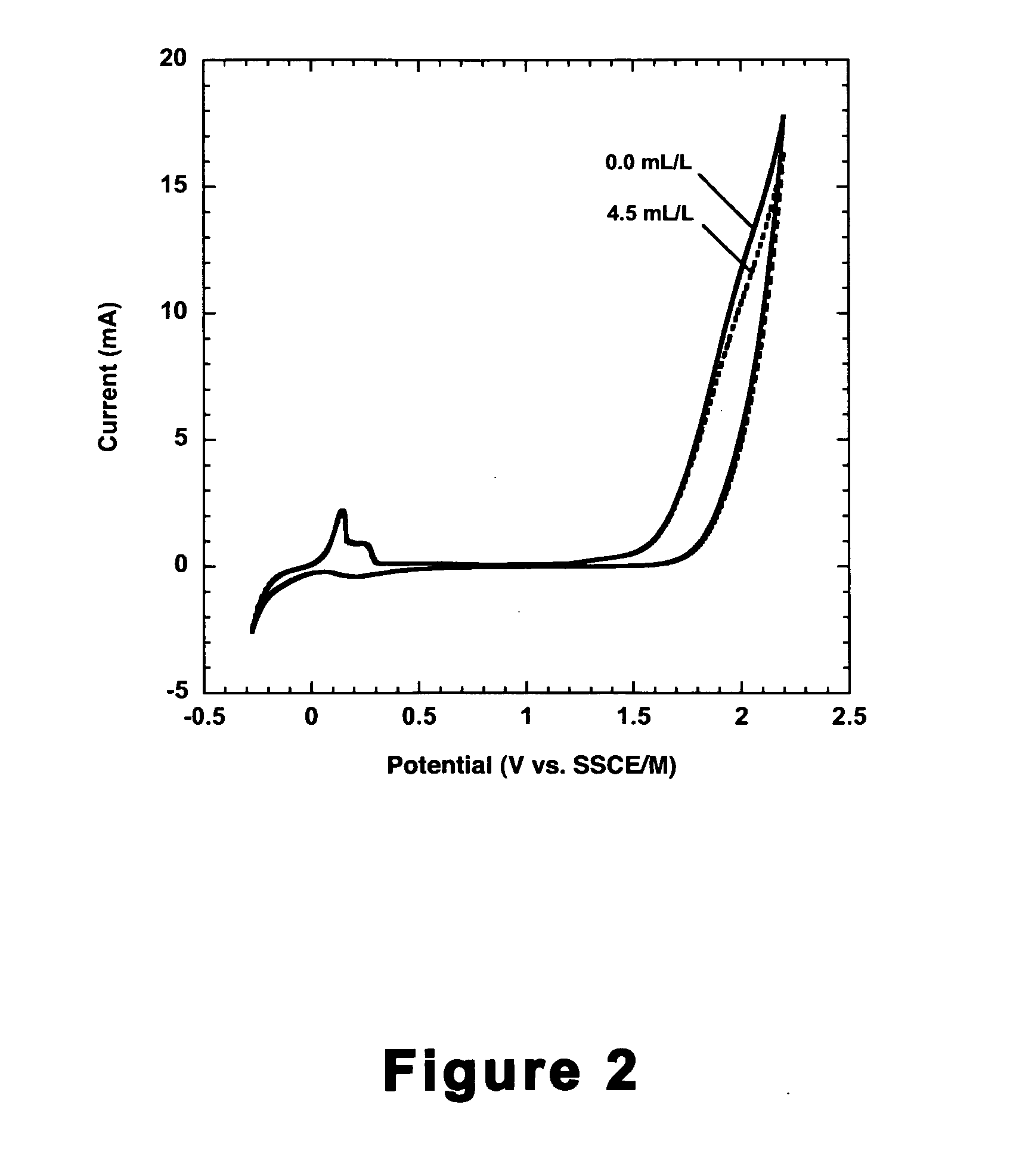

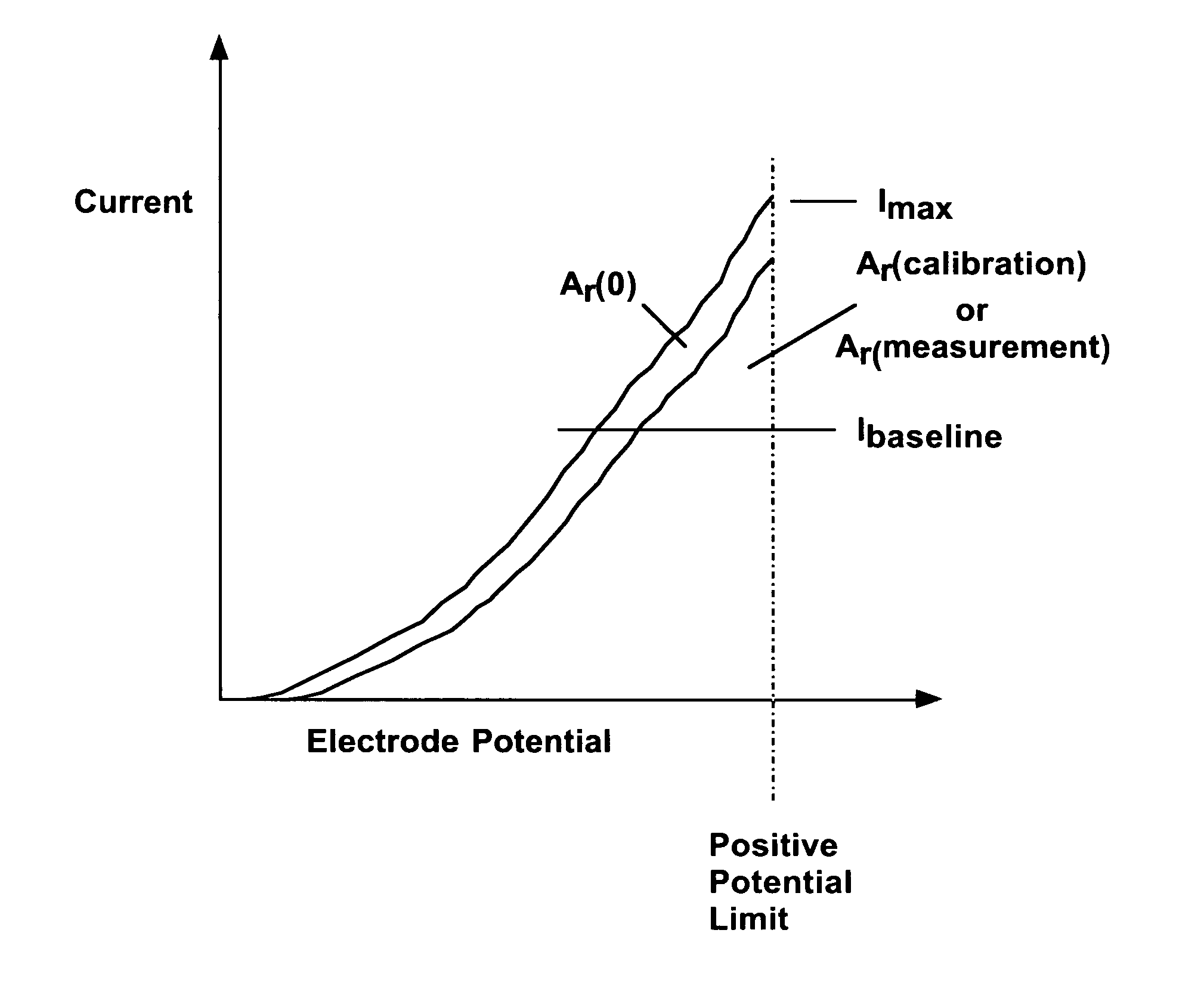

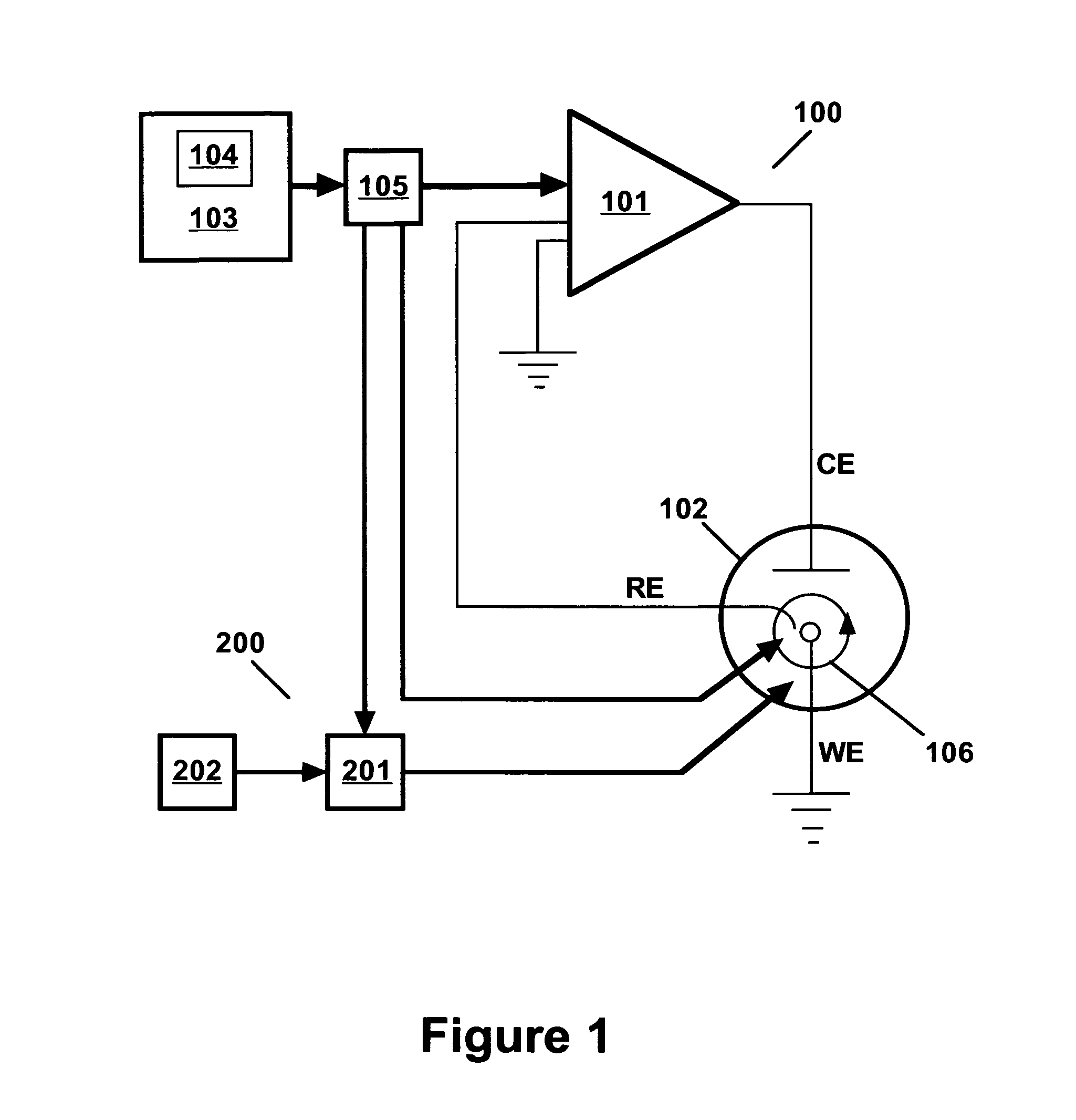

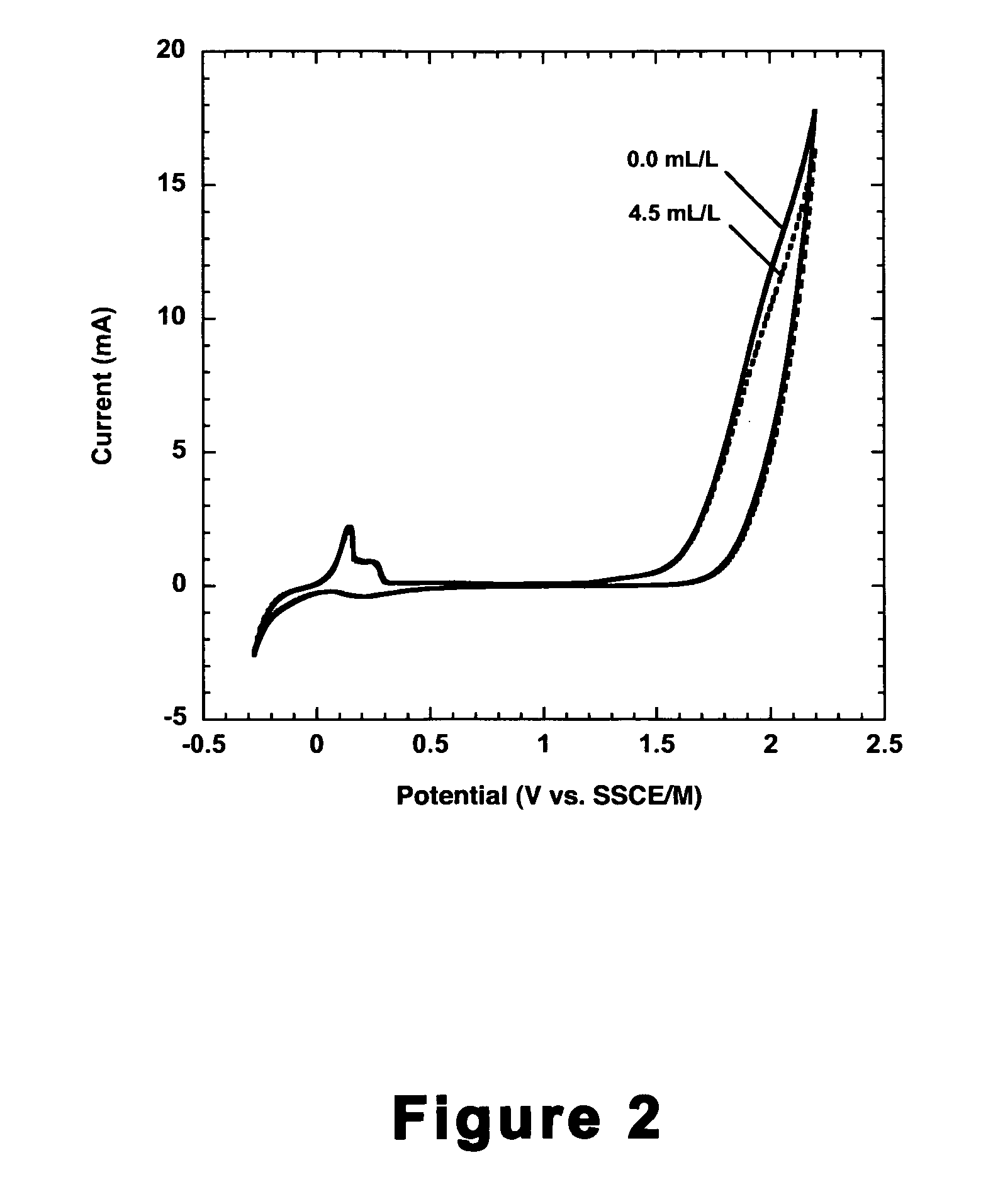

Analysis of an auxiliary leveler additive in an acid copper plating bath

An auxiliary leveler additive that cannot be analyzed by conventional CVS methods for acid copper plating baths is analyzed by cyclic voltammetry at a platinum rotating disk electrode from its effect on the anodic current at very positive potentials.

Owner:ECI TECH

Preparation method of water hyacinth-Fe biochar and application of water hyacinth-Fe biochar

ActiveCN109675564AGood catalyticConducive to catalytic reductionMetal/metal-oxides/metal-hydroxide catalystsElectrodesNitrogen gasWater Hyacinths

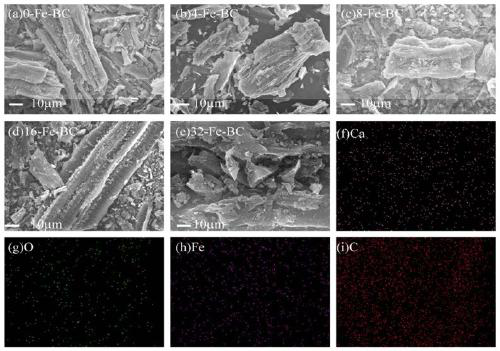

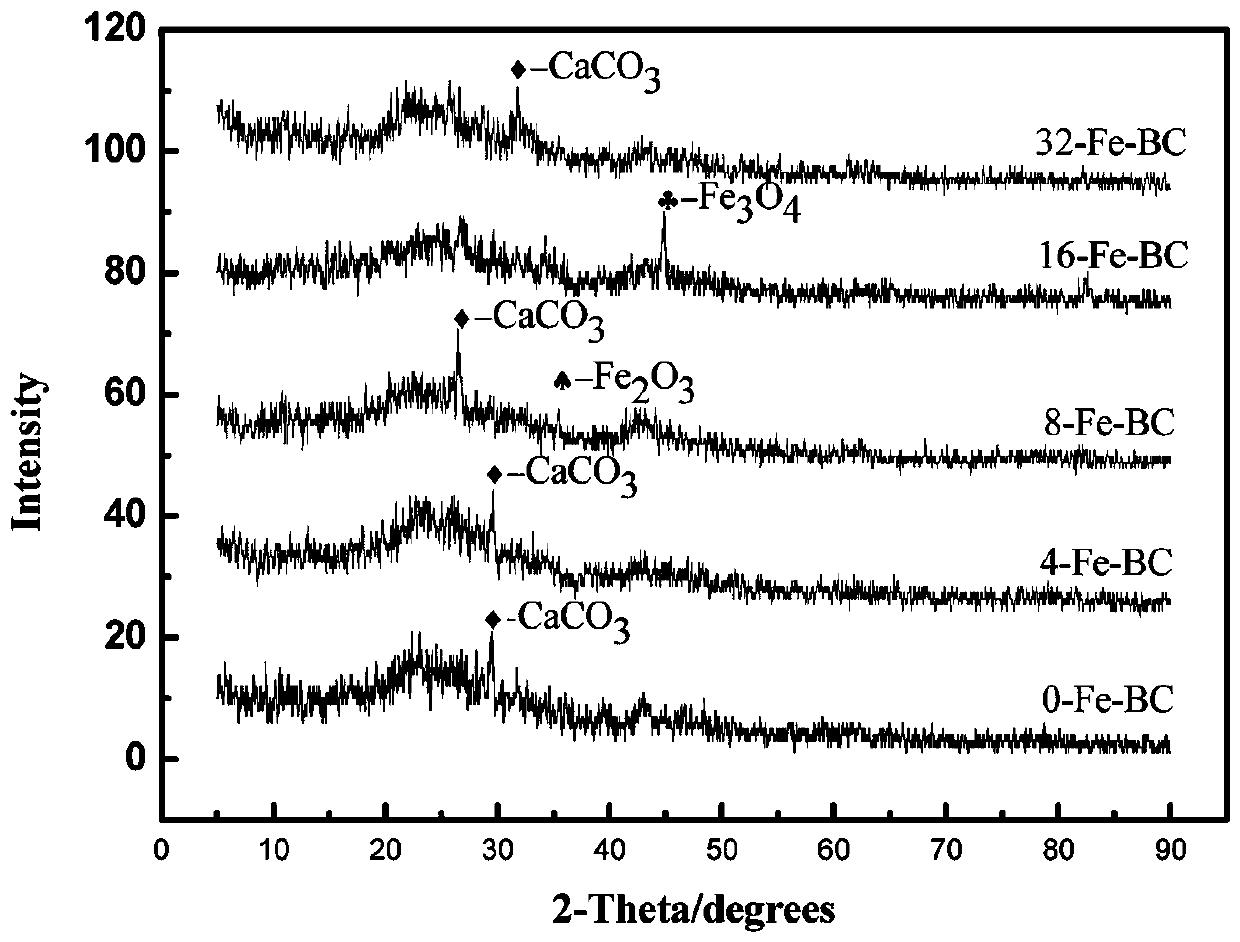

The invention provides a preparation method of water hyacinth-Fe biochar and application of the water hyacinth-Fe biochar. The preparation method comprises the following steps: taking water hyacinth as a raw material and cultivating the water hyacinth with plant solution for one month, so as to obtain water hyacinth enriching 4-64 mg.L<-1> of Fe; performing low pyrolysis on the Fe-enriched water hyacinth at the temperature of 500-900 DEG C in a nitrogen atmosphere, so as to prepare a series of Fe-loaded water hyacinth biochar with different concentrations. A result shows that the water hyacinth biochar is rough in surface and has a lumpy structure on the surface, and Fe in the biochar exists in forms of two oxides: Fe2O3 and Fe3O4. A glassy carbon rotating disk electrode modified by various biochar particles is utilized to explore the electrocatalytic reduction reaction of H2O2 in a neutral medium on different biochar catalysts according to a cyclic voltammetry scanning method, the exploration discovers that a water hyacinth biochar sample has the maximum reduction current value and is most excellent in electro-catalytic property on H2O2, and different scanning experiments also verifies that the water hyacinth biochar sample also has the potential property of energy storage.

Owner:CHINA THREE GORGES UNIV

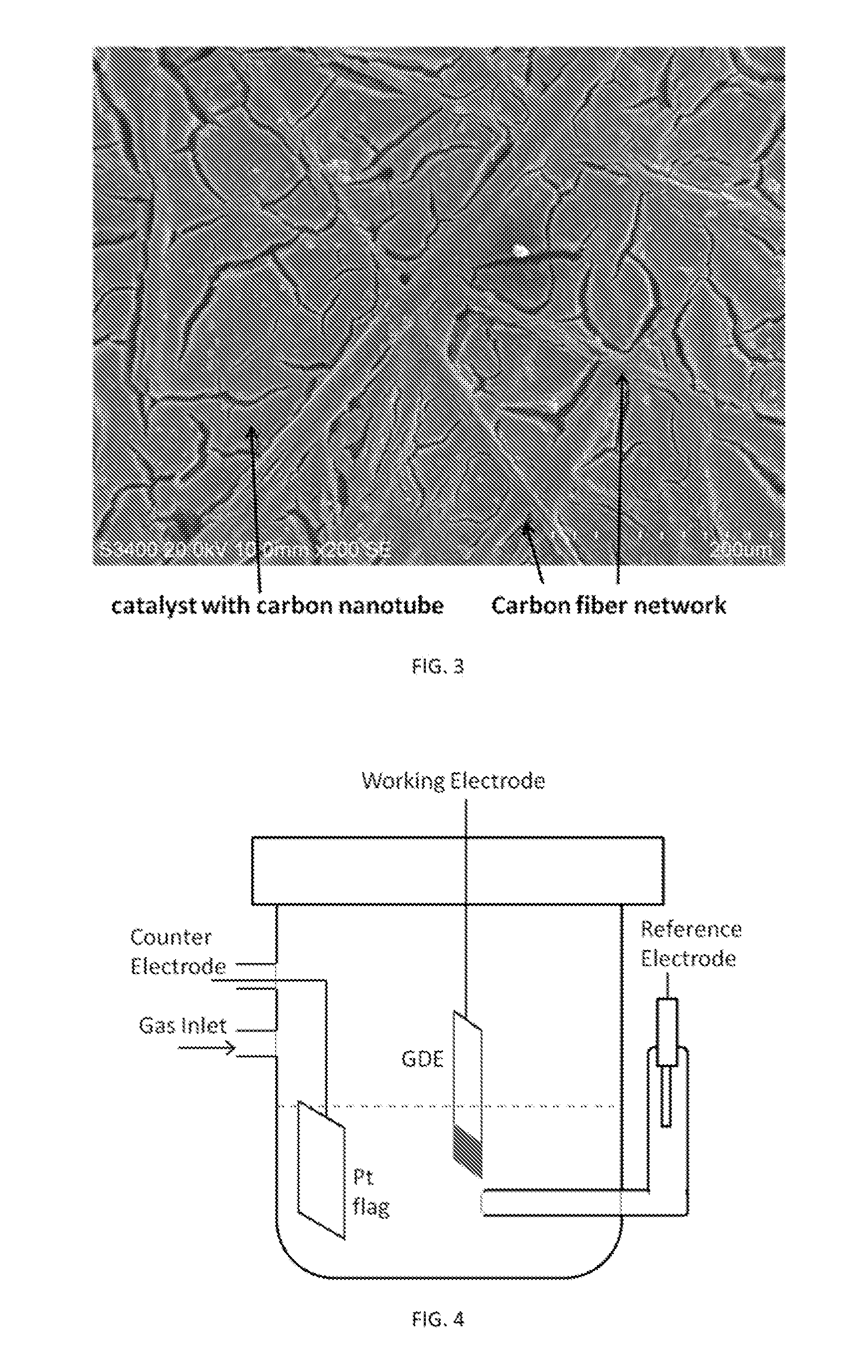

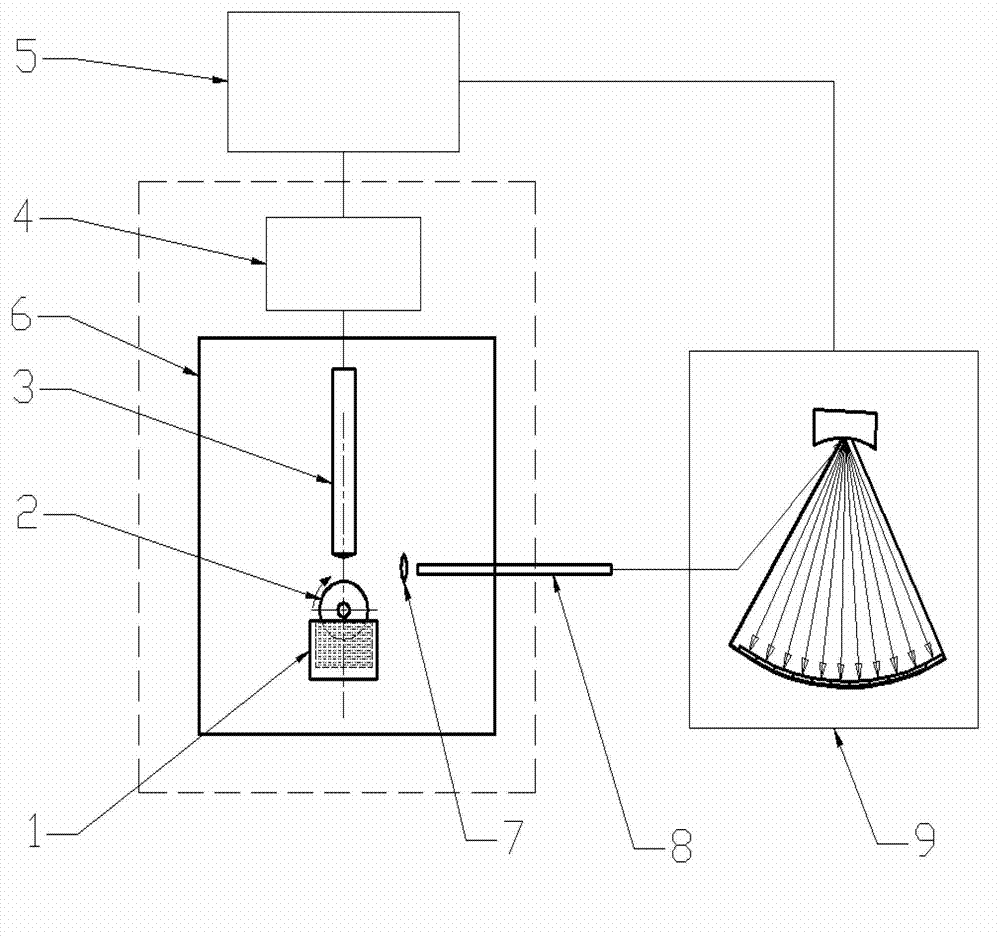

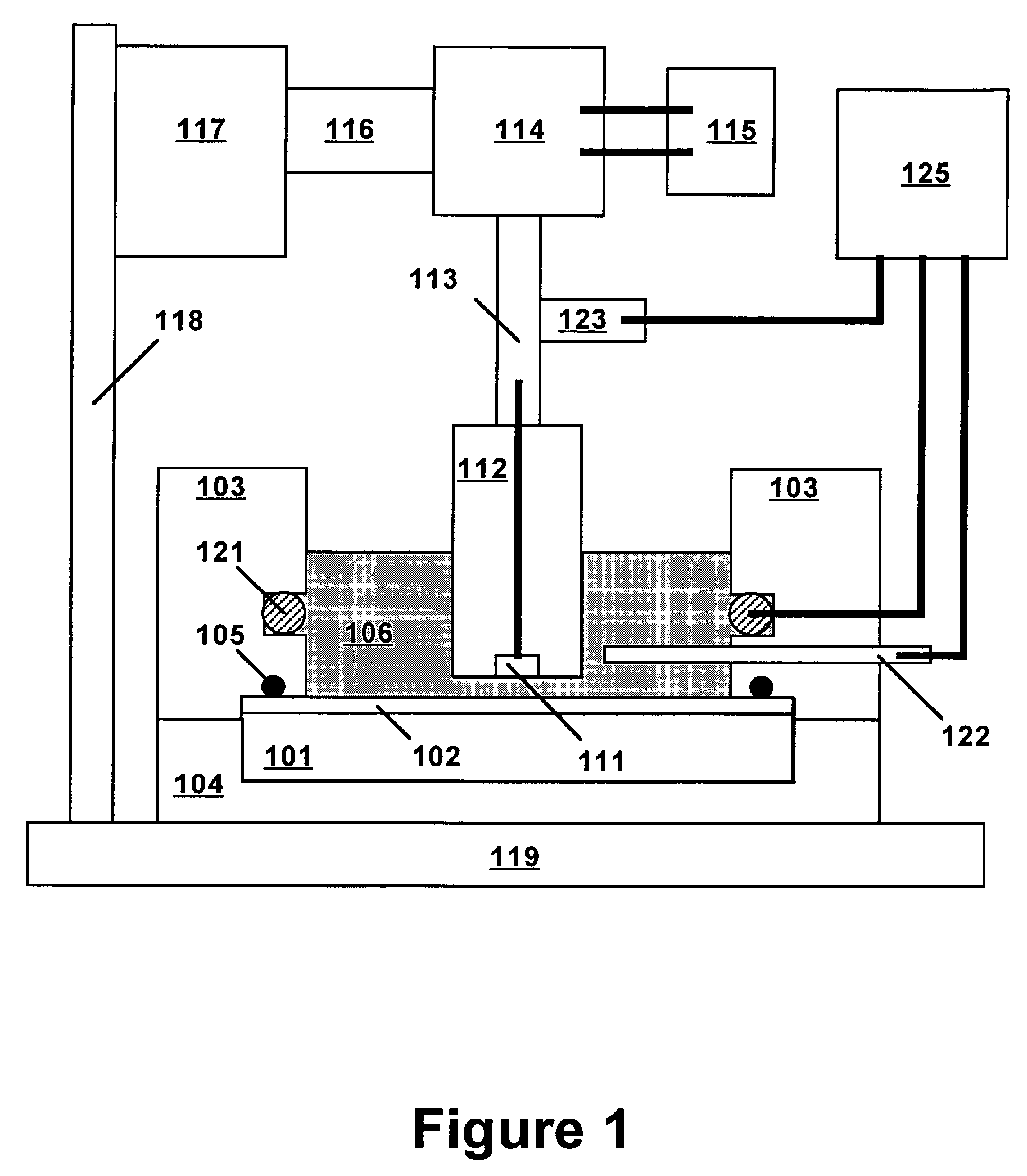

Gas Diffusion Electrodes and Methods for Fabricating and Testing Same

InactiveUS20150376803A1Improve performanceLow costCellsMachining electrodesDiffusion resistanceCurrent range

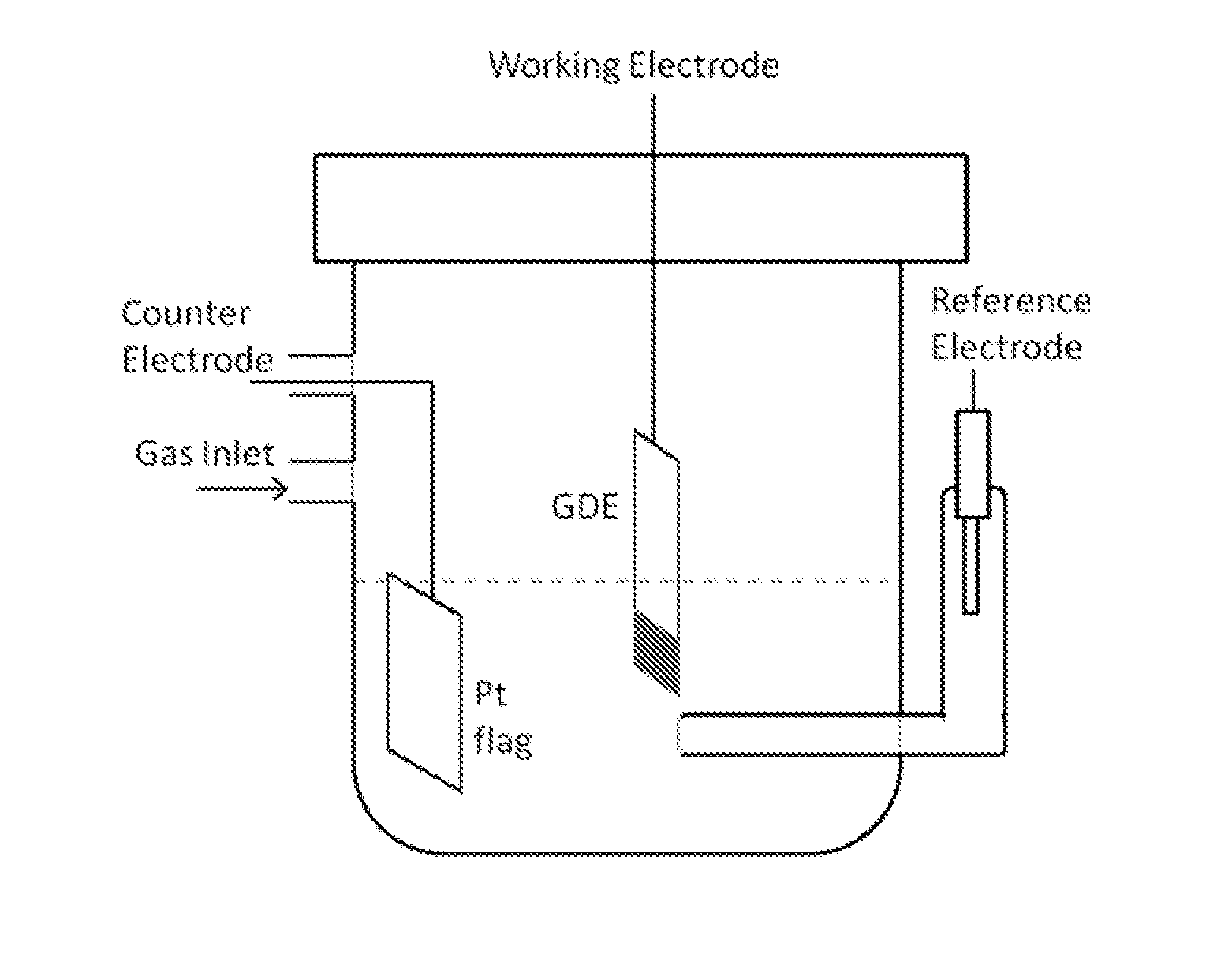

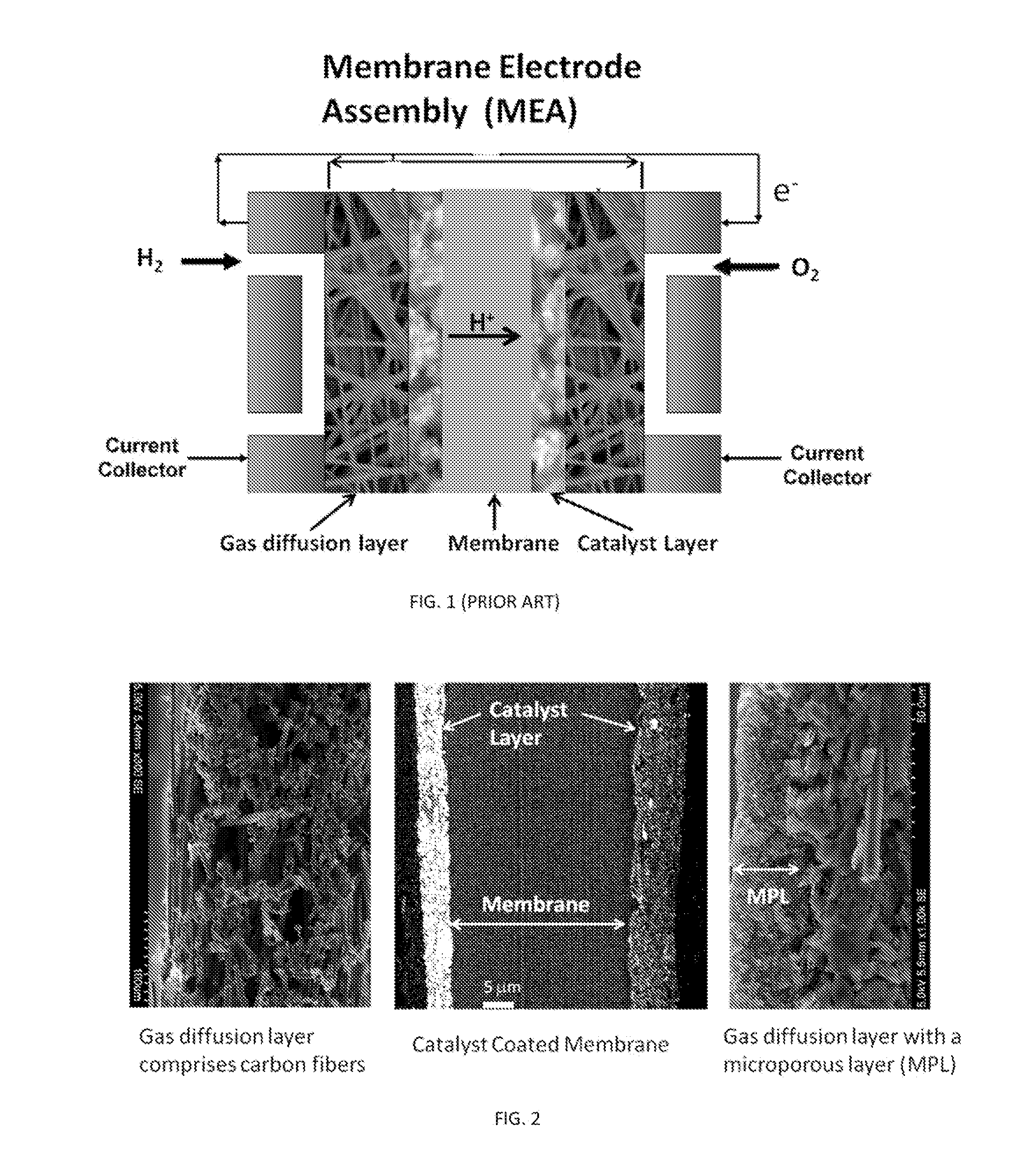

Highly effective, standalone gas-diffusion electrodes (GDEs) and the methods for their manufacture and test are disclosed, Nanocataiysis are directly bonded on a gas diffusion layer, so that the integrity of the catalyst layer holds without polymer electrolyte membrane, facilitating minimization of electronic, prottmtc, and diffusion resistances in the catalyst layer. The devised embodiments provide examples showing a facile hanging-strip method for testing the standalone GDEs in a solution electrochemical cell, which removes the mA-cm−2-scale mass transport limited currents on rotating disk electrodes to allow studies of reaction kinetics on single electrode over sufficiently wide current ranges (up to A cm−2) without mass transport limitation. Ultralow-Pi-content GDEs are fabricated as the cathode for hydrogen evolution in water eiectrolyzers and as the anode for hydrogen oxidation in hydrogen fuel cells. High performance GDEs with low loadings of platinum group metals are being developed for oxygen evolution reaction at the anode of water electrolyzers and for the oxygen reduction reaction at the cathode of fuel cells.

Owner:BROOKHAVEN SCI ASSOCS

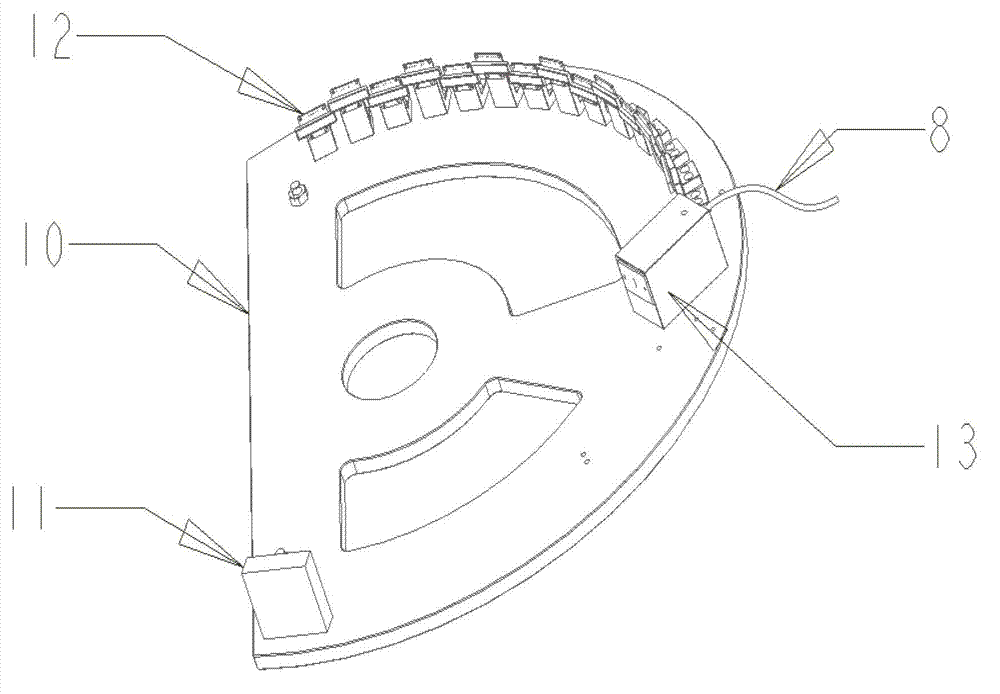

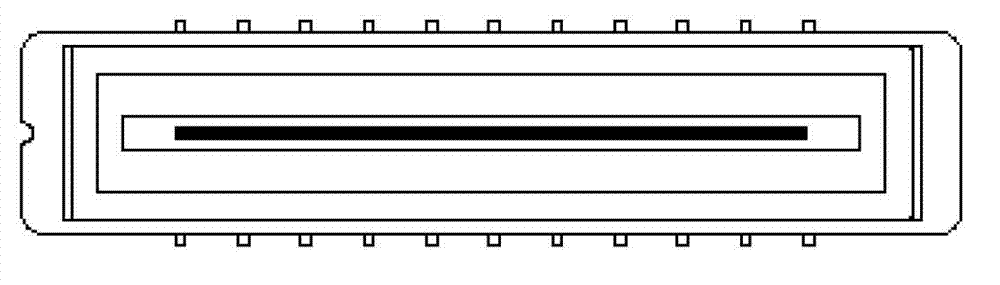

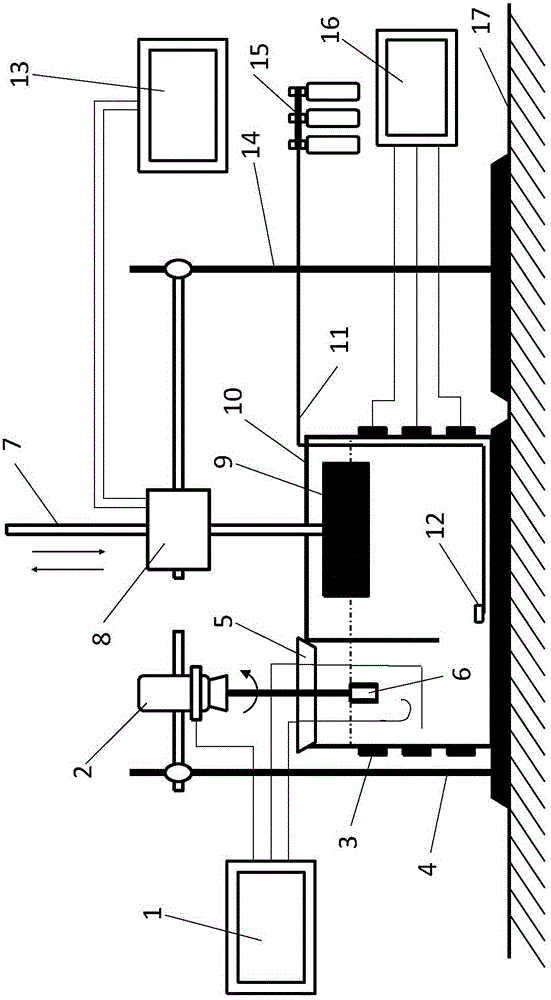

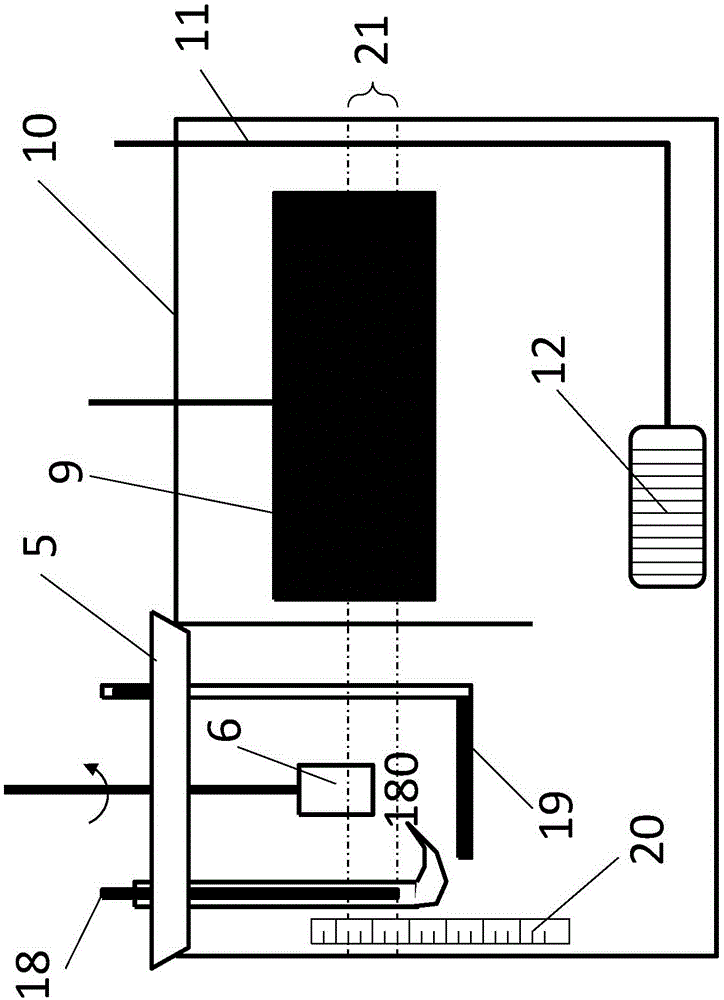

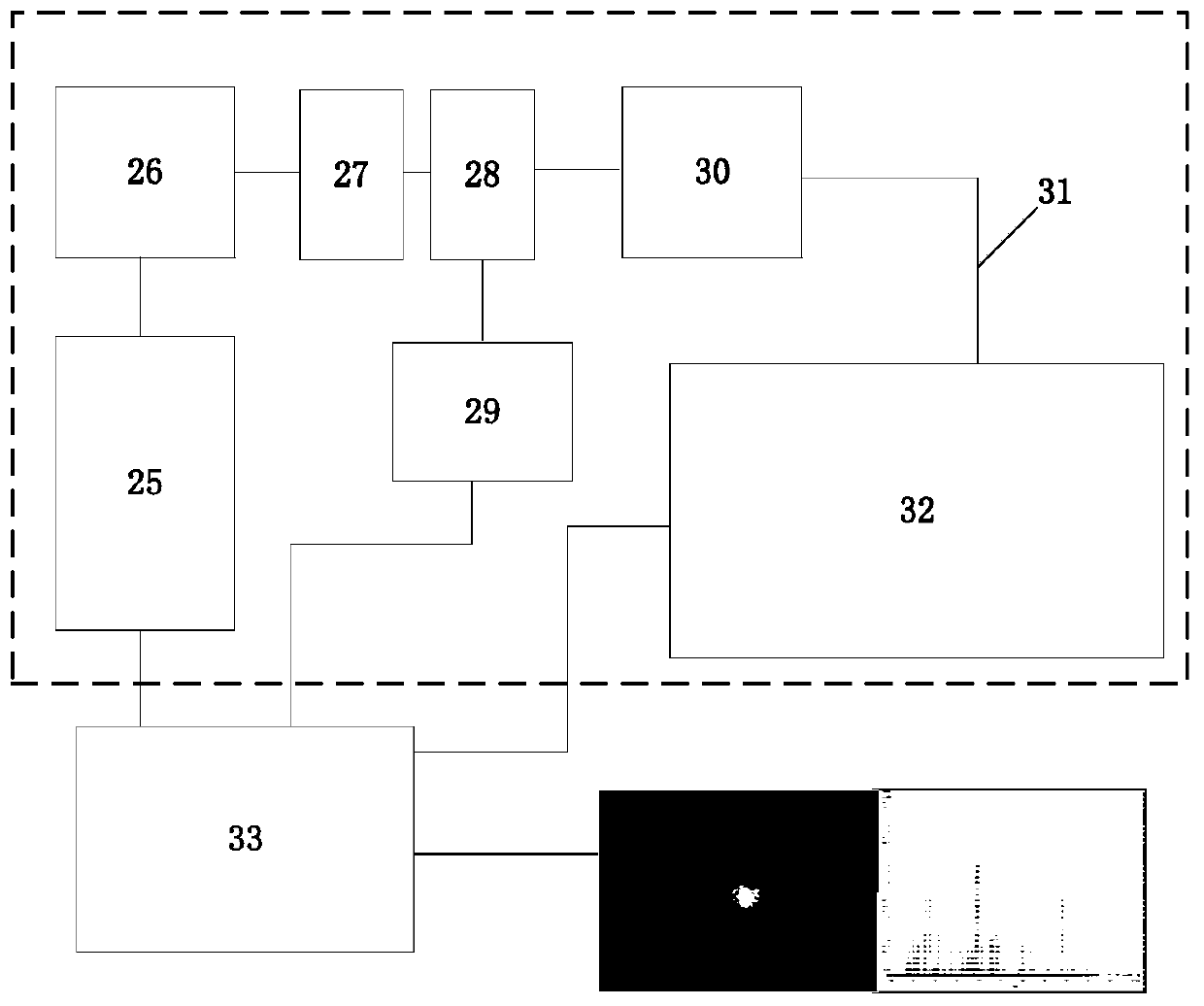

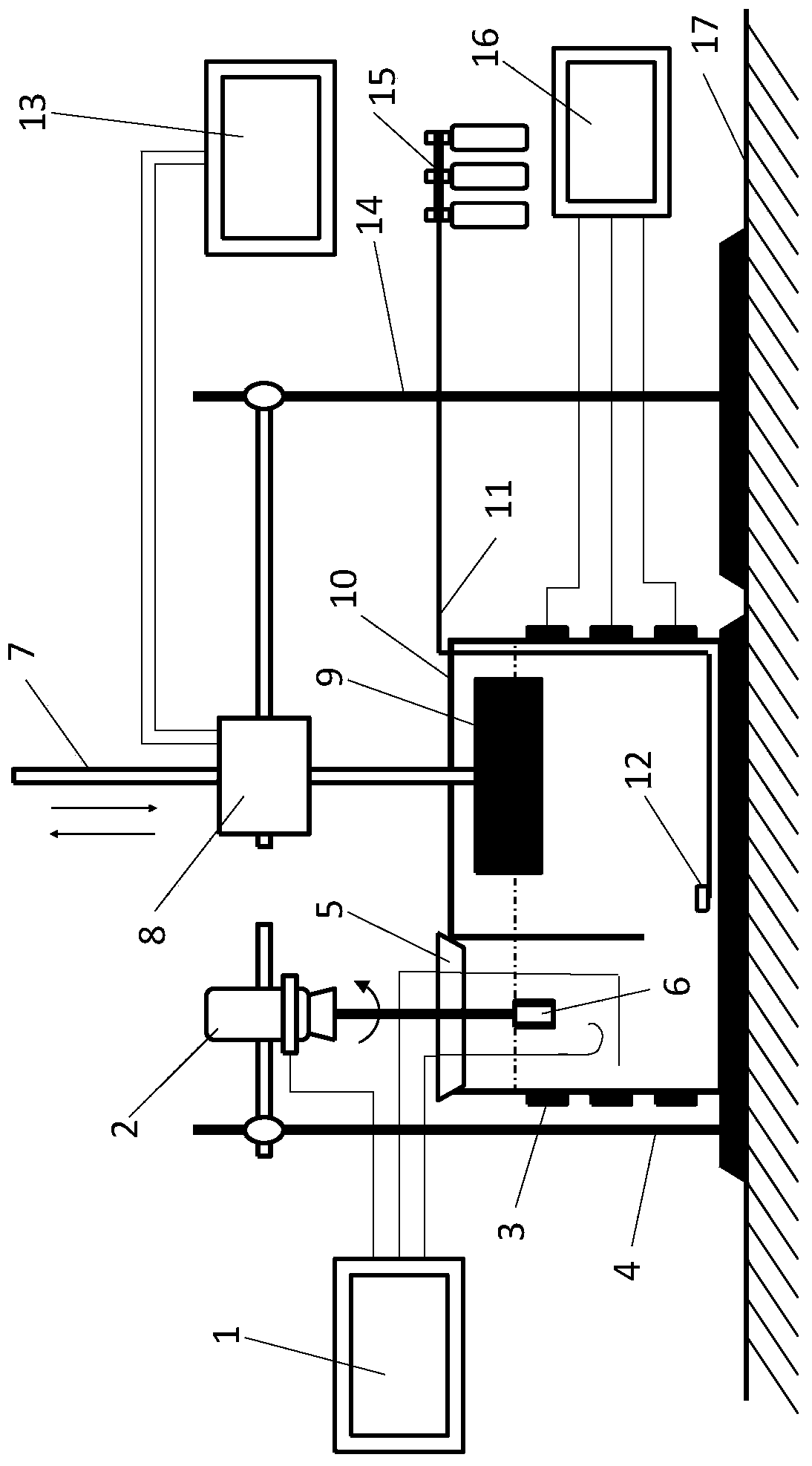

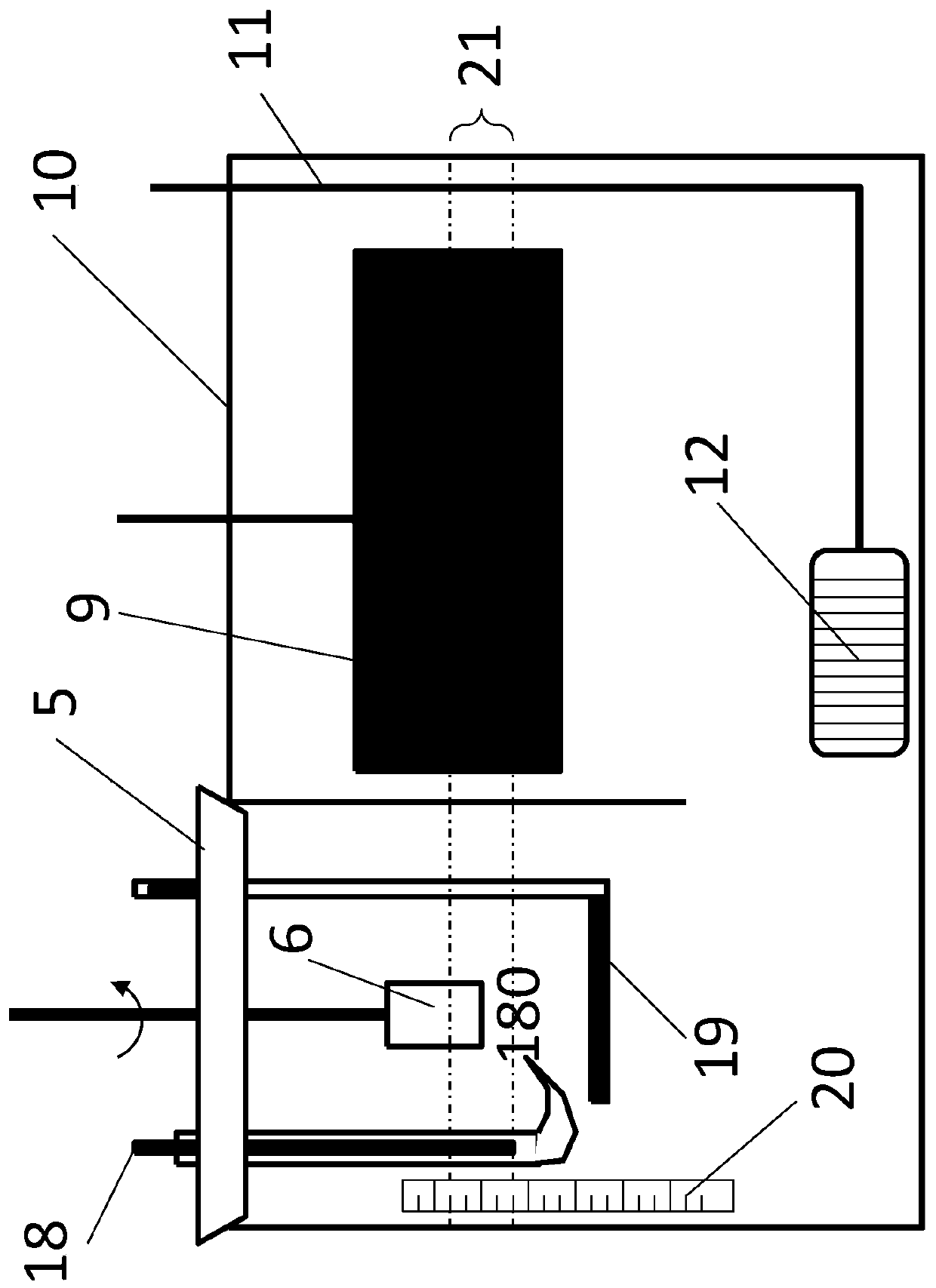

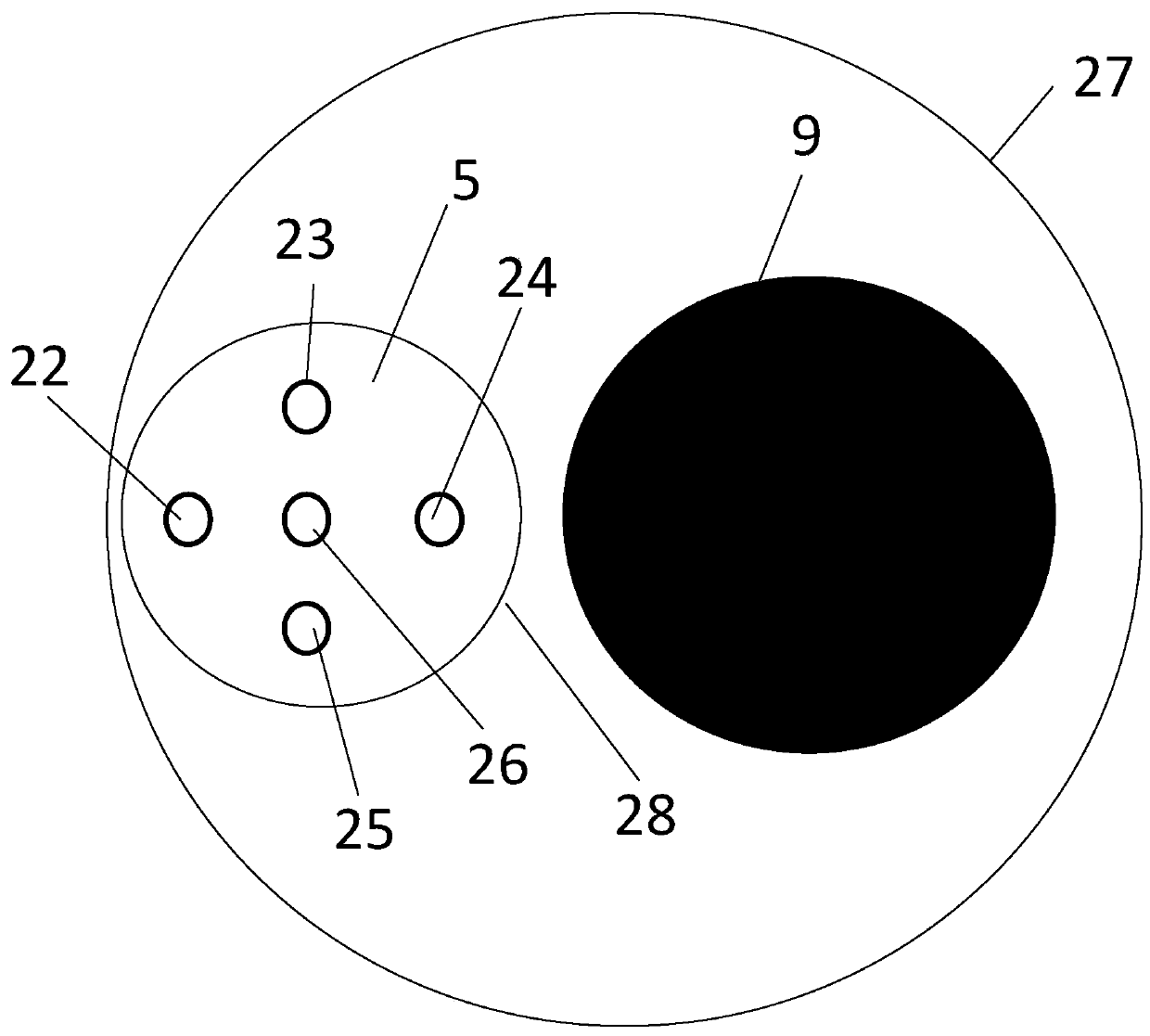

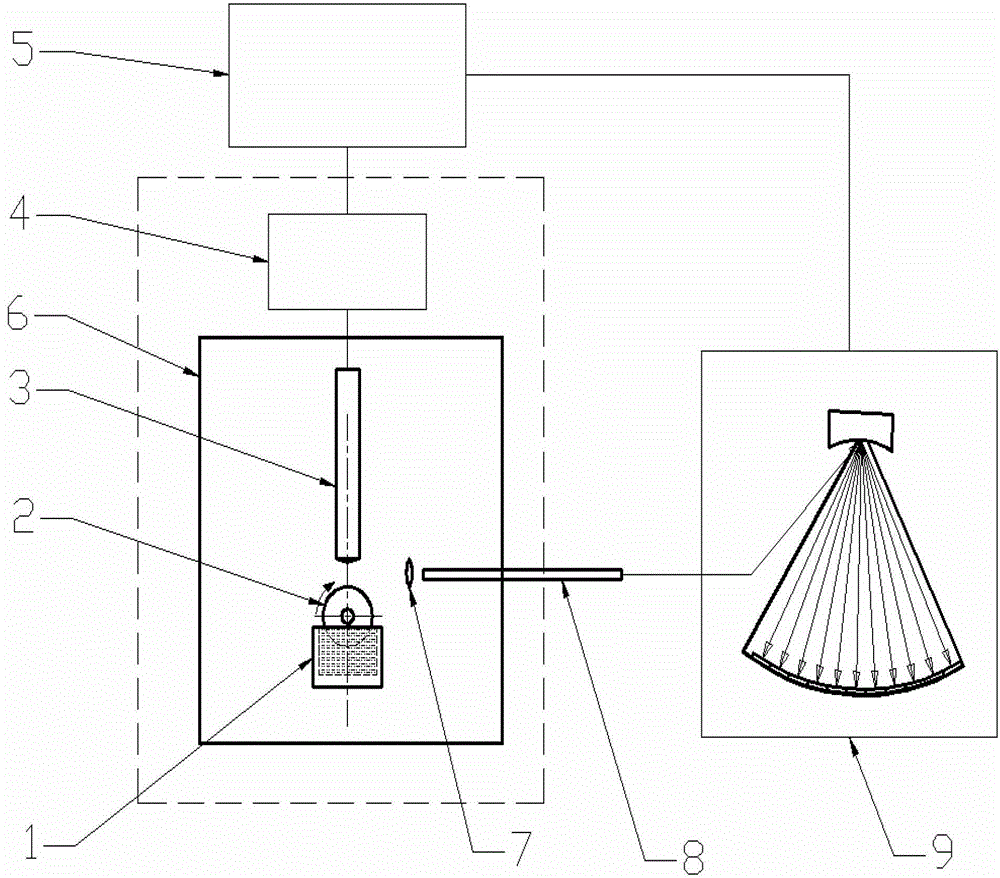

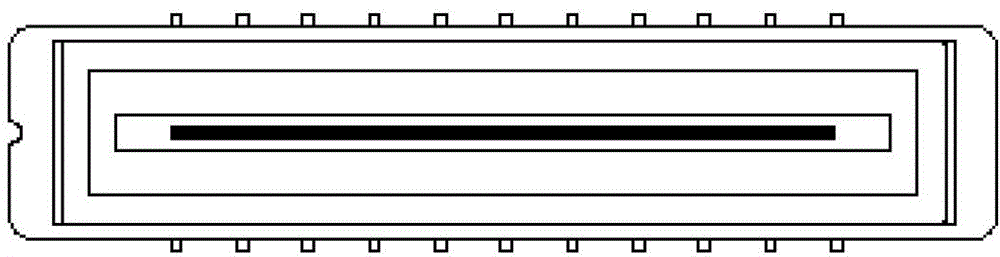

Special oil analysis device based on gathered optical fiber signal transmission and double-layer multi-CCD (Charge Coupled Device) detection

ActiveCN103115915AReduce volumeImprove mobile reliabilityAnalysis by electrical excitationGratingHigh pressure

The invention discloses a special oil analysis device based on gathered optical fiber signal transmission and double-layer multi-CCD (Charge Coupled Device) detection, and the special oil analysis device is used for detecting the content of various metal elements in an oil sample. A rotating disc electrode drives oil to an analytical gap, spark discharge is generated by high voltage between two electrodes, and the metal elements in the oil sample are excited to generate emission spectra; and light with different wavelengths is transmitted to a grating to be split through optical fibers and then irradiated to different CCDs, and the content of multiple elements is obtained through light intensity signal detection and digital operation of spectral lines. The special oil analysis device comprises a light source part, an optical fiber transmission system, a light splitting system, a photoelectric detection system and a control circuit, wherein the light source part comprises a high-voltage generator, a rod electrode and the rotating disc electrode; and the light splitting system fixedly arranges an incidence gap, a concave grating and the CCDs on a Rowland circle device by virtue of a Paschen-Runge device. Compared with an existing instrument, the special oil analysis device disclosed by the invention has the characteristics of fast analysis, simultaneous detection on more than ten elements, direct sampling, no sample pretreatment, easiness for operation and convenience for maintenance.

Owner:广东中科谛听科技有限公司

Oxygen reduction catalyst and preparation method thereof

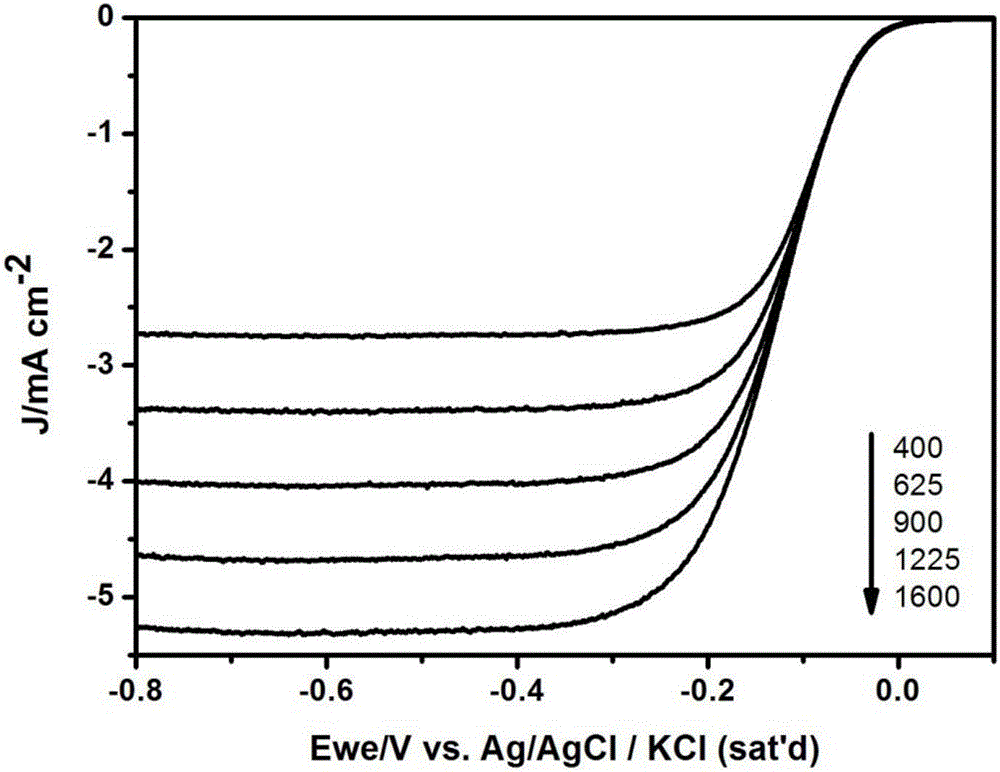

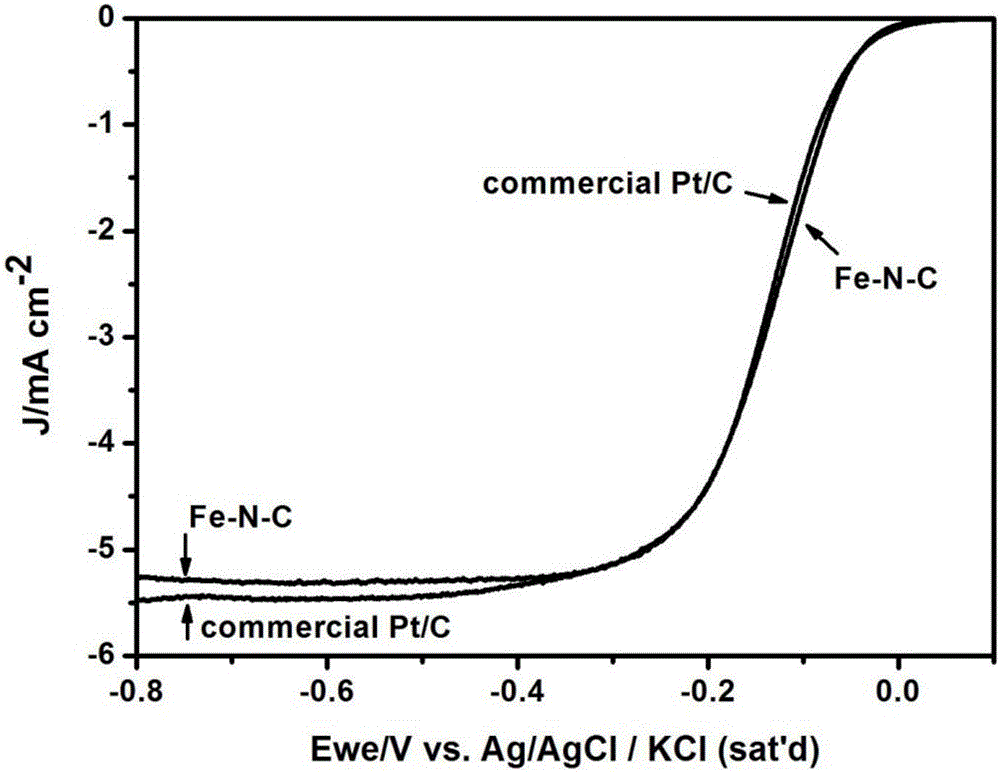

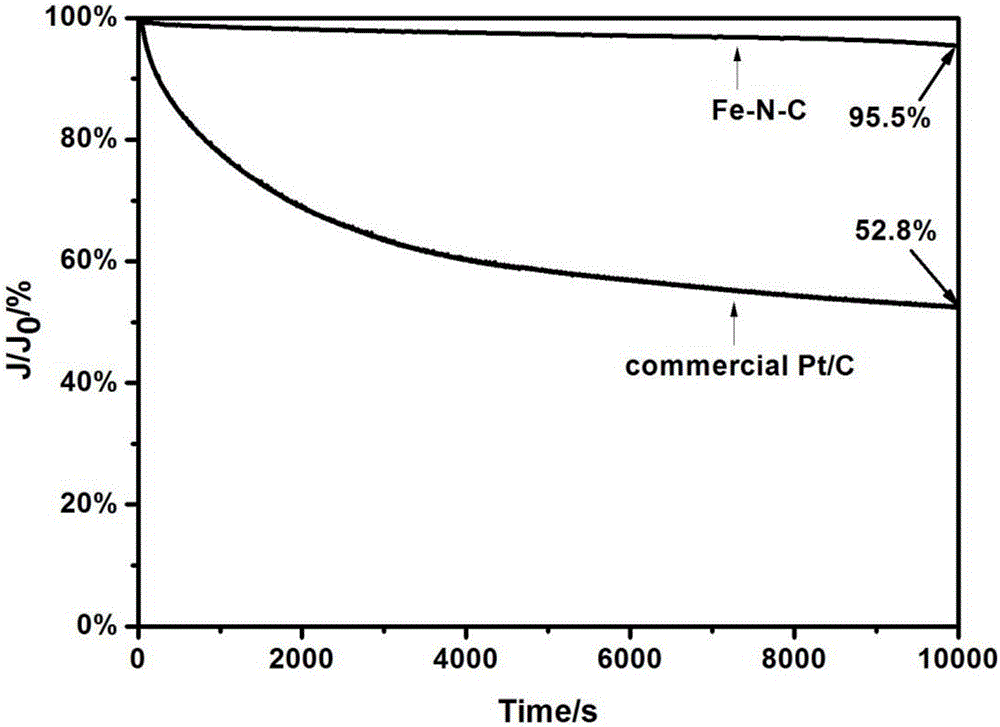

The invention provides an oxygen reduction catalyst and a preparation method thereof. The preparation method includes the steps of mixing a carbon support with a solvent to obtain a carbon support suspension liquid; mixing uric acid, molysite and the carbon support suspension liquid, and desolventizing to obtain a solid mixture; sintering the solid mixture at an inert atmosphere to obtain the oxygen reduction catalyst. According to a result of an embodiment, the oxygen reduction catalyst is provided with an take-off potential at -0.01v vsAg / AgC1 / KC1(sat'd), an extreme diffusion current of the oxygen reduction catalyst can reach to -5.25mA / cm<2> as tested in a 1600rpm rotating disk electrode test, and accordingly, the oxygen reduction catalyst is excellent in oxygen reduction performance. Compared with a commercial platinized carbon catalyst, the oxygen reduction catalyst is more correct in half wave point and much lower in decrement amount which is 4.5%.

Owner:CAPITAL NORMAL UNIVERSITY

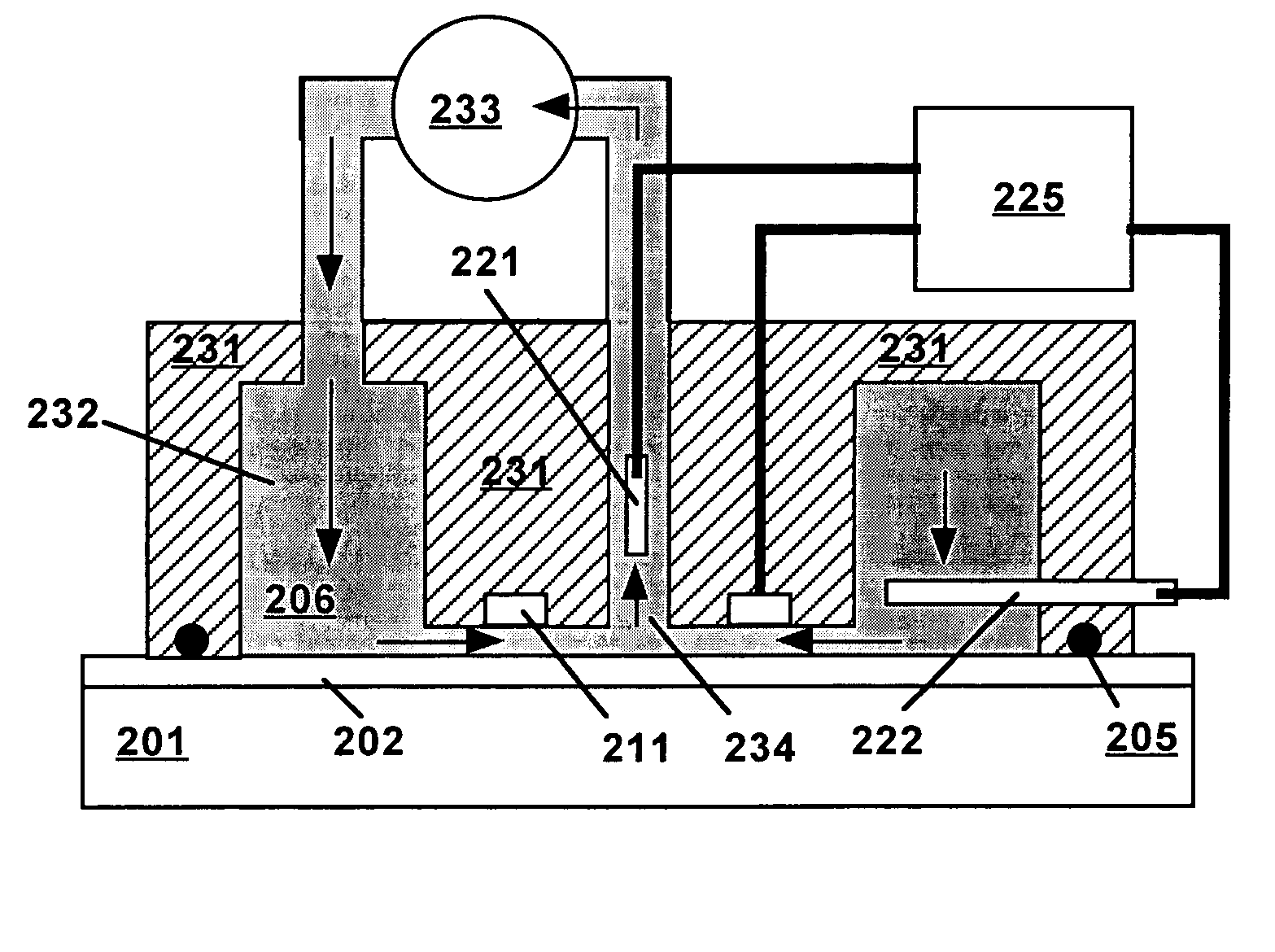

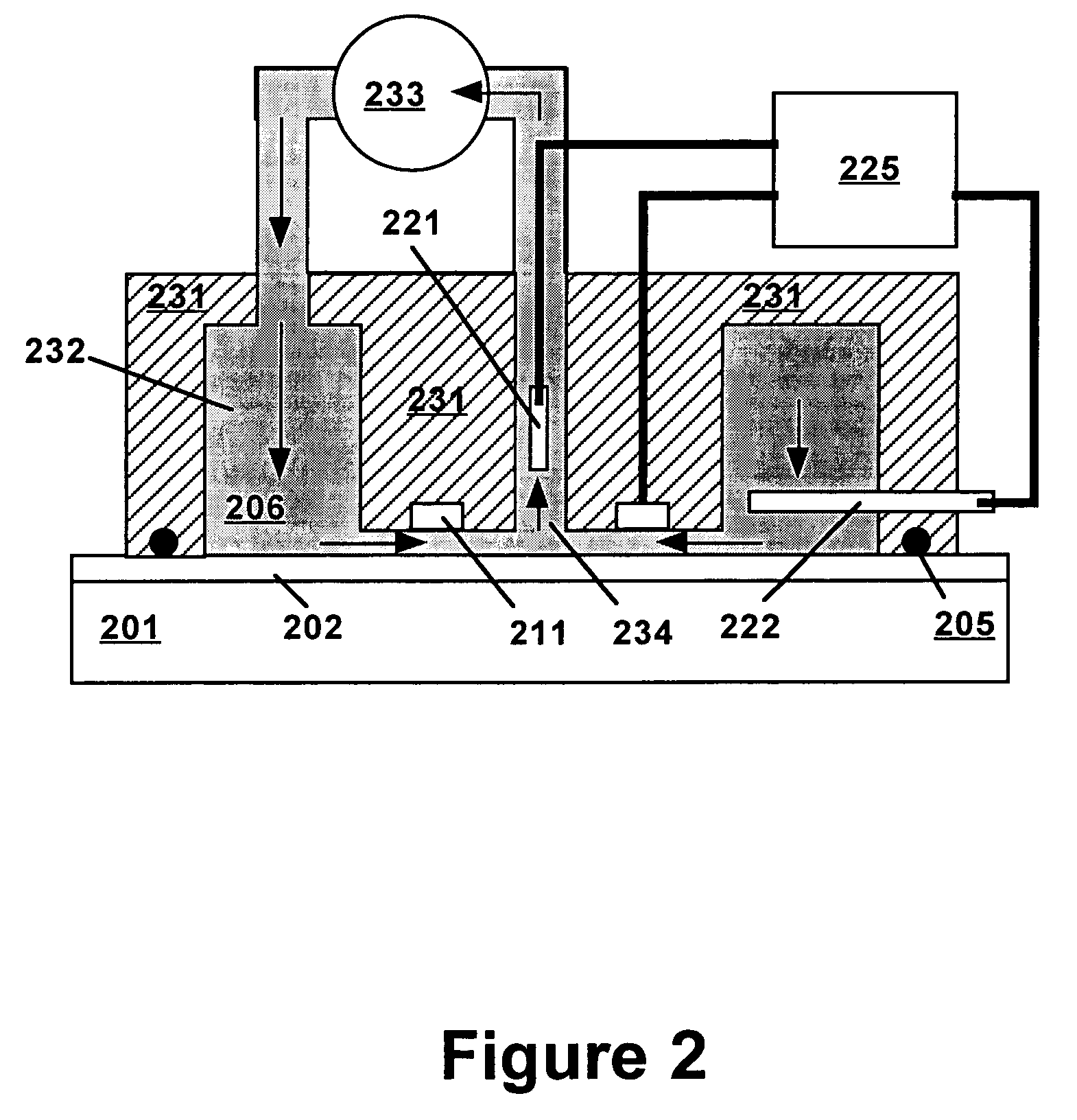

Oil-water alternating wetting corrosion simulation device and method

ActiveCN105092460AQuick responseFull disclosureWeather/light/corrosion resistanceCircular discHandling system

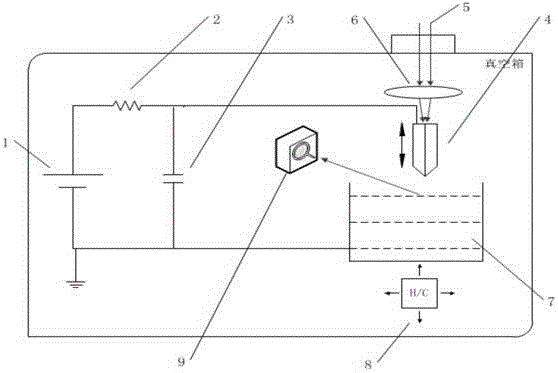

The invention discloses an oil-water alternating wetting corrosion simulation device and method; the device includes an electrochemical signal processing system, an oil-water alternating wetting simulation electrolytic cell, a rotating disk electrode system, an oil-water interface control system, an aeration system and a temperature control system which is used for heating the oil-water alternating wetting simulation electrolysis cell. The device provided by the invention can realize rapid response of a carbon steel corrosion signal in an oil-water alternating wetting environment, seizes main characteristics of the oil-water two-phase flow environment, and can reveal a corrosion law more comprehensively and deeply.

Owner:CHINA PETROCHEMICAL CORP +2

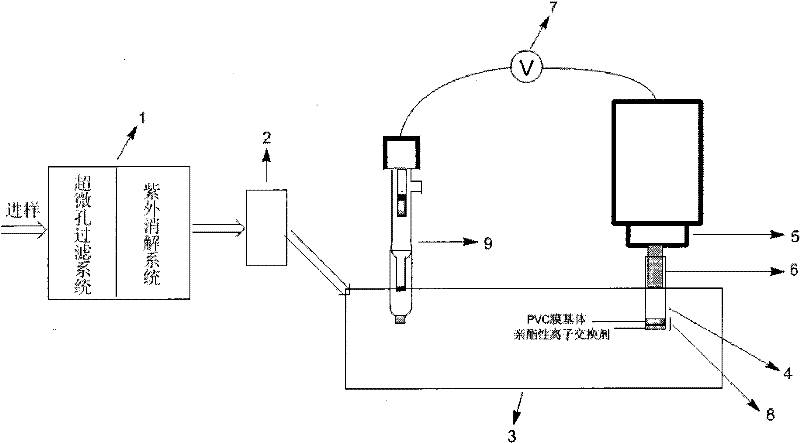

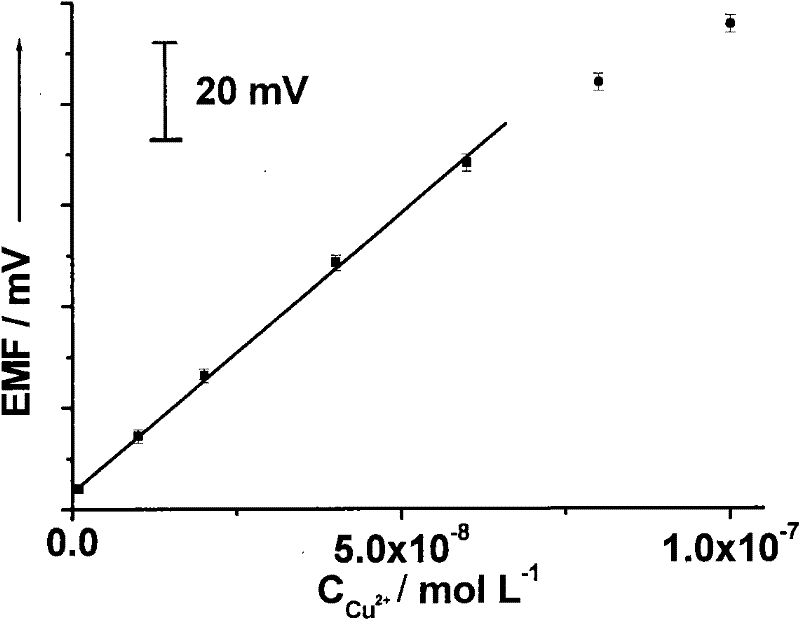

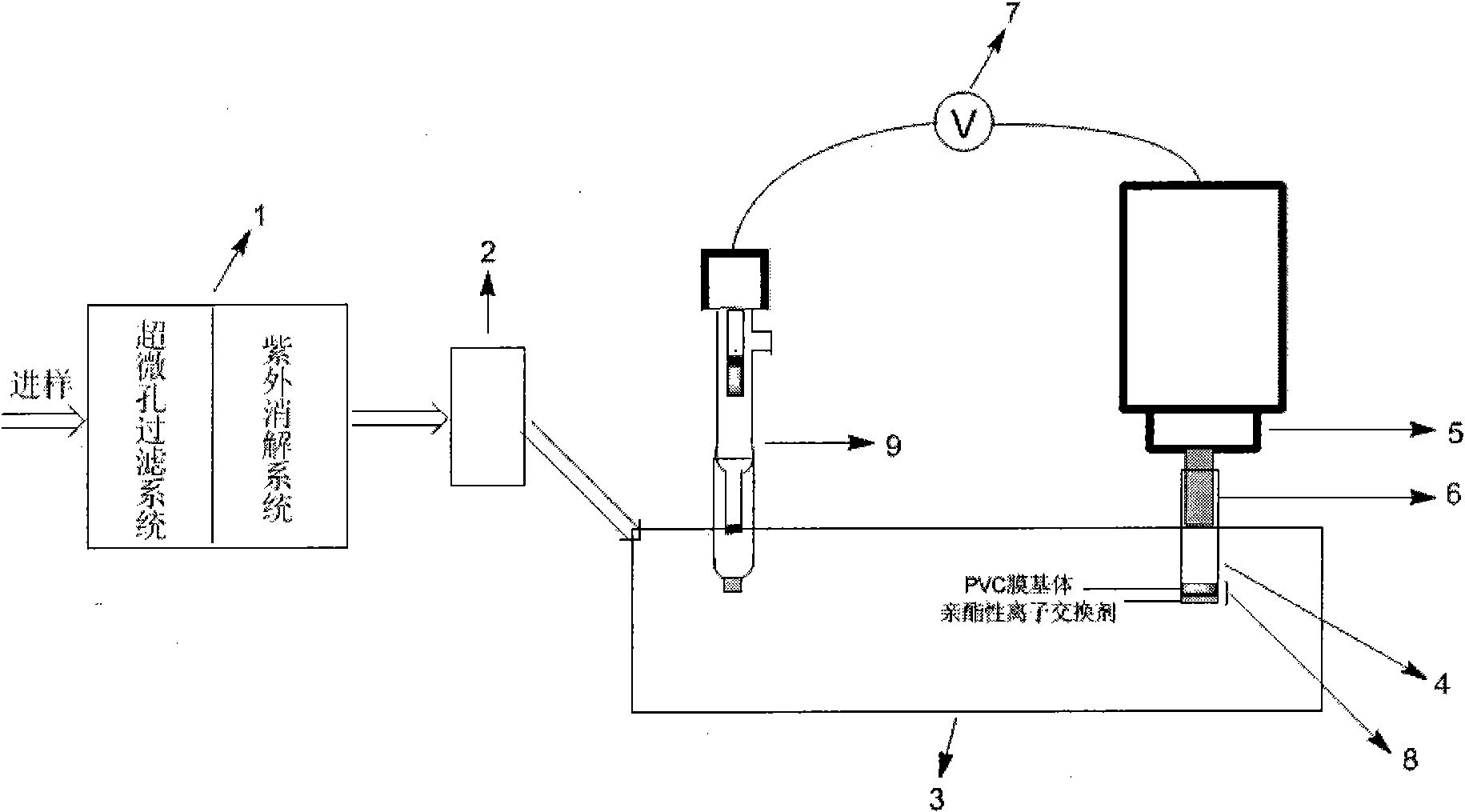

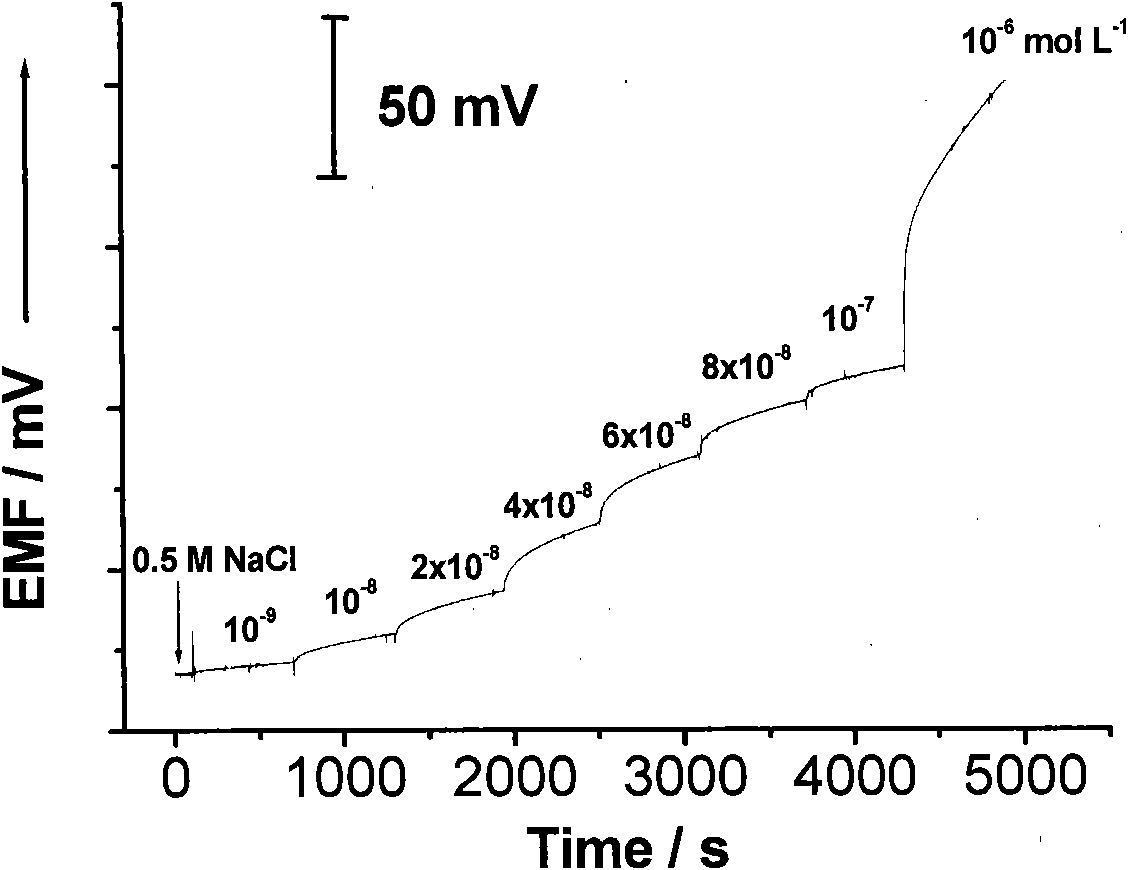

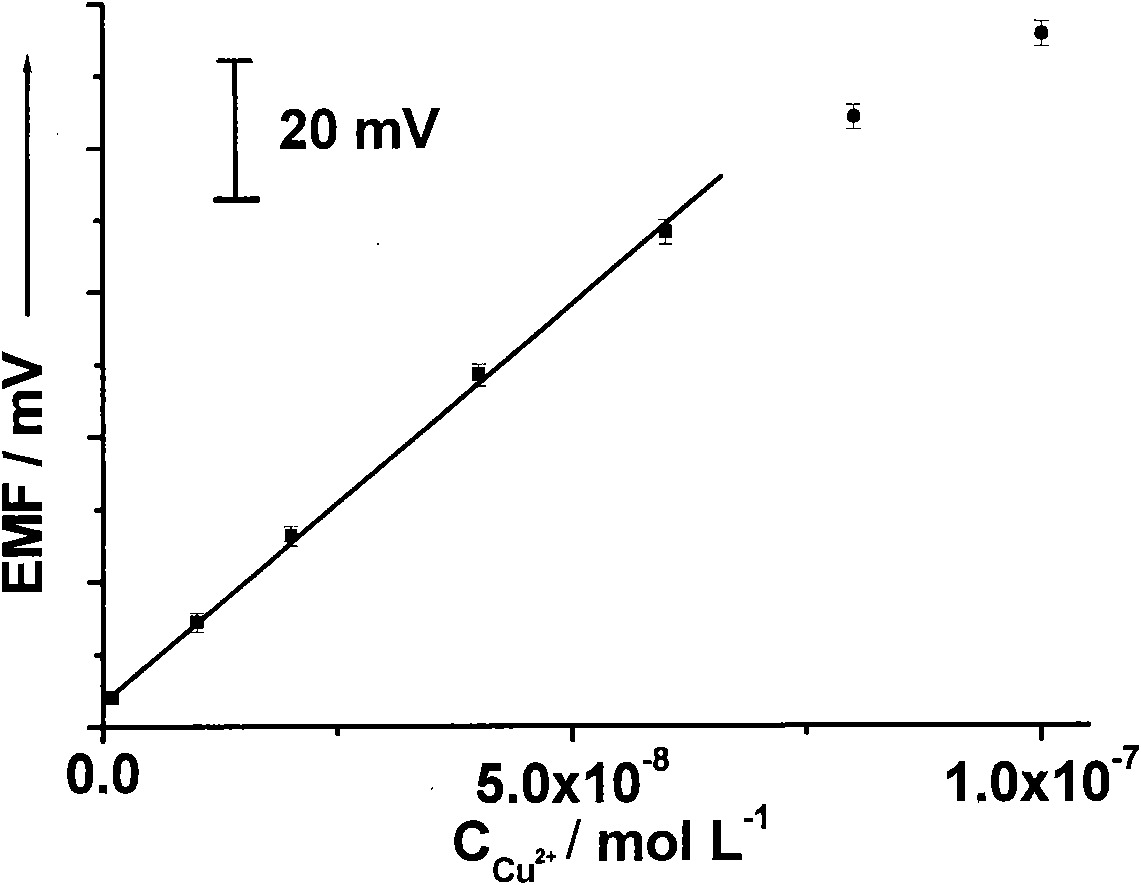

Sensor based on asymmetric polymer film as well as detection method and applications thereof

ActiveCN102539500AEliminate primary ion fluxLow detection limitMaterial electrochemical variablesPolyvinyl chlorideIon exchange

Owner:YANTAI INST OF COASTAL ZONE RES CHINESE ACAD OF SCI

Electrochemical technique to measure concentration of multivalent cations simultaneously

ActiveUS8486256B2Weather/light/corrosion resistanceVolume/mass flow measurementPotentiostatSteady state

Owner:OHIO UNIV

Evaluation of the corrosion inhibiting activity of a coating

InactiveUS7422678B2Rapid and inexpensive and non-destructive evaluationHigh corrosion inhibiting activityWeather/light/corrosion resistanceVolume/mass flow measurementCoated surfaceMaterials science

The corrosion inhibiting activity of a coating is determined from the effect of corrosion inhibiting species released by the coating on the oxygen reduction current for a cathode placed very close to the coating. A rotating disk electrode or pumped solution flow is used to sweep the corrosion inhibiting species from the coating surface to the cathode. The oxygen reduction current is measured under conditions of oxygen diffusion control.

Owner:TELEDYNE SCI & IMAGING

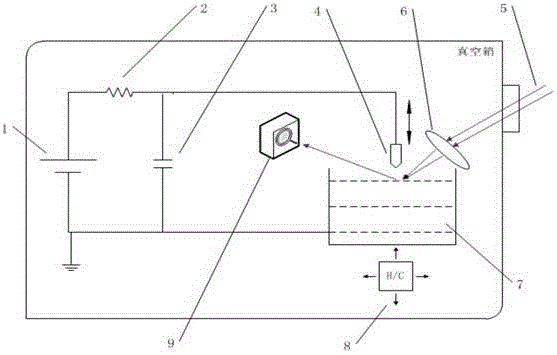

Plasma apparatus for laser-induced discharge of liquid tin target

InactiveCN106370645AAchieving extreme ultraviolet radiationImprove stabilityAnalysis by thermal excitationElectricityLiquid state

The invention provides a plasma apparatus for laser-induced discharge of a liquid tin target. The plasma apparatus comprises an energy supply module, an extreme ultraviolet light generation module and an extreme ultraviolet detector, wherein the energy supply module is used for providing the extreme ultraviolet light generation module with energy needed in discharge; the extreme ultraviolet light generation module comprises the liquid tin target, and extreme ultraviolet light is generated when laser irradiates the tin liquid level of the liquid tin target; and the extreme ultraviolet detector is arranged to form an angle of 45 DEG with the tin liquid level of the liquid tin target and used for receiving the extreme ultraviolet light. After focusing, laser acts on the liquid tin target to realize gasification and ionization of the liquid tin target so as to produce pre-plasma; meanwhile, the liquid tin target is used as an electrode, a copper electrode is placed above tin liquid, and high voltage is applied between the two electrodes; and the high voltage breaks down the pre-plasma for discharge and enables the pre-plasma to be further ionized so as to produce main plasma and radiate extreme ultraviolet light with a length of 13.5 nm. According to the invention, liquid tin is used as the electrode to replace a conventional rotating-disk electrode, so a system is simplified and the stability of the system is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

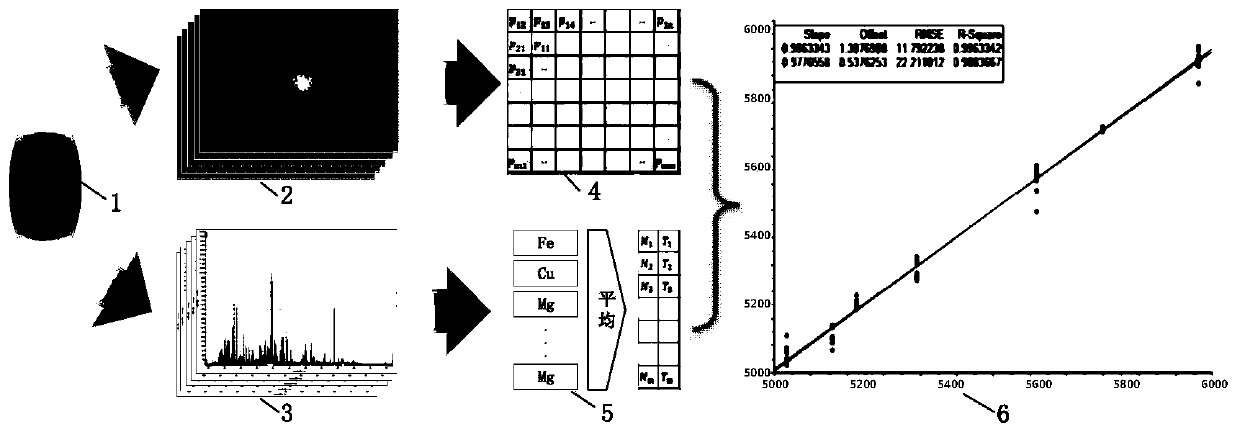

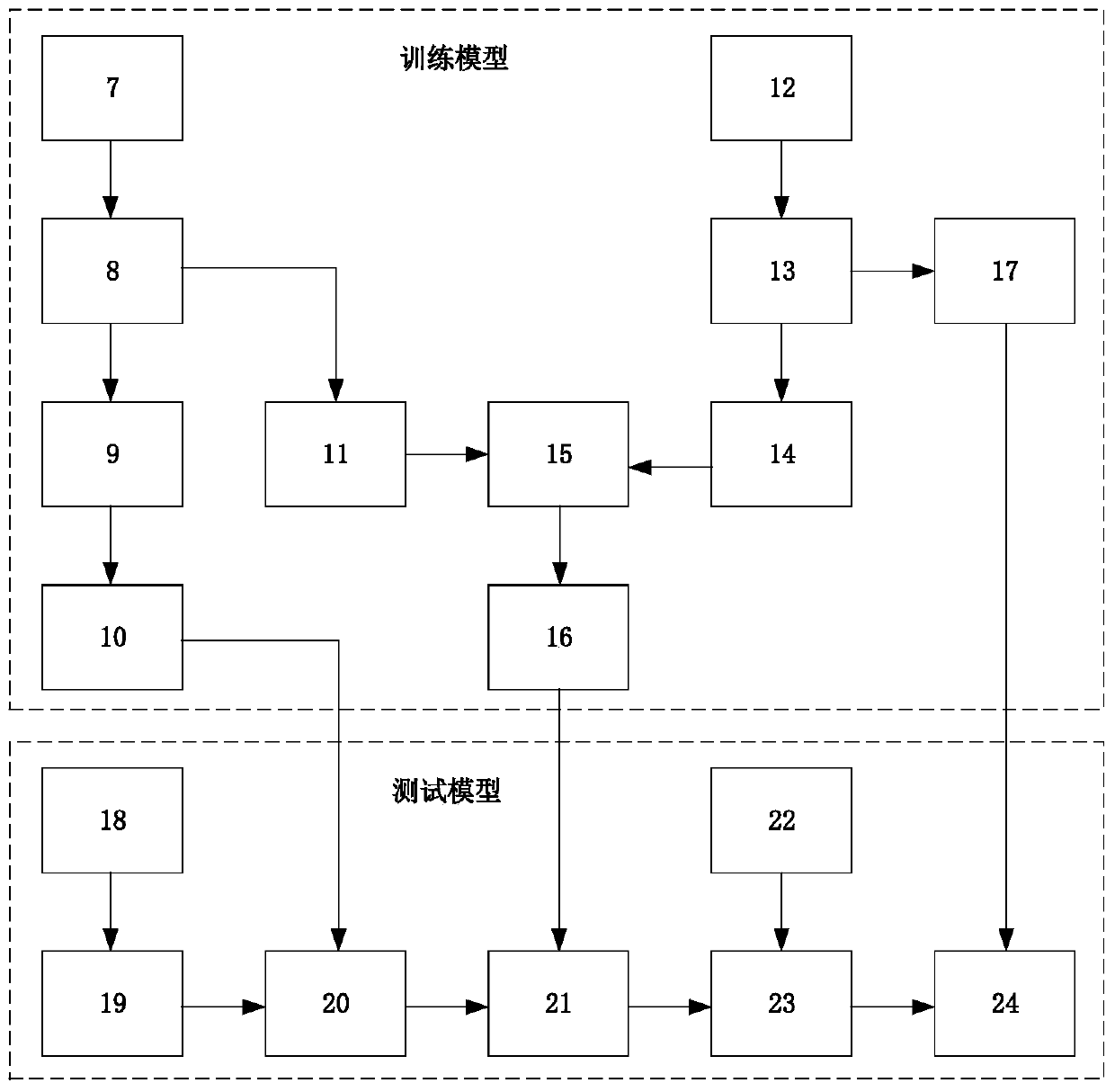

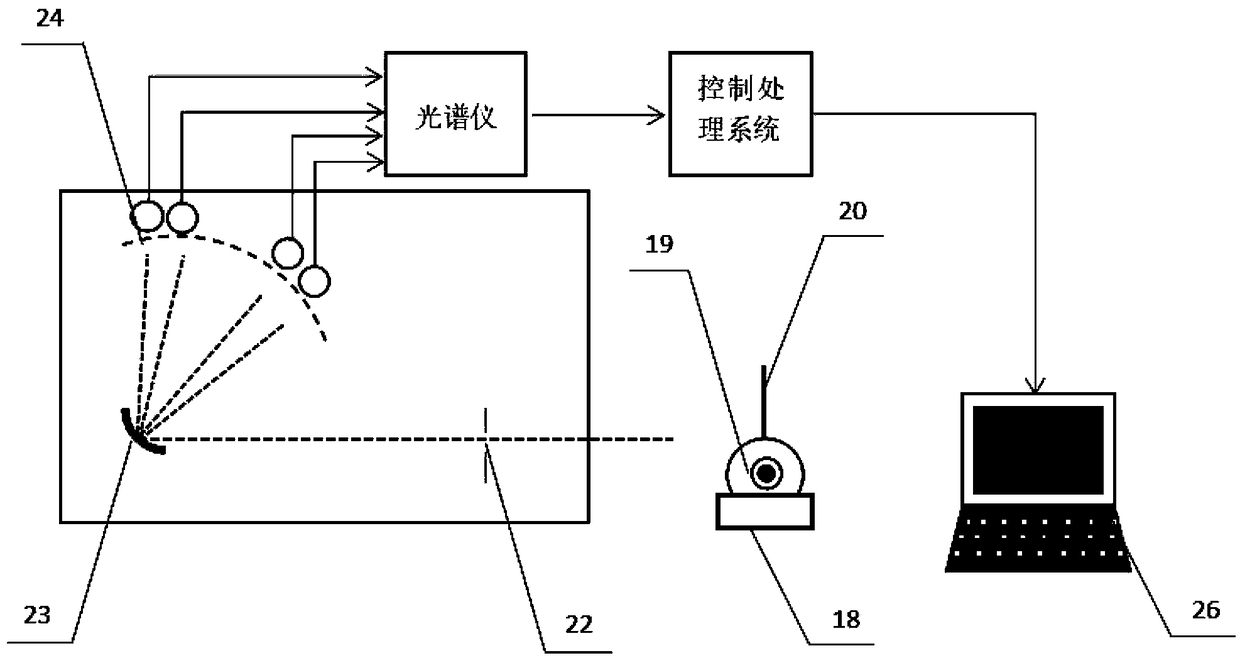

Method and device for detecting oil elements based on image-assisted atomic emission spectroscopy

ActiveCN110823862AImprove on-site detection accuracyGood repeatabilityAnalysis by electrical excitationWater resource assessmentParticle physicsEmission spectrum

The invention discloses a method and device for detecting oil elements based on image-assisted atomic emission spectroscopy, and the method comprises the following steps of (1) synchronously collecting an arc plasma image and an atomic emission spectrum of oil samples by means of a camera and a rotating disk electrode atomic emission spectrometer, estimating state parameters of the plasma by usingelement spectral lines, and establishing an internal relationship between the plasma image and the state parameters; (2) establishing an image-spectral training model and a test model by using the partial least squares algorithm (PLS) based on arc plasma image and atomic emission spectrum data, obtaining a compensation proportional coefficient by first solving the training model, and obtaining the strength of the compensated spectral line by solving the test model; and (3) realizing the content detection of oil elements by using the strength of the compensated spectral line and combining a quantitative analysis algorithm. The method can significantly improve the field detection accuracy of oil elements and improve the repeatability of element detection without increasing the cost obviously.

Owner:TIANJIN UNIV

Preparation method for transition metal oxide nitrogen-and-phosphorus-doped catalyst applied to zinc-air battery

ActiveCN108336373AExcellent oxygen reduction activitySimple preparation processFuel and primary cellsCell electrodesPhytic acidZinc–air battery

The invention discloses a preparation method for a transition metal oxide nitrogen-and-phosphorus-doped catalyst applied to a zinc-air battery. The preparation method comprises the following steps: subjecting acetate containing M metal ions and phytic acid to coordination to form a supramolecular compound; with the transition metal supramolecular compound as a precursor, carrying out high-temperature calcination in an inert atmosphere; and finally, with ammonia gas as a N source, carrying out N doping at high temperature so as to obtain a final transition metal phosphorus oxynitride. The transition metal phosphorus oxynitride, used as an oxygen reduction catalyst, effectively reduces the overpotential of the ORR; and a rotating disk electrode (RDE) and a rotating ring disk electrode (RRDE)indicate that the ORR process is based on a four-electron catalytic mechanism and is an ideal ORR reaction process. The electrocatalyst of the invention gives full play to the synergistic effect of transition metal and hetero atom elements in electrocatalysis, and shows excellent catalytic performance in application to the zinc-air battery.

Owner:山东科源新材料有限公司

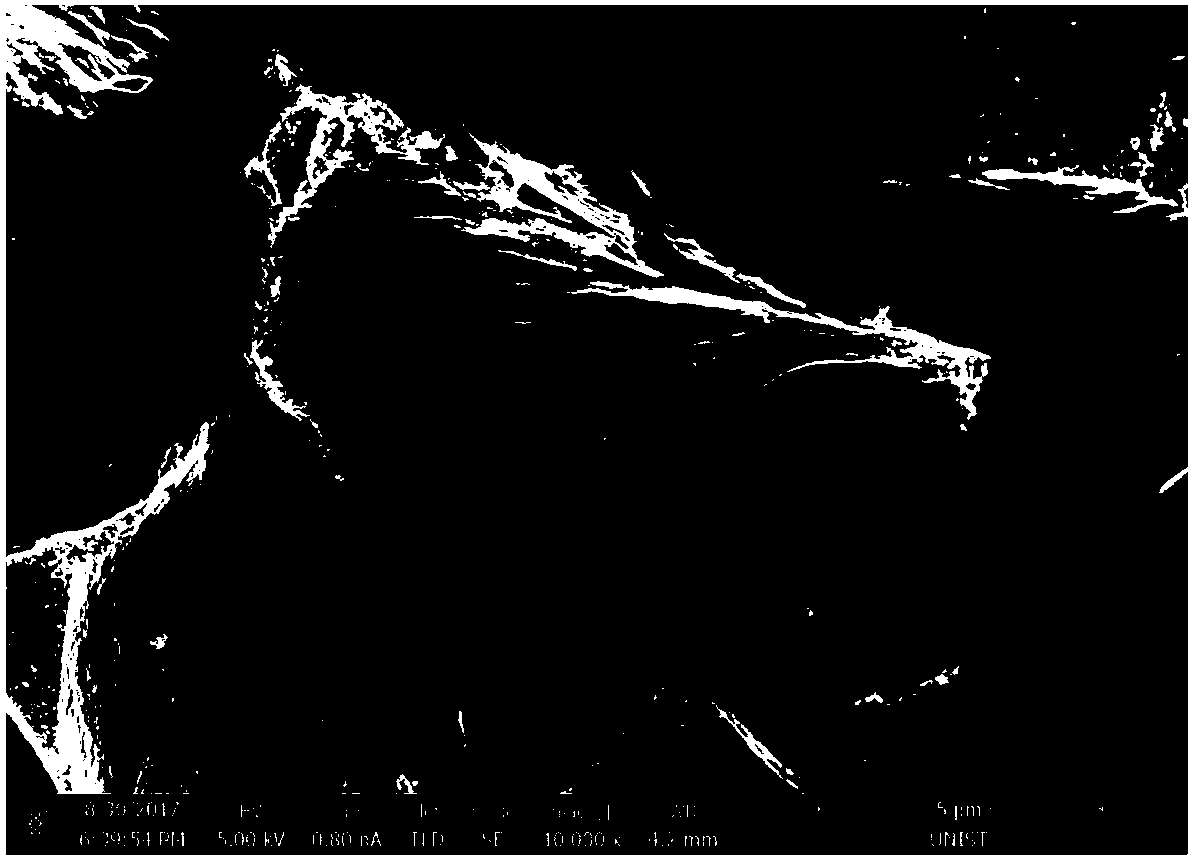

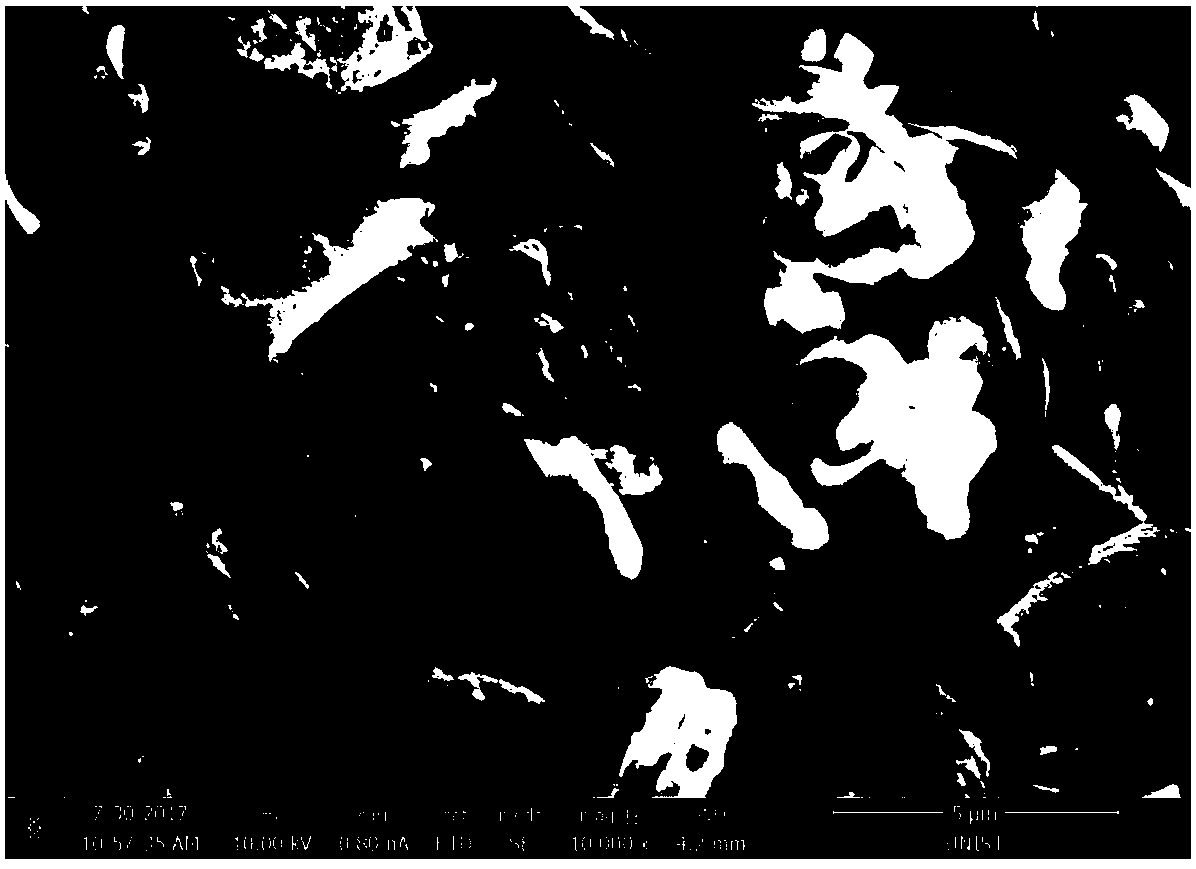

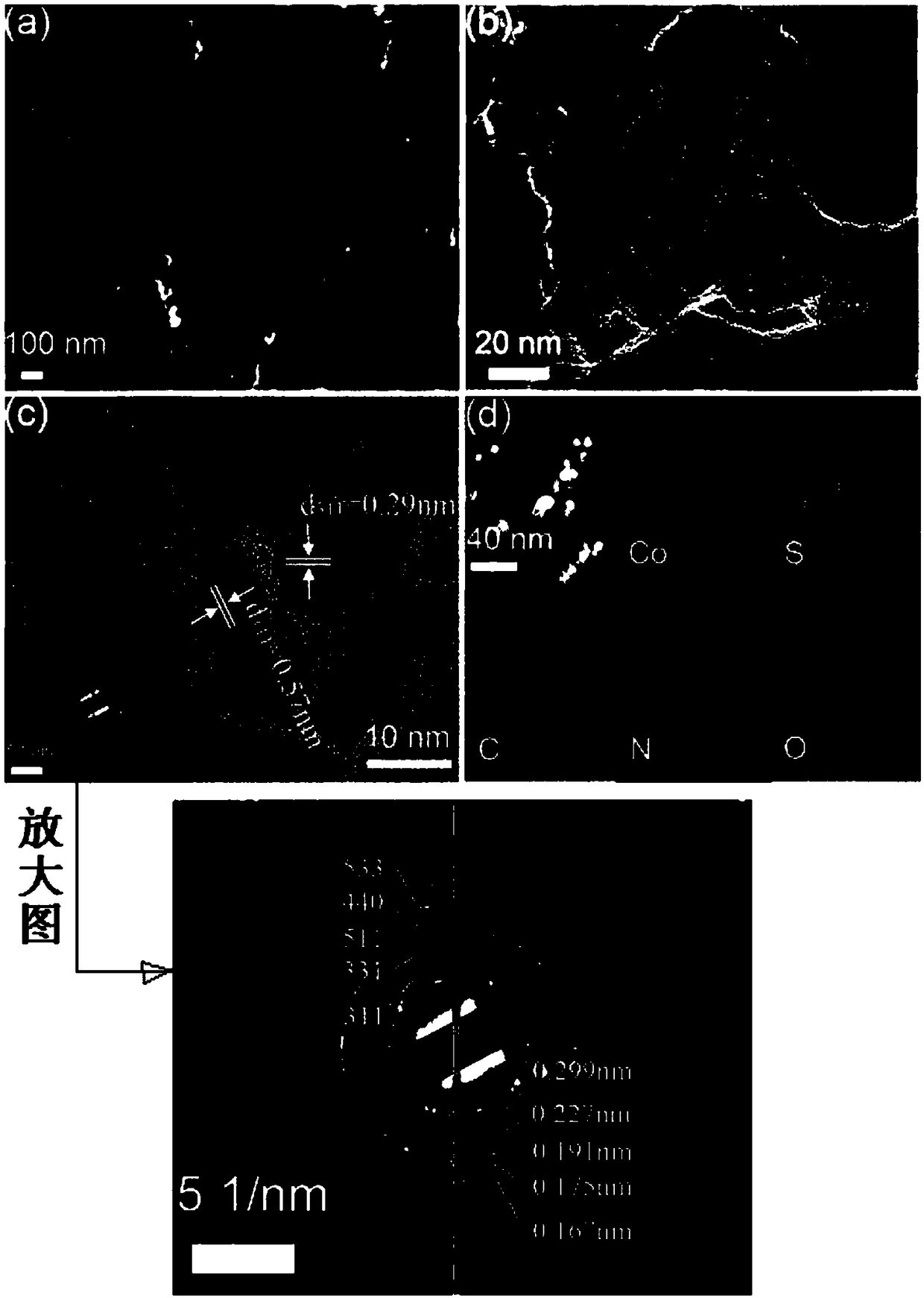

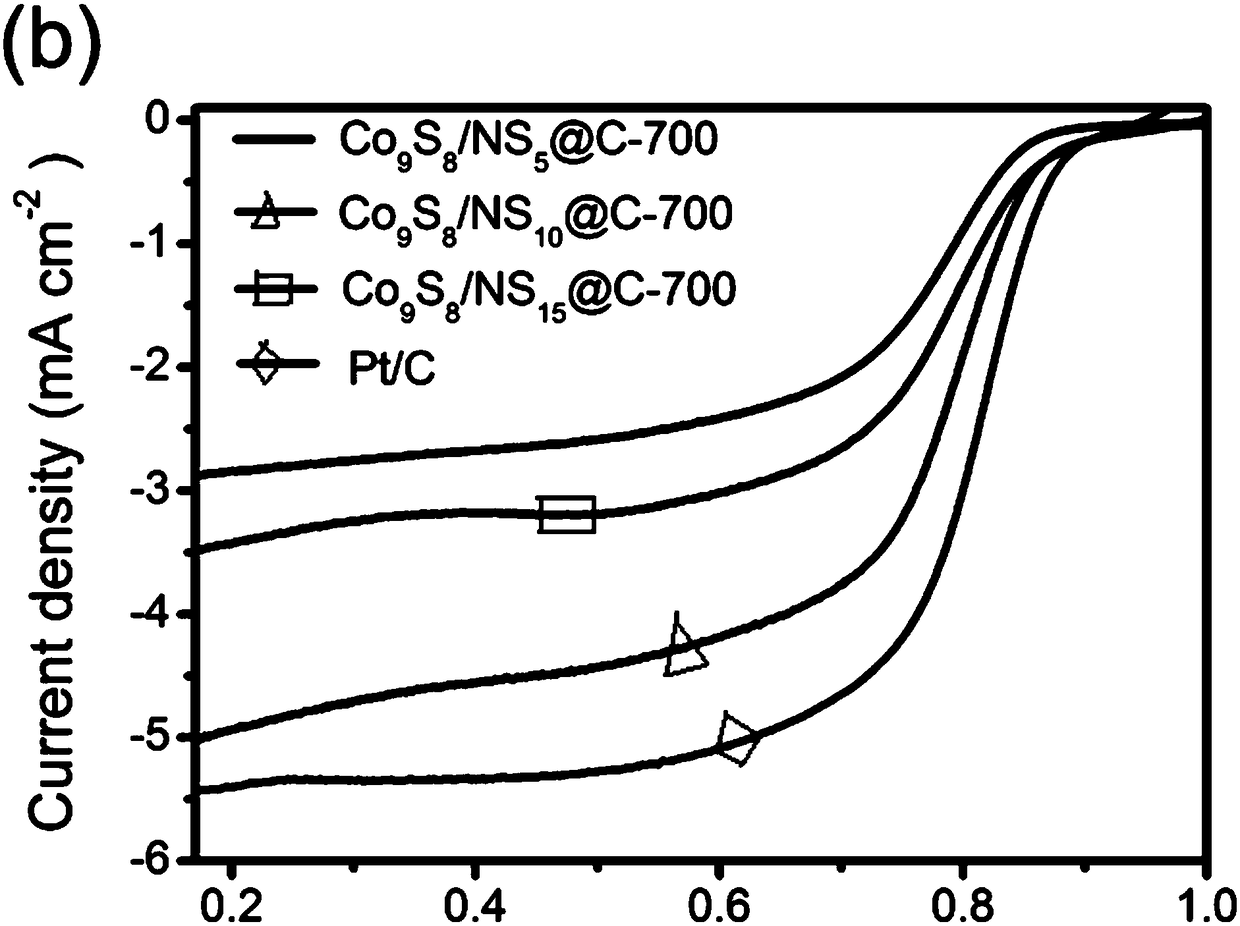

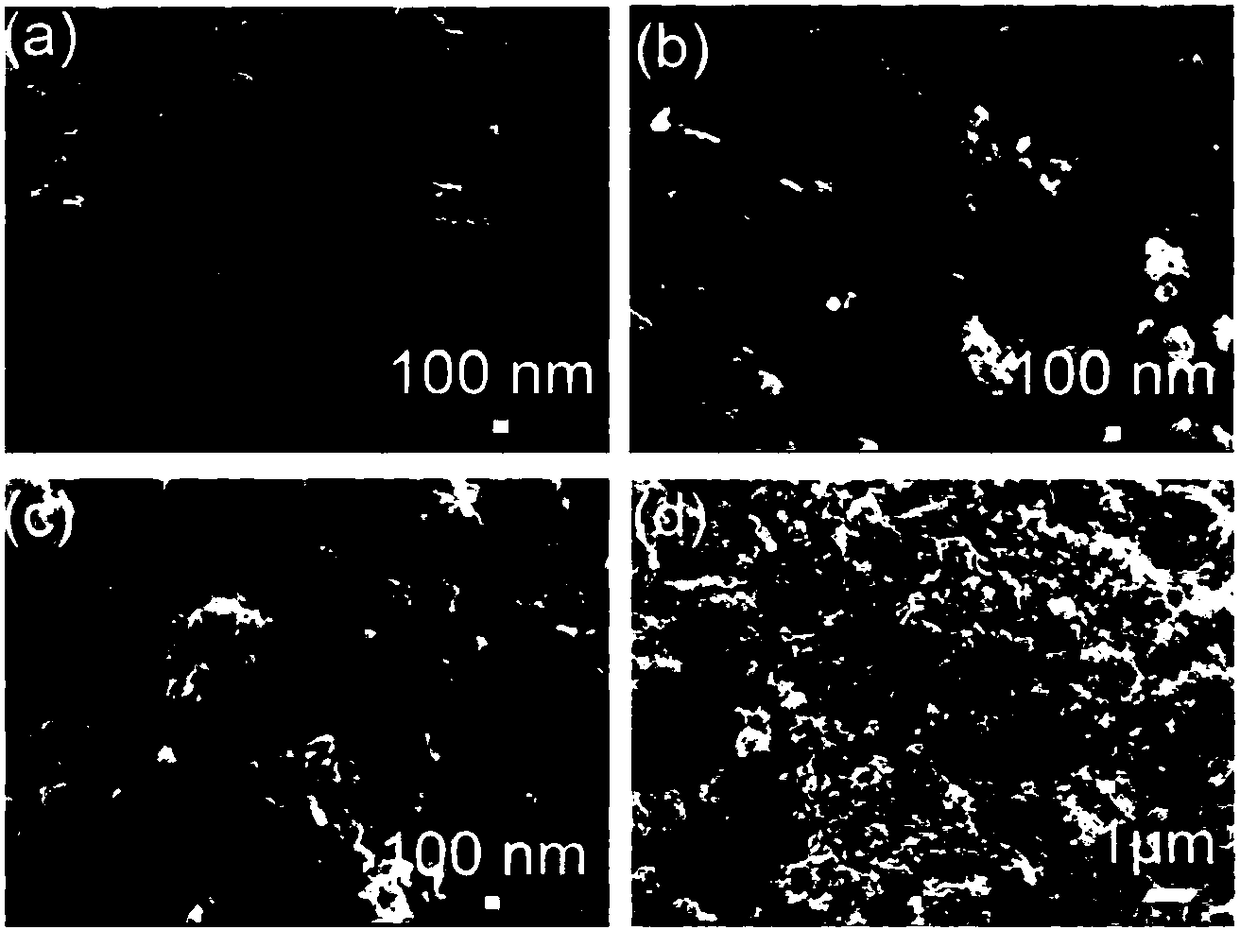

Method for preparing oxygen reduction catalyst from cobalt sulfide

InactiveCN108417850AThe synthesis method is simpleEasy to makeCell electrodesMetal-organic frameworkSlow cooling

The invention provides a method for preparing an oxygen reduction catalyst from cobalt sulfide. The method comprises the following steps: (1) dissolving 52.4 mg of cobalt nitrate hexahydrate (with a molar mass of 0.2 mmol) and 48.4 mg of 4,4'-bpdc (with a molar mass of 0.2 mmol) in 23 mL of DMF and dissolving 31.5mg of 1,3-bib (with a molar mass of 0.15 mmol) in 2mL of DMF, respectively; (2) afterrespective ultrasonic treatment of solution samples obtained in step (1) for 1 minute, mixing the obtained solutions, transferring the obtained mixture to a reactor with a volume of 50 cm<3>, carrying out heating to 120 DEG C at a heating rate of 1.2 DEG C / min, keeping the mixture at 120 DEG C for 48 hours, then carrying out slow cooling to room temperature at a rate of 0.4 DEG C / min, after cooling to room temperature, separating purple crystals by decanting mother liquor, carrying out washing with DMF, and carrying out drying after cleaning so as to obtain a cobalt-based metal organic framework; (3) weighing a part of a sample prepared in the step (2) and thioacetamide, putting the weighed sample and thioacetamide into ceramic vessels respectively transferring the weighed sample and thioacetamide to the outlet end and the inlet end of a tube furnace, and carrying out pyrolysis in a nitrogen atmosphere at a heating rate of 5 DEG C / min to obtain black powder; and (4) testing the ORR performance of the produced black powder by using an electrochemical workstation and a rotating disk electrode.

Owner:SHANDONG SUNRISE NEW MATERIAL TECH CO LTD

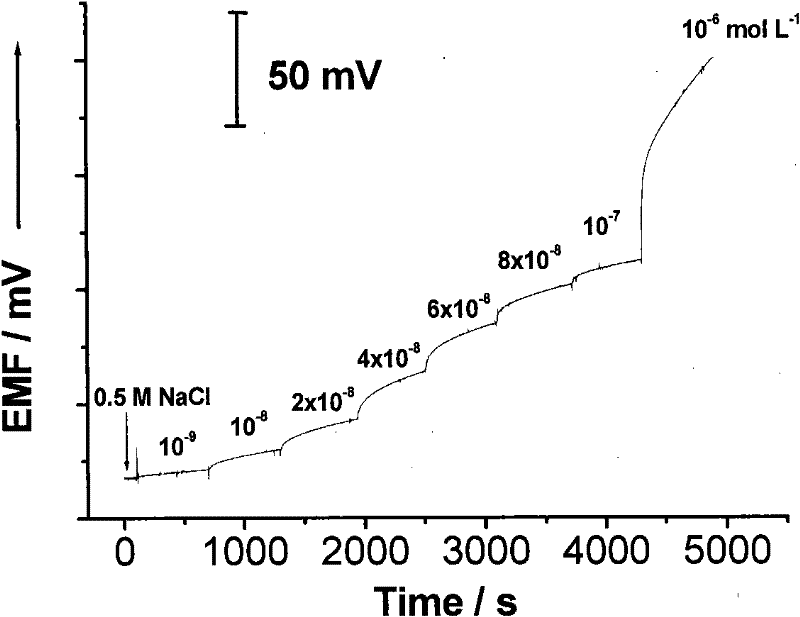

Rotating potentiometric electrode

InactiveUS6908542B2High sensitivityQuality improvementWeather/light/corrosion resistanceMicrobiological testing/measurementPolyurethane membraneTridodecylmethylammonium chloride

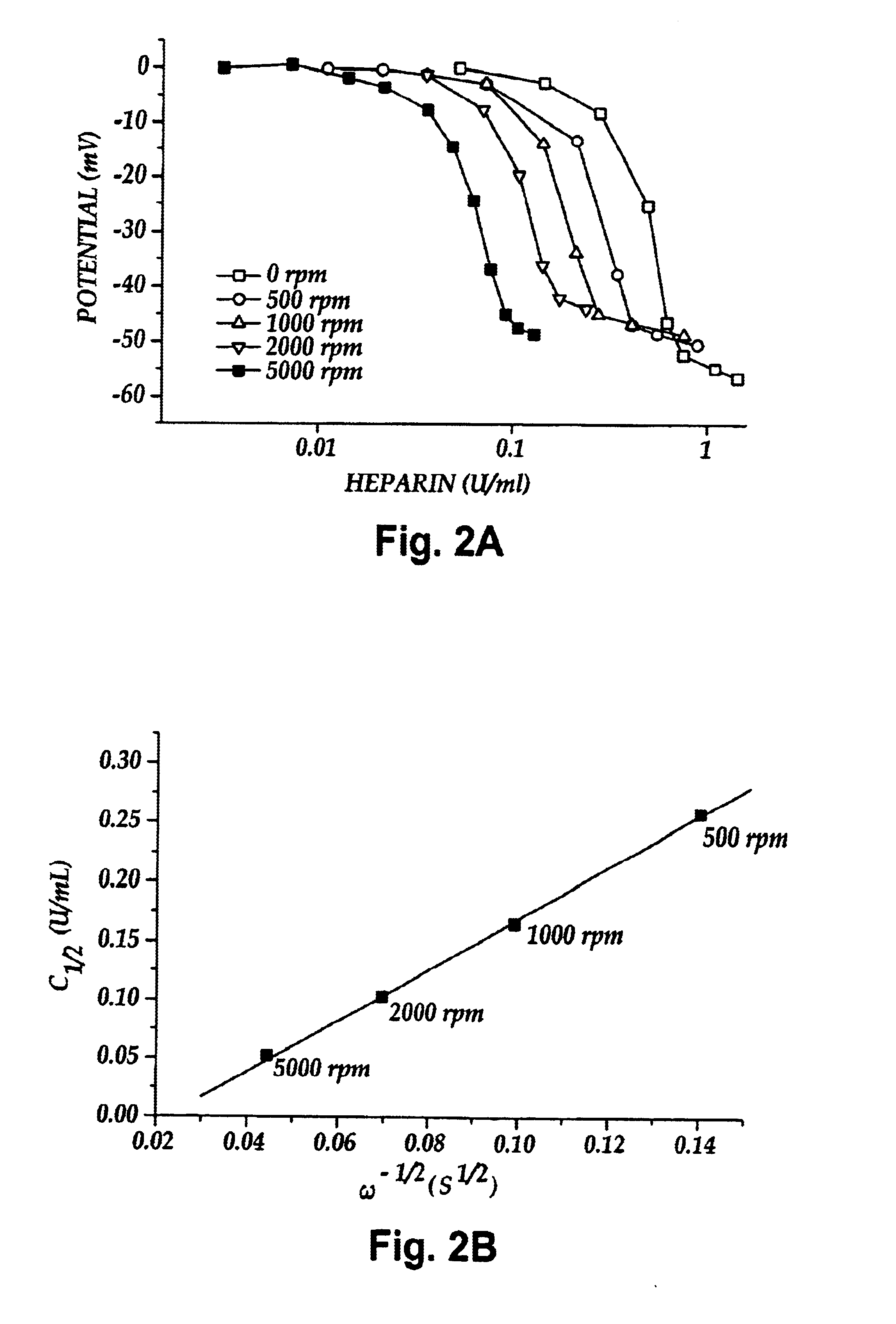

A rotating electrode configuration lowers the detection limits of polyion-sensitive membrane electrodes. Planar potentiometric polycation and polyanion-sensitive membrane electrodes were prepared by incorporating tridodecylmethylammonium chloride and calcium dinonylnaphthalene sulfonate, respectively, into plasticized PVC or polyurethane membranes, and mounting discs of such films on an electrode body housed in a rotating disk electrode apparatus of the type used in voltammetry. Due to the unique non-equilibrium response mechanism of such sensors, rotation of the polyion-sensitive membrane electrodes at 5000 rpm resulted in an enhancement in the detection limits toward heparin (polyanion) and protamine (polycation) of at least 1 order of magnitude (to 0.01 U / ml for heparin; 0.02 μg / ml for protamine) over that observed when the EMF responses of the same electrodes were assessed using a stir-bar to achieve convective mass transport.

Owner:RGT UNIV OF MICHIGAN

Oil-water alternating wetting corrosion simulation device and method

ActiveCN105092460BQuick responseFull disclosureWeather/light/corrosion resistanceDeep levelMaterials science

The invention discloses an oil-water alternating wetting corrosion simulation device and method; the device includes an electrochemical signal processing system, an oil-water alternating wetting simulation electrolytic cell, a rotating disk electrode system, an oil-water interface control system, an aeration system and a temperature control system which is used for heating the oil-water alternating wetting simulation electrolysis cell. The device provided by the invention can realize rapid response of a carbon steel corrosion signal in an oil-water alternating wetting environment, seizes main characteristics of the oil-water two-phase flow environment, and can reveal a corrosion law more comprehensively and deeply.

Owner:CHINA PETROCHEMICAL CORP +2

Analysis of an auxiliary leveler additive in an acid copper plating bath

An auxiliary leveler additive that cannot be analyzed by conventional CVS methods for acid copper plating baths is analyzed by cyclic voltammetry at a platinum rotating disk electrode from its effect on the anodic current at very positive potentials.

Owner:KLA CORP

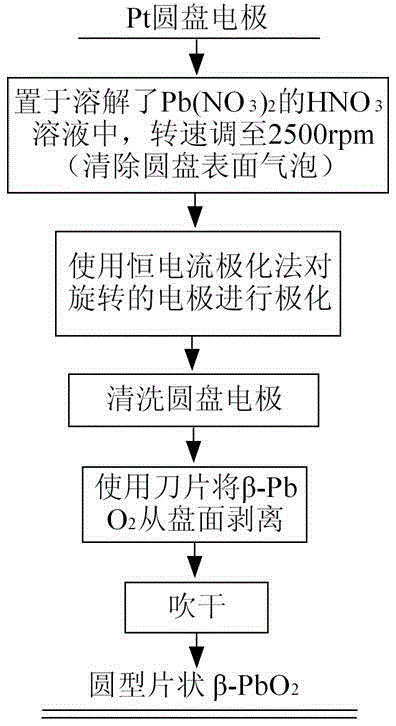

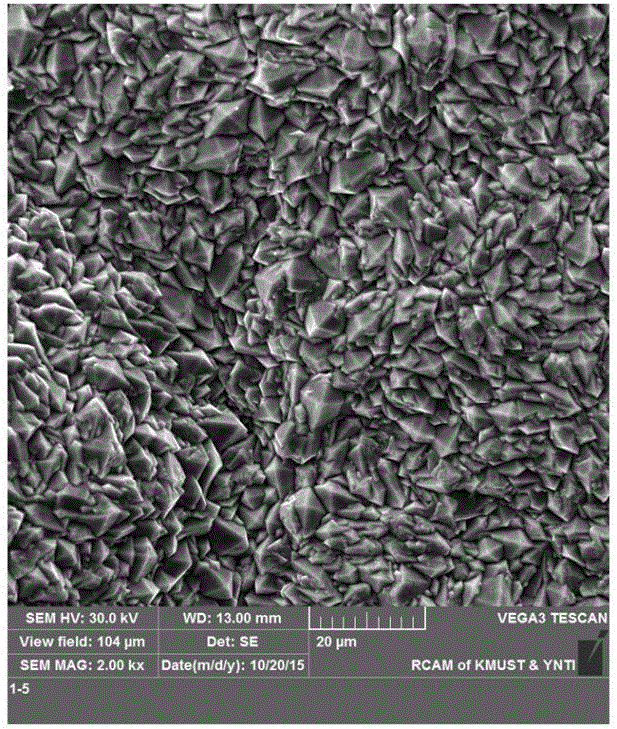

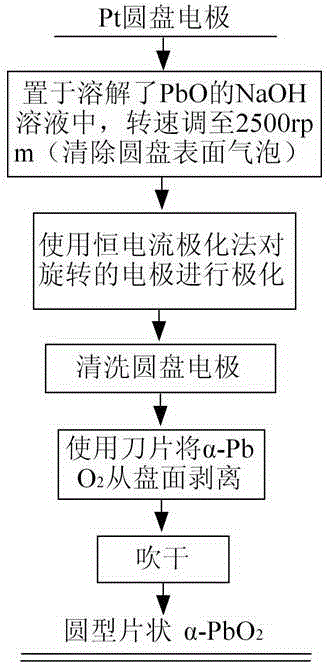

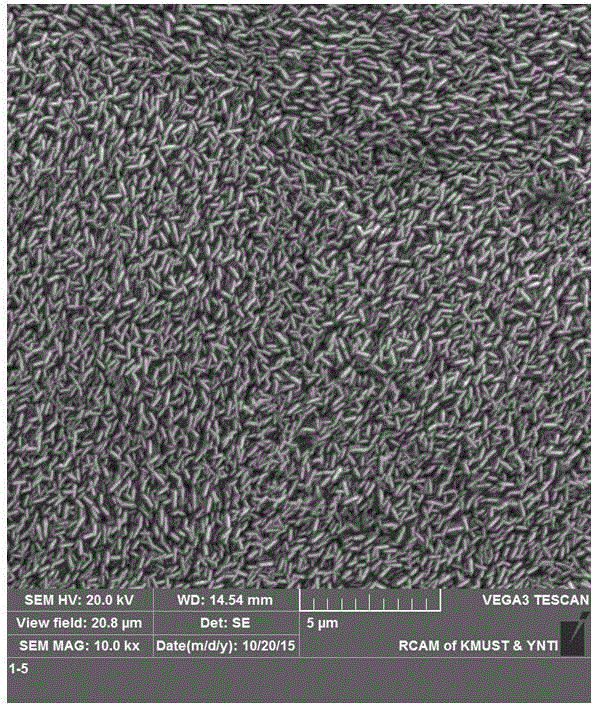

Method for electrochemically synthesizing beta-PbO2 on rotating disk electrode

ActiveCN105401192ACompact structureIncreased microhardnessElectrolytic inorganic material coatingPlatinumMaterials preparation

The invention relates to a method for electrochemically synthesizing beta-PbO2 on a rotating disk electrode and belongs to the technical field of electrochemistry and material preparation. A three-electrode system is adopted, specifically, a Pt disk electrode serves as the working electrode, a saturated calomel electrode serves as the reference electrode, and a platinum sheet with the surface area being 2 cm<2> serves as the auxiliary electrode. The electrodes are placed in a beta-PbO2 plating solution, constant current polarization is carried out under the conditions that the synthesis temperature ranges from 40 DEG C to 50 DEG C and the polarization current ranges from 40 mA / cm<2> to 50 mA / cm<2>, beta-PbO2 can be deposited on the surface of the Pt disk, and the beta-PbO2 is stripped from the surface of the Pt disk and then blow-dried so as to obtain the disc-shaped beta-PbO2. Through the method, the disc-shaped beta-crystal-form PbO2 which is compact in structure, flat in surface and high in microhardness can be obtained.

Owner:KUNMING UNIV OF SCI & TECH

Single-element standard oil and preparation method thereof

ActiveCN105181403AStrong designabilityUniform systemPreparing sample for investigationPolyolefinManganese

The present invention belongs to the technical field of chemical metering. Poly-alpha-olefin as a base oil carrier, cyclohexane butyric acid metal compound as a metal element additive, and a suitable supplemented co-solvent are subjected to mixing and dissolving, so as to obtain the single-element standard oil. The single-element standard oil provided by the present invention comprises poly-alpha-olefin base oil with kinematic viscosity at 100 DEG C of 2-10cSt, a co-solvent and a cyclohexane butyric acid metal compound with metal element content of between 1-10000 mug / g. The single-element standard oil has strong designability, system uniformity, and good storage stability; and the preparation method is simple and easy to control. The single-element standard oil is applicable to determination of barium, magnesium, manganese, lead and zinc content, especially applicable to establishment of standard curve by inductively coupled plasma atomic emission spectrometry (ICP-AES) and rotating disk electrode spectrum for content determination of barium, magnesium, manganese, lead and zinc in lubricating oil.

Owner:NO 53 RES INST OF CHINA NORTH IND GRP

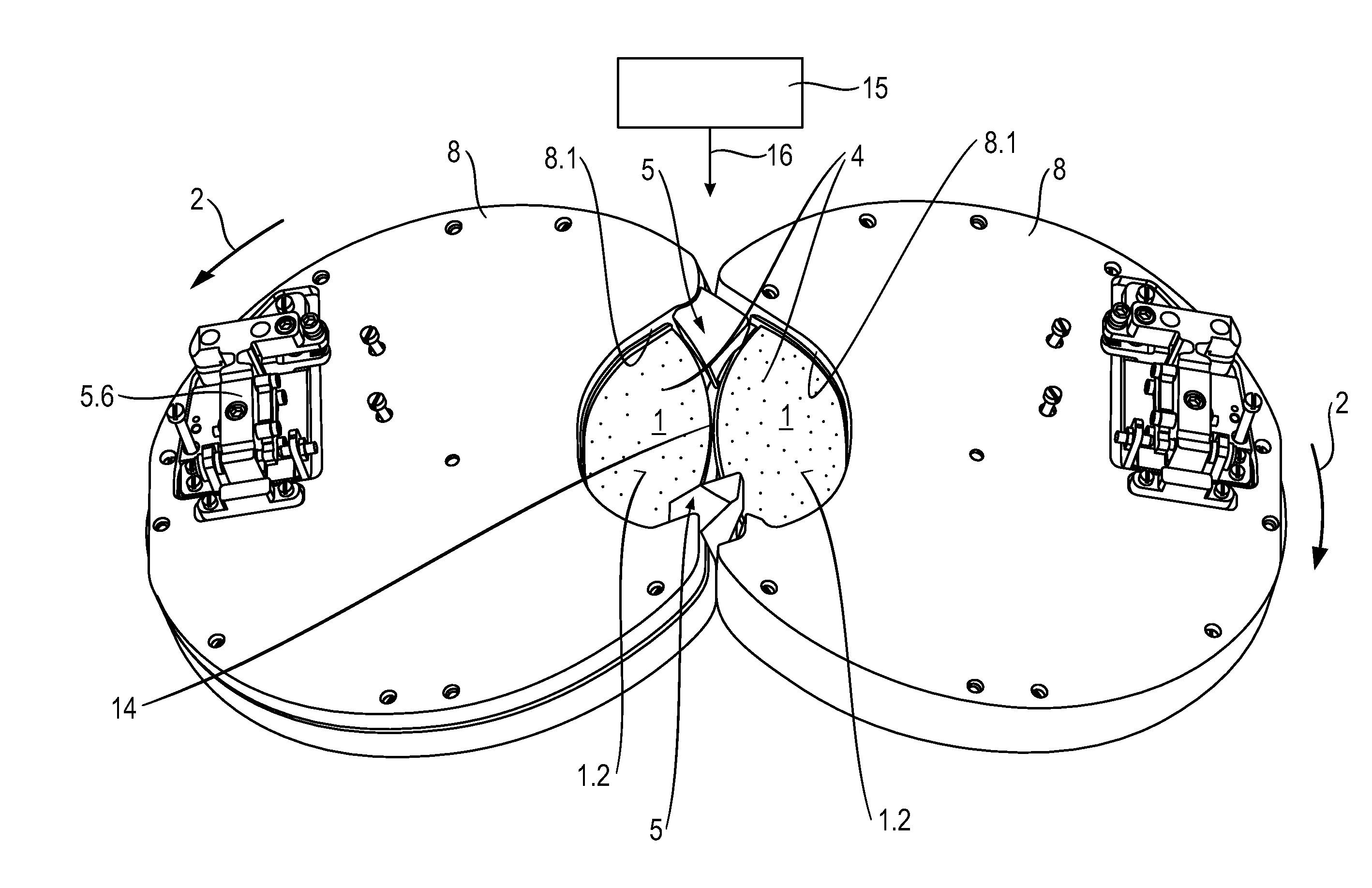

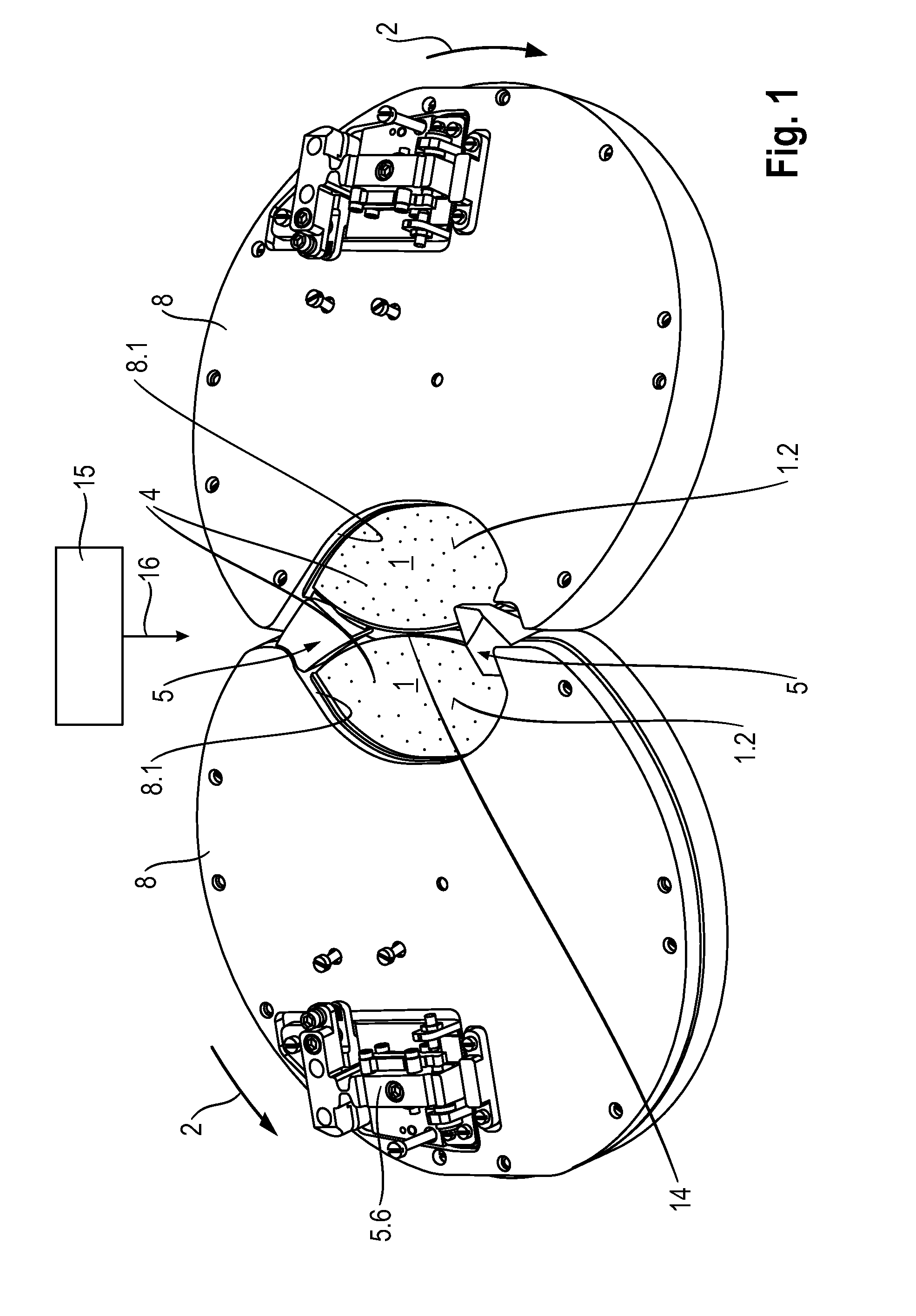

Device for generating short-wavelength electromagnetic radiation based on a gas discharge plasma

ActiveUS20140103807A1Uniform layer thicknessIncreased backpressure-asElectric discharge tubesElectric arc lampsGas-discharge lampCircular disc

A device for generating short-wavelength electromagnetic radiation based on a gas discharge plasma calls for suppressing droplet formation of liquid coating material that is applied to disk electrodes rotated at high rotational frequencies and ensuring a uniform layer thickness. The device has two rotating disk electrodes, each having two lateral surfaces and a circumferential surface, provided with a reservoir with liquid coating material and a wiper for removing excess coating material. The wiper, which has a U-shaped form comprising two legs parallel to the lateral surfaces of the disk electrode and a crosspiece transversely over the circumferential surface, is at least axially movably supported and has impingement elements at the legs so that it is automatically axially adjustable by means of the coating material which is transported on the lateral surfaces and pressed into the gap during the rotation of the disk electrode.

Owner:USHIO DENKI KK

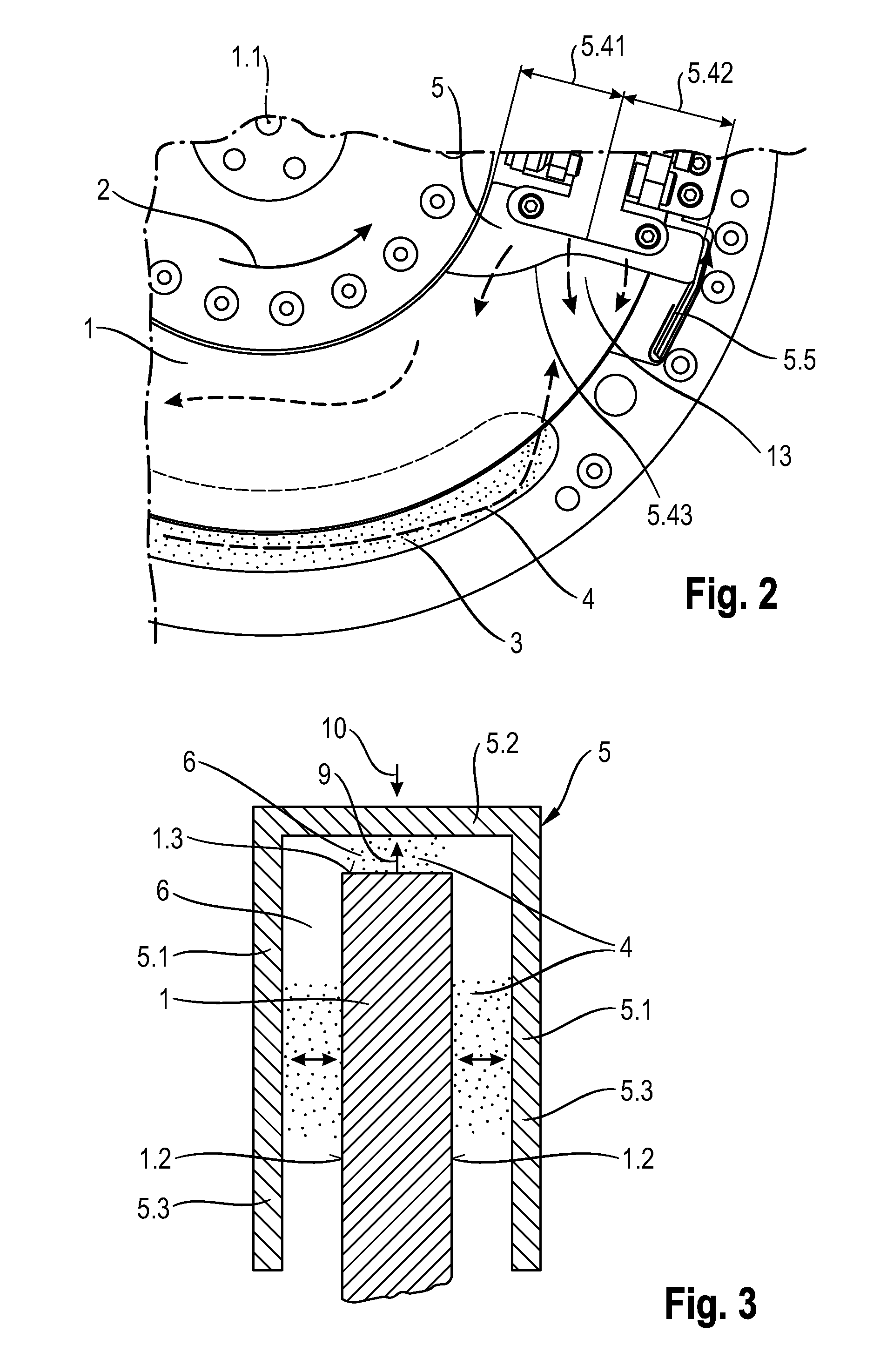

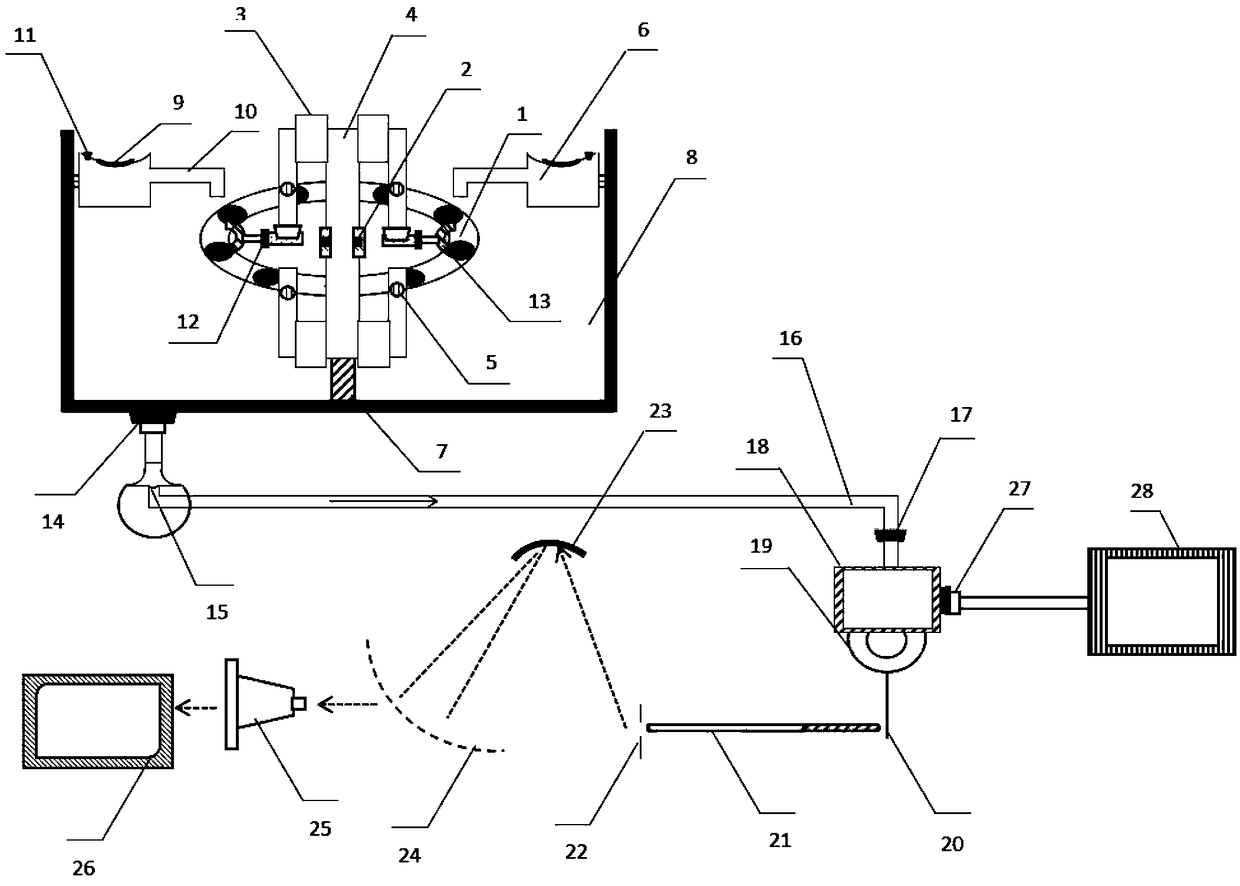

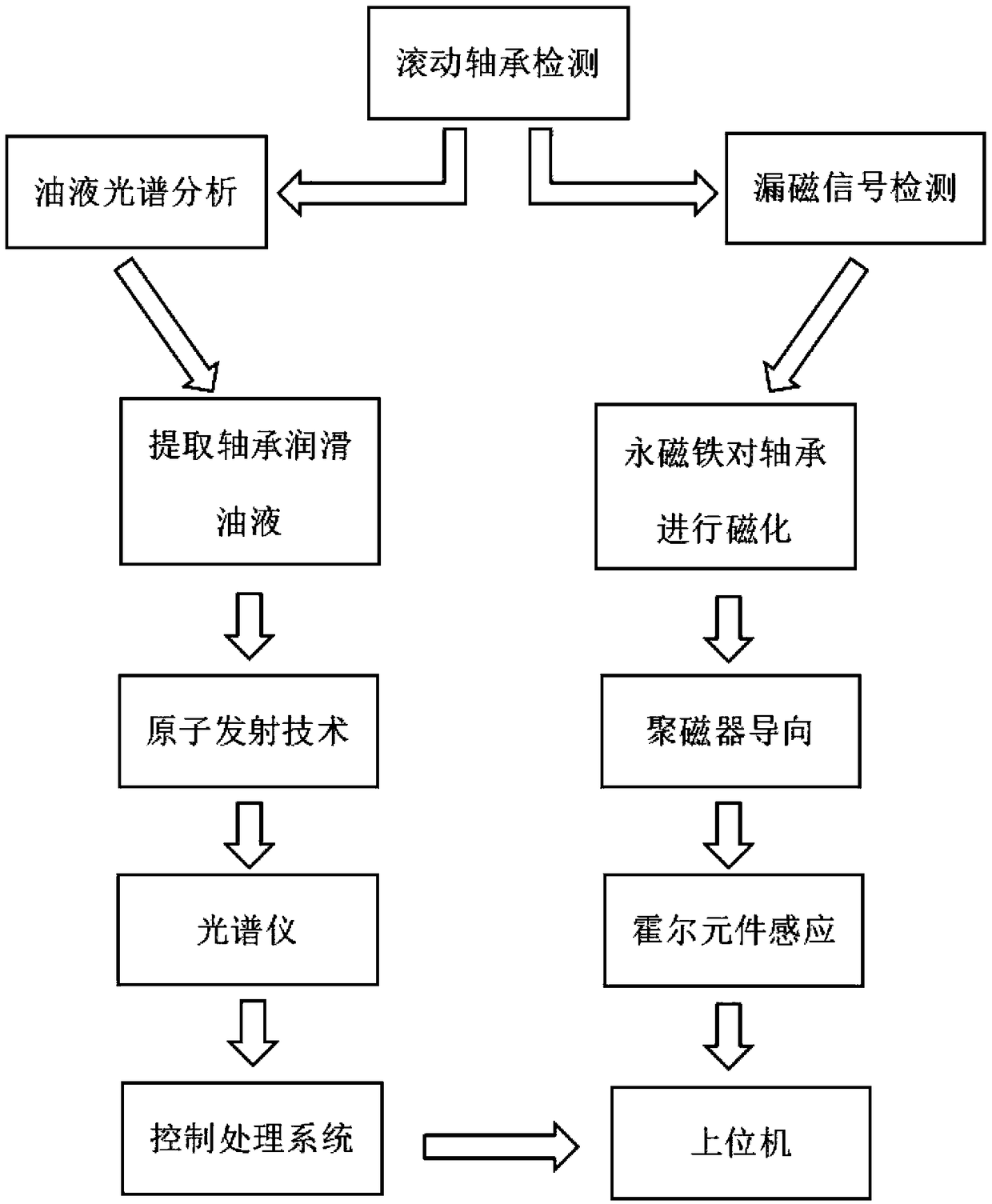

Rolling bearing defect detecting device based on oil spectrum analysis and magnetic flux leakage testing

PendingCN109324034AVersatilityQuick measurementAnalysis by electrical excitationMaterial magnetic variablesGratingSpectrograph

The invention discloses a rolling bearing defect detecting device based on oil spectrum analysis and magnetic flux leakage testing. The rolling bearing defect detecting device consists of a rolling bearing to be detected, a Hall element, a permanent magnet, a magnet yoke, a magnetism gathering device, an oil injection cavity, a rotating base, a collecting tank, a piezoelectric oil atomizer, an oilinjection port, an oil inlet, a telescopic support, an adjustable bayonet, a first valve, a filter cavity, a latex tube, a second valve, a detection cavity, a rotary table electrode, a graphite rod electrode, an optical fiber, an entrance slit, an optical grating, an exit slit, a spectrograph, a computer work station, a third valve and a recycle cavity. The technology of atomic emission spectroscopy is combined with the technology of magnetic flux leakage testing, and the disadvantage that abrasive particles of greater than 10 microns cannot be detected in the technology of atomic emission spectroscopy is solved; the device is of multifunctionality, the work environments of rolling bearings can be simulated, and the detection for different dimensions of rolling bearings is realized; the influence of irrelevant impurities on measurement cannot be eliminated, and recycling treatment is carried out on oil after detection. Repeated rapid and accurate measurement is realized, and the device is of innovativeness and practical value.

Owner:CHINA JILIANG UNIV

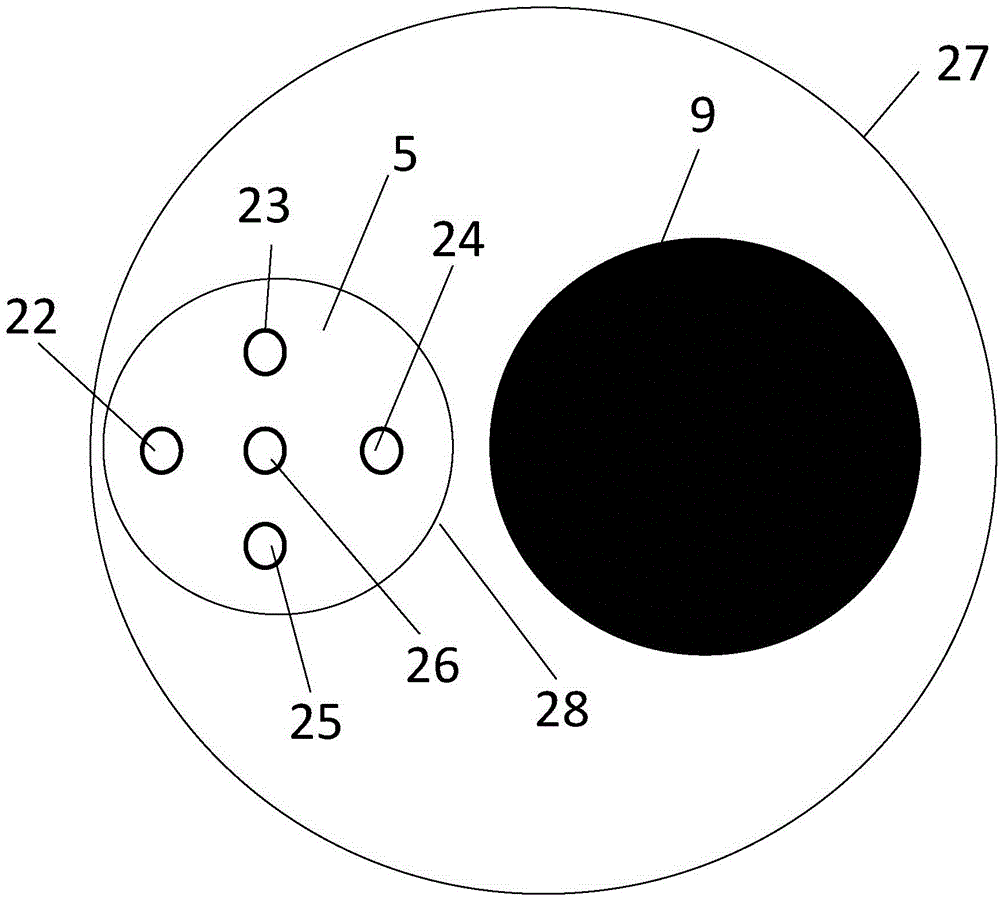

Sensor based on asymmetric polymer film as well as detection method and applications thereof

ActiveCN102539500BEliminate primary ion fluxLow detection limitMaterial electrochemical variablesPolyvinyl chlorideIon exchange

The invention relates to detection on heavy metal ions, and particularly relates to a sensor based on an asymmetric polymer film as well as a detection method and applications thereof. An ionometer is respectively connected with a reference electrode and a working electrode by virtue of leads, a working electrode and the reference electrode are inserted in a to-be-detected sample pool, the working electrode is composed of an ion selective electrode and a rotating disk electrode inserted in the ion selective electrode, the ion selective electrode is a polyvinyl chloride tube, and an asymmetric polymer film is adhered to the bottom of the polyvinyl chloride tube; and the asymmetric polymer film is composed of a polymer film substrate and a lipophilic ion exchange bed. According to the invention, an asymmetric polymer film ion selective electrode is adopted, so that the sensitivity of heavy metal ion detection is remarkably improved, and the detection limit is reduced; and through combining with a rotating disk electrode technology, the detection time is shortened.

Owner:YANTAI INST OF COASTAL ZONE RES CHINESE ACAD OF SCI

Silver element standard oil and preparation method thereof

The invention belongs to the technical field of stoichiometry, and relates to a silver element standard oil which is prepared by mixing and dissolving poly-alpha-olefin used as a base oil carrier, silver 2-ethylhexoate used as a silver element additive and a proper cosolvent used as an assistant. The silver element standard oil is composed of the poly-alpha-olefin base oil with the 100-DEG C kinematic viscosity of 4-6 cSt, cosolvent and silver 2-ethylhexoate, wherein the silver element content of the silver 2-ethylhexoate is 100-5000 mu g / g. The silver element standard oil has the advantages of high designability, uniform system and favorable storage stability. The preparation method is simple and controllable. The silver element standard oil is suitable for determining the silver element in lubricating oil, and suitable for determining the silver element in lubricating oil by establishing a standard curve by inductively coupled plasma-emission spectroscopy (ICP-AES) and rotating-disk-electrode spectroscopy.

Owner:NO 53 RES INST OF CHINA NORTH IND GRP

Special device for oil analysis based on concentrated optical fiber signal transmission and double-layer multi-ccd detection

The invention discloses a special oil analysis device based on gathered optical fiber signal transmission and double-layer multi-CCD (Charge Coupled Device) detection, and the special oil analysis device is used for detecting the content of various metal elements in an oil sample. A rotating disc electrode drives oil to an analytical gap, spark discharge is generated by high voltage between two electrodes, and the metal elements in the oil sample are excited to generate emission spectra; and light with different wavelengths is transmitted to a grating to be split through optical fibers and then irradiated to different CCDs, and the content of multiple elements is obtained through light intensity signal detection and digital operation of spectral lines. The special oil analysis device comprises a light source part, an optical fiber transmission system, a light splitting system, a photoelectric detection system and a control circuit, wherein the light source part comprises a high-voltage generator, a rod electrode and the rotating disc electrode; and the light splitting system fixedly arranges an incidence gap, a concave grating and the CCDs on a Rowland circle device by virtue of a Paschen-Runge device. Compared with an existing instrument, the special oil analysis device disclosed by the invention has the characteristics of fast analysis, simultaneous detection on more than ten elements, direct sampling, no sample pretreatment, easiness for operation and convenience for maintenance.

Owner:广东中科谛听科技有限公司

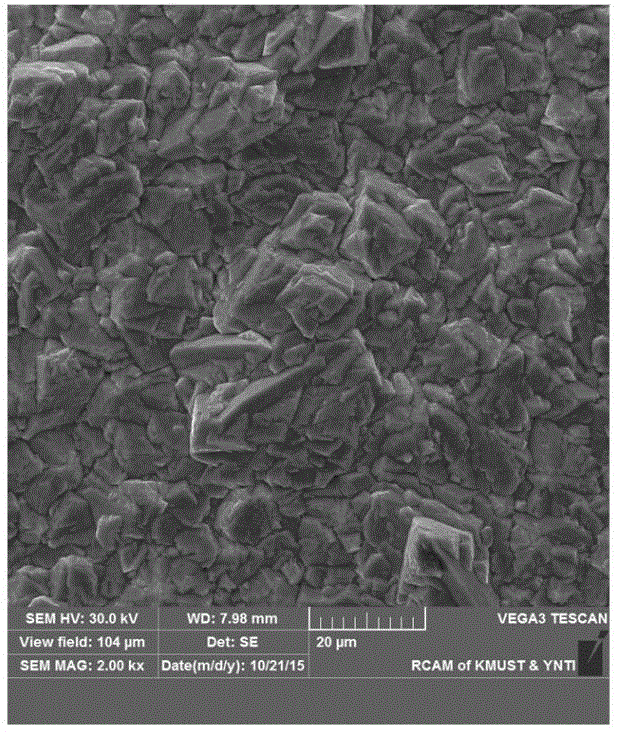

Method for electrochemically synthesizing alpha-PbO2 on rotating disk electrode

ActiveCN105401191ACompact structureIncreased microhardnessElectrolytic inorganic material coatingPlatinumMaterials preparation

The invention relates to a method for electrochemically synthesizing alpha-PbO2 on a rotating disk electrode and belongs to the technical field of electrochemistry and material preparation. Three electrode systems are adopted, specifically, the Pt disk electrode serves as a working electrode, a saturated calomel electrode serves as a reference electrode, and a platinum sheet with the surface area being 1-2 cm<2> serves as an auxiliary electrode. The electrodes are placed in an alpha-PbO2 plating solution, constant current polarization is carried out under the conditions that the synthesis temperature ranges from 30 DEG C to 40 DEG C and the polarization current ranges from 10 mA / cm<2> to 15 mA / cm<2>, alpha-PbO2 can be deposited on the surface of the Pt disk, and the alpha-PbO2 is stripped from the surface of the Pt disk and then blow-dried so as to obtain the disc-shaped alpha-PbO2. Through the method, the disc-shaped alpha-crystal-form PbO2 which is compact in structure, flat in surface and high in microhardness can be obtained.

Owner:KUNMING UNIV OF SCI & TECH

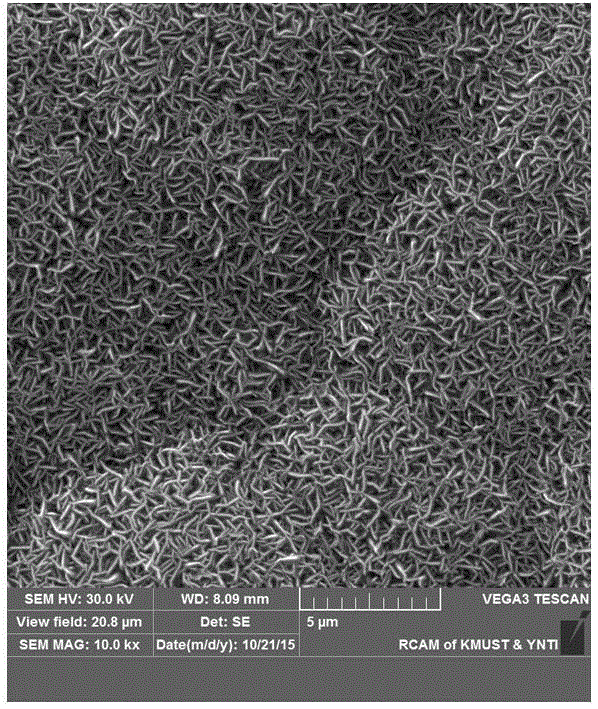

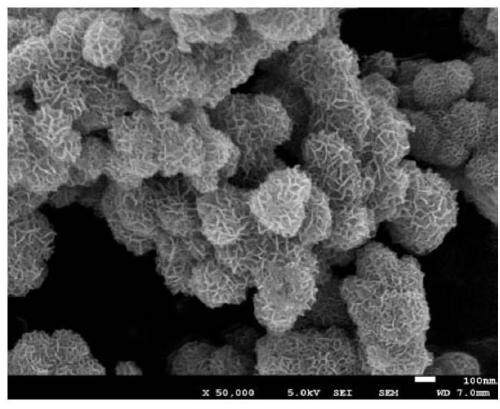

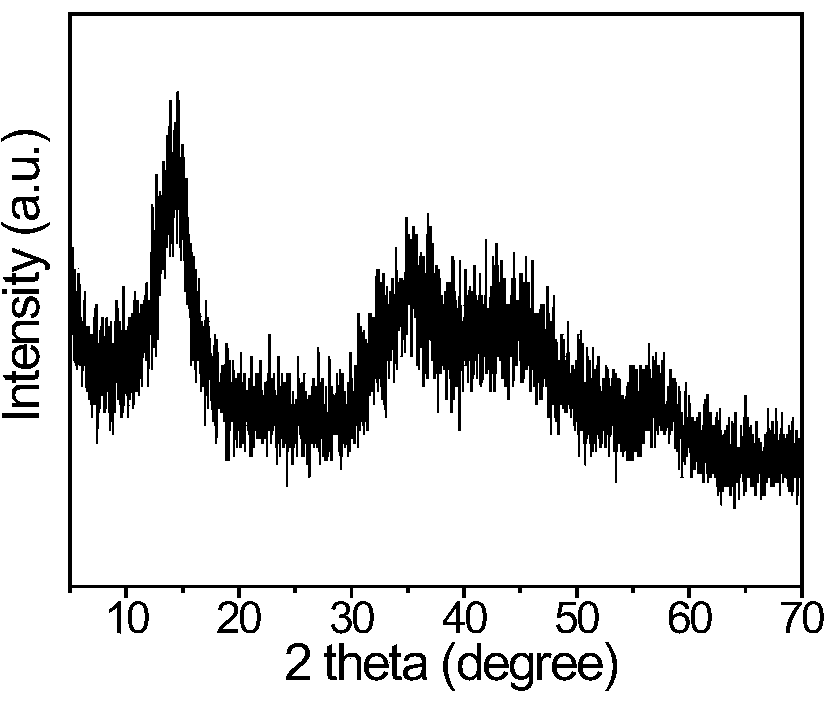

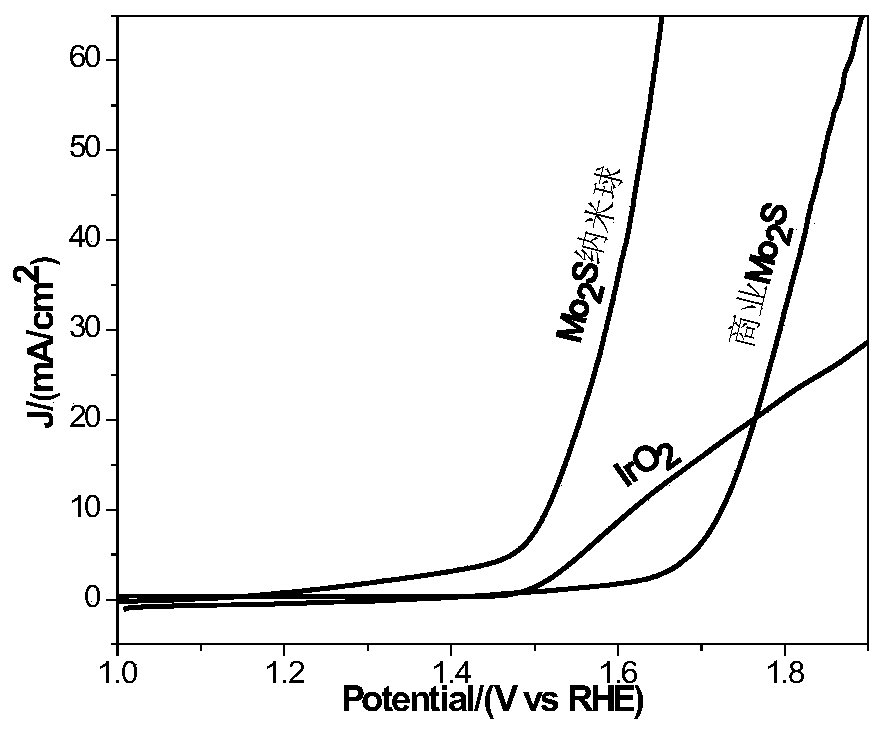

A kind of mos2 nanosphere bifunctional oxygen catalyst with hierarchical structure and its preparation method and application

ActiveCN106622301BRaw materials are cheap and easy to getEasy to manufactureElectrolysis componentsCell electrodesOxygenRotating ring-disk electrode

The invention relates to a MoS2 nanosphere difuncitonal oxygen catalyst of a hierarchy structure a preparation method thereof and application thereof in electrocatalyzing oxygen in an alkaline medium. The MoS2 nanosphere difuncitonal oxygen catalyst is MoS2 nanospheres which are synthesized by taking Na2MoO4 and KSCN as raw materials and adopting a hydrothermal method and have the hierarchy structure, and the MoS2 nanospheres are formed by a plurality of MoS2 nanosheets, so that the MoS2 nanospheres have a large specific surface area, and edge sits of the MoS2 nanosheets are fully exposed. Due to multiporous flower-shaped nanospheres formed by ultra-thin MoS2 nanosheet units, the effective electrochemical catalysis area and the catalytic sites are increased, and the electron conduction rate is quickened, so that overpotential of an oxygen evolution reaction and an oxygen reduction reaction can be effectively reduced; a rotating disk electrode and a rotating ring disk electrode show that the oxygen reduction process is based on a four-electron catalytic mechanism and is a relatively ideal oxygen reduction reaction process.

Owner:江苏乐士源新能源科技有限公司

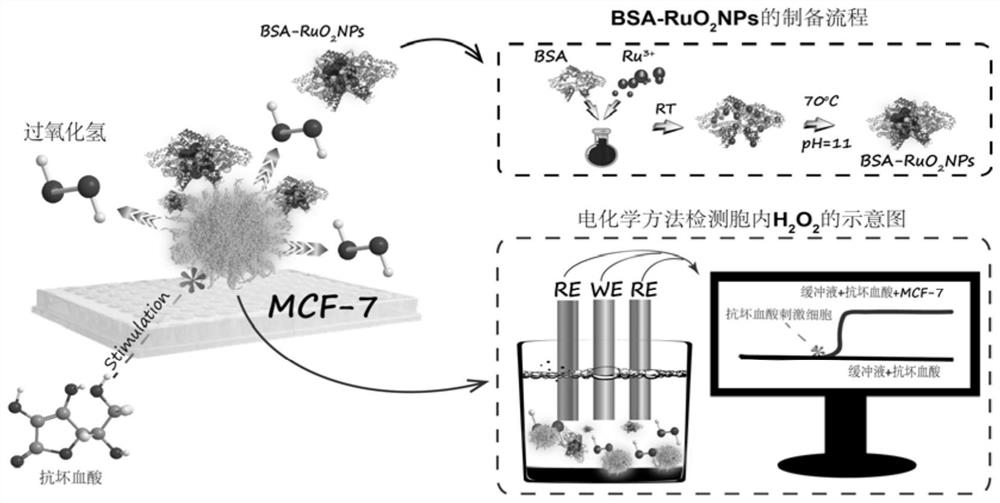

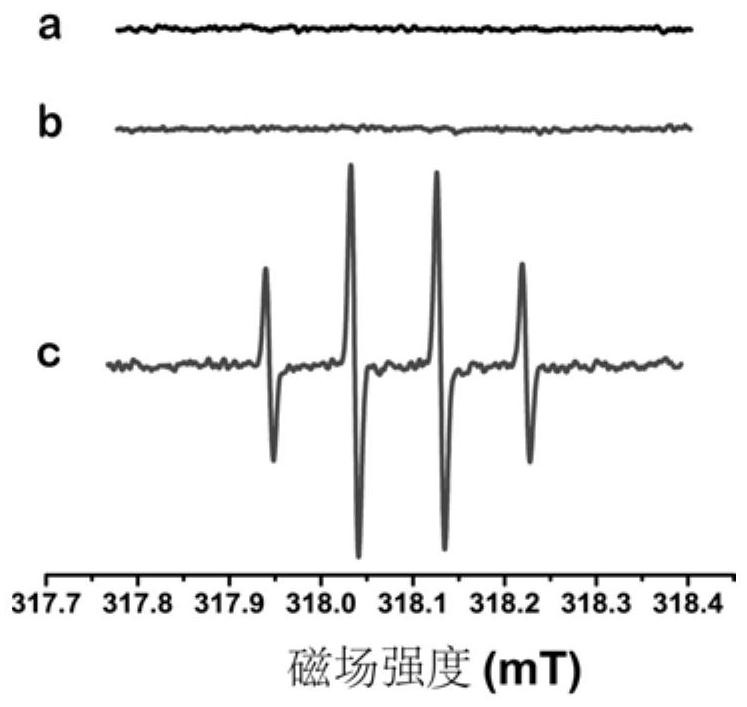

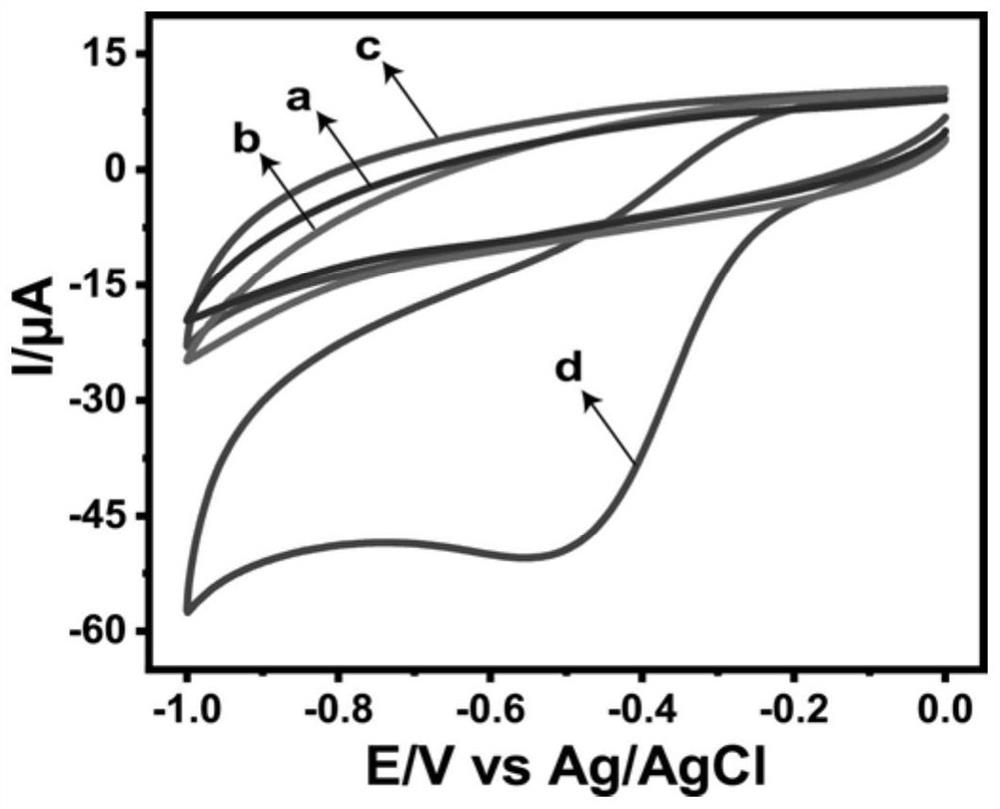

Electrochemical analysis method constructed based on bovine serum albumin-ruthenium dioxide nanoparticles and used for detecting intracellular hydrogen peroxide

PendingCN113252756AHigh sensitivityGood reproducibilityMaterial analysis by electric/magnetic meansBovine serum albuminH2O2 - Hydrogen peroxide

The invention discloses an electrochemical analysis method constructed based on bovine serum albumin-ruthenium dioxide nanoparticles and used for detecting intracellular hydrogen peroxide. An electron spin resonance spectrum is utilized to prove the catalytic process that BSA-RuO2NPs catalyzes H2O2 to generate hydroxyl radicals, a BSA-RuO2NPs modified glassy carbon electrode has an obvious catalytic effect on H2O2, the reduction peak is about -0.5 V, and the peak current has a linear relationship (R2=0.9965) in a range of 20-200 mV / s along with a scanning speed. When the differential pulse voltammetry is applied to the catalytic process of the BSA-RuO2NPs modified rotating disk electrode on H2O2, the peak current and the H2O2 concentration have a linear relationship (R2=0.9967) at 0.40-3850 [mu] mol / L, and the lowest detection limit is 0.18 [mu] mol / L. The electrochemical analysis method is successfully applied to detection of H2O2 in cells.

Owner:FUJIAN MEDICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com