Patents

Literature

31results about How to "Excellent oxygen reduction activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

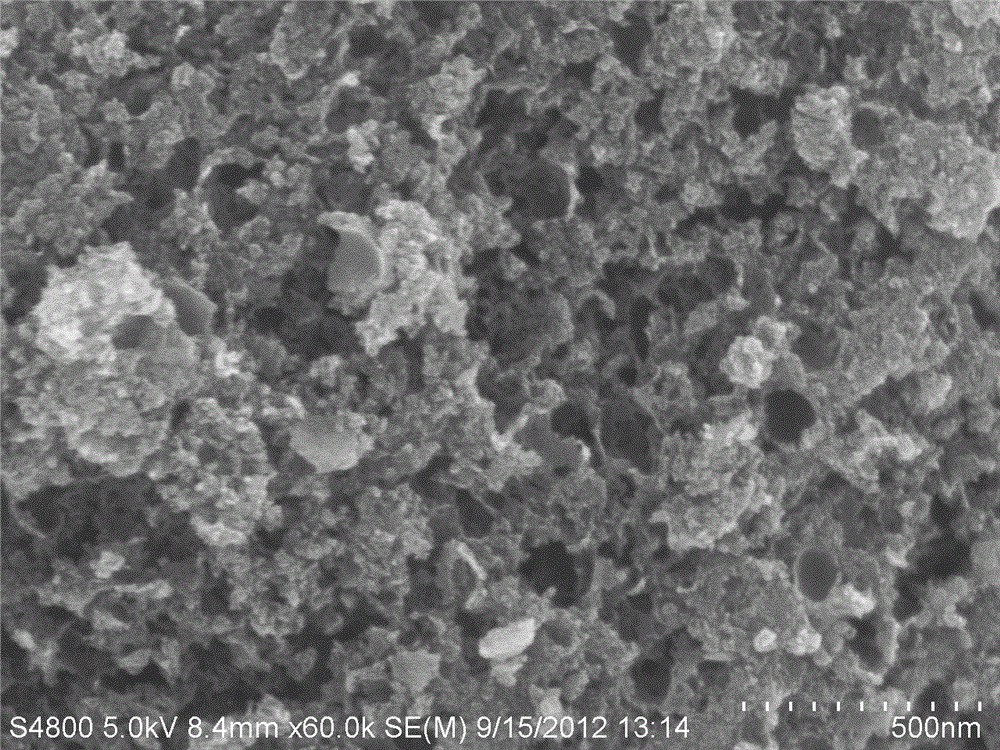

Non-noble metal nitrogen-doped MOF double-effect electrocatalyst and preparation method thereof

ActiveCN110444776AHigh activityLow costMaterial nanotechnologyCell electrodesCarbon layerCarbonization

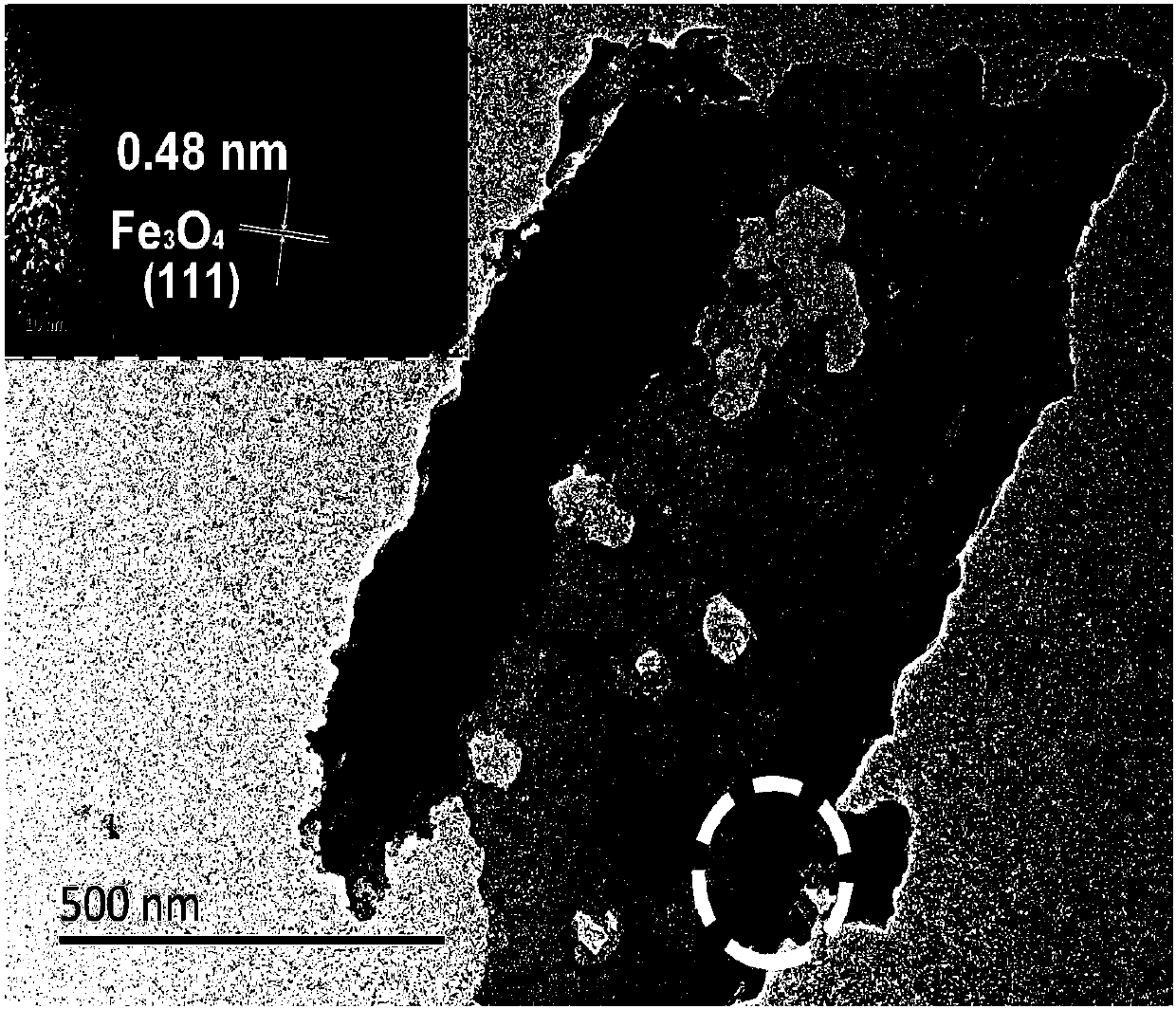

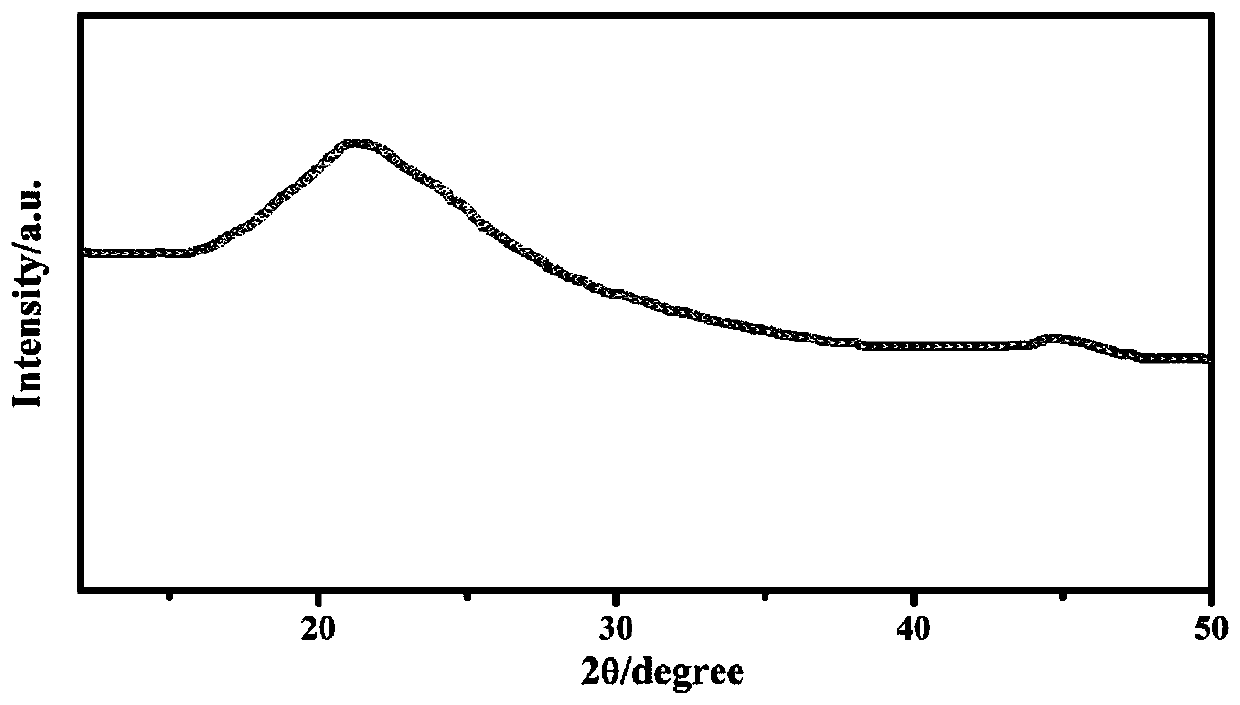

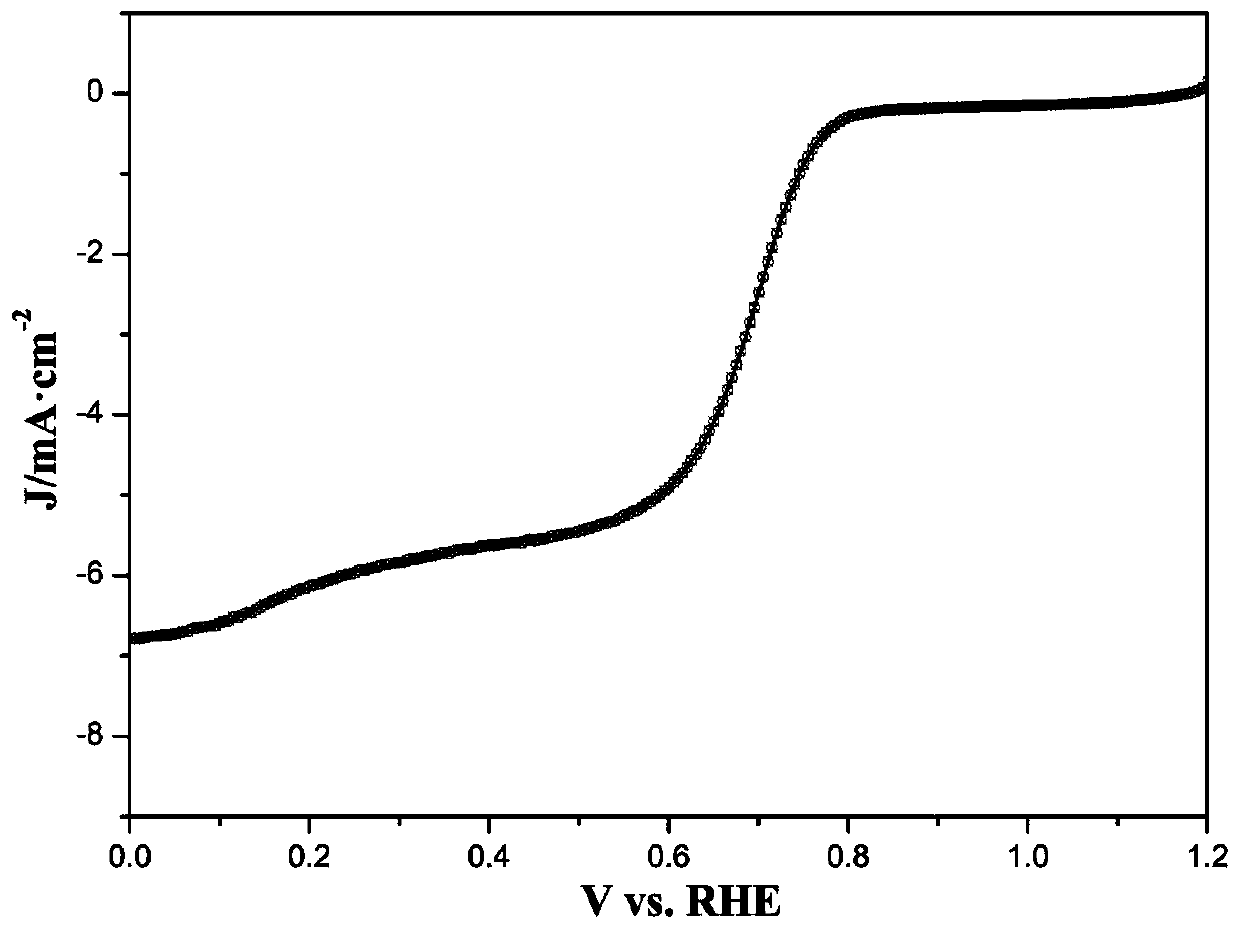

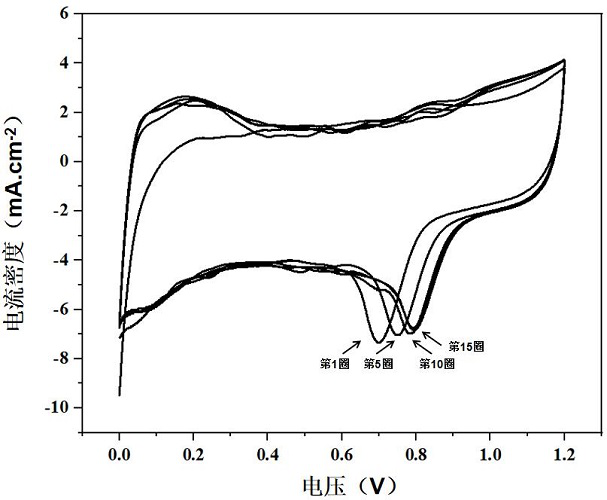

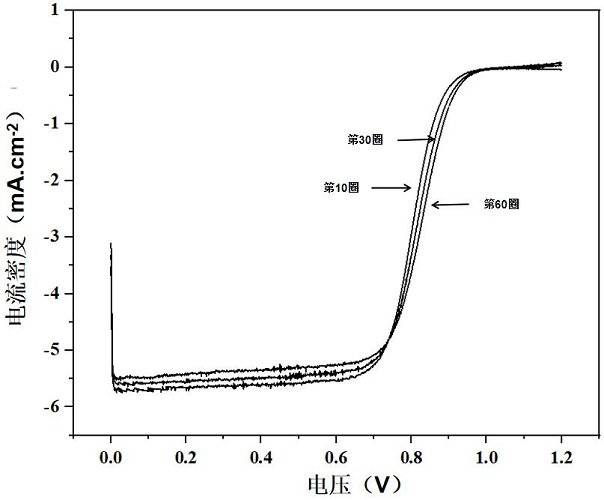

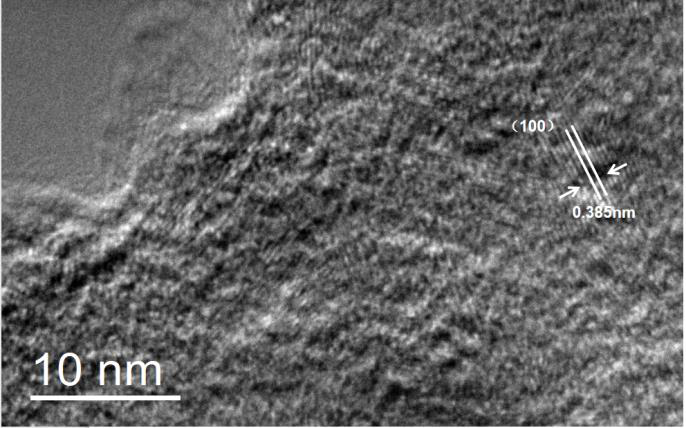

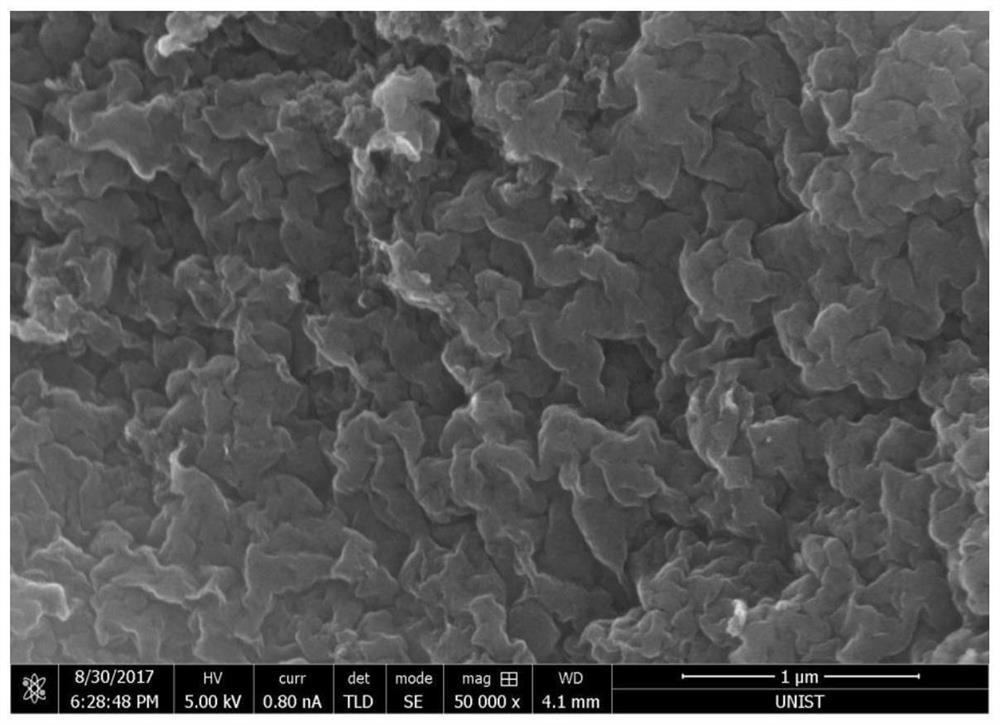

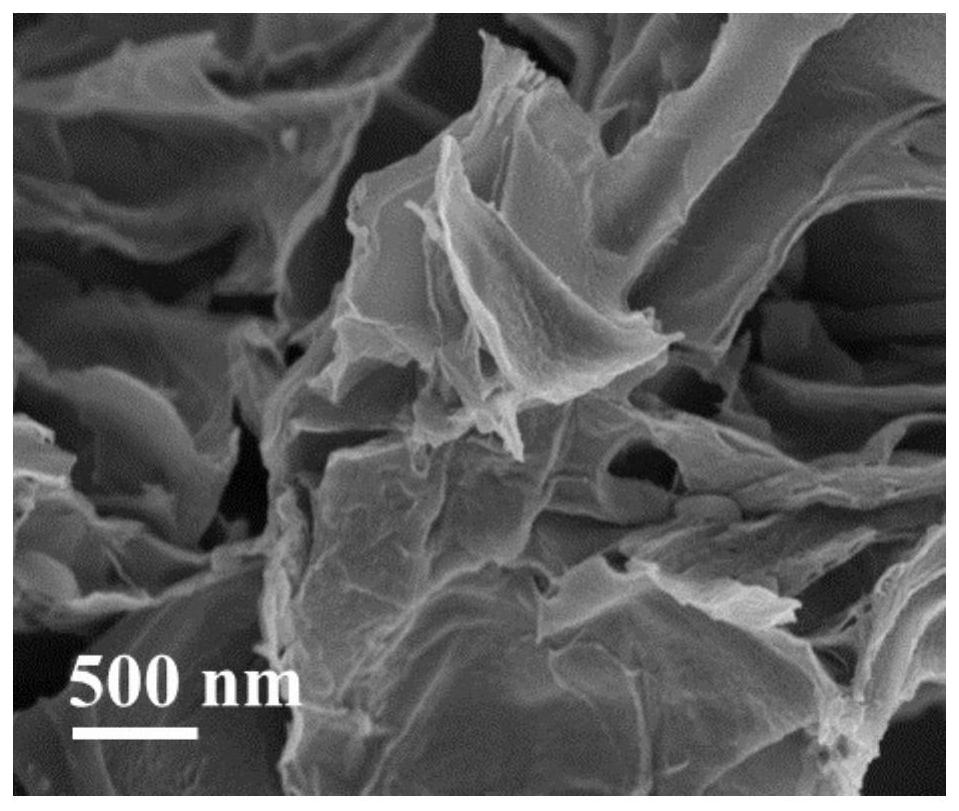

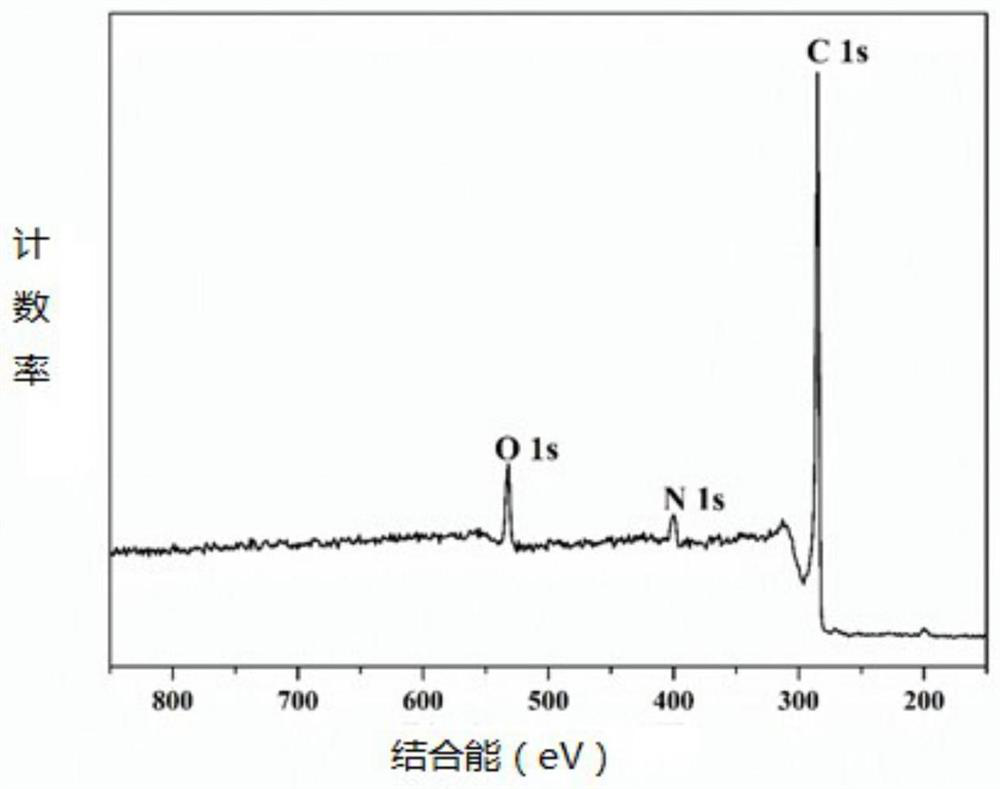

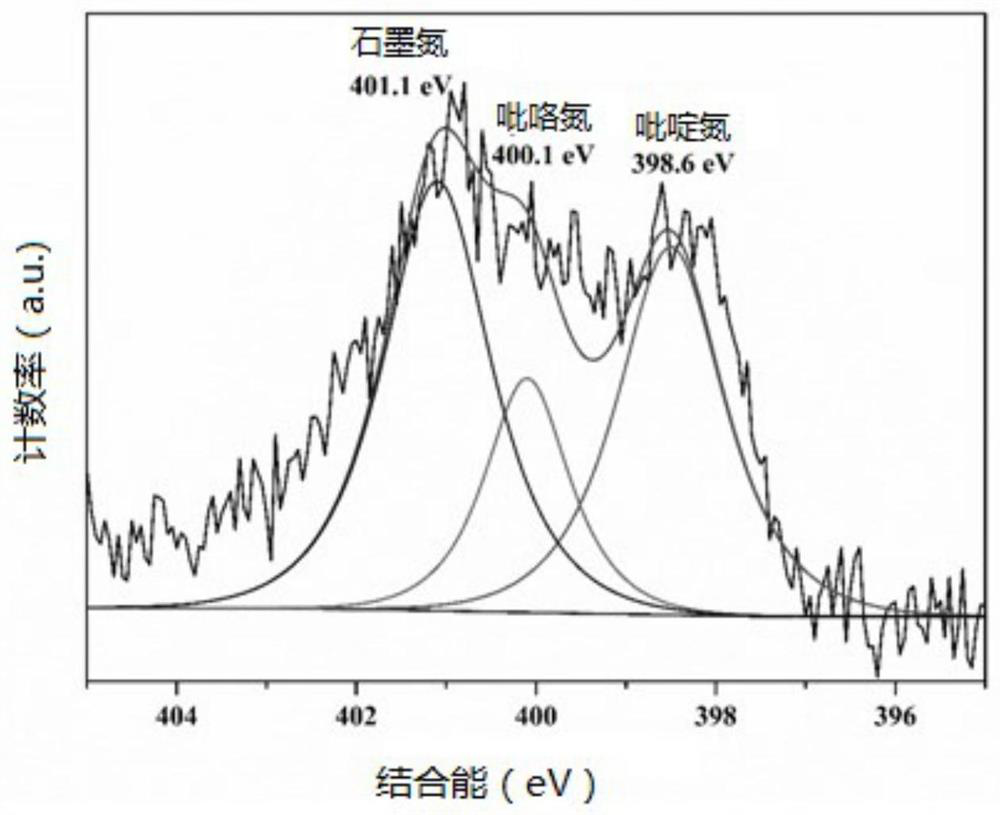

The invention relates to a super-dispersion non-noble metal nitrogen-doped MOF double-effect electrocatalyst and a preparation method thereof. The preparation method comprises the following steps of 1) adding a hydroxyl-rich carbon source organic matter and a nitrogen-rich organic matter into a surfactant dispersed solution, and carrying out stirring and mixing; and enabling the carbon-nitrogen source organic matters to be reacted in the solution to obtain a primary precursor; 2) adding a transition metal solution, stirring at a constant temperature and sufficiently chelating with the organicprecursor; 3) putting the object obtained in the step 2) into a high-temperature kettle to carry out hydrothermal crystallization to promote crystals to grow slowly; 4) carrying out centrifuging, washing and drying on the object obtained in the step 3); and 5) carrying out high-temperature carbonization on the object obtained in the step 4) to obtain the catalyst. The catalyst has the advantages that the uniformly dispersed ultrafine metal nanoparticles are embedded and wrapped in a carbon shell, and the carbon layer structure is activated; and the catalyst has rich transition metals and nitrogen-bonded M-N chelating active sites, so that the catalyst stably exists in an acid solution, and has important application value and significance in the fields of fuel cells, water electrolysis andother electro-catalysis.

Owner:TSINGHUA UNIV

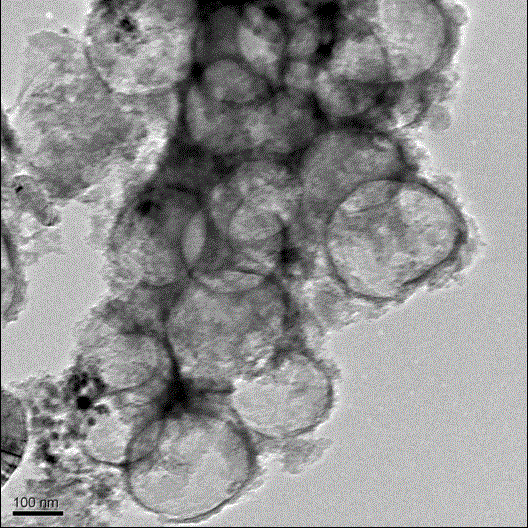

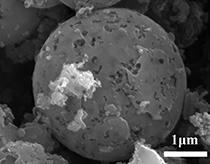

Cathode non-platinum catalyst of proton exchange membrane fuel cell and preparation method thereof

InactiveCN102916203AIncreased oxygen reduction activityHigh active specific surface areaCell electrodesMetal/metal-oxides/metal-hydroxide catalystsNon platinumActivity ratios

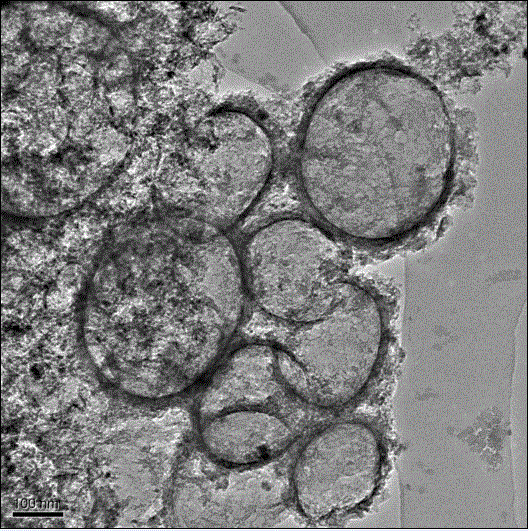

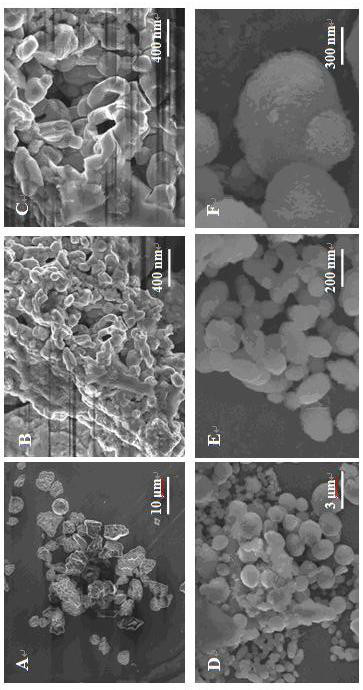

The invention relates to a cathode non-platinum catalyst of a proton exchange membrane fuel cell and a preparation method thereof. The method comprises the following steps: melamine-formaldehyde resin preparation reaction is carried out, and metal salt is added into the melamine formaldehyde resin; complexing reaction occurs between the melamine formaldehyde resin and the metal salt to form a complex; and after solvent of the complex is evaporated, the complex is decomposed by heat treatment to form the cathode non-platinum catalyst with a hollow spherical structure of the proton exchange membrane fuel cell. The non-platinum catalyst has following advantages that firstly the non-platinum catalyst has a large activity ratio surface, so that the oxygen reduction activity of a catalyst is greatly improved; secondly the catalyst has a rich nitrogen source; thirdly the catalyst has an excellent activity of oxygen reduction; and fourthly the preparation method of the non-platinum catalyst is simple, and cheap metals such as Fe, Co and the like are used as the catalyst, so that the synthesis cost is lowered.

Owner:WUHAN UNIV OF TECH

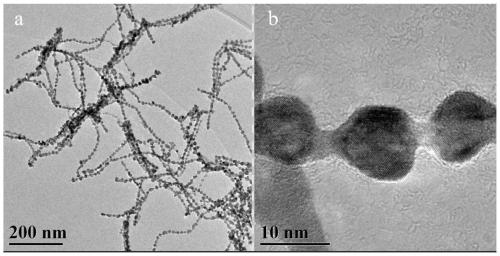

One-dimensional porous platinum-containing alloy nanowire catalyst and preparation method thereof

InactiveCN111509236AReduce usageLow cost of industrializationCell electrodesNanotechnologyPtru catalystNanowire

The invention belongs to the field of electrocatalysis, and particularly relates to a one-dimensional porous low-platinum nanowire catalyst capable of being applied to oxygen reduction reactions in various energy conversion technologies, and a preparation method thereof. The preparation method comprises the following steps: dissolving a platinum metal salt and a salt of another one or more transition metals in a solvent, adding a surfactant and a reducing agent, and reacting at a certain temperature to prepare a platinum alloy nanowire with one-dimensional structural morphology; and then preparing the one-dimensional porous platinum-containing alloy nanowire by adopting an acid corrosion mode. The catalyst has a one-dimensional nanowire and a porous structure, has relatively high oxygen reduction catalytic activity and stability, and can be applied to oxygen reduction catalysts in various energy conversion devices. The method has the characteristics of high yield, simple synthesis process, high catalytic activity and the like, is suitable for large-scale industrial production, and has important significance for promoting the commercialization process of various energy conversion devices.

Owner:HUAZHONG UNIV OF SCI & TECH

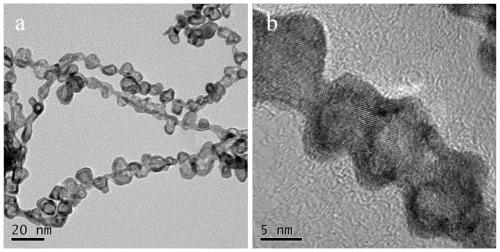

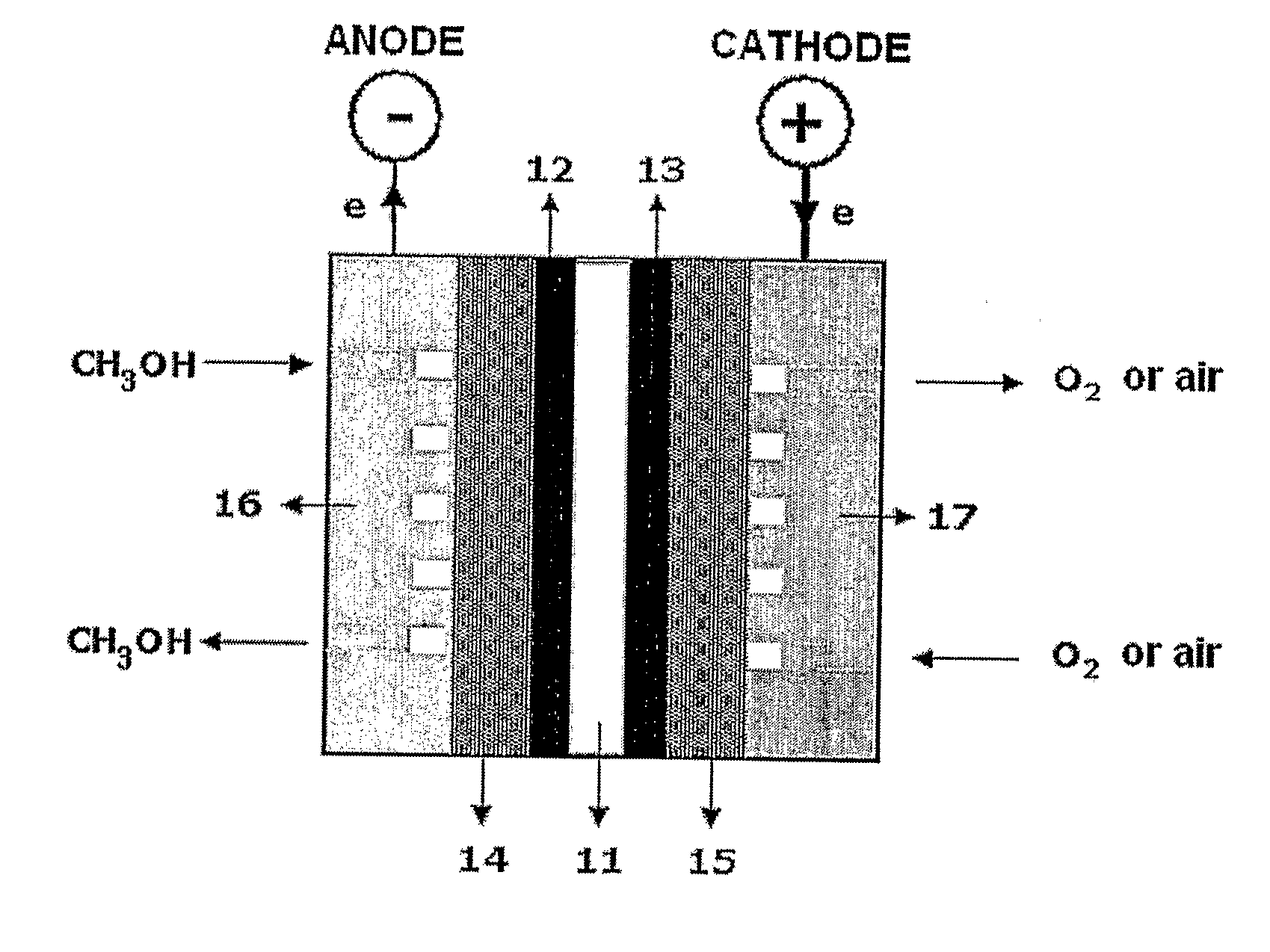

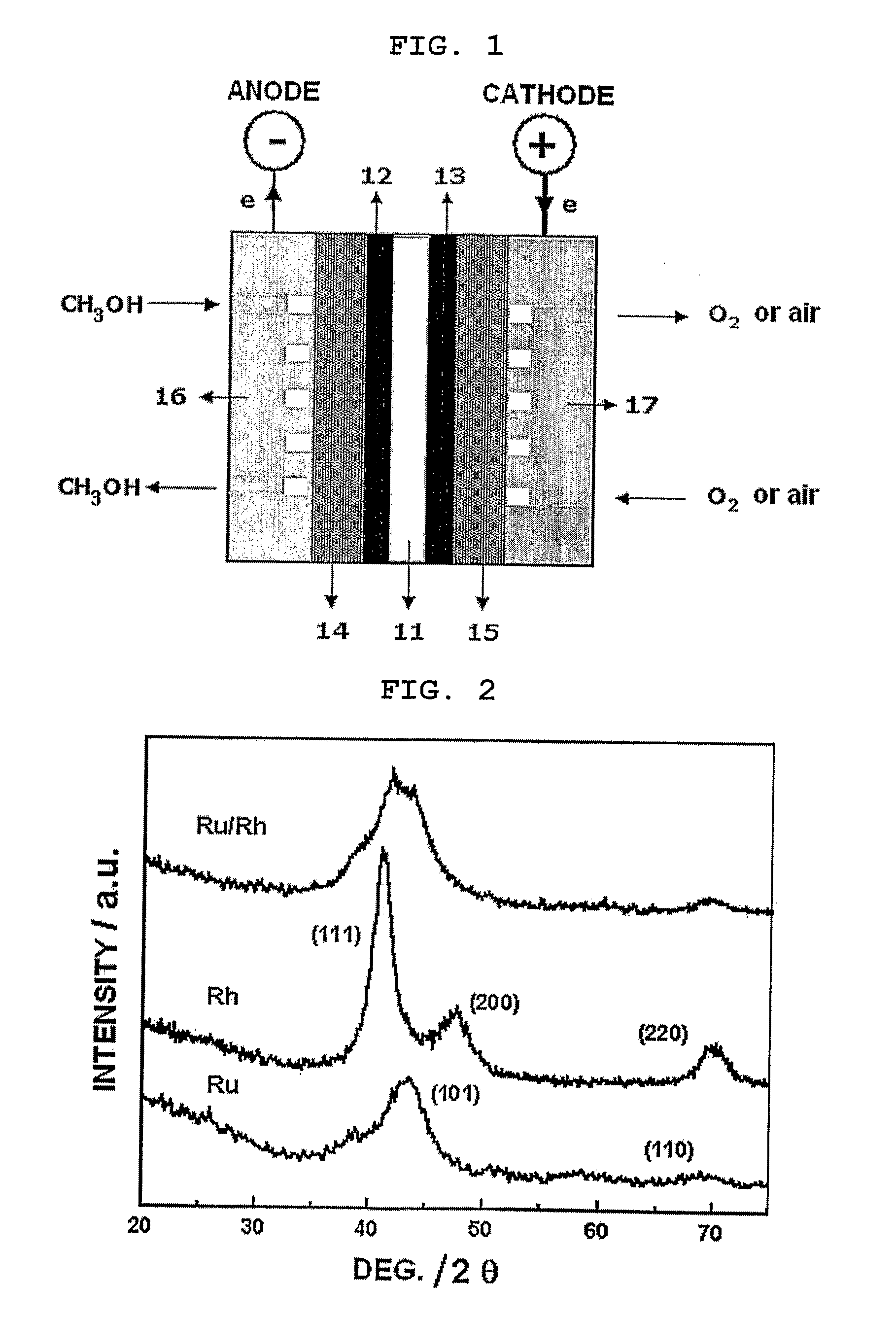

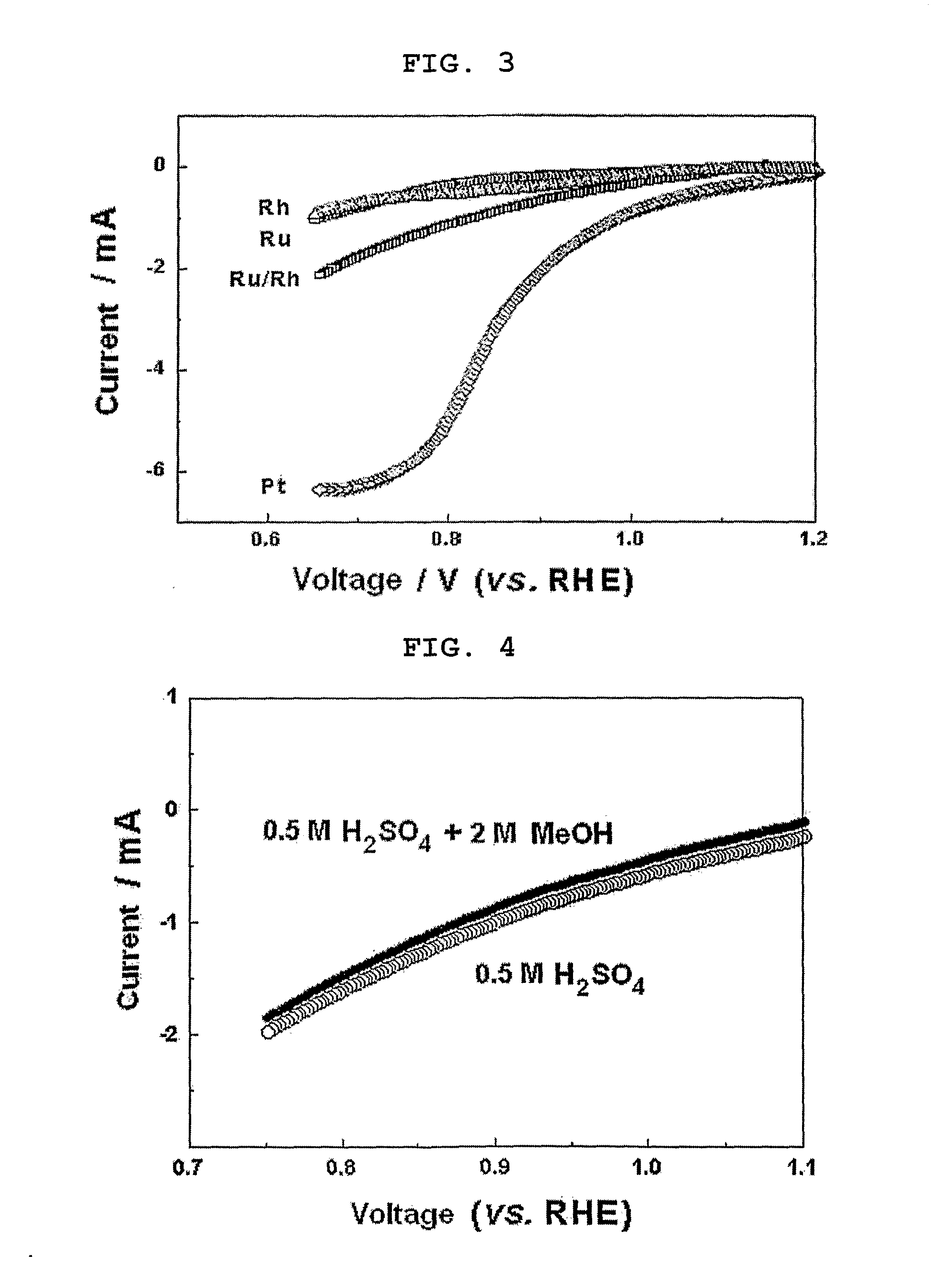

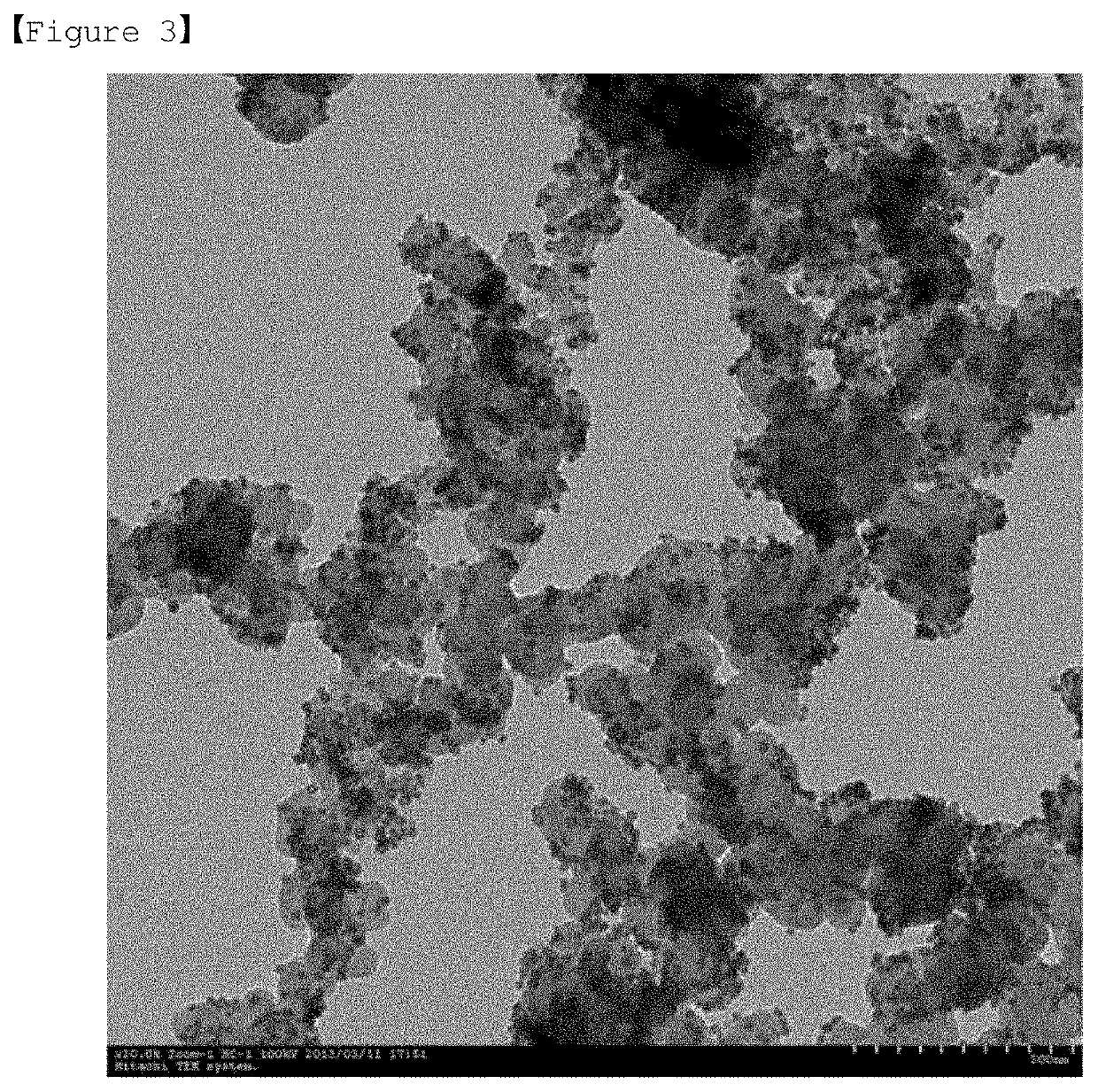

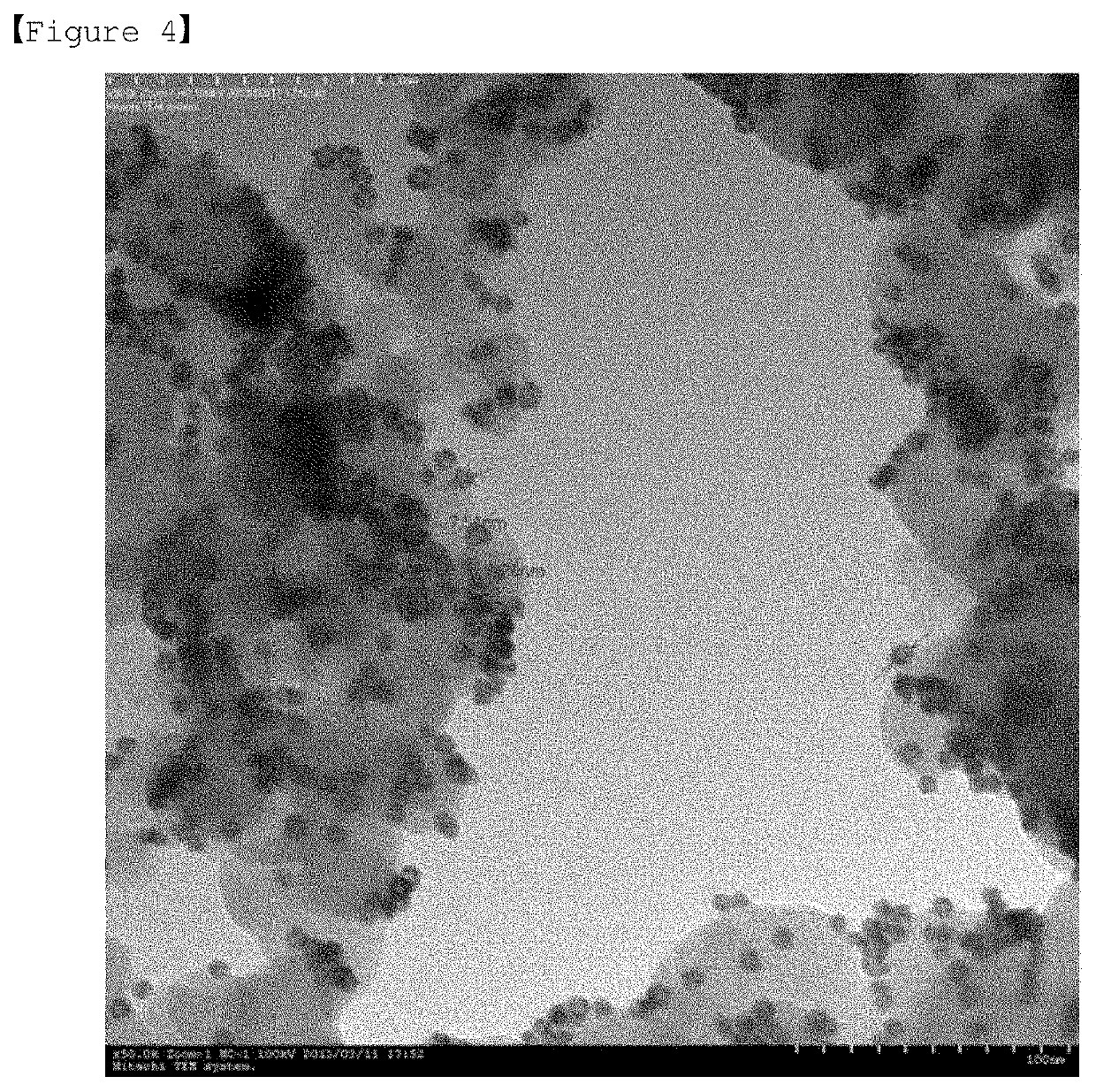

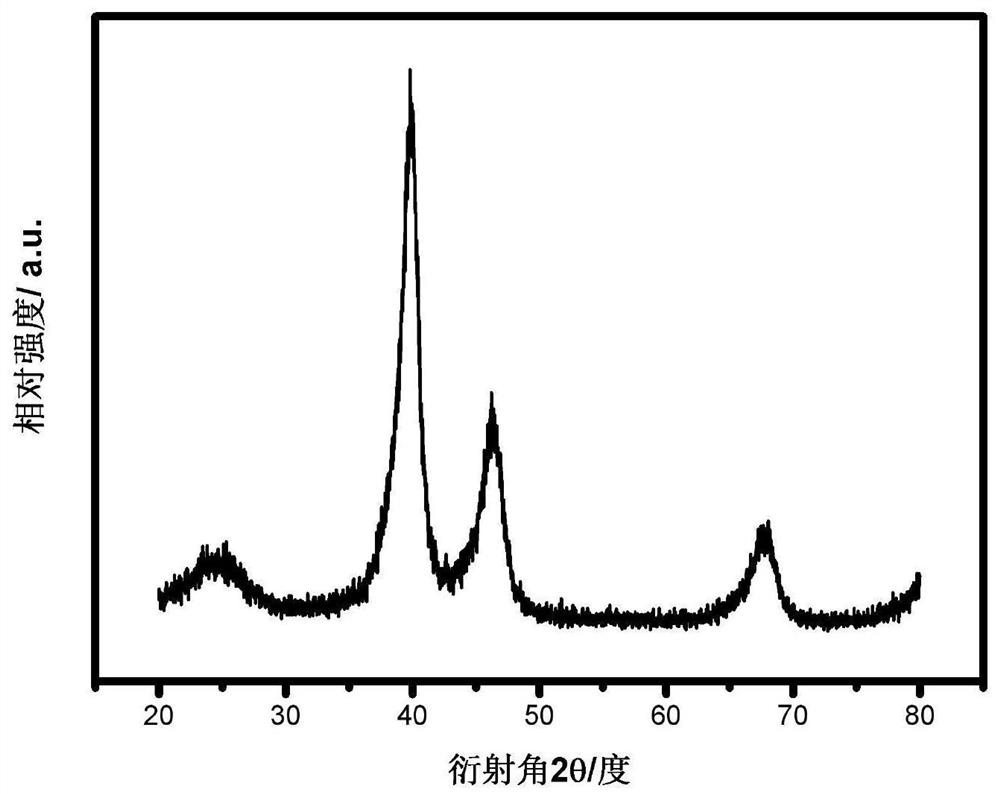

Ruthenium-rhodium alloy electrode catalyst and fuel cell comprising the same

InactiveUS20070184332A1Excellent oxygen reduction activityQuality improvementSolid-state devicesActive material electrodesAlloy electrodeAlloy

Disclosed is an electrode catalyst comprising a ruthenium (Ru)-rhodium (Rh) alloy. A membrane electrode assembly (MEA) comprising the same electrode catalyst and a fuel cell comprising the same membrane electrode assembly are also disclosed. The ruthenium-rhodium alloy catalyst has not only good oxygen reduction activity but also excellent methanol resistance compared to conventional platinum and platinum-based alloy catalysts, and thus can be used as high-quality and high-efficiency electrode catalyst having improved catalytic availability and stability.

Owner:LG CHEM LTD

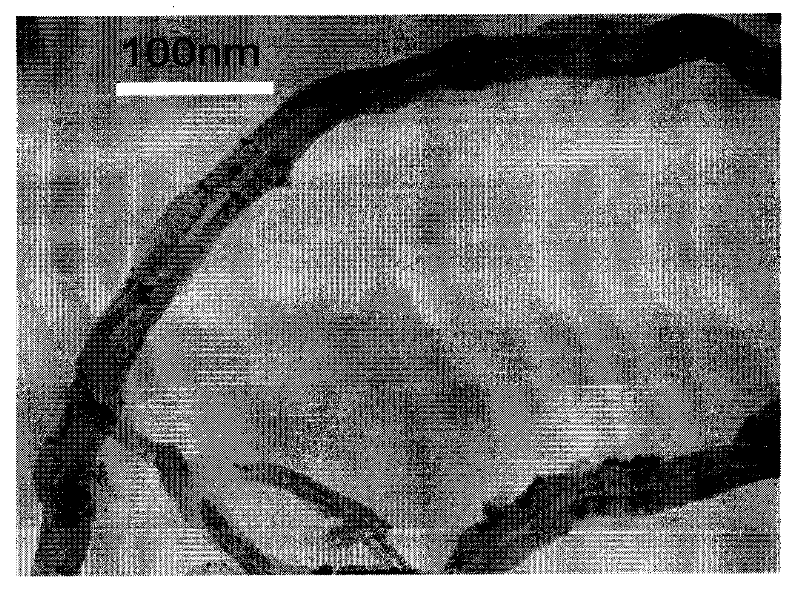

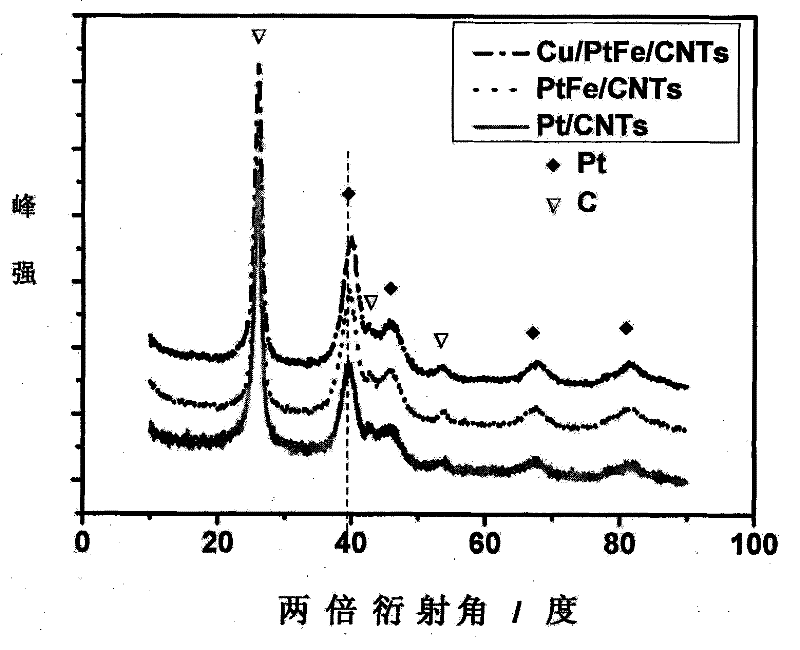

High activity methanol-resistance direct methanol fuel cell cathode catalyst and production method thereof

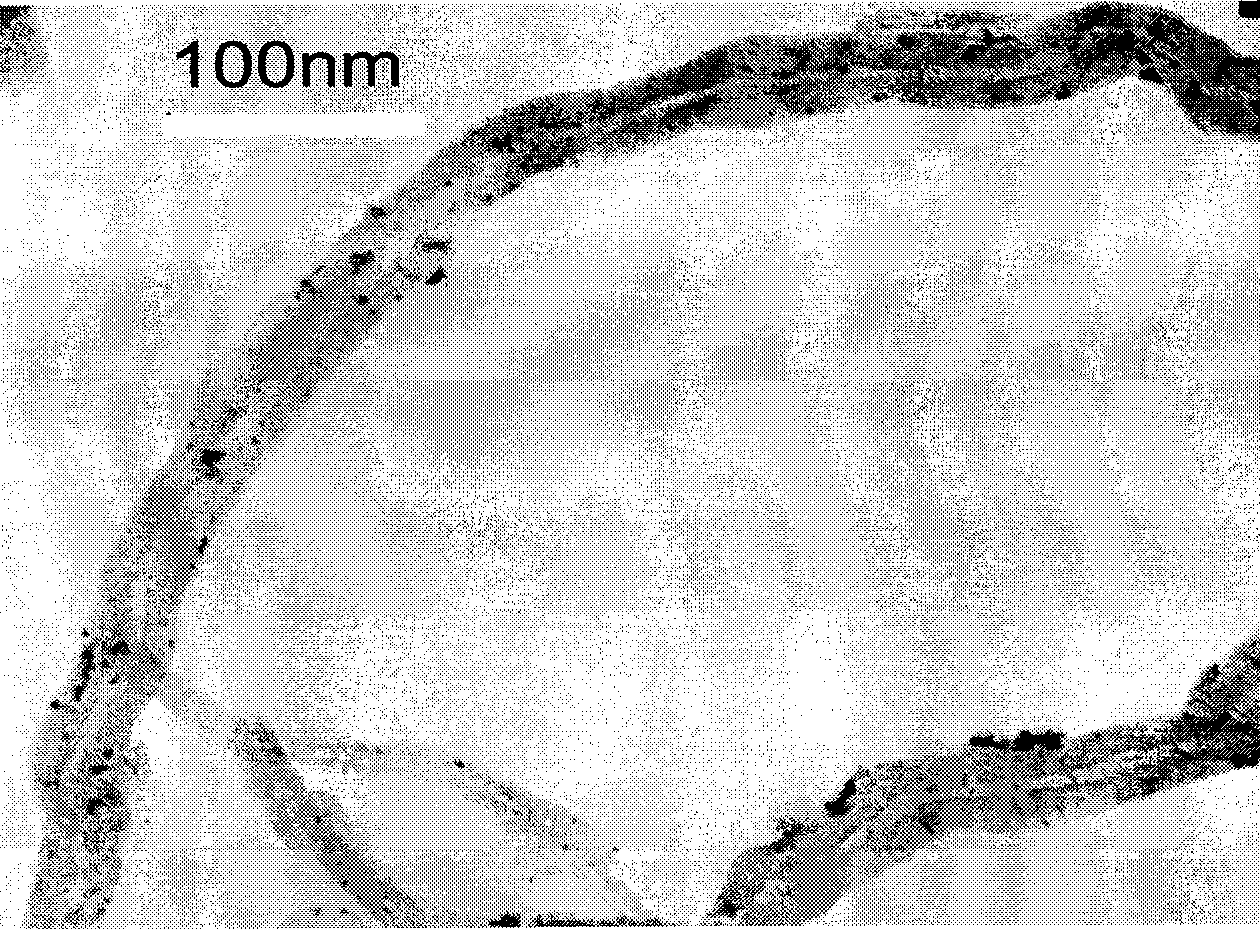

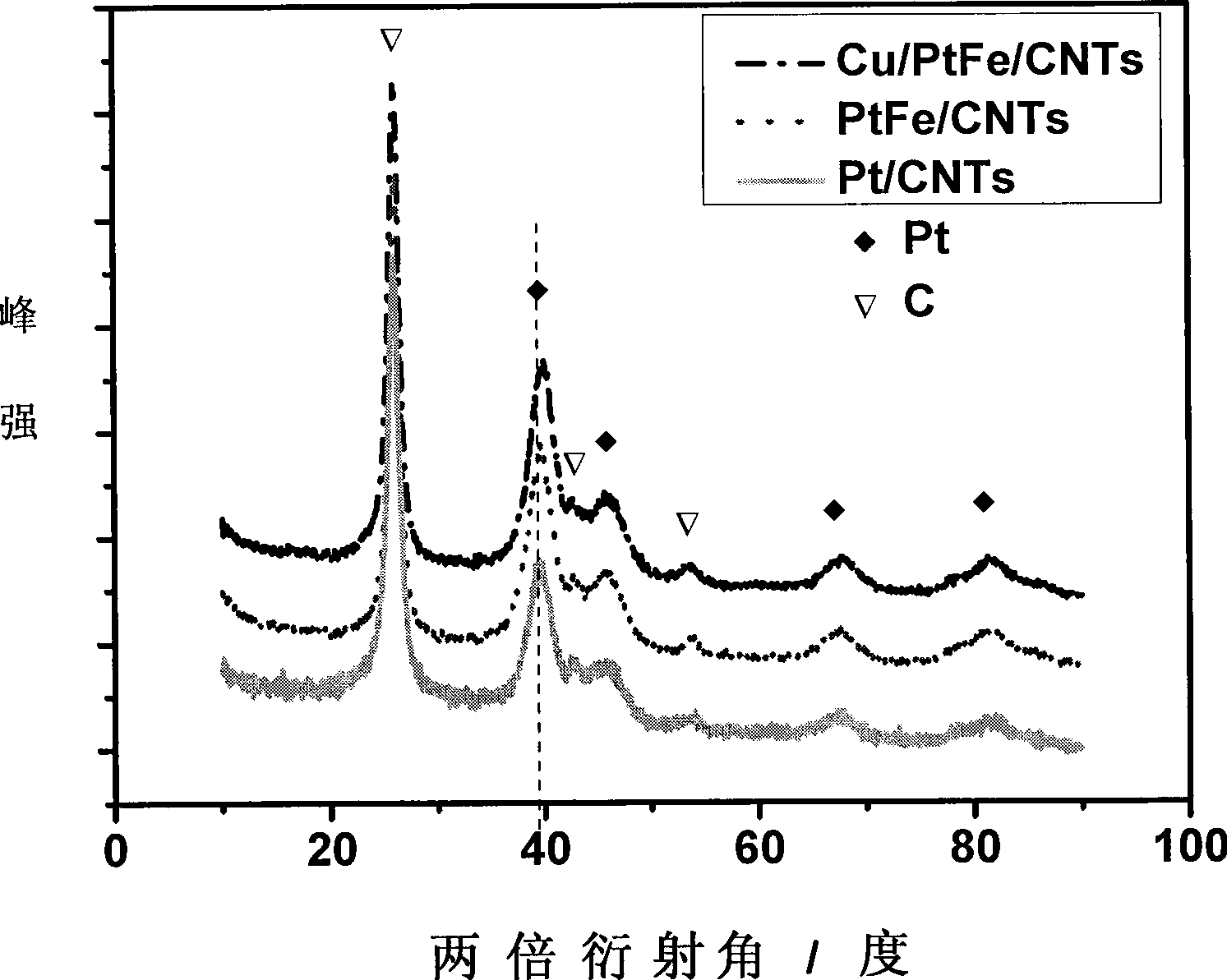

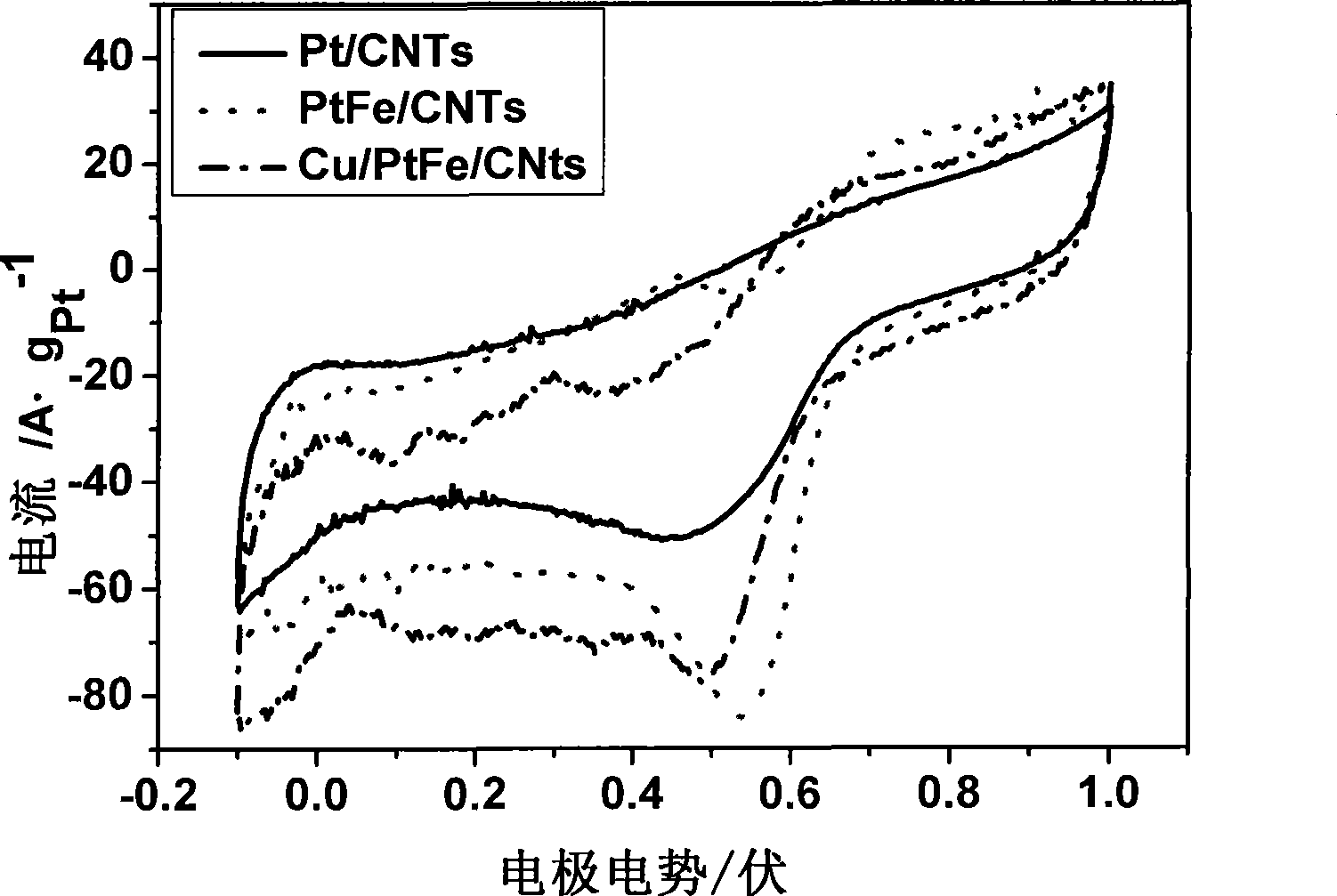

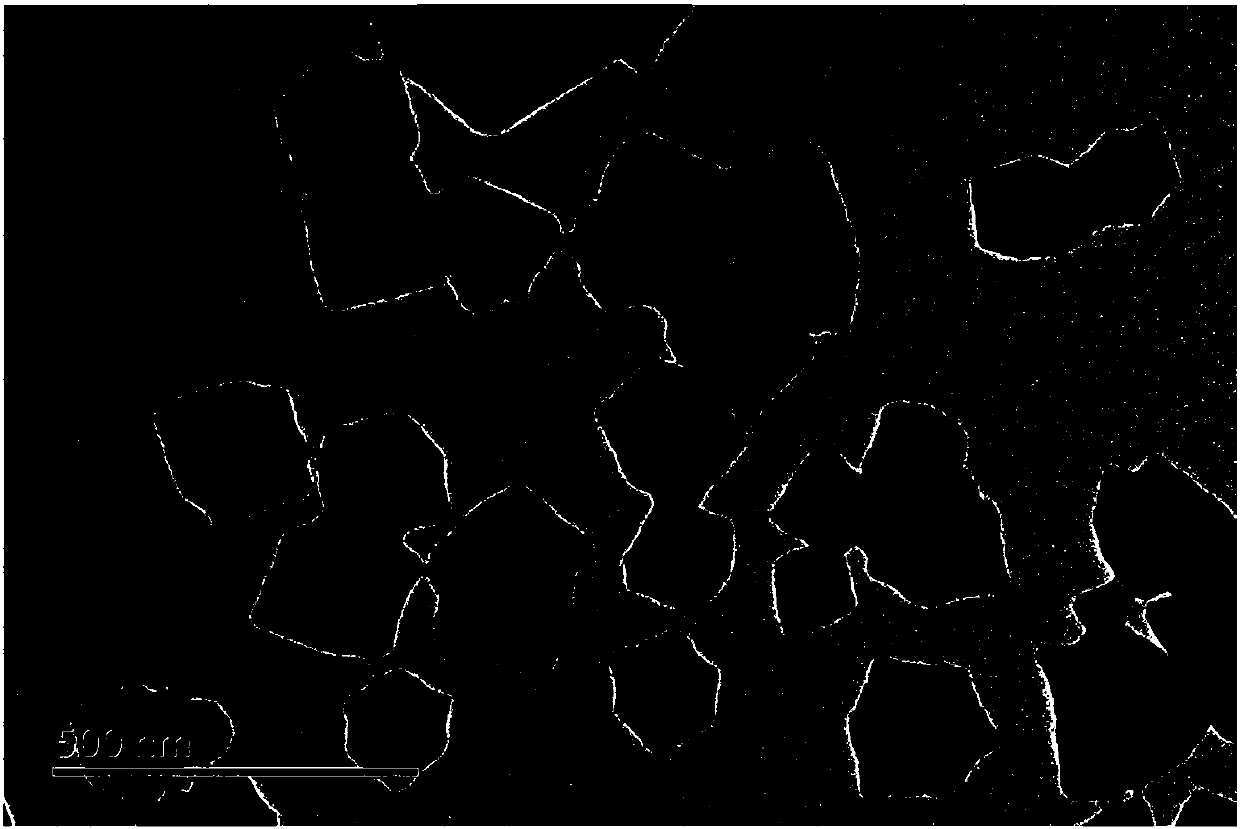

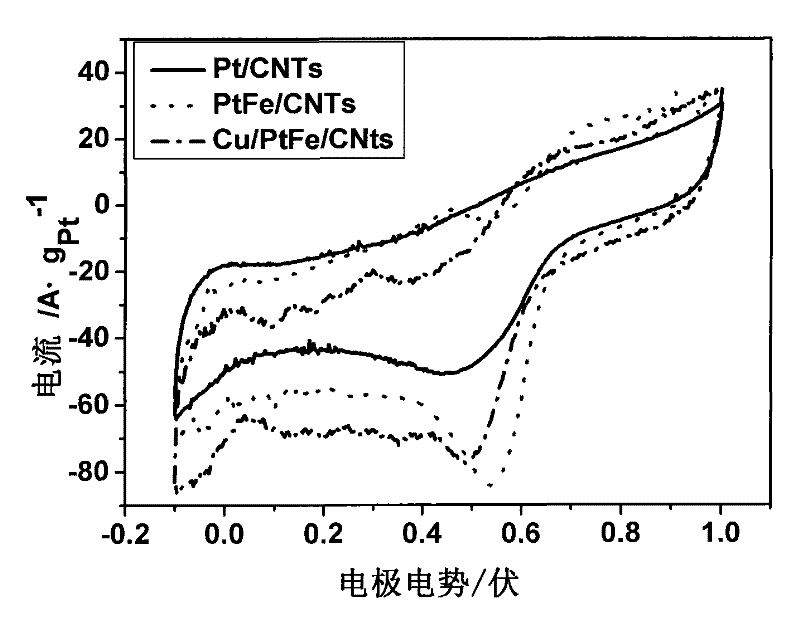

InactiveCN101380584AExcellent oxygen reduction activityAerobic reduction activityCell electrodesMetal/metal-oxides/metal-hydroxide catalystsCarbon nanotubeBiological activation

The invention discloses a high-activity methanol-resistance direct methanol fuel cell cathode catalyst and a preparation method thereof. The activity composition of the catalyst is Cu / PtM, the carrier is a carbon nanotube, wherein, PtM is used for improving oxygen reduction activation and Cu is used for improving methanol-resistance performance. The preparation method is as follows: firstly, the carbon nanotube, the compounds of metal M, and platinic chloride solution are scattered in glycol ultrasonically, the pH value is adjusted, the temperature is increased and reflux is carried out, platinum based catalyst loaded by the carbon nanotube is prepared by filtering, washing and drying; then the prepared platinum based catalyst loaded by the carbon nanotube is scattered in the glycol and is added with copper sulfate, then the pH value is adjusted, the temperature is increased and the reflux is carried out, and then the platinum direct methanol fuel cell cathode catalyst loaded by the carbon nanotube coated with Cu is prepared by the filtering, washing and drying. The preparation method is simple, operational condition is mild and the controllability is good; besides, the catalyst prepared by the method has high oxygen reduction activation and good methanol-resistance performance.

Owner:SOUTH CHINA UNIV OF TECH

Preparation and application of non-noble metal nitrogen-doped hollow carbon nanotube electrocatalyst

ActiveCN109921041ALarge specific surface areaRich varietyMaterial nanotechnologyCell electrodesFuel cellsIn situ polymerization

The invention relates to a preparation method of a non-noble metal nitrogen-doped hollow carbon nanotube electrocatalyst. Specifically, in a hydrochloric acid solution, a self-made or commercial non-noble metal organic framework material (MOF) is taken as a metal source and carbon source precursor under the condition of no surfactant; in-situ polymerization is carried out on the surface of the metal source and carbon source precursor to generate polyaniline (PANI); and pyrolysis is carried out twice at a high temperature to obtain the non-noble metal nitrogen-doped hollow carbon nanotube catalyst. An electrocatalyst material obtained by the preparation method has a huge application prospect in the aspects of fuel cells and electrolytic tanks.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Oxygen reduction catalyst, and preparation method and application thereof

The invention discloses an oxygen reduction catalyst. The oxygen reduction catalyst comprises a carbon material and two or more doping elements doped in the carbon material, wherein the doping elements are non-metallic elements excluding carbon and oxygen elements in the group IIIA and the group VA to the group VIIA. The invention further discloses a preparation method and an application of the above oxygen reduction catalyst. The oxygen reduction catalyst disclosed by the invention has a large specific surface area, good electrical conductivity, high stability, excellent oxygen reduction activity and simple preparation method, and thus is suitable for commercial application.

Owner:KELAS ENVIRONMENTAL PROTECTION TECH CO LTD +1

Fuel cell electrocatalyst and preparation method and application thereof

ActiveCN112510221AReduce loadIncrease profitMaterial nanotechnologyCell electrodesPtru catalystPlatinum salts

The invention discloses a fuel cell electrocatalyst and a preparation method and application thereof. The fuel cell electrocatalyst comprises a metal nitrogen-carbon carrier material, platinum precursors are adsorbed to micropores of the metal nitrogen-carbon carrier material, and platinum reduced through an electrochemical reduction method and metal in a carrier form an alloy. The preparation method of the catalyst comprises the following steps: (1) preparing a metal nitrogen-carbon carrier; (2) preparing a catalyst precursor; and (3) platinum reduced by an electrochemical reduction method and the transition metal in the carrier forming an alloy. According to the catalyst, metal nitrogen carbon is used as a carrier to adsorb platinum salt, the particle size of platinum particles is limited through the confinement effect of pore channels, transition metal contained in the carrier and Pt form an alloy, the Pt loading capacity can be reduced, the Pt utilization rate can be increased, thepreparation process is simple, and a product has excellent oxygen reduction activity and can be applied to proton exchange membrane fuel cells.

Owner:NANJING UNIV

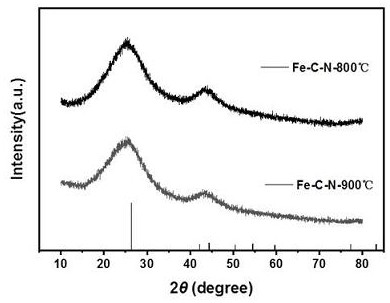

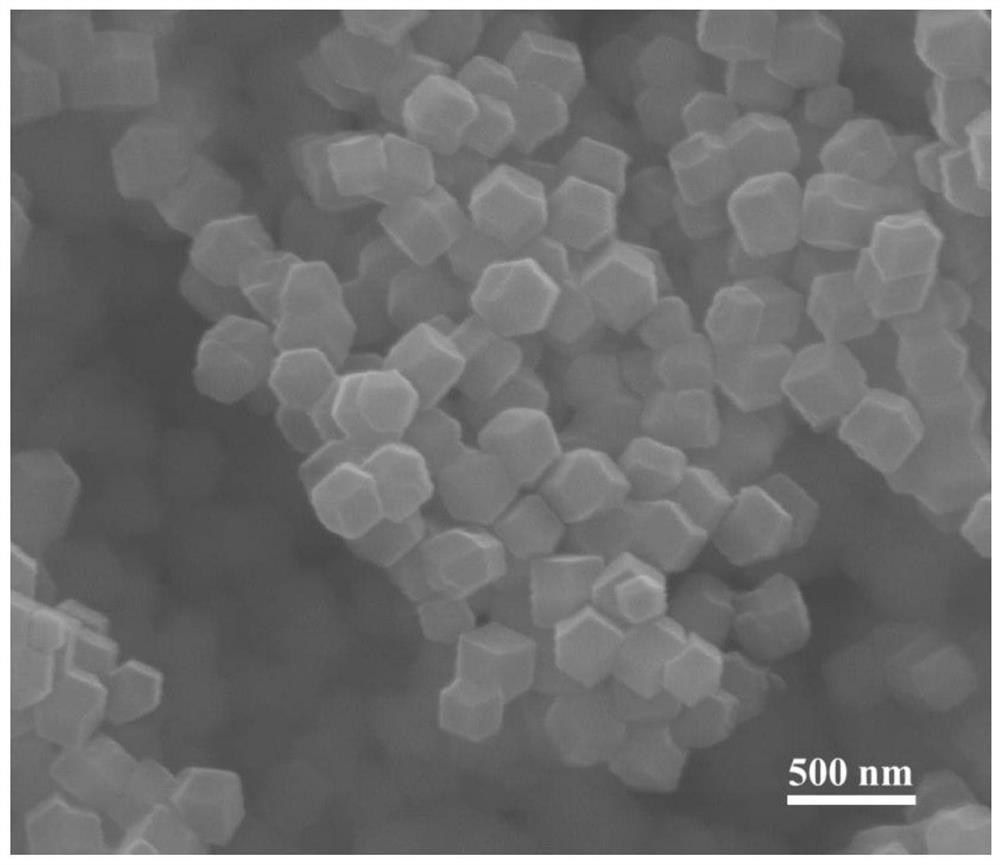

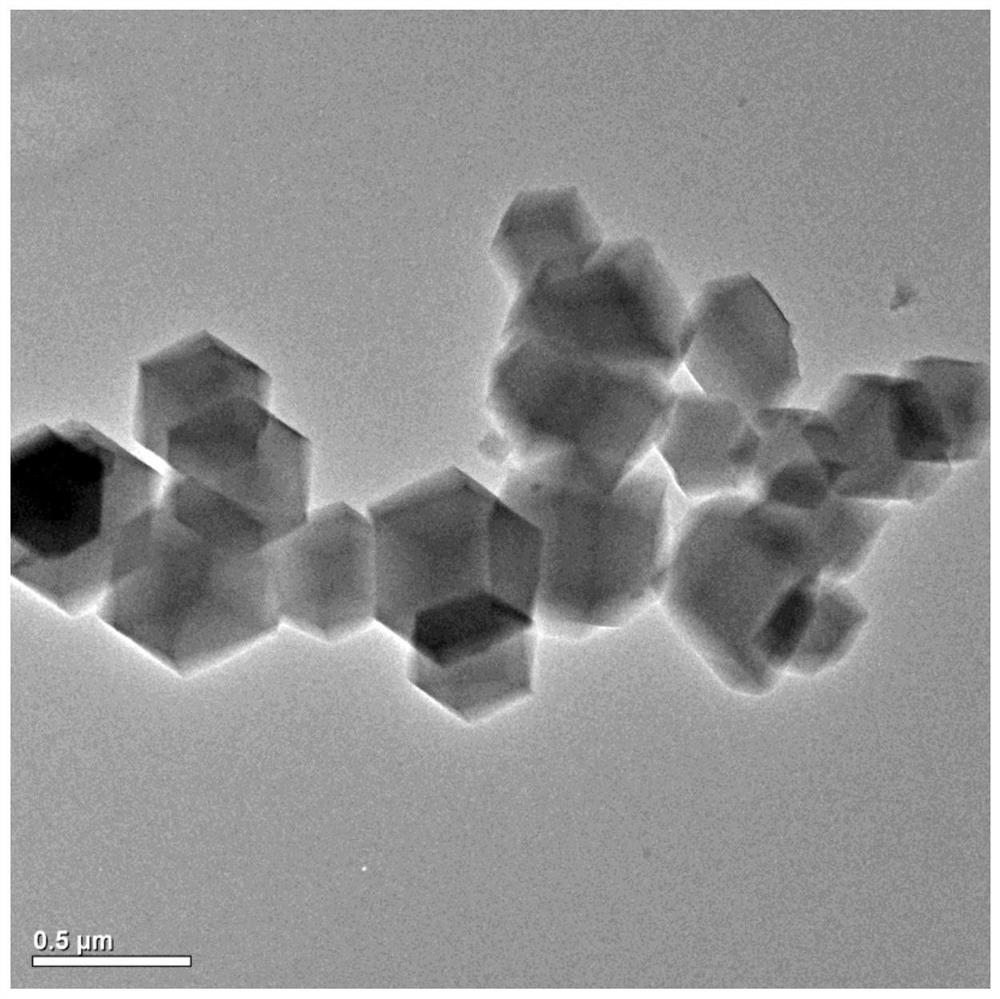

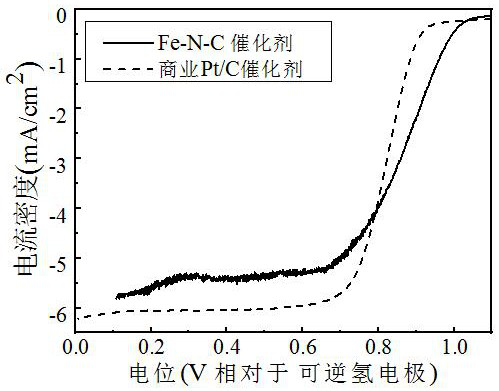

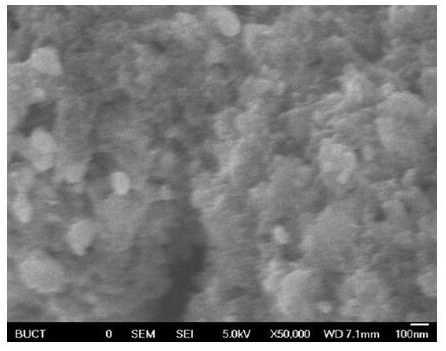

Preparation method of bifunctional atom dispersion iron-nitrogen coordination material catalyst

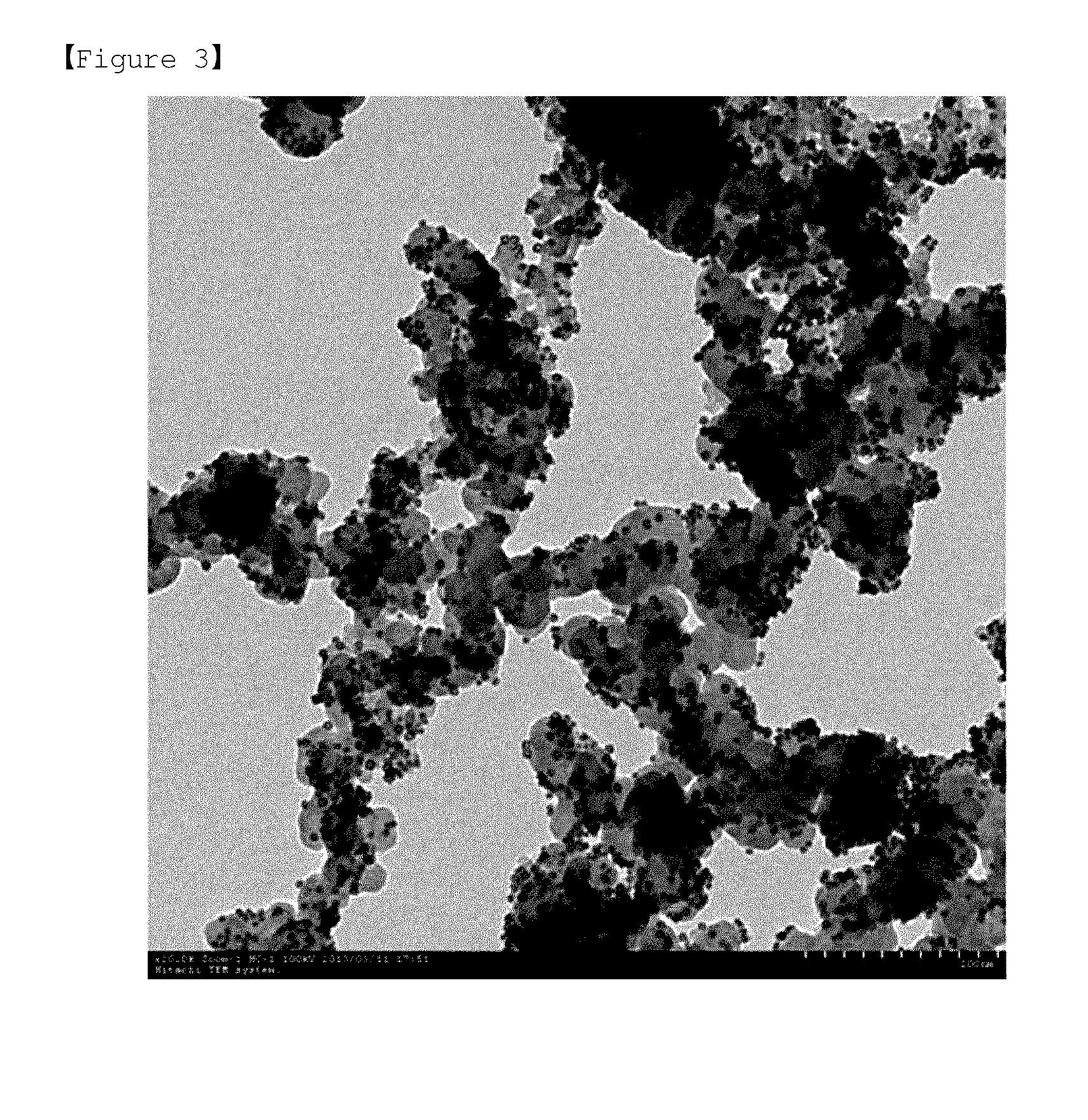

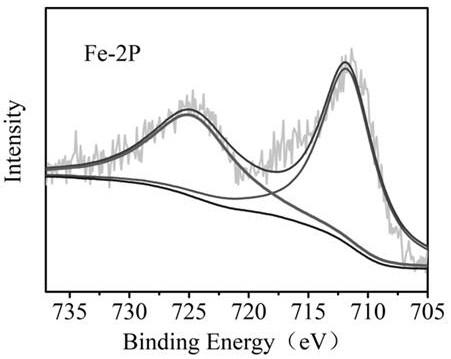

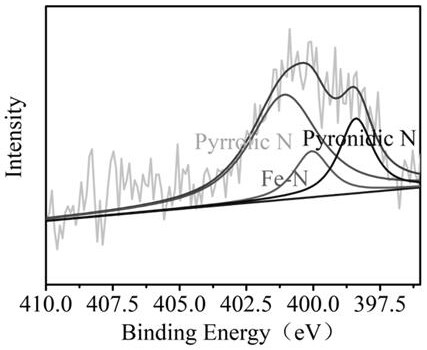

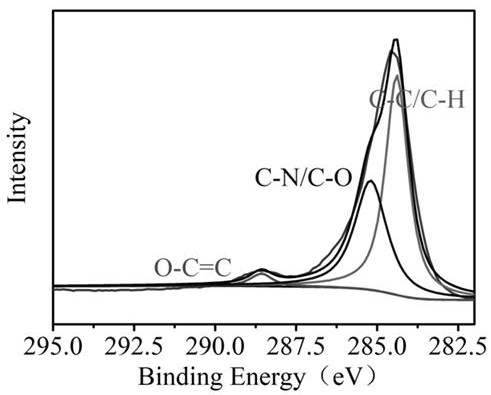

InactiveCN111841616AUniform adsorptionHigh catalytic efficiencyPhysical/chemical process catalystsElectrodesPtru catalystNanoparticle

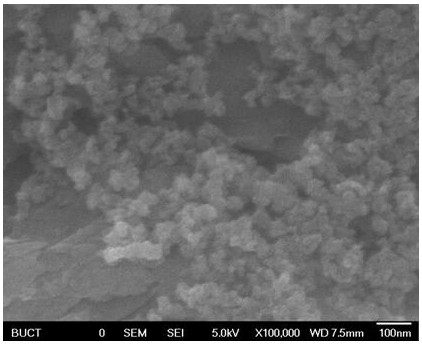

The invention relates to a preparation method of a bifunctional atom dispersion iron-nitrogen coordination material catalyst. The preparation method comprises the following specific steps: step 1, preparing metal framework compound ZIF-8 nanoparticles; 2, dispersing the ZIF-8 nanoparticles in an isopropanol solution of ferric chloride, carrying out ultrasonic treatment to uniformly adsorb the ZIF-8 nanoparticles, carrying out magnetic stirring for a period of time, and carrying out centrifugal drying to obtain a catalyst precursor; and 3, carbonizing the catalyst precursor at high temperaturein a nitrogen atmosphere to obtain the final high-activity Fe-N-C catalyst. The method has the advantages that the process is simple, the raw materials are rich, uniform adsorption of the iron elementin the precursor can be achieved through simple adsorption, high-energy-consumption and high-noise process steps such as ball milling are not needed, and large-scale production is facilitated.

Owner:NANCHANG HANGKONG UNIVERSITY

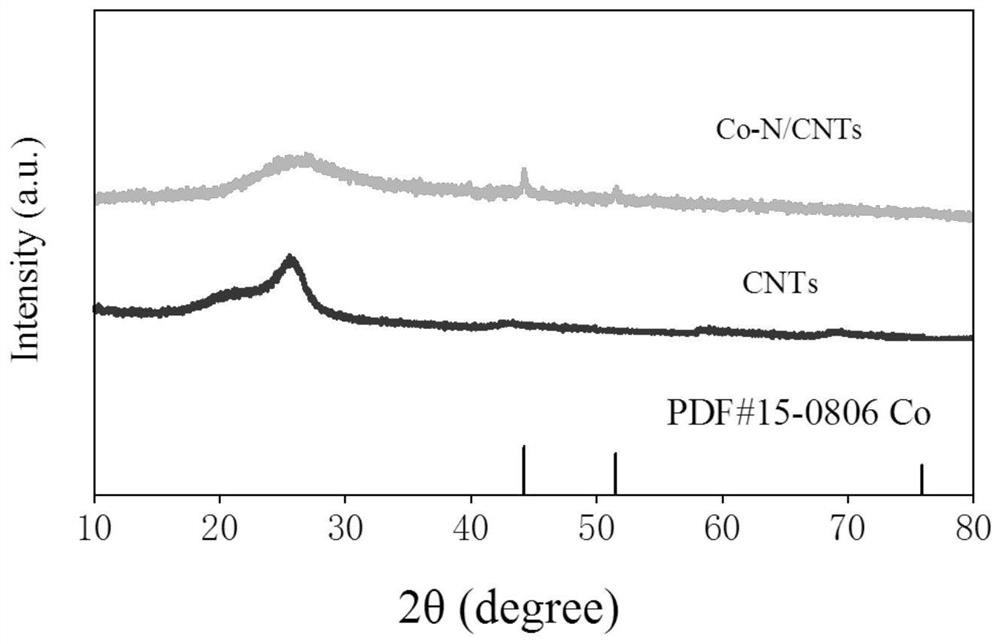

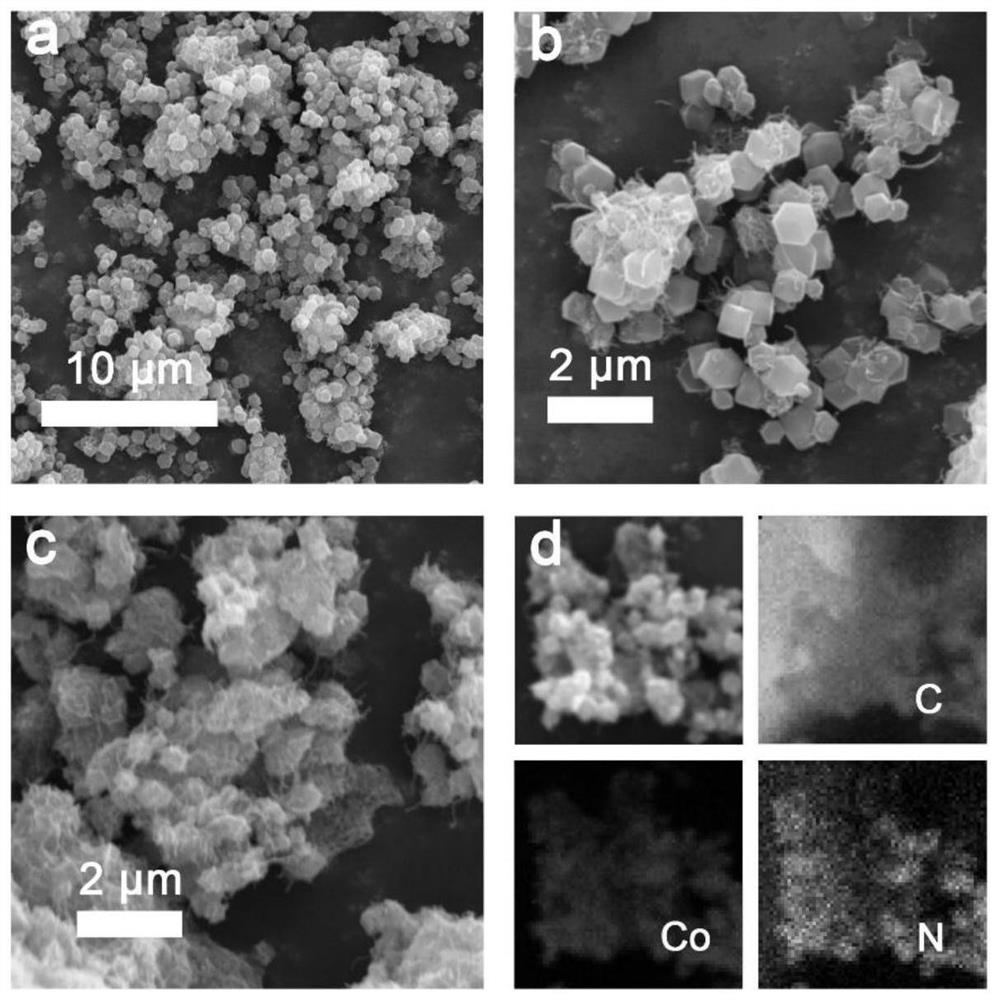

Preparation method of Co-N/CNTs catalytic material, catalytic material obtained through preparation method and application of Co-N/CNTs catalytic material

PendingCN113206261AUniform growthHigh catalytic activityCell electrodesFinal product manufacturePtru catalystCarboxyl radical

The invention discloses a Co-N / CNTs catalytic material and a preparation method and application thereof. The method comprises the following steps: 1) dissolving carboxylated multi-walled carbon nanotubes in a methanol solution for ultrasonic treatment; (2) adding cobalt chloride into the suspension of the carbon nanotubes and performing stirring; (3) dissolving an organic ligand 2-methylimidazole into a methanol solution, then dropwise adding the mixture into the mixed solution, and then putting the mixed solution into a high-temperature reaction kettle to react; 4) filtering and washing the obtained product with methanol and ethanol for several times, and then performing drying and grinding to obtain powder; 5) performing high-temperature carbonization on the prepared powder in an inert atmosphere to prepare the Co-N / CNTs material. The invention provides the oxygen reduction reaction catalyst which is low in price, convenient and simple, has many active sites and can be widely applied, and the catalyst has excellent catalytic oxygen reduction performance under a neutral condition, can greatly improve the output power of a microbial fuel cell, and is used for improving the oxygen reduction performance and the electricity generation performance of the microbial fuel cell.

Owner:SOUTHEAST UNIV

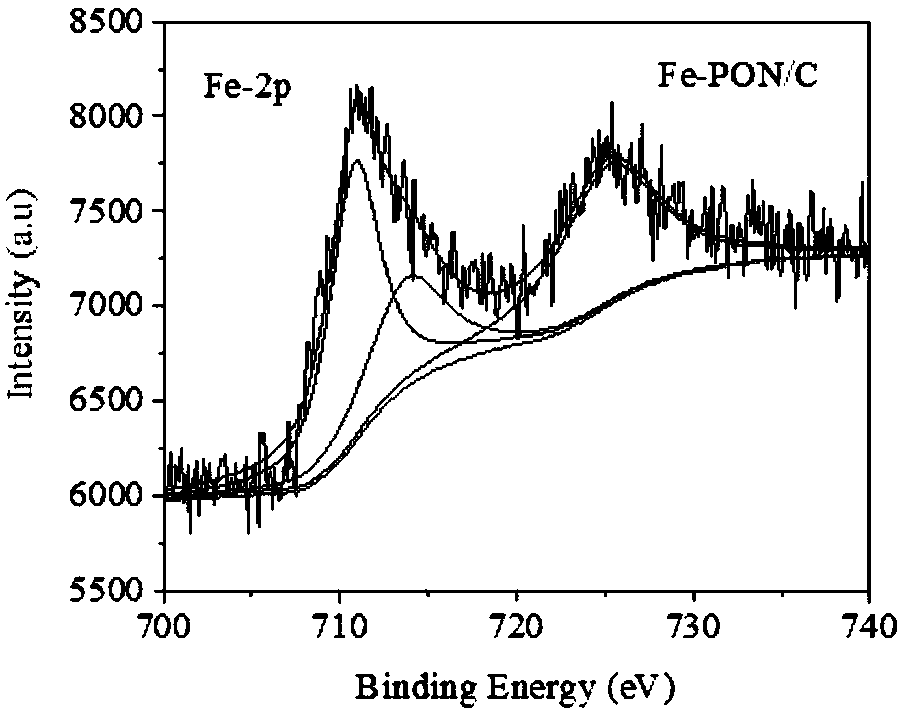

Preparation method of iron-phosphorus oxynitride applied to zinc-air battery and fuel battery

InactiveCN108455677AExcellent oxygen reduction activitySimple preparation processNitrogen compoundsCell electrodesOverpotentialMetal

The invention discloses a preparation method of iron-phosphorus oxynitride applied to a zinc-air battery and a fuel battery. The method comprises the following specific steps that firstly, metal glueformed by coordinating transition metal with phytic acid is synthesized, the metal glue of the transition metal is used as a precursor and subjected to high-temperature calcination under the inert atmosphere, the calcinated product is subjected to acid pickling treatment, finally, ammonia is used as an N source, N doping is conducted at the high temperature, and final transition metal phosphorus oxynitride is obtained. Transition metal phosphorus oxynitride is used as an oxygen reduction catalyst and has high electrical conductivity and specific surface area, the overpotential of ORR is effectively lowered, and it is expressed through a rotating disk electrode (RDE) and a rotating ring disk electrode (RRDE) that the ORR process is a four-electronic catalytic mechanism and is an ideal ORR process. According to the electrocatalyst, the transition metal and heteroatom elements sufficiently have the synergistic effect in electrocatalysis, and the electrocatalyst shows excellent catalytic performance in application of the zinc-air battery.

Owner:QINGDAO UNIV OF SCI & TECH

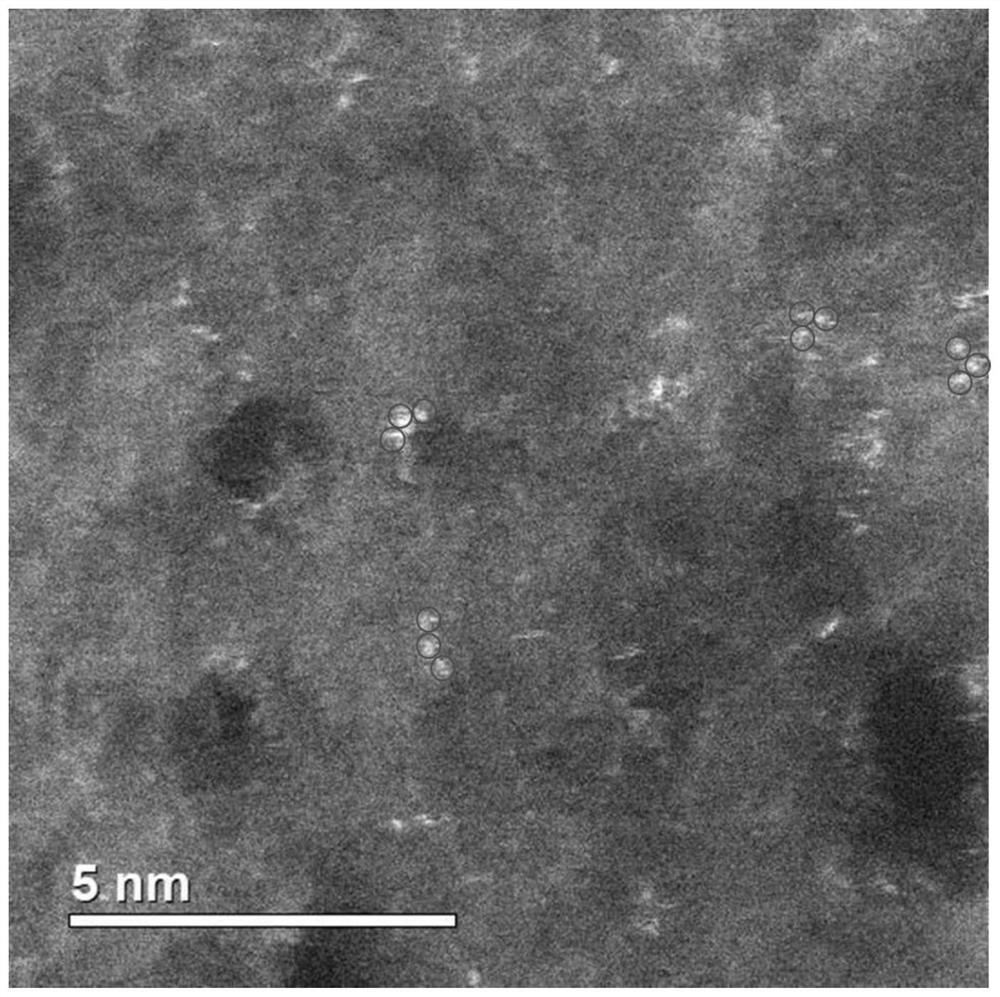

Triatomic-scale dispersed metal cluster loaded nitrogen-doped nano carbon fuel cell catalyst

PendingCN111755705AExcellent oxygen reduction activityImprove battery performanceCell electrodesPtru catalystFuel cells

The invention relates to a three-atomic-scale dispersed metal cluster fuel cell catalyst. The catalyst comprises a triatomic metal cluster and a nitrogen-doped nanocarbon material, metal in the triatomic metal cluster is dispersed on a substrate in the form of the triatomic cluster, the nitrogen-doped nanocarbon comprises a carbon source and a nitrogen source, and the triatomic metal cluster is loaded on the nitrogen-doped nanocarbon. A fuel cell assembled by the material exhibits an excellent cell performance. The catalyst has the advantages of simple and controllable steps, good reproducibility, and easy realization of industrial production.

Owner:浙江晨阳新材料有限公司

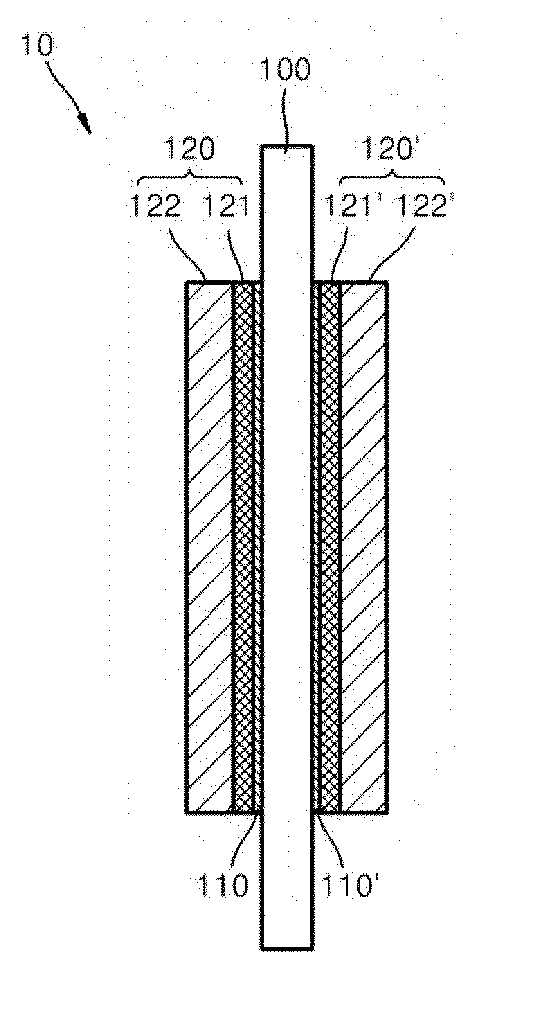

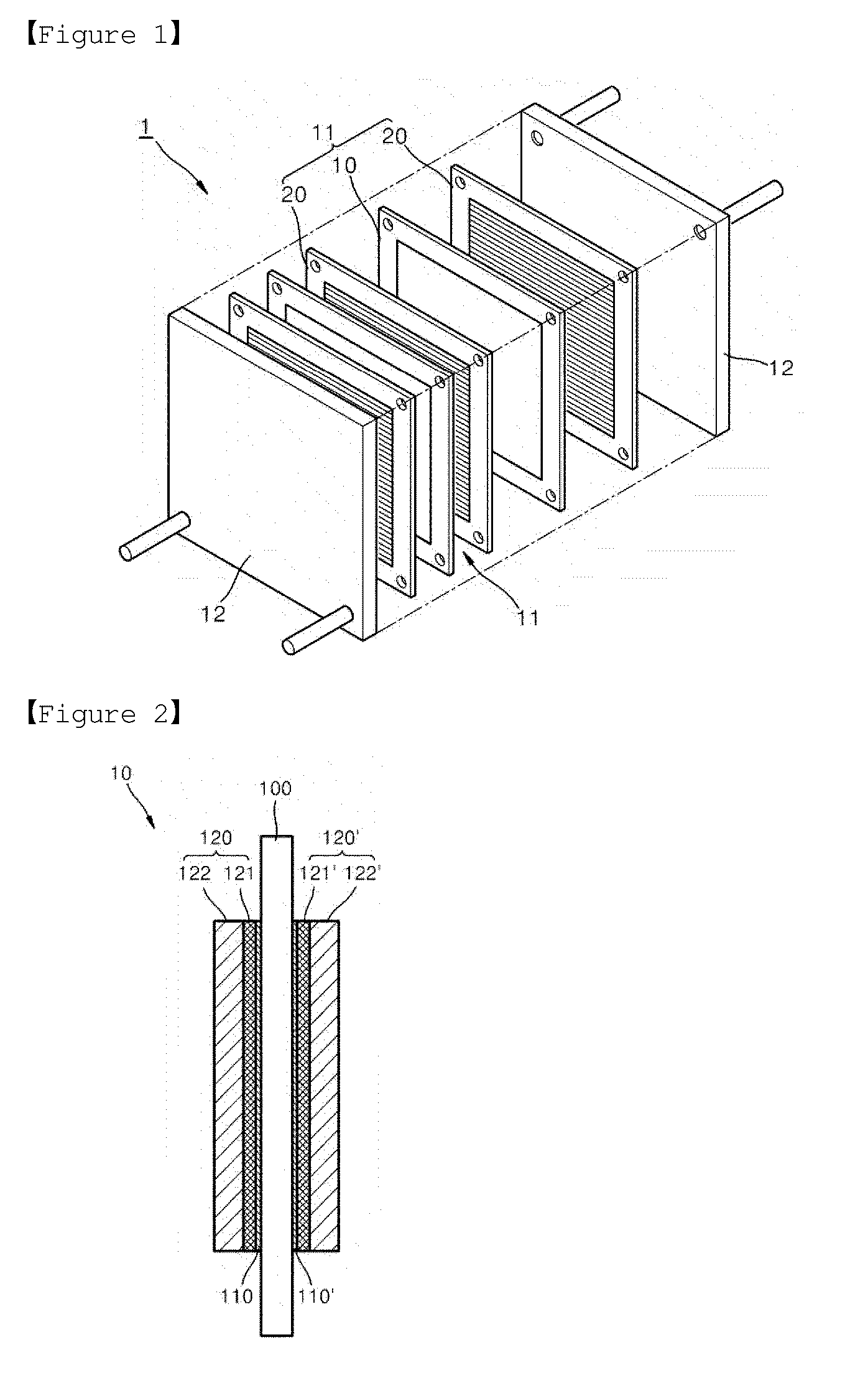

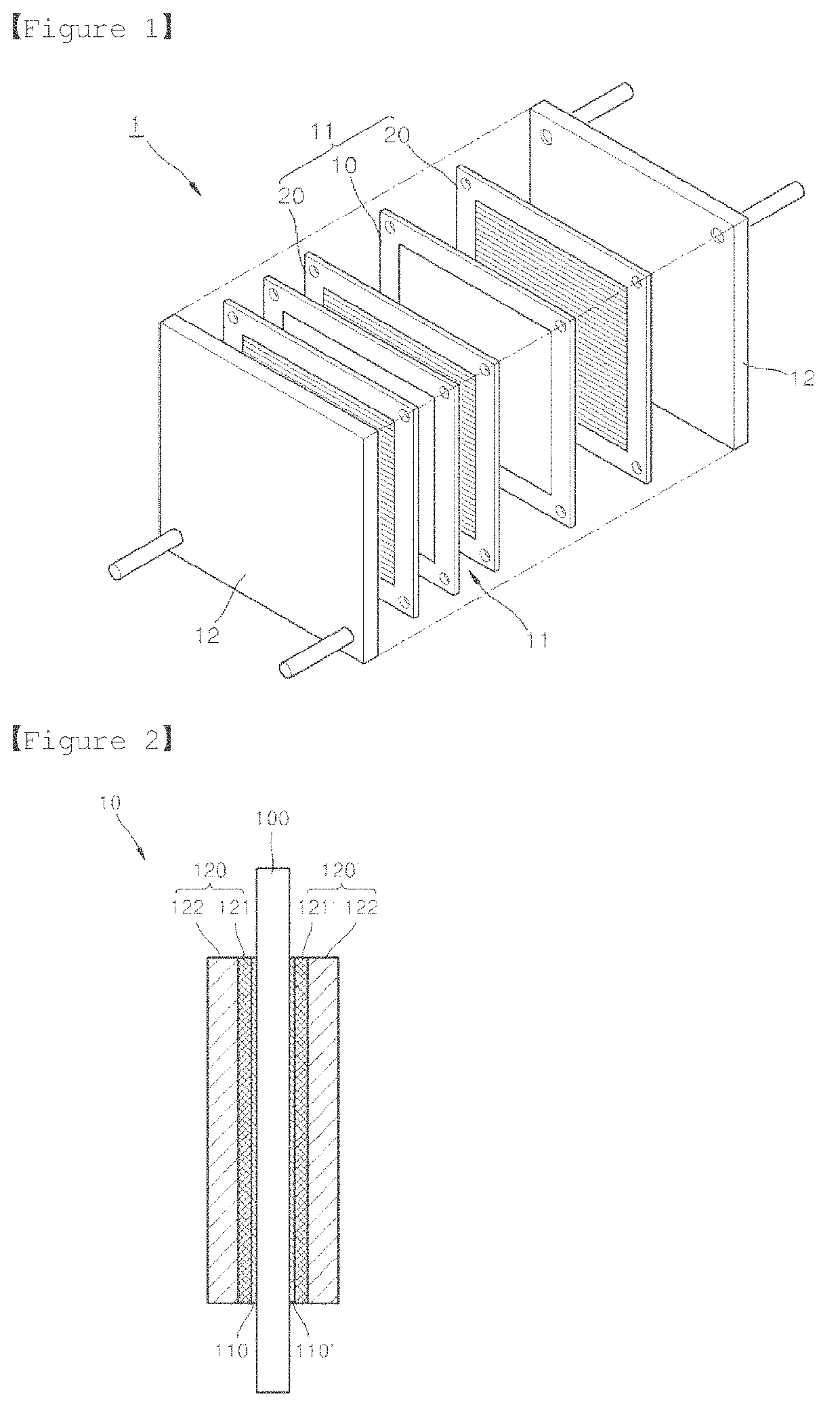

Fuel cell and method for manufacturing same

ActiveUS20160301085A1High activityExcellent oxygen reduction activityCell electrodesSolid electrolyte fuel cellsFuel cellsEngineering

Owner:LG CHEM LTD

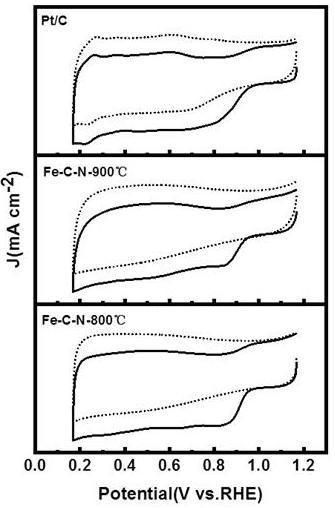

Preparation method of iron-based triazine ring polymer catalyst

PendingCN114653392AExcellent oxygen reduction activityIncreased oxygen reduction activityCell electrodesCatalyst activation/preparationPtru catalystNitrogen gas

The invention discloses a preparation method of an iron-based triazine ring polymer catalyst, which comprises the following steps of: mixing 1, 4-terephthalonitrile, anhydrous ferric chloride and conductive carbon black, grinding, packaging in an ampoule tube in vacuum, heating to 250-350 DEG C in a muffle furnace at the speed of 5 DEG C / min, preserving heat for 20 hours, taking out a reactant, fully grinding, transferring into a tube furnace, heating to 250-350 DEG C at the speed of 5 DEG C / min, and cooling to room temperature to obtain the iron-based triazine ring polymer catalyst. And heating to 850-950 DEG C at the speed of 5 DEG C / min in a nitrogen atmosphere, preserving heat for 2 hours, carrying out acid leaching on the reactant by 0.5 mol / L hydrochloric acid at 55-65 DEG C for 6 hours, washing and drying, transferring into a tubular furnace, heating to 850-950 DEG C at the speed of 5 DEG C / min in the nitrogen atmosphere, and preserving heat for 2 hours, thereby obtaining the high-purity silicon carbide. Compared with a traditional method, the method has the advantages that the covalent triazine ring is directly doped into a metal monatomic active site during synthesis, the catalyst does not need to be modified subsequently, the activity of the iron-based triazine ring polymer catalyst prepared by the method in an acidic electrolyte is greatly improved, and the iron-based triazine ring polymer catalyst shows good oxygen reduction stability.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method and application of Zn/Co-N-C carbon nanotube oxygen reduction catalyst for autocatalytic growth

PendingCN113594474AAvoid gatheringAvoid reunionCell electrodesCarbon nanotubesElectrolytic agentPtru catalyst

The invention discloses a preparation method and application of a Zn / Co-N-C carbon nanotube oxygen reduction catalyst for autocatalytic growth. The preparation method comprises the following steps: stirring a methanol dispersion of 2-methylimidazole zinc salt and a methanol dispersion of zinc nitrate hexahydrate, graphene oxide and cobalt acetylacetonate (III) at room temperature to obtain a mixture; carrying out centrifugation, methanol washing and drying treatment, carrying out high-temperature calcination under the protection of inert gas, and cooling to room temperature; and soaking the product in acid, washing for multiple times, and drying to obtain the target product Zn / Co-N-C carbon nanotube oxygen reduction catalyst. The carbon nanotube oxygen reduction catalyst prepared by the invention has a hierarchical porous property, and shows excellent oxygen reduction activity, cycling stability and methanol tolerance in both alkaline and acidic electrolytes. When the prepared carbon nanotube oxygen reduction catalyst is applied to a cathode of a zinc air battery, good power density and satisfactory cycling stability are shown.

Owner:HENAN NORMAL UNIV

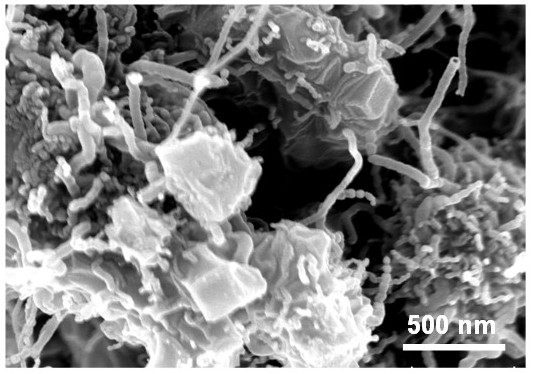

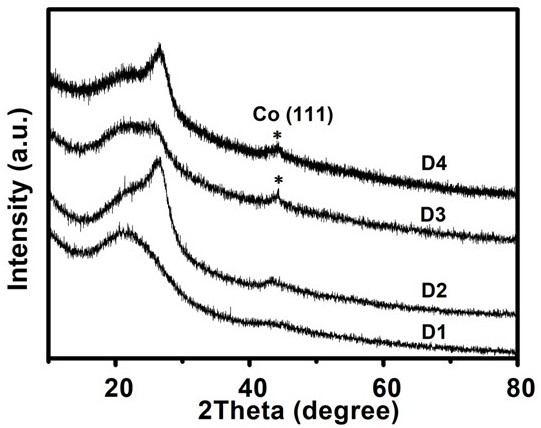

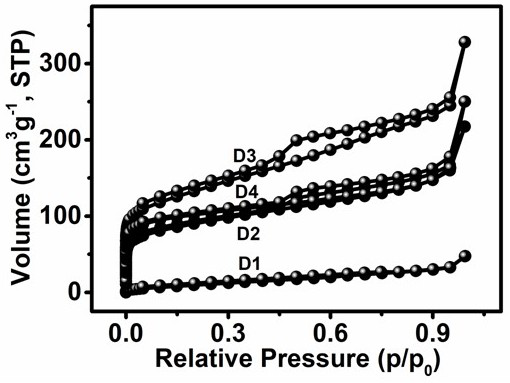

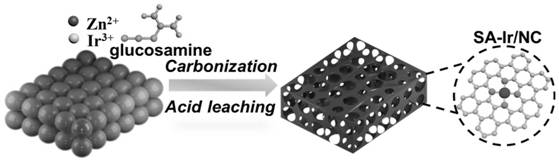

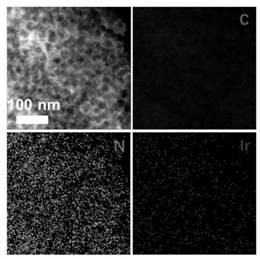

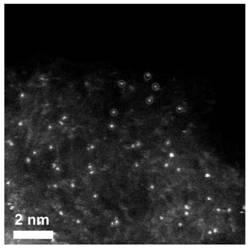

Iridium monatomic catalyst and preparation method and application thereof

ActiveCN112892571AExcellent oxygen reduction activityIncreased oxygen reduction activityFuel and secondary cellsMicrobiological testing/measurementIridiumPhotochemistry

The invention discloses an iridium monatomic catalyst and a preparation method and application thereof, the catalyst is a nanostructure system, carbon atoms, nitrogen atoms and iridium atoms are distributed in the nanostructure system, in the nanostructure system, the carbon atoms form a carrier structure, and the iridium atoms and the nitrogen atoms are embedded in the carrier structure. After the prepared catalyst is applied, the problems that an energy supply system in a self-energy-supply sensing system is poor in stability and low in glucose detection sensitivity can be solved.

Owner:HUAZHONG NORMAL UNIV

High activity methanol-resistance direct methanol fuel cell cathode catalyst and production method thereof

InactiveCN101380584BExcellent oxygen reduction activityAerobic reduction activityCell electrodesMetal/metal-oxides/metal-hydroxide catalystsCarbon nanotubeBiological activation

The invention discloses a high-activity methanol-resistance direct methanol fuel cell cathode catalyst and a preparation method thereof. The activity composition of the catalyst is Cu / PtM, the carrier is a carbon nanotube, wherein, PtM is used for improving oxygen reduction activation and Cu is used for improving methanol-resistance performance. The preparation method is as follows: firstly, the carbon nanotube, the compounds of metal M, and platinic chloride solution are scattered in glycol ultrasonically, the pH value is adjusted, the temperature is increased and reflux is carried out, platinum based catalyst loaded by the carbon nanotube is prepared by filtering, washing and drying; then the prepared platinum based catalyst loaded by the carbon nanotube is scattered in the glycol and is added with copper sulfate, then the pH value is adjusted, the temperature is increased and the reflux is carried out, and then the platinum direct methanol fuel cell cathode catalyst loaded by the carbon nanotube coated with Cu is prepared by the filtering, washing and drying. The preparation method is simple, operational condition is mild and the controllability is good; besides, the catalyst prepared by the method has high oxygen reduction activation and good methanol-resistance performance.

Owner:SOUTH CHINA UNIV OF TECH

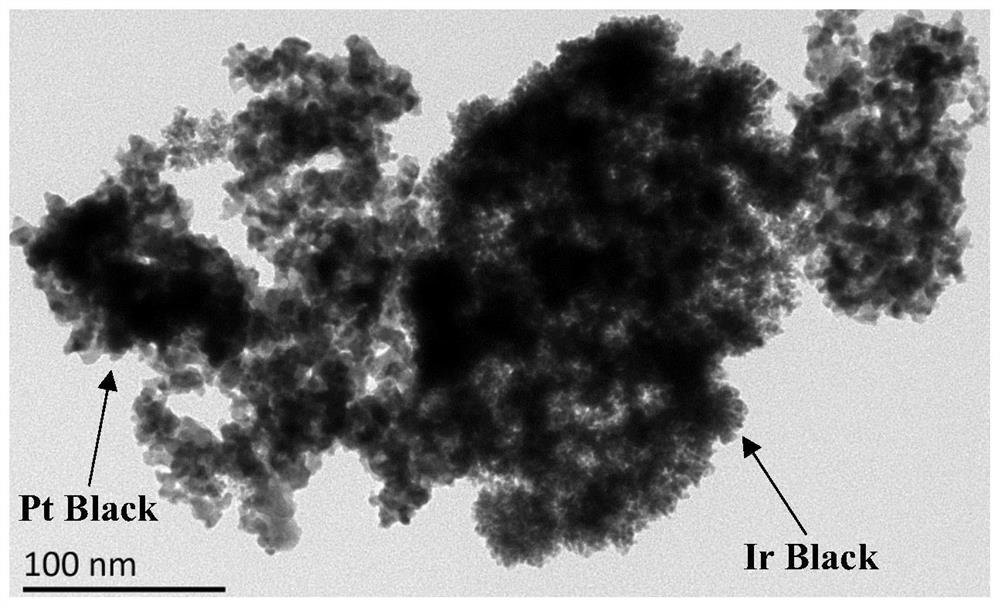

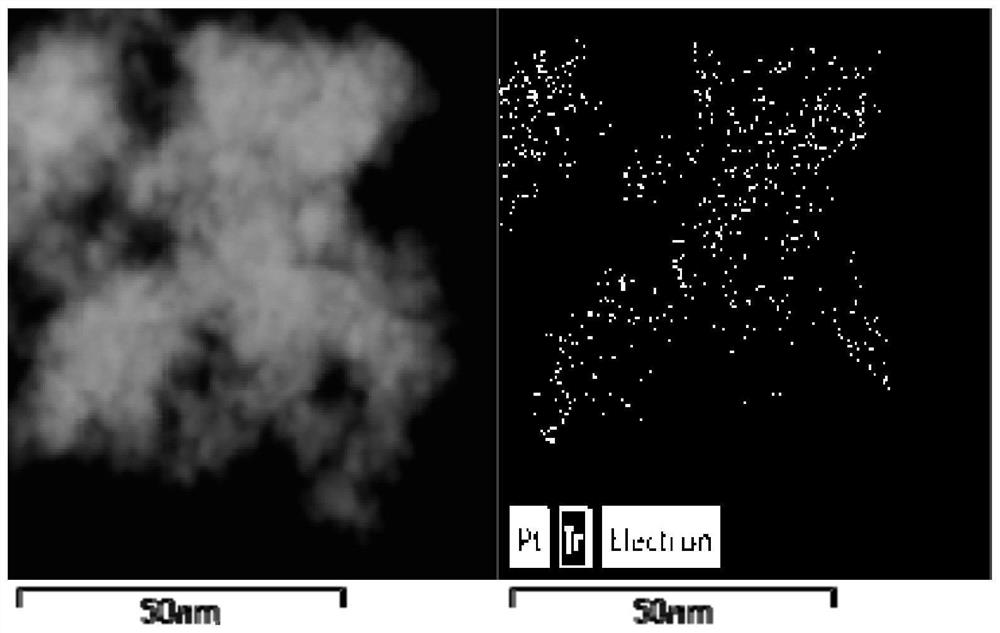

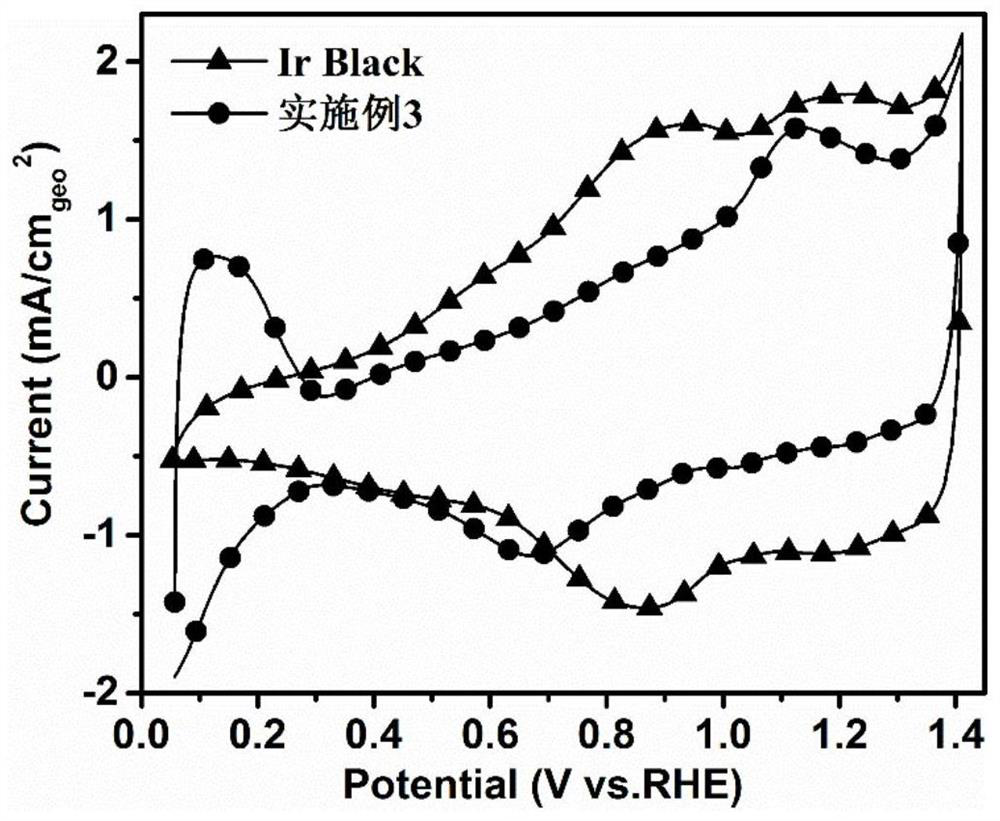

Preparation and application of a double-effect oxygen electrode catalyst with metal iridium surface-modified platinum

ActiveCN108899560BExcellent catalytic oxygen reduction functionGood catalytic oxygen reduction functionCell electrodesIridiumPtru catalyst

The invention discloses a preparation method of a carrier metal iridium surface platinum-modified bi-functional oxygen electrode catalyst. Metal iridium serving as a carrier has an oxygen evolution function, and precious metal-induced metal ions are subjected to a reduction reaction to modify the precious metal platinum having a catalytic oxygen reduction function. Since the metal iridium has excellent oxygen evolution activity, the metal platinum has excellent oxygen reduction activity. The catalyst can be applied to an oxygen electrode of an integrated regenerative fuel cell. Compared with asimple commercialized catalyst, namely a mechanical mixture of iridium black and platinum black, the bi-functional oxygen electrode catalyst disclosed by the invention has the advantage that the oxygen reduction performance can be obviously improved while not sacrificing oxygen precipitation activity. In addition, according to the method disclosed by the invention, no organic reagent is used, sothe catalyst is very environment-friendly and meets the green development requirement.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

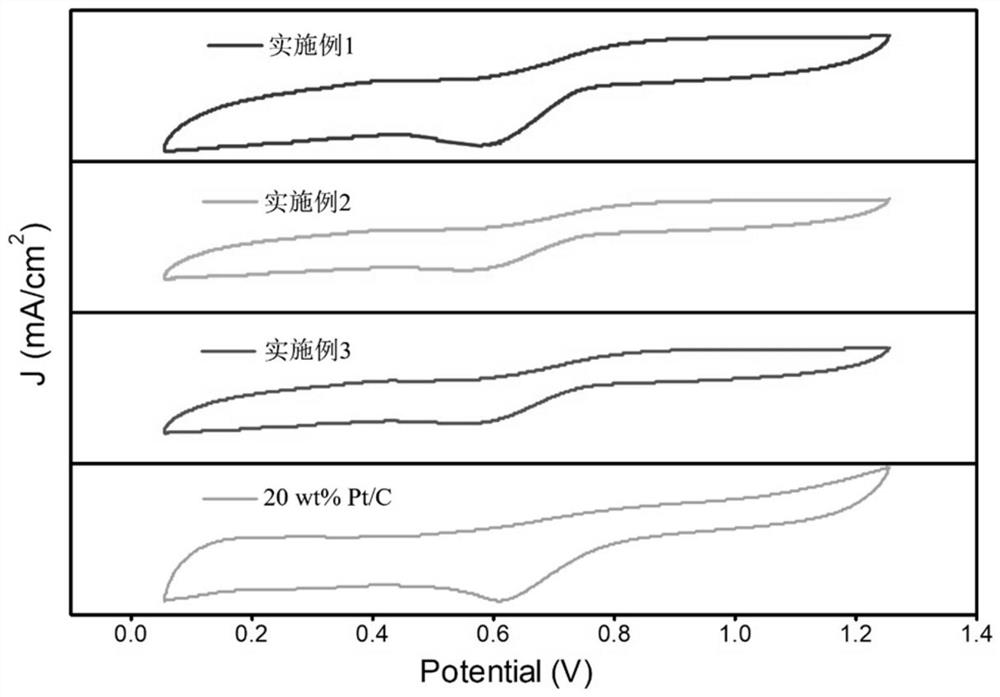

A kind of non-noble metal nitrogen-doped MOF double-effect electrocatalyst and preparation method thereof

ActiveCN110444776BHigh activityLow costMaterial nanotechnologyCell electrodesCarbon layerPtru catalyst

The invention relates to a super-dispersion non-noble metal nitrogen-doped MOF double-effect electrocatalyst and a preparation method thereof. The preparation method comprises the following steps of 1) adding a hydroxyl-rich carbon source organic matter and a nitrogen-rich organic matter into a surfactant dispersed solution, and carrying out stirring and mixing; and enabling the carbon-nitrogen source organic matters to be reacted in the solution to obtain a primary precursor; 2) adding a transition metal solution, stirring at a constant temperature and sufficiently chelating with the organicprecursor; 3) putting the object obtained in the step 2) into a high-temperature kettle to carry out hydrothermal crystallization to promote crystals to grow slowly; 4) carrying out centrifuging, washing and drying on the object obtained in the step 3); and 5) carrying out high-temperature carbonization on the object obtained in the step 4) to obtain the catalyst. The catalyst has the advantages that the uniformly dispersed ultrafine metal nanoparticles are embedded and wrapped in a carbon shell, and the carbon layer structure is activated; and the catalyst has rich transition metals and nitrogen-bonded M-N chelating active sites, so that the catalyst stably exists in an acid solution, and has important application value and significance in the fields of fuel cells, water electrolysis andother electro-catalysis.

Owner:TSINGHUA UNIV

A preparation method of a transition metal oxide nitrogen and phosphorus doped catalyst applied to a zinc-air battery

ActiveCN108336373BReduce overpotentialMake the most of synergiesFuel and primary cellsCell electrodesPtru catalystHeteroatom

The invention discloses a preparation method of a transition metal oxide nitrogen and phosphorus doped catalyst applied to a zinc-air battery, which specifically comprises the following steps: a supramolecular compound formed by coordinating acetate containing M metal ions and phytic acid, The transition metal supramolecular compound is used as the precursor for high-temperature calcination under an inert atmosphere, and finally ammonia gas is used as the N source, and N doping is carried out at high temperature to obtain the final transition metal oxyphosphorus nitride. Transition metal oxyphosphorus nitride as an oxygen reduction catalyst can effectively reduce the overpotential of ORR, and the ORR process is shown to be a 4-electron catalytic mechanism by rotating disk electrode (RDE) and rotating ring disk electrode (RRDE), which is an ideal ORR reaction. process. The electrocatalyst fully utilizes the synergistic effect of transition metals and heteroatom elements in electrocatalysis, and exhibits excellent catalytic performance in the application of zinc-air batteries.

Owner:山东科源新材料有限公司

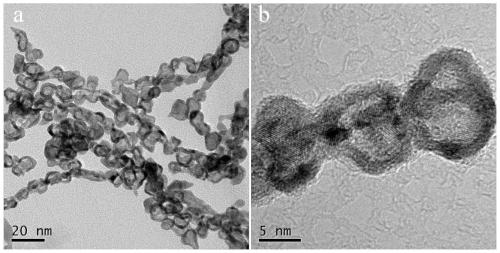

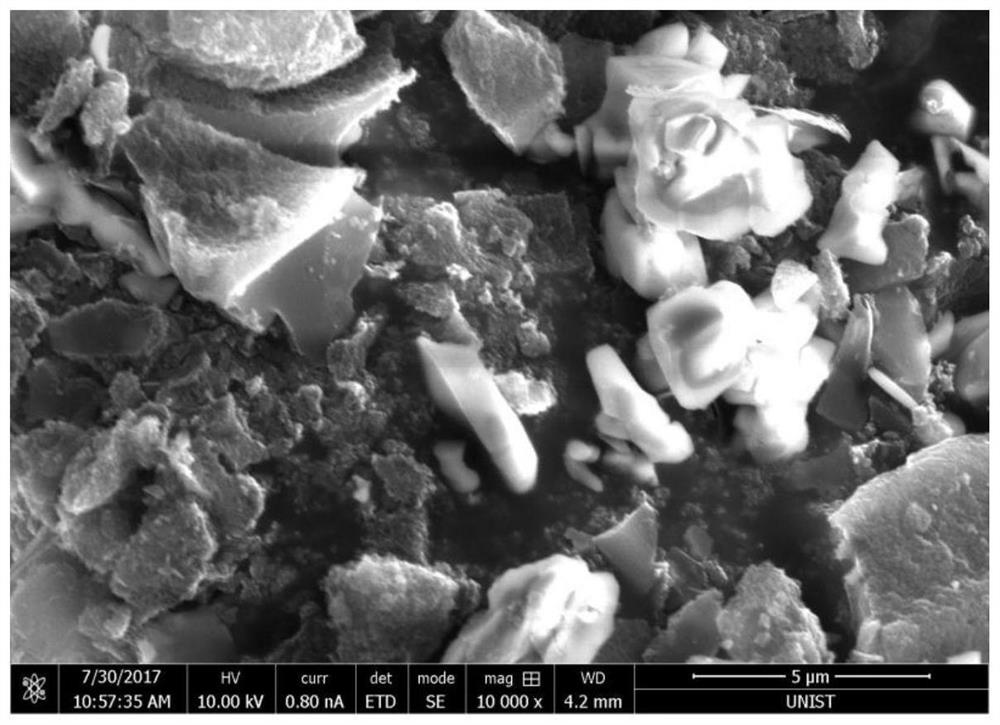

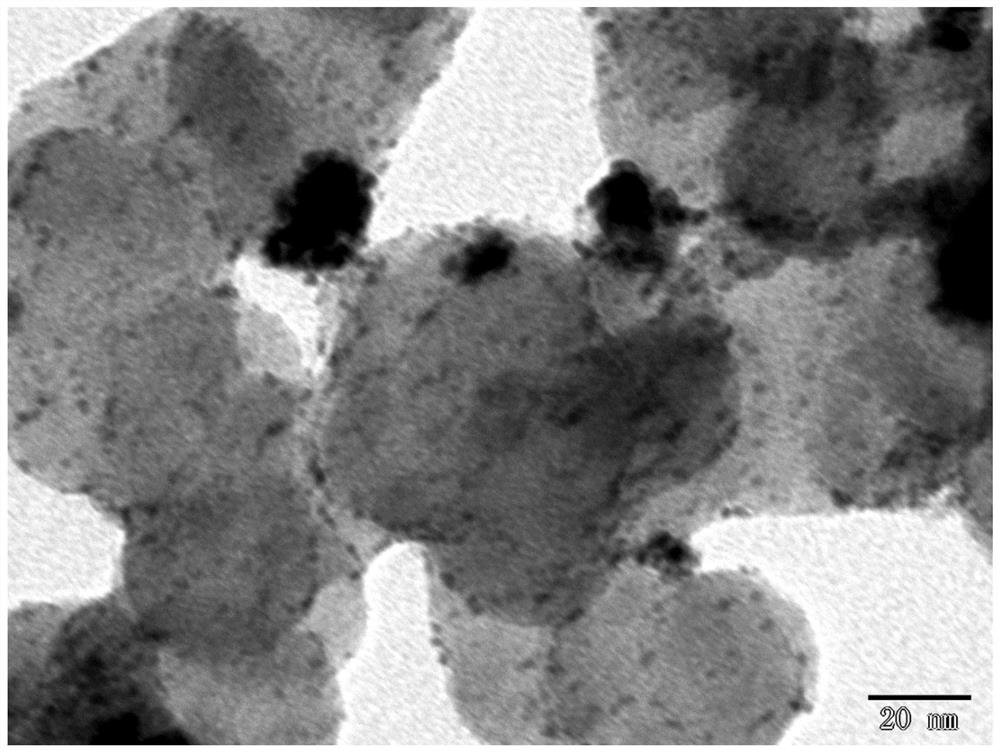

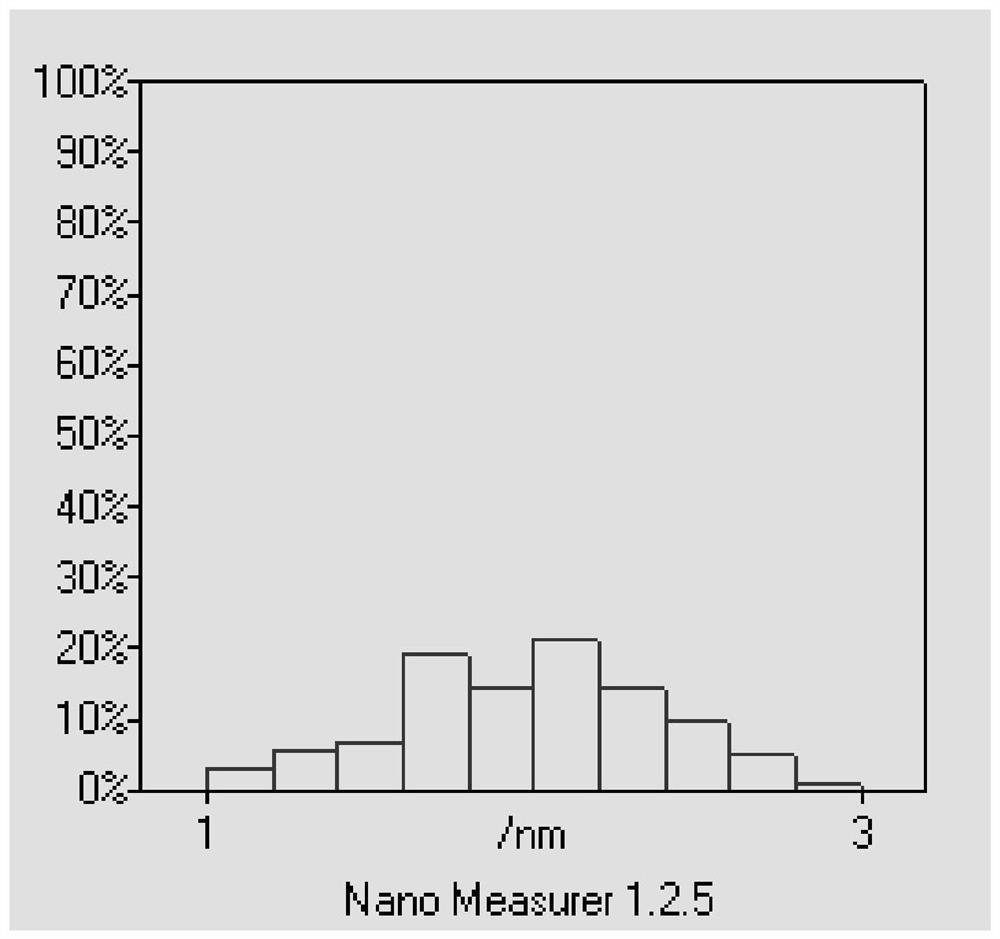

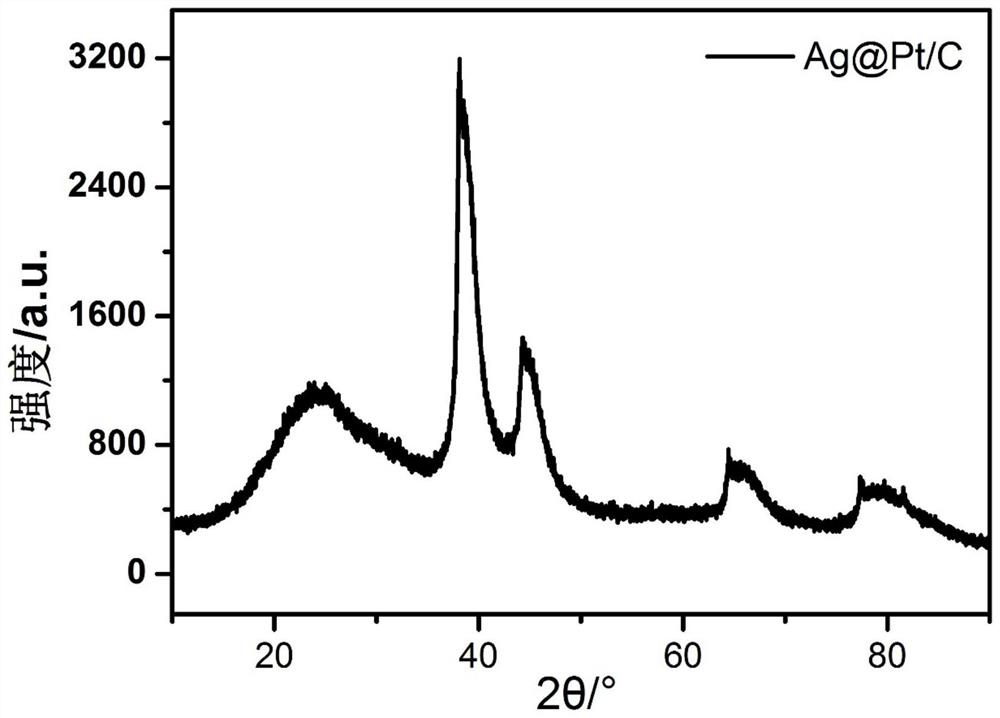

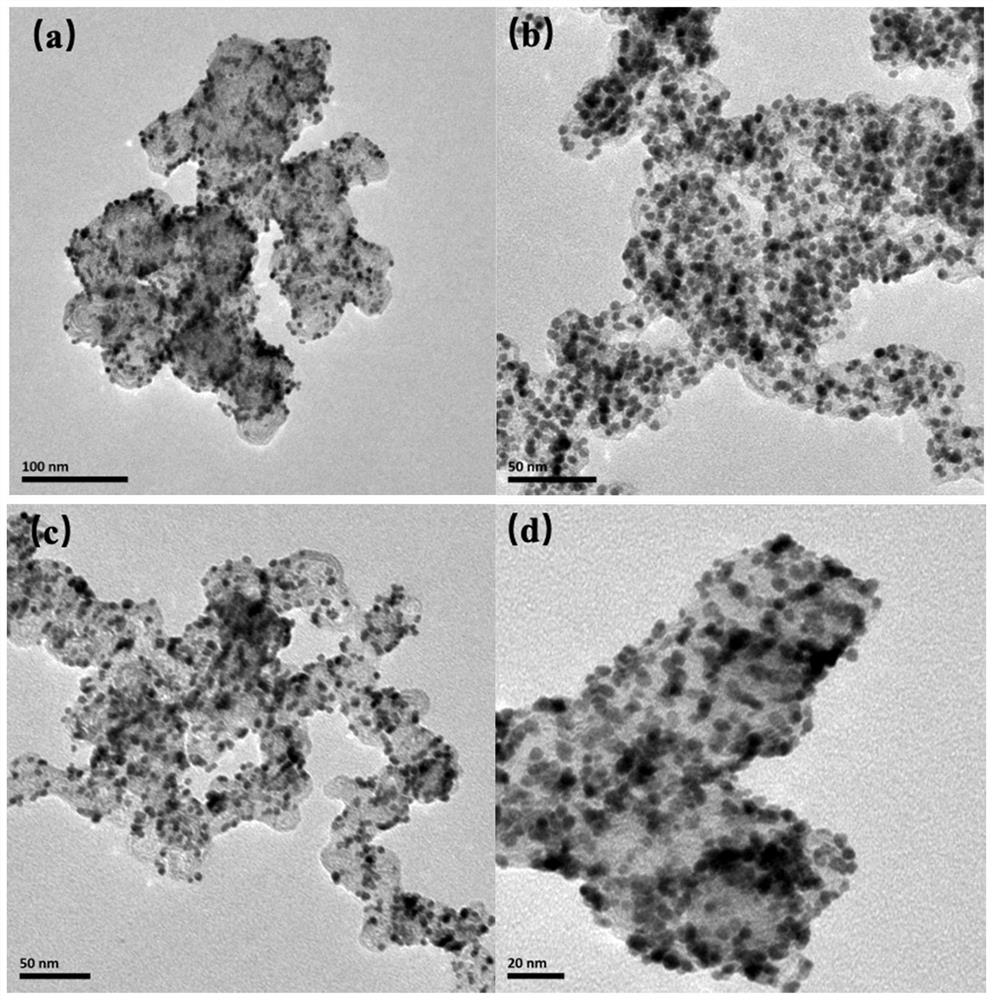

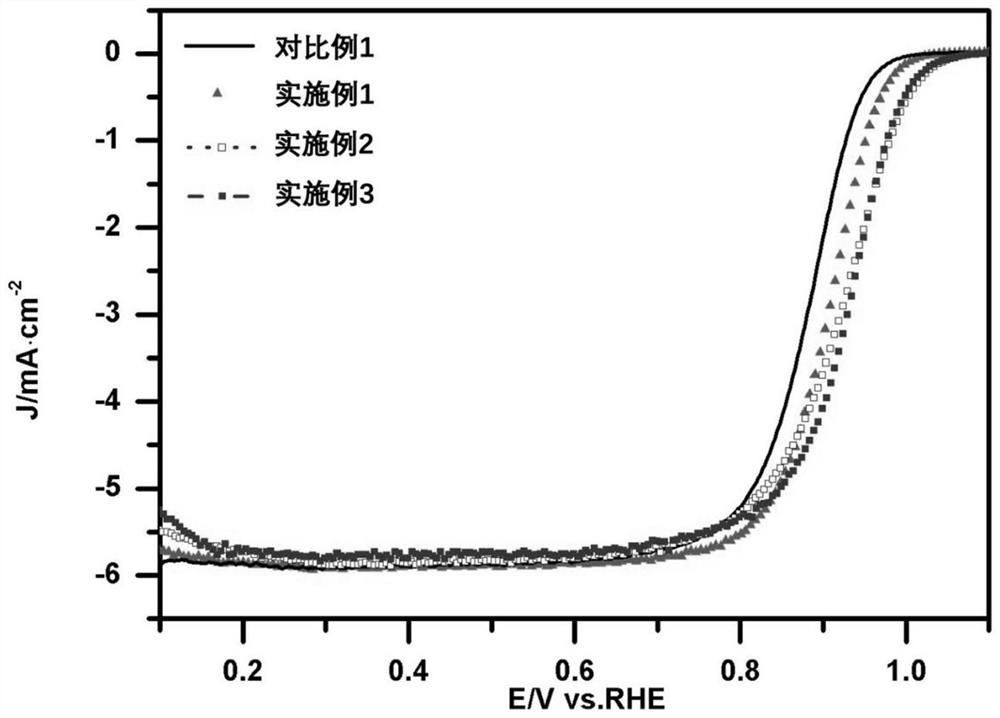

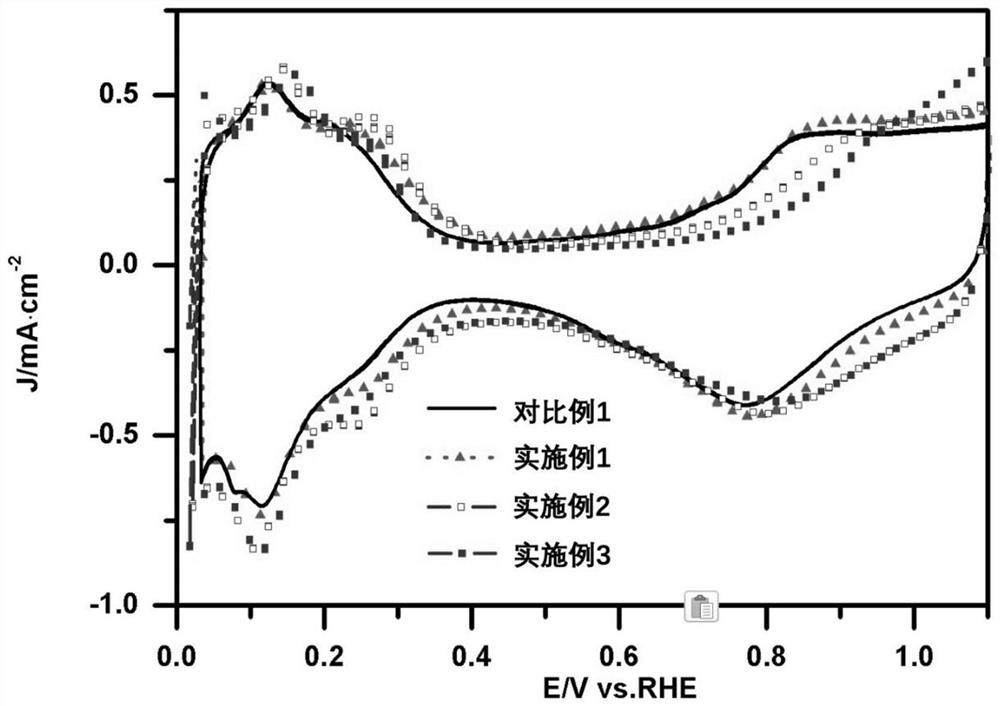

A precious metal alloy core-shell catalyst prepared by using an organic reducing agent and its preparation method

ActiveCN110586090BHigh activityImprove stabilityMaterial nanotechnologyCell electrodesPtru catalystFuel cells

The invention belongs to the technical field of fuel cells and electrochemical catalysis, and in particular relates to a high-performance ultrafine low-Pt core-shell catalyst prepared by an organic reduction method and a preparation method thereof. The invention provides a noble metal alloy core-shell catalyst, which has a carbon atomic percentage of 90-96 at.%, an O element atomic percentage of 2-7% at.%, a surface Pt loading of 0.1-2 at.%, and a metal particle size of 0.5-5nm. . The invention prepares a low-platinum-shell-core alloy catalyst by controlling the reduction of organic carboxyl and hydroxyl reducing agents, and exhibits excellent oxygen reduction activity and electrocatalytic performance under acidic conditions.

Owner:TSINGHUA UNIV

Preparation method of high-activity Pt/C catalyst

PendingCN114843532ANo pollution in the processImprove protectionCell electrodesPtru catalystOrganic solvent

The invention provides a high-activity Pt / C catalyst preparation method, which comprises: (1) dissolving a metal oxide precursor in an organic solvent, adding a carbon carrier, uniformly mixing, evaporating the solvent, drying, grinding into powder, and sintering to obtain a carbon-loaded metal oxide; (2) uniformly mixing the carbon-loaded metal oxide obtained in the step (1) with an alcohol solution to obtain a mixed solution; (3) dropwise adding an alcoholic solution of a water-soluble platinum salt, and uniformly mixing; and (4) after dropwise adding is completed, continuously heating and keeping for 10-60 minutes, cooling to normal temperature, separating, washing and drying to obtain the high-activity Pt / C catalyst. The Pt / C catalyst is synthesized under the assistance of the metal oxide, the operation is simple, the synthesis time is short, and the production efficiency is improved; alcohol is adopted as a solvent for reduction, the reduction temperature is low, and environment friendliness is achieved; the catalyst is washed by using a mixed solution of a volatile organic solvent and deionized water, so that the drying temperature is reduced, the drying time is shortened, and the stability of the catalyst is favorably improved.

Owner:TAN KAH KEE INNOVATION LAB +1

Proton exchange membrane fuel cell cathode non-platinum catalyst and preparation method thereof

InactiveCN102916203BIncreased oxygen reduction activityHigh active specific surface areaCell electrodesMetal/metal-oxides/metal-hydroxide catalystsMelamine formaldehyde resinNon platinum

Owner:WUHAN UNIV OF TECH

A high density fe-n 4 Preparation method and application of active site oxygen reduction electrocatalyst

ActiveCN112397734BWith transmissionImprove conductivityCell electrodesSolid electrolyte fuel cellsReduction ActivityPtru catalyst

The present invention provides a high-density Fe-N 4 The invention discloses a preparation method and application of an active site oxygen reduction electrocatalyst, belonging to the field of polymer electrolyte membrane fuel cell catalysts. The metal zirconium salt is evenly dispersed in the solvent, wherein, Zr in the zirconium salt 4+ The concentration in the solvent is 2-8mg / ml, add two kinds of macrocyclic compounds including macrocyclic compound Ⅰ, metal macrocyclic compound Ⅱ and organic acid, under the condition of 20-40℃, ultrasonic treatment for 10-30min, at 120℃ React for 8-12 hours, filter with suction, wash until the filtrate is colorless, dry, and pyrolyze at 600-900°C for 1-2 hours to obtain high-density Fe-N 4 Active-site oxygen reduction electrocatalysts. The invention is simple to operate, easy to control, and environmentally friendly, and the prepared high-density Fe-N 4 Active-site oxygen-reducing electrocatalysts with excellent oxygen-reduction activity can be used in polymer electrolyte membrane fuel cells.

Owner:DALIAN UNIV OF TECH

Preparation method of non-noble metal oxygen reduction catalyst

PendingCN114678542AAdjustableImprovement activity is not highCell electrodesPtru catalystPotassium hydroxide

The preparation method comprises the following steps: (1) adding a pyridine ring nitrogen-containing transition metal ligand into a solution, stirring until the pyridine ring nitrogen-containing transition metal ligand is completely dissolved, adding a diamino heterocyclic compound until the diamino heterocyclic compound is completely dissolved, and adding a metal salt solution into the previous solution for polymerization reaction; (2) adding sodium chloride metal salt, mixing, ball-milling and drying; (3) introducing protective gas, heating, cooling, and carrying out first heat treatment; (4) acid pickling, suction filtration, water cleaning and drying, and (5) secondary heat treatment which is the same as the step (3) to obtain the non-noble metal oxygen reduction catalyst. The non-noble metal monatomic oxygen reduction catalyst prepared by the method disclosed by the invention has good oxygen reduction activity in 1.0 M potassium hydroxide, the peak potential is only 1.03 V, the half-wave point reaches 0.9 V in 3mA cm < 2 >, and the half-wave is 0.8 V in a 0.5 M sulfuric acid solution.

Owner:GUANGXI UNIV

Fuel cell and method for manufacturing same

ActiveUS10693147B2High activityExcellent oxygen reduction activityCell electrodesSolid electrolyte fuel cellsFuel cellsMechanical engineering

Owner:LG CHEM LTD

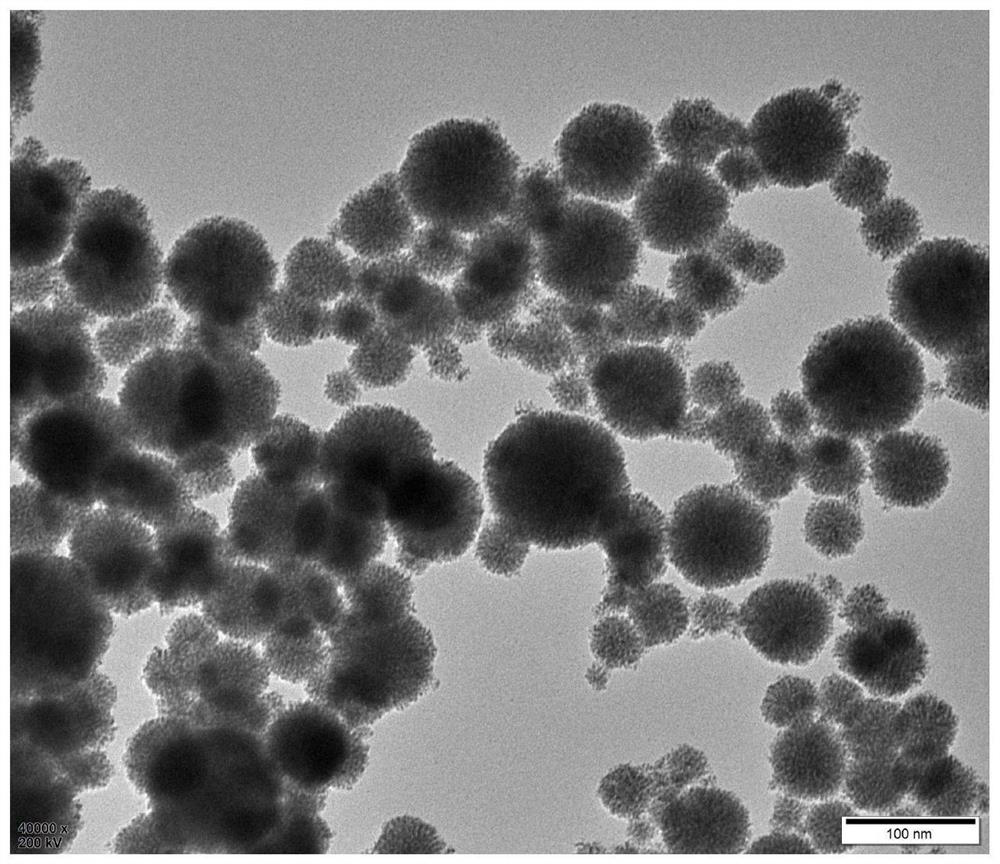

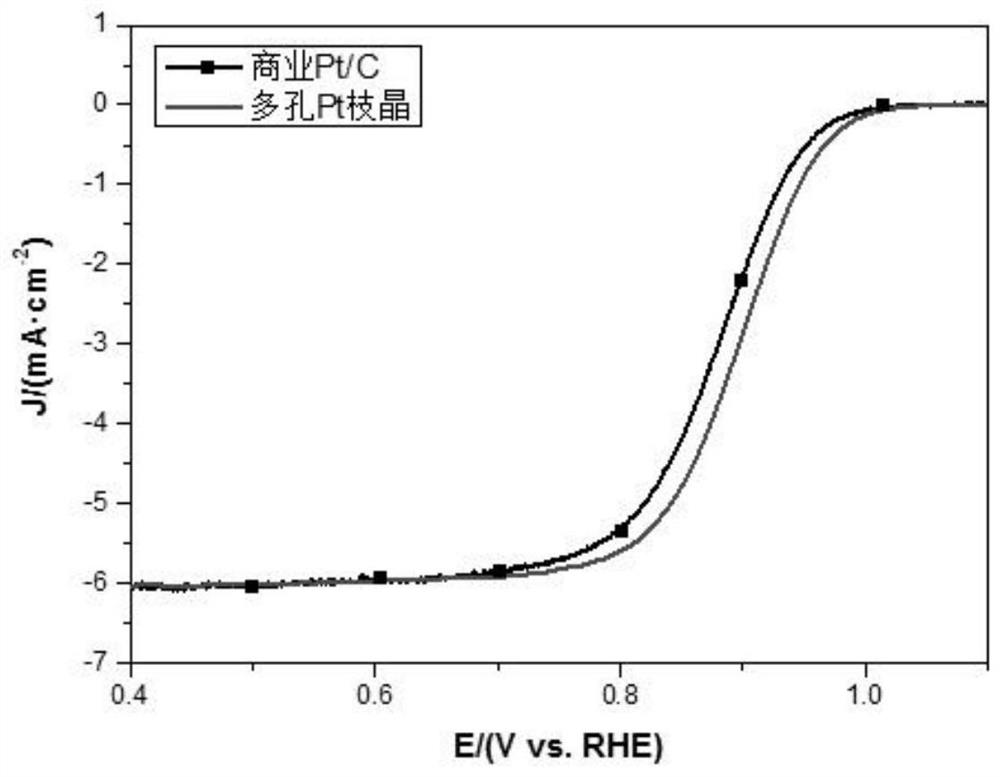

Porous platinum nano dendritic crystal electrocatalyst and preparation method thereof

PendingCN113839057AReduce energy consumptionEasy to operateMaterial nanotechnologyCell electrodesPtru catalystActive agent

The invention discloses a preparation method of a porous platinum nano dendritic crystal electrocatalyst, which comprises the following steps of weighing a certain mass of surfactant according to the molar ratio of the surfactant to a platinum compound of (0-100): 1, dissolving the surfactant in water, continuously dissolving the platinum compound in the water, and introducing protective gas until the mixed solution is saturated to obtain a precursor solution, and injecting a reducing agent into the precursor solution, reacting for at least 0.5 hour, centrifuging the product solution, and washing solids to obtain the porous platinum nano dendritic crystal electrocatalyst. The porous platinum nano dendritic crystal electrocatalyst is of a porous nanosphere structure, the particle size of nanospheres ranges from 5 nm to 300 nm, nanodendritic crystalsare woven into a three-dimensional network to form the porous nanospheres, the length of the nanodendritic crystal ranges from 3 nm to 15 nm, and the diameter ranges from 0.5 nm to 3 nm. The preparation method disclosed by the invention is simple and easy to implement, suitable for large-scale production, low in energy consumption, simple to operate and convenient in post-treatment. The porous platinum nano dendritic crystal electrocatalyst has high oxygen reduction performance, excellent catalytic activity and high stability.

Owner:SHANGHAI UNIV

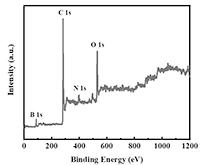

Method for degrading phenol by nitrogen-boron co-doped carbon-based microbial fuel cell cathode

PendingCN113121009AEasy to prepareLow costTreatment by combined electrochemical biological processesWater treatment compoundsEnvironmental chemistryCarbon source

The nitrogen-boron co-doped carbon-based catalyst (BNBC) is prepared by utilizing a two-step synthesis method and taking shaddock peel as a carbon source, melamine as a nitrogen source, boric acid as a boron source and CoCl2. 6H2O as a cocatalyst, and the nitrogen-boron co-doped carbon-based catalyst is used as a cathode catalyst of a microbial fuel cell (MFC). Through structural characterization and performance testing, the electricity generation performance of the BNBC cathode MFC and the degradation effect of the BNBC cathode MFC on phenol are obtained. The process comprises the following steps: 1, preparing a BNBC cathode catalyst; 2, preparing a BNBC cathode electrode; 3, assembling a single-chamber MFC reactor; and 4, operation of the MFC reactor and degradation of phenol. Results show that the BNBC cathode MFC has stable power output, and when the initial concentration of phenol is 200mg / L, the degradation rate of phenol wastewater can reach 98.2%, which indicates that the BNBC cathode MFC has an excellent degradation effect on phenol in wastewater while effectively generating electricity. The method is simple in preparation process, low in cost and environment-friendly, has very good degradation efficiency on phenol, and can effectively reduce energy consumption in the phenol wastewater treatment process.

Owner:HEILONGJIANG UNIV

Electrocatalyst for fuel cell and preparation method of electrocatalyst

ActiveCN113363508AExcellent oxygen reduction activitySuitable for large-scale commercial applicationsCell electrodesFuel cellsPtru catalyst

The invention provides an electrocatalyst for a fuel cell and a preparation method of the electrocatalyst. The electrocatalyst is prepared from the following raw materials in parts by mass: 1 part of folic acid and 3-7 parts of ferric trichloride. The preparation method comprises the steps of S1, mixing folic acid and ferric trichloride according to a mass ratio of 1: 3-1: 7; S2, annealing the mixture obtained in the step S1 for 6 hours; S3, washing a product obtained after annealing in the S2 is completed; and S4, drying the product washed in the step S3 to obtain the electrocatalyst. Folic acid is adopted as a main raw material, the carbon material electrocatalyst doped with a large amount of nitrogen elements is obtained through high-temperature pyrolysis, and the electrocatalyst is high in catalytic activity, low in cost, simple in process and suitable for commercial production.

Owner:JINGGANGSHAN UNIVERSITY

Method for preparing ferrate through electrolysis of non-noble metal catalyzed gas diffusion electrode

PendingCN111893502AExcellent oxygen reduction activityLow costCatalyst activation/preparationElectrodesGas diffusion electrodeNon noble metal

The invention relates to a method for preparing ferrate through electrolysis of a non-noble metal catalytic gas diffusion electrode. A Fe-N-C catalyst is prepared by a simple and cheap pyrolysis method, the catalyst has excellent oxygen reduction activity, the non-noble metal catalytic gas diffusion electrode is prepared from the Fe-N-C catalyst, the gas diffusion electrode does not contain noblemetal, and the cost is obviously reduced. The ferrate is prepared by taking the gas diffusion electrode as a cathode, iron as an anode and a concentrated alkaline solution as an electrolyte through electrolysis. When the method is used for producing ferrate through electrolysis, the cell voltage is reduced to 39.56%-54.12% of the cell voltage of an electrolysis method without adopting a gas diffusion electrode, the unit consumption of electric energy is reduced to 31.96%-56.67%, and a remarkable energy-saving effect is achieved.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com