Preparation method of bifunctional atom dispersion iron-nitrogen coordination material catalyst

A technology of atomic dispersion and catalyst, applied in the field of electrocatalysis, can solve the problems of low electrocatalytic current density, unsuitable for large-scale production, and few active sites, and achieve high catalytic efficiency, convenient large-scale production, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A method for preparing a bifunctional atom-dispersed iron-nitrogen coordination material catalyst, the specific steps are as follows:

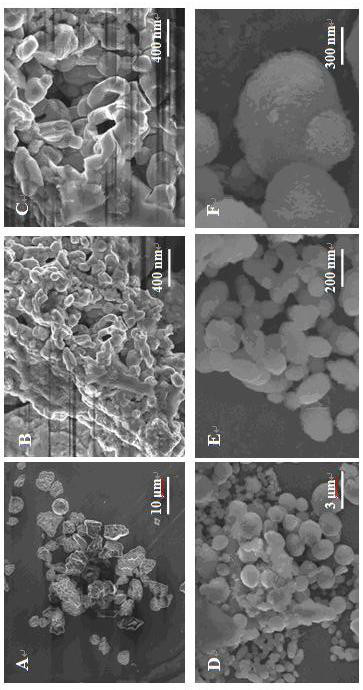

[0023] The first step is to prepare metal skeleton compound ZIF-8 nanoparticles; at room temperature, Zn(NO 3 ) 2 ·6H 2 O and 2-methylimidazole were dissolved in methanol, stirred, centrifuged and washed to obtain ZIF-8 nanoparticles.

[0024] The second step is to disperse ZIF-8 nanoparticles in the isopropanol solution of ferric chloride, ultrasonically make it adsorbed evenly, and after a period of magnetic stirring, then centrifugally dry to obtain the catalyst precursor; ZIF-8 nanoparticles take 100 mg , FeCl 3 Take 5 mg, 10 mL of isopropanol, ultrasonic for 2 h, magnetically stirred for 2 h, and dry in a vacuum oven at 60 °C for 5 h.

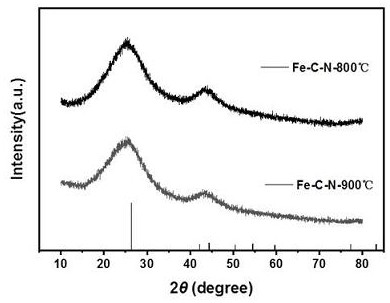

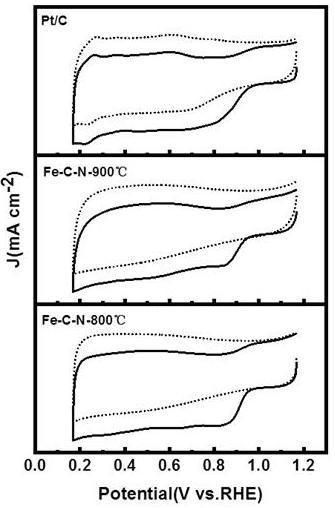

[0025] In the third step, the catalyst precursor was carbonized at high temperature in a nitrogen atmosphere to obtain the final Fe-N-C catalyst; the heating temperature was 800-900 °C for 2 h, ...

Embodiment 1

[0028] The preparation of the bifunctional atom-dispersed iron-nitrogen coordination material catalyst of the present invention, the specific steps are as follows:

[0029] In the first step, 2.4 g of zinc nitrate hexahydrate and 4.7 g of 2-methylimidazole were dissolved in 100 mL of methanol respectively, and the two were mixed and ultrasonicated for 10 min, then magnetically stirred at room temperature for 12 h;

[0030] In the second step, the final product of the first step was centrifuged at 10,000 r / min for 5 min, washed three times with ethanol, and dried in a vacuum oven at 60°C for 5 h to obtain ZIF-8 nanoparticles.

[0031] The third step is to disperse 100 mg ZIF-8 nanoparticles in 5 mg ferric chloride in isopropanol solution, take 10 mL of isopropanol solution, ultrasonicate for 2 h to make it evenly adsorbed; magnetically stir for 2 h, and centrifugally dry , to obtain the catalyst precursor.

[0032] In the fourth step, the catalyst precursors were heated in a n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com