Method for preparing ferrate through electrolysis of non-noble metal catalyzed gas diffusion electrode

A gas diffusion electrode, non-precious metal technology, applied in the field of electrochemistry, can solve the problems of the non-precious metal catalyzed gas diffusion electrode's poor catalytic performance and few commercial applications, and achieve excellent oxygen reduction activity, cost reduction, and cell voltage reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] 1. Preparation of Fe-N-C catalyst

[0046] 1. Add 1 g of dicyandiamide to 20 ml of deionized water and stir at 80°C until completely dissolved;

[0047] 2. Add 0.1 g anhydrous FeCl 3 , stirred until dissolved;

[0048] 3. Add 0.1 g of carbon black, stir for 4 h, dry and grind to make a precursor;

[0049] 4. The precursor was calcined at 550°C for 3h in an argon atmosphere, then heated at 750°C for 1h, cooled to room temperature with the furnace, and ground to obtain the Fe-N-C catalyst.

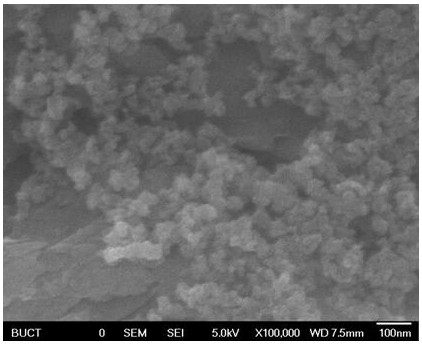

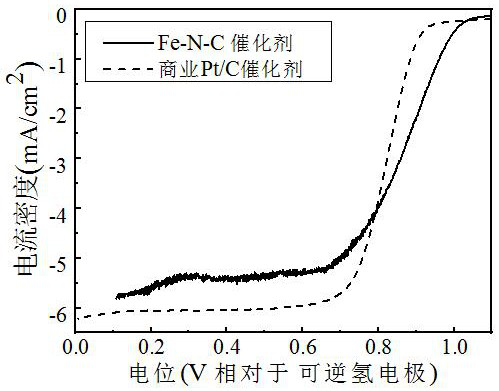

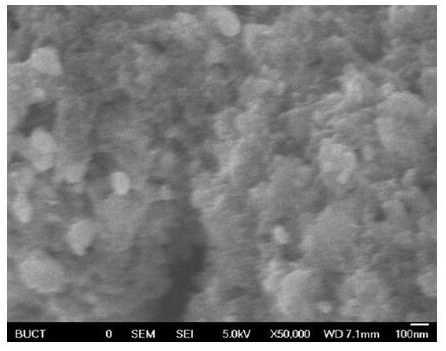

[0050] The scanning electron micrographs of the prepared Fe-N-C catalyst are as follows: figure 1 As shown, the catalysts are uniform nanoparticles. Using Shanghai Chenhua CH660 electrochemical workstation, in the KOH solution with an oxygen saturation concentration of 0.1 mol / L, the linear sweep voltammetry curve of the Fe-N-C catalyst was tested, and the commercial Pt containing 20 wt% Pt was tested under the same conditions / C catalyst linear sweep voltammetry curve, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com