Porous platinum nano dendritic crystal electrocatalyst and preparation method thereof

An electrocatalyst, platinum nanotechnology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of high price and unenvironmental protection of organic solvents, and achieve low cost and simple method. , the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A preparation method of porous platinum nano dendrite electrocatalyst, comprising the following steps:

[0046] According to the ratio of surfactant cetyltrimethylammonium bromide and chloroplatinic acid molar ratio of 24:1, take a certain mass of cetyltrimethylammonium bromide and dissolve it in water, and then continue to dissolve chlorine Platinic acid, to obtain the precursor solution, seal the precursor solution for use; then inject a sufficient amount of ascorbic acid into the precursor solution under the air atmosphere until the mixture is saturated, and react for 4 hours; centrifuge, wash, and Vulcan XC- 72R conductive carbon black was composited to obtain carbon-supported porous platinum nanodendritic electrocatalysts.

[0047] Test Characterization and Analysis:

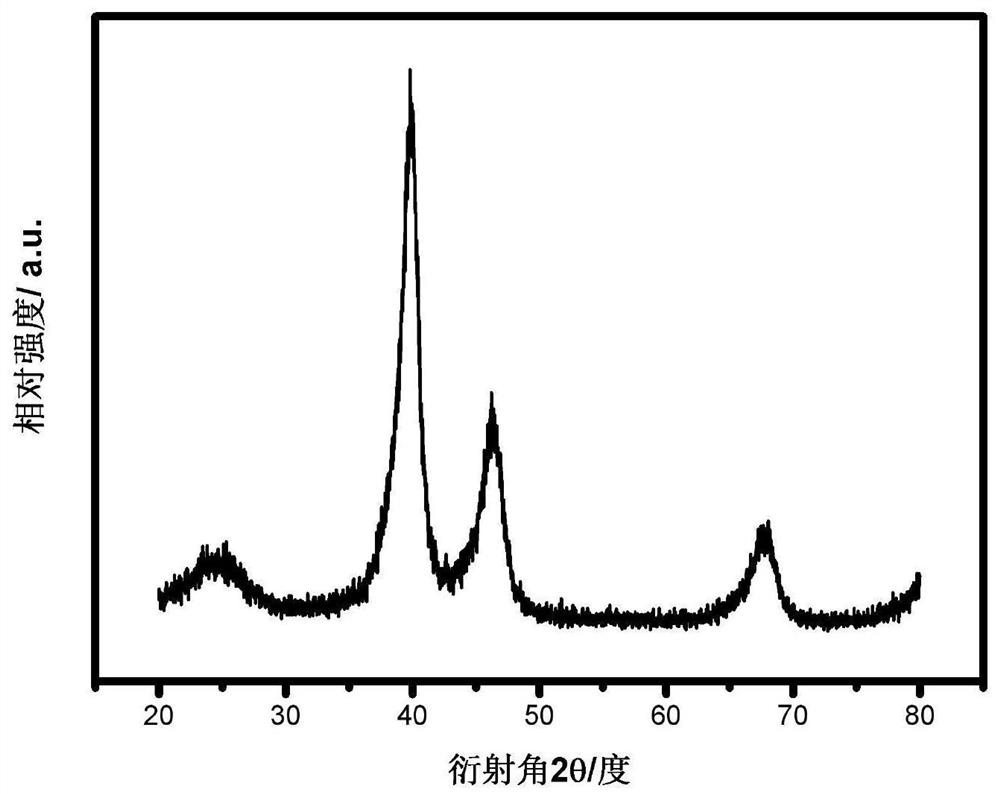

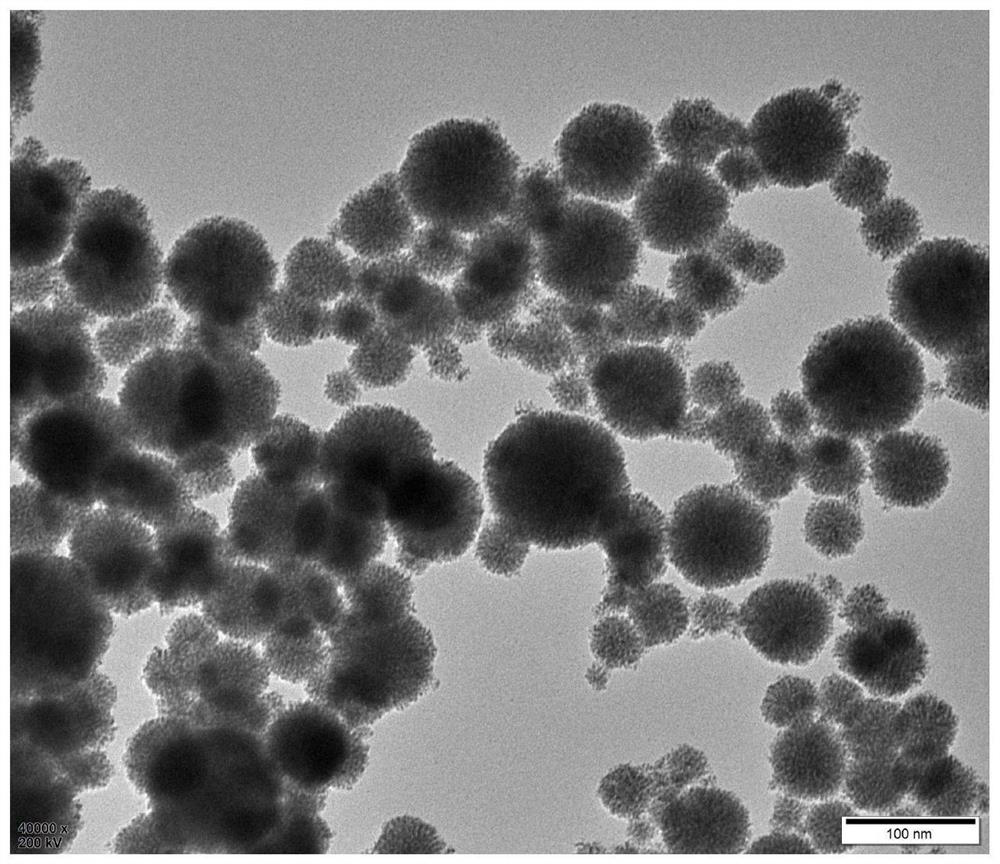

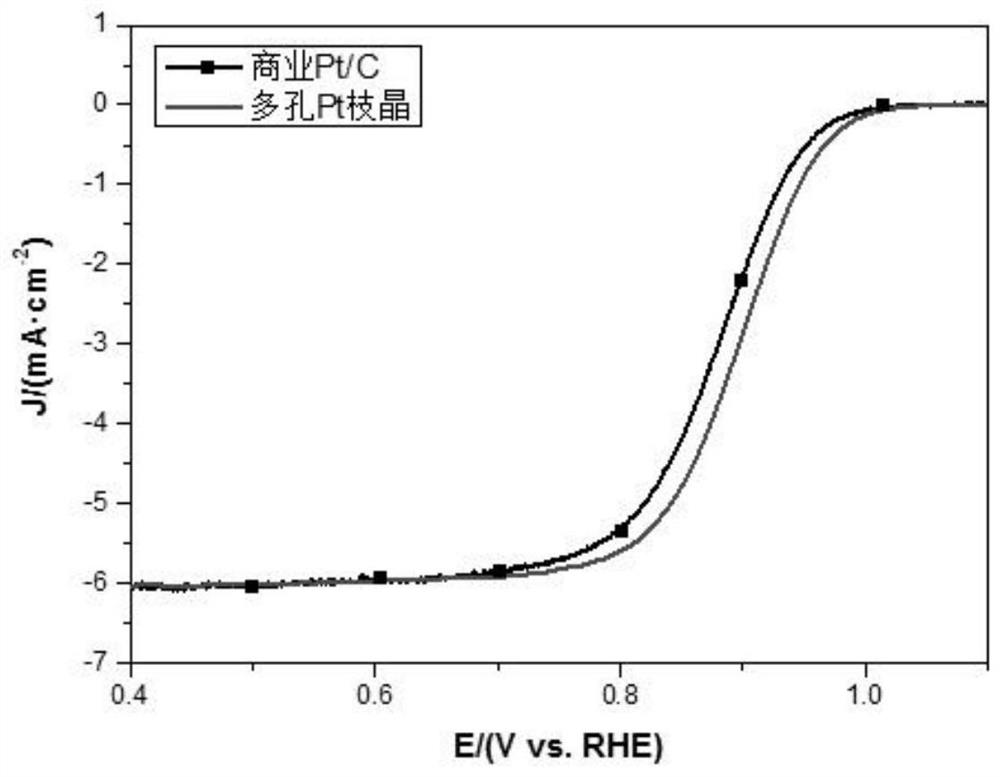

[0048] like figure 1 As shown, the XRD test curve shows that the porous platinum nanodendritic electrocatalyst of this example exhibits typical platinum metal characteristic peaks. TEM results such ...

Embodiment 2

[0054] This embodiment is basically the same as Embodiment 1, especially in that:

[0055] In this embodiment, a method for preparing a porous platinum nano-dendritic electrocatalyst uses an anionic surfactant to prepare a porous platinum nano-dendritic electrocatalyst, comprising the following steps:

[0056] According to the ratio of sodium dodecylbenzenesulfonate to chloroplatinic acid molar ratio of 24:1, weigh a certain mass of sodium dodecylbenzenesulfonate and dissolve it in water, and then continue to dissolve chloroplatinic acid to obtain a precursor solution , seal the precursor solution for use; then inject a sufficient amount of ascorbic acid into the precursor solution in an air atmosphere until the mixture is saturated, and react for 4 hours; centrifuge, wash, and compound with Vulcan XC-72R conductive carbon black to obtain carbon Supported porous platinum nanodendritic electrocatalysts.

[0057] Test Characterization Pre-Analysis:

[0058] TEM results such as...

Embodiment 3

[0061] This embodiment is basically the same as the above-mentioned embodiment, especially in that:

[0062] In this embodiment, a method for preparing a porous platinum nanodendritic electrocatalyst comprises the following steps:

[0063] According to the ratio of F127 and chloroplatinic acid molar ratio of 24:1, weigh a certain mass of F127 and dissolve it in water, then continue to dissolve chloroplatinic acid to obtain a precursor solution, seal the precursor solution for use; Inject a sufficient amount of ascorbic acid into the precursor solution until the mixture is saturated, and react for 4 hours; centrifuge, wash, and compound with Vulcan XC-72R conductive carbon black to obtain a carbon-supported porous platinum nanodendritic electrocatalyst.

[0064] Test Characterization and Analysis:

[0065] TEM results such as Figure 7 As shown, it is a porous nanosphere structure with a particle size of about 40-70nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com