Preparation method of high-activity Pt/C catalyst

A high-activity, catalyst technology, applied in the field of nanomaterials, can solve the problems of long time, complex process, high cost, and achieve the effects of less solvent, simple operation method and short synthesis time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

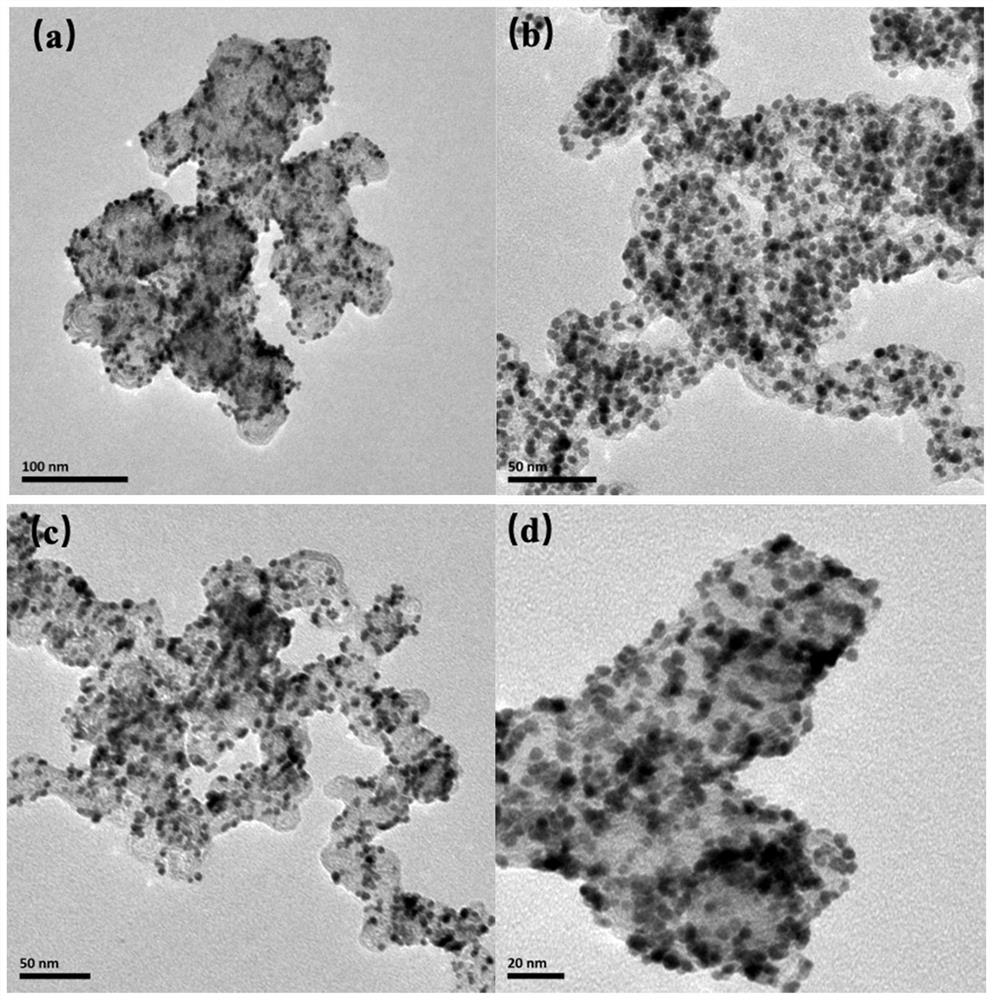

Image

Examples

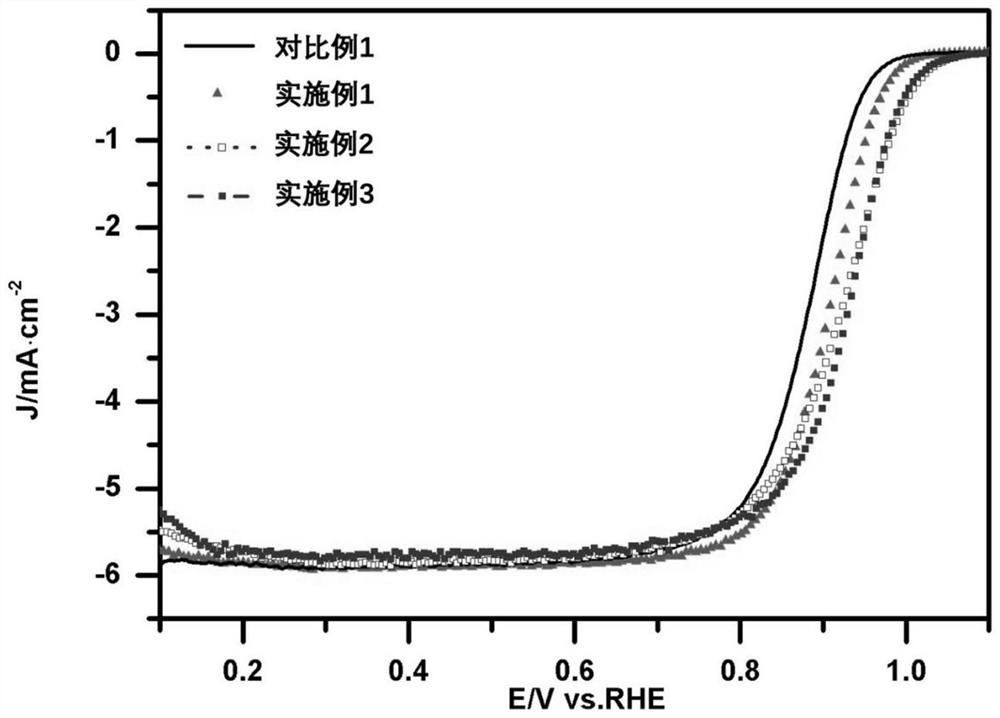

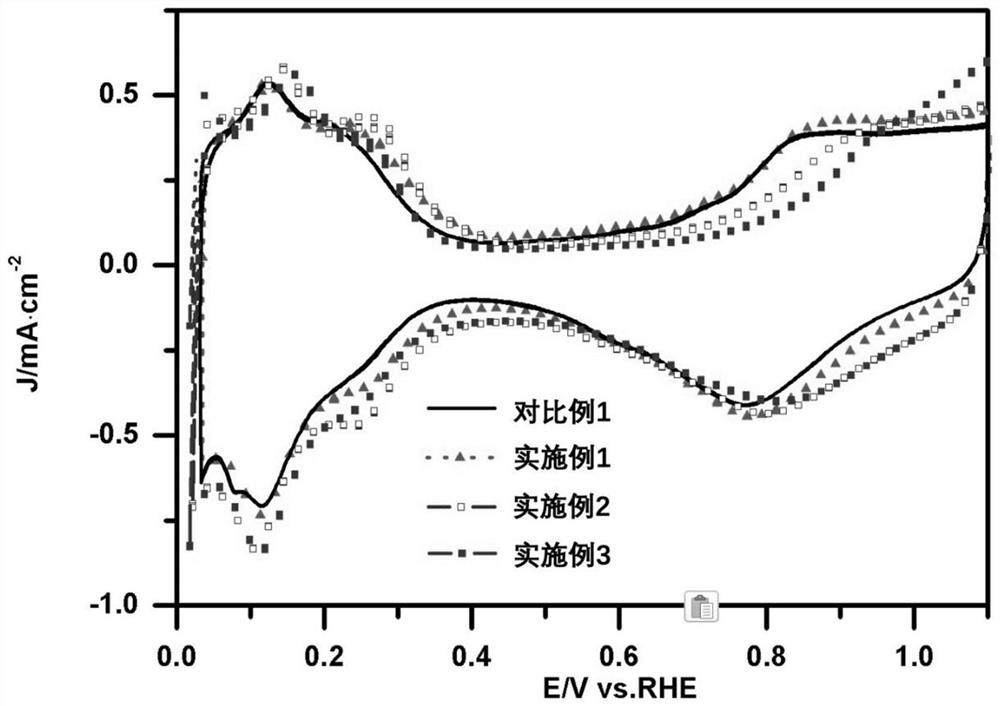

Embodiment 1

[0036] (1) 3.73g of magnesium sulfate was weighed and dissolved in 250mL of ethanol. After it was completely dissolved, 5g of Cabot's XC-72 carbon black was added. After stirring for 5h, the ethanol was evaporated at 80°C, dried and ground, and placed in a tube furnace. Sintering at 1000 °C for 0.5 h in a helium atmosphere to obtain a MgO / XC-72 carrier with a mass fraction of 20%;

[0037] (2) Weigh 0.1g of MgO / XC-72 carrier and 5mL of ethylene glycol solution in a 30mL glass bottle, and stir until the carrier is evenly dispersed in the solution;

[0038] (3) put the reaction system in (2) into the oil bath pot of 80 ℃ and heat and stir until the temperature is stable;

[0039] (4) adopt the syringe pump to slowly add the ethylene glycol solution of 2.6mL 0.02M chloroplatinic acid hexahydrate, dropwise in 3 minutes, and after the dropwise addition is completed, be incubated for 20min;

[0040] (5) after the reaction is cooled, wash with acetone and deionized water for many ti...

Embodiment 2

[0043] (1) Weigh 2.32g of aluminum nitrate and dissolve it in 400mL of ethanol. After it is completely dissolved, add 10g of Ketjen black (KB), stir for 6h, evaporate the ethanol at 100°C, dry and grind it, put it in a tube furnace under argon Sintering at 500 °C for 1 h in a gas atmosphere to obtain Al with a mass fraction of 10% 2 O 3 / KB vector;

[0044] (2) Weigh 1g Al 2 O 3 / KB carrier, 100mL ethylene glycol and isopropanol mixed solution solution in a 250mL glass bottle, stir until the carrier is evenly dispersed in the solution;

[0045] (3) put the reaction system in (2) into the oil bath pot of 120 DEG C and heat and stir until the temperature is stable;

[0046](4) adopt syringe pump to slowly add the mixed solution of ethylene glycol and isopropanol of the tetraammine platinum nitrate of 68.3mL 0.04M, drip in 3 minutes and complete, after dripping is completed, be incubated 20min;

[0047] (5) after the reaction is cooled, wash with acetone and deionized water ...

Embodiment 3

[0050] (1) Weigh 0.524g of calcium acetate monohydrate and dissolve it in 60mL of propanol. After it is completely dissolved, add 1g of Ketjen Black (KB), stir for 6h, evaporate the propanol at 90°C, dry and grind it, and put it in a tube In the furnace under nitrogen atmosphere at 400 ℃, sintered for 1 h to obtain a CaO / KB carrier with a mass fraction of 15%;

[0051] (2) Weigh 0.25g CaO / KB carrier and 8mL isopropanol solution in a 30mL glass bottle, and stir until the carrier is evenly dispersed in the solution;

[0052] (3) put the reaction system in (2) into the oil bath pot of 100 ℃ and heat and stir until the temperature is stable;

[0053] (4) adopt the constant pressure funnel to slowly add the isopropanol solution of 6.83mL 0.1M platinum tetrachloride, complete dropwise addition in 10 minutes, after the dropwise addition is completed, keep warm for 30min;

[0054] (5) after the reaction is cooled, wash with ethanol and deionized water for many times, and finally chec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com