Preparation method of iron-based triazine ring polymer catalyst

A technology of iron-based triazine rings and polymers, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of unsatisfactory zinc metal active sites and difficult removal, etc., to achieve Good oxygen reduction stability, activity enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

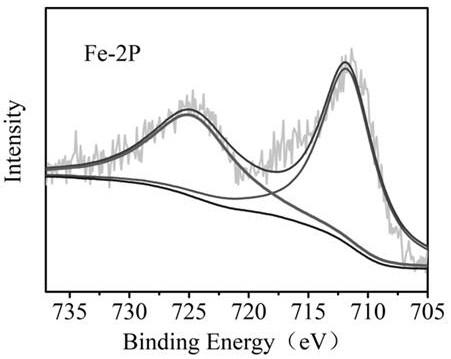

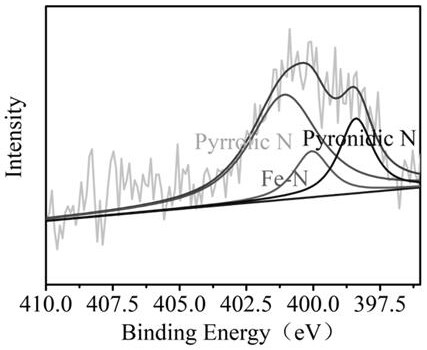

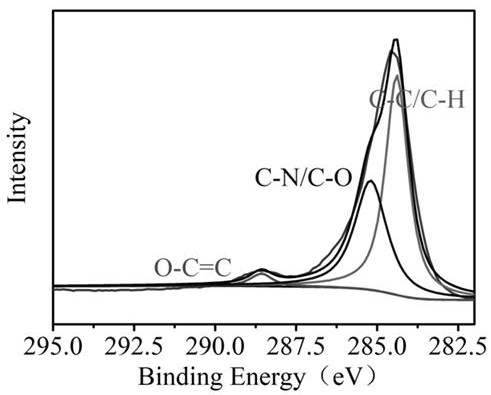

[0020] After mixing 0.391g of 1,4-terephthalonitrile, 2.43g of anhydrous ferric chloride, and 0.09g of conductive carbon black (super-p), they were thoroughly ground in a glove box, and then transferred to an ampoule tube for vacuum packaging, Place the packaged mixture in a muffle furnace to raise the temperature to 300°C at 5°C / min and keep it warm for 20 hours, then take out the reactant and grind it thoroughly, then transfer it to a tube furnace, and raise the temperature at 5°C / min under a nitrogen atmosphere to 900°C and keep it warm for 2h, and finally the reactant was pickled with 0.5mol / L hydrochloric acid at 60°C for 6h, washed and dried with deionized water, then transferred to a tube furnace, and heated at 5°C / min under a nitrogen atmosphere. Raise the temperature to 900°C and keep it warm for 2 hours to prepare an iron-based triazine ring polymer catalyst;

[0021] Simultaneously, anhydrous zinc chloride is used as raw material to prepare zinc-based triazine ring ...

Embodiment 2

[0028] After mixing 0.534g of 1,2,4,5-pyromene tetracarbonitrile, 1.95g of anhydrous ferric chloride, and 0.09g of conductive carbon black (super-p), they were thoroughly ground in a glove box, and then transferred to ampoules Vacuum packaging, the packaged mixture is placed in a muffle furnace and heated to 300 °C at 5 °C / min and kept for 20 hours, then the reactants are taken out and fully ground, then transferred to a tube furnace, and heated at 5 °C under a nitrogen atmosphere. / min to 900°C and keep it warm for 2h. Finally, the reactant was pickled with 0.5mol / L hydrochloric acid at 60°C for 6h, washed and dried with deionized water, and then transferred to a tube furnace. °C / min, the temperature was raised to 900 °C and kept for 2 hours to prepare an iron-based triazine ring polymer catalyst;

[0029] Simultaneously, anhydrous zinc chloride is used as raw material to prepare zinc-based triazine ring polymer, and all the other processes are the same as above, as a contras...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| half wave potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com