A preparation method of a transition metal oxide nitrogen and phosphorus doped catalyst applied to a zinc-air battery

A transition metal, zinc-air battery technology, applied in the direction of fuel cell half-cells and primary battery half-cells, battery electrodes, circuits, etc., can solve the problems of expensive cathode catalysts and limited resources, and achieve benefits for large-scale The effects of large-scale development and utilization, simple preparation process, and excellent oxygen reduction activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

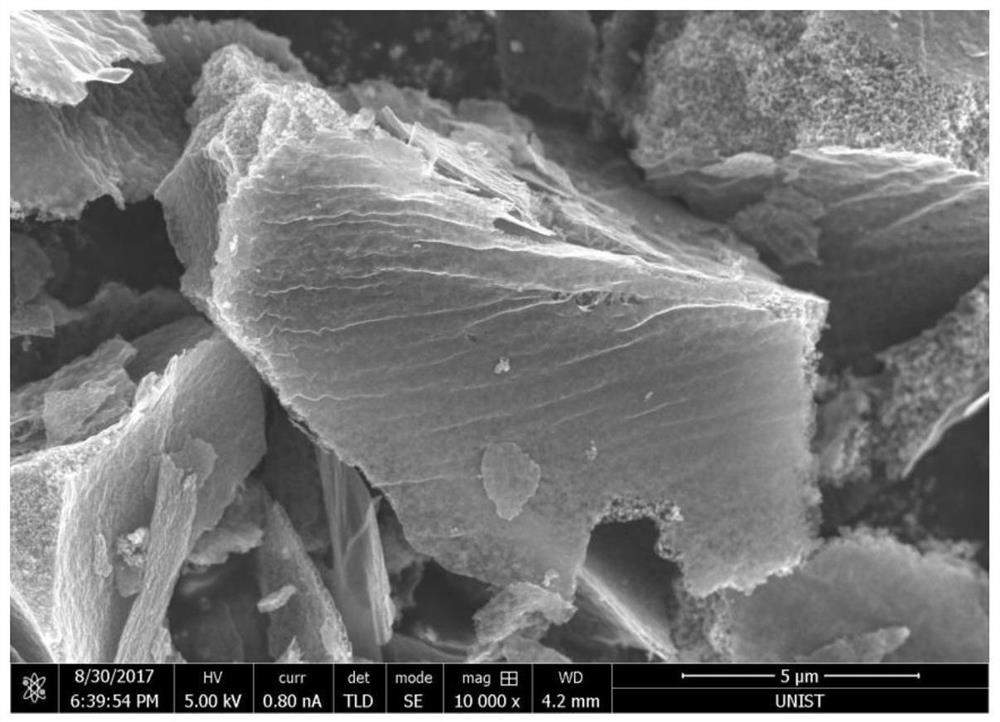

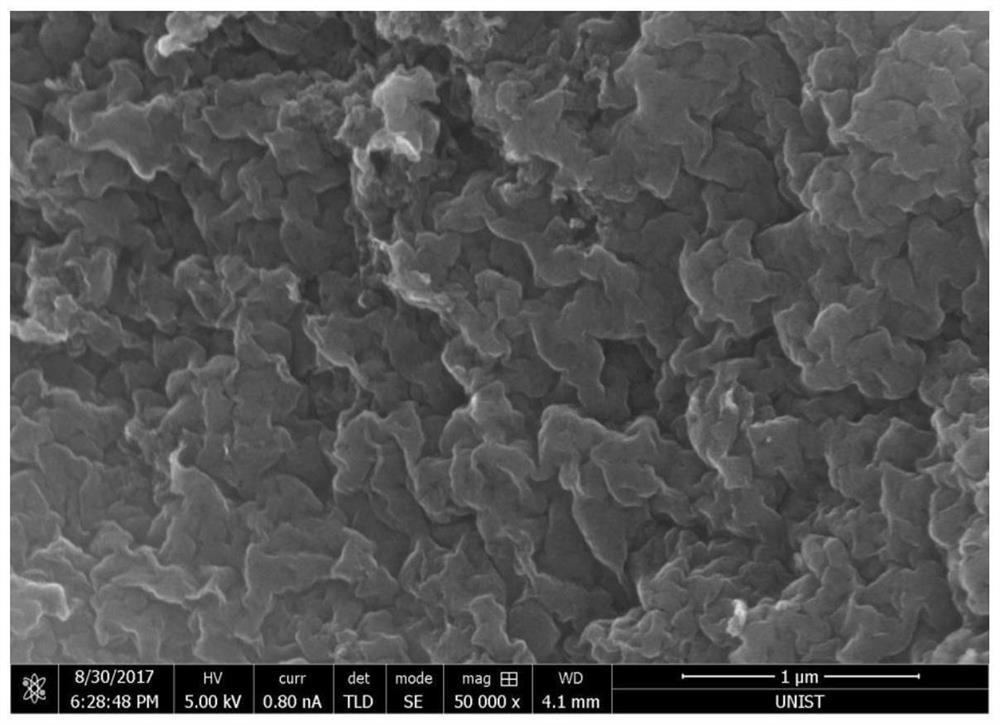

[0033] A method for preparing a transition metal oxide nitrogen and phosphorus doped catalyst applied to a zinc-air battery, specifically comprising the following steps:

[0034] The first step, at room temperature, add 0.25g manganese acetate to quantitative phytic acid and ultrasonically for 20min to dissolve all the metal salts; then add excess acetone to the solution to produce supramolecular compound precipitation, finally pour out the solvent, and wash the supramolecular compound repeatedly with acetone Compound 3 times. In the second step, the supramolecular compound obtained in the first step was transferred to the porcelain boat of the tube furnace, and the temperature was raised to 800°C at a rate of 5°C / min under an argon atmosphere, and then kept at a constant temperature for 2 hours, and finally Cool to room temperature. In the third step, the sample obtained in the previous step is fully ground, transferred to a single-necked flask, added with excess 2M hydrochl...

Embodiment 2

[0036] A method for preparing a transition metal oxide nitrogen and phosphorus doped catalyst applied to a zinc-air battery, specifically comprising the following steps:

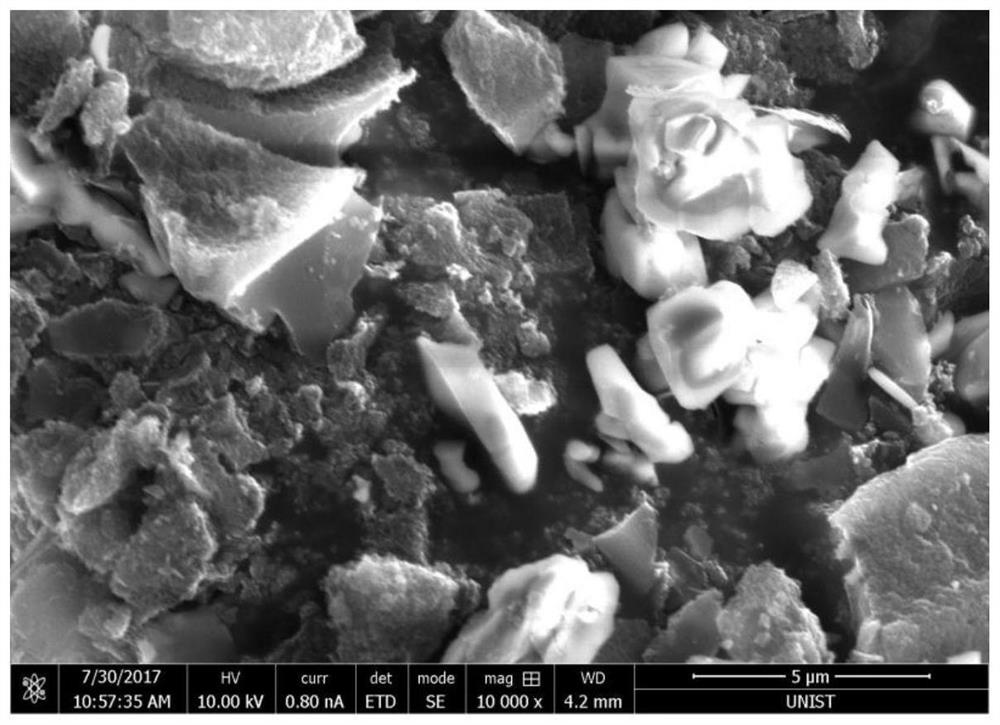

[0037] The first step is to add 0.25g of copper acetate to 2ml of phytic acid at room temperature and ultrasonically for 20 minutes to dissolve all the metal salts; then add excess acetone to the solution to produce supramolecular compound precipitation, and finally pour out the solvent and wash the supramolecular compound repeatedly with acetone Compound 3 times. In the second step, the supramolecular compound obtained in the first step was transferred to the porcelain boat of the tube furnace, and the temperature was raised to 800°C at a rate of 5°C / min under an argon atmosphere, and then kept at a constant temperature for 2 hours, and finally Cool to room temperature. The third step is to fully grind the sample obtained in the previous step, transfer it to a single-necked flask, add excess 2M hydrochlori...

Embodiment 3

[0039] A method for preparing a transition metal oxide nitrogen and phosphorus doped catalyst applied to a zinc-air battery, specifically comprising the following steps:

[0040]The first step is to add 0.25g of cobalt acetate to 2ml of phytic acid at room temperature and ultrasonically for 20 minutes to dissolve all metal salts; then add excess acetone to the solution to produce supramolecular compound precipitation, and finally pour out the solvent and wash the supramolecular compound repeatedly with acetone Compound 3 times. In the second step, the supramolecular compound obtained in the first step was transferred to the porcelain boat of the tube furnace, and the temperature was raised to 800°C at a rate of 5°C / min under an argon atmosphere, and then kept at a constant temperature for 2 hours, and finally Cool to room temperature. The third step is to fully grind the sample obtained in the previous step, transfer it to a single-necked flask, add excess 2m hydrochloric aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com