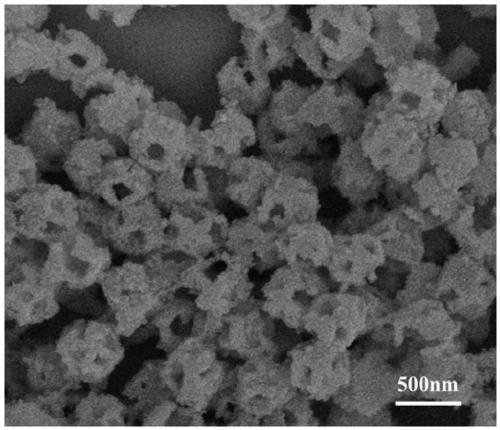

Noble metal supported nano frame catalyst and preparation method and application thereof

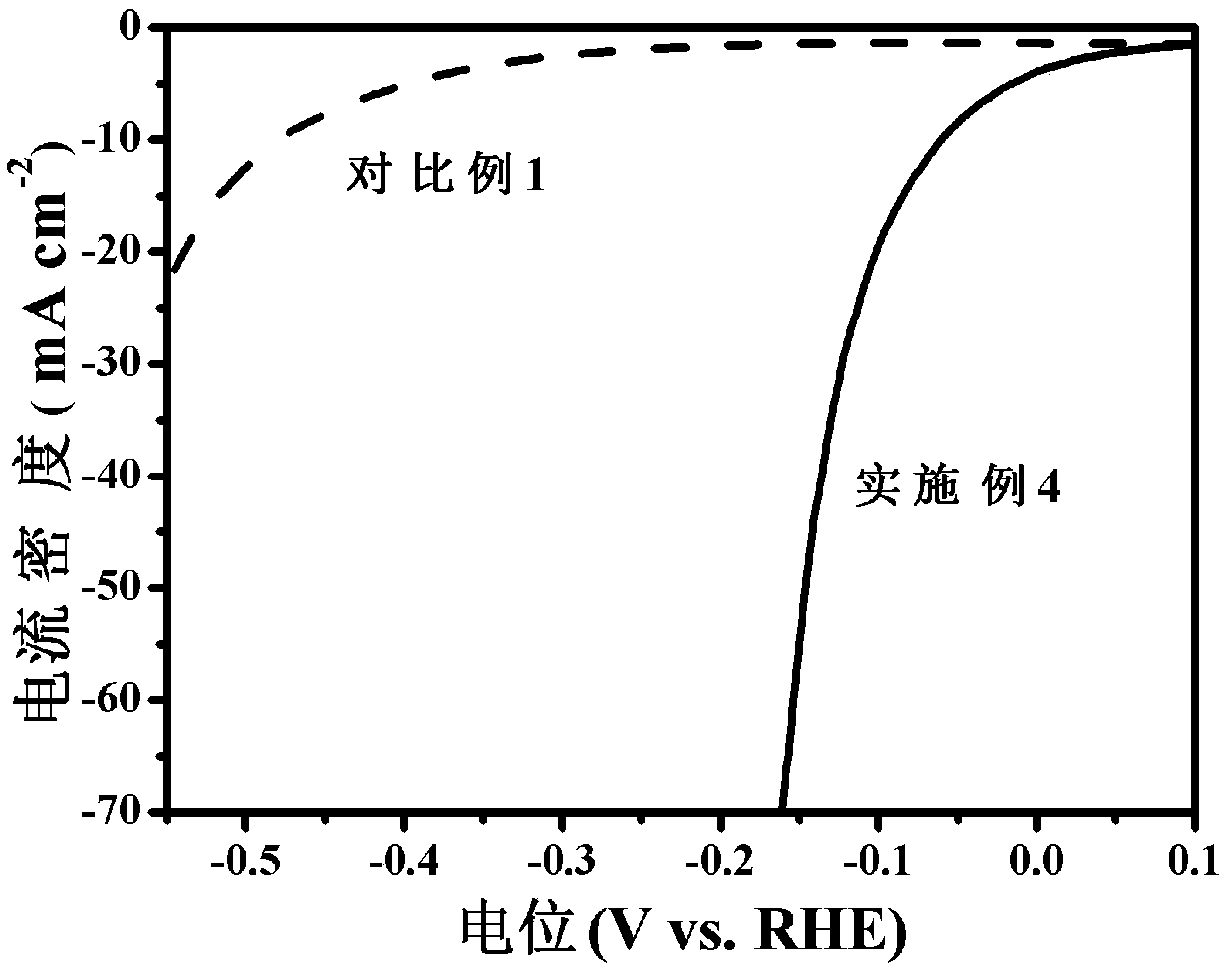

A catalyst and noble metal technology, applied in the field of noble metal-supported nickel-cobalt hydroxide nano-frame catalysts and their preparation, can solve the problems of many steps in the catalyst preparation process, difficulty in forming hollow cubes, shape changes, etc., and achieve large electroactivation surface area, The effect of improving electrocatalytic performance and reducing overpotential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] Its preparation method comprises the following steps:

[0077] (1) mixing cuprous oxide nanoframe dispersion liquid with nickel salt and cobalt salt to obtain mixed liquid;

[0078] (2) adding thiosulfate solution to the mixed solution obtained in step (1), reacting to obtain nickel-cobalt hydroxide;

[0079] (3) Mix the nickel-cobalt hydroxide solution obtained in step (2) with the noble metal salt, add a reducing agent, and react to obtain a noble metal-supported nano-frame catalyst.

Embodiment 1

[0082] This embodiment provides a method for preparing a cuprous oxide nanoframe, the method comprising the following steps:

[0083] (1) 0.35g copper sulfate, 1.25g potassium sodium tartrate and 0.225g potassium hydroxide are respectively added in water to obtain a mixed solution;

[0084] (2) Add 9.6 mg of palladium chloride and 0.450 g of glucose to the mixed solution obtained in step (a), stir evenly, react in a water bath at 75° C. for 3 h, centrifuge, wash and dry to obtain cuprous oxide nanoframes.

Embodiment 2

[0086] This embodiment provides a method for preparing a cuprous oxide nanoframe, the method comprising the following steps:

[0087] (1) 0.41g copper nitrate, 1.25g potassium sodium tartrate and 0.161g sodium hydroxide were added in water respectively to obtain a mixed solution;

[0088] (2) Add 20.5 mg of palladium chloride and 0.683 g of glucose to the mixed solution obtained in step (a), stir evenly, react in a water bath at 60° C. for 4 hours, centrifuge, wash and dry to obtain cuprous oxide nanoframes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com