An electrode system for electrochemical detection and its application

An electrode system and electrode technology, applied in the direction of electrochemical variables of materials, measuring devices, scientific instruments, etc., can solve the problems of high manufacturing cost of non-enzymatic electrodes, failure to meet actual detection requirements, and narrow detection range of sensors, and achieve good resistance. Interference ability and selectivity, wide detection concentration range, effect of wide detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

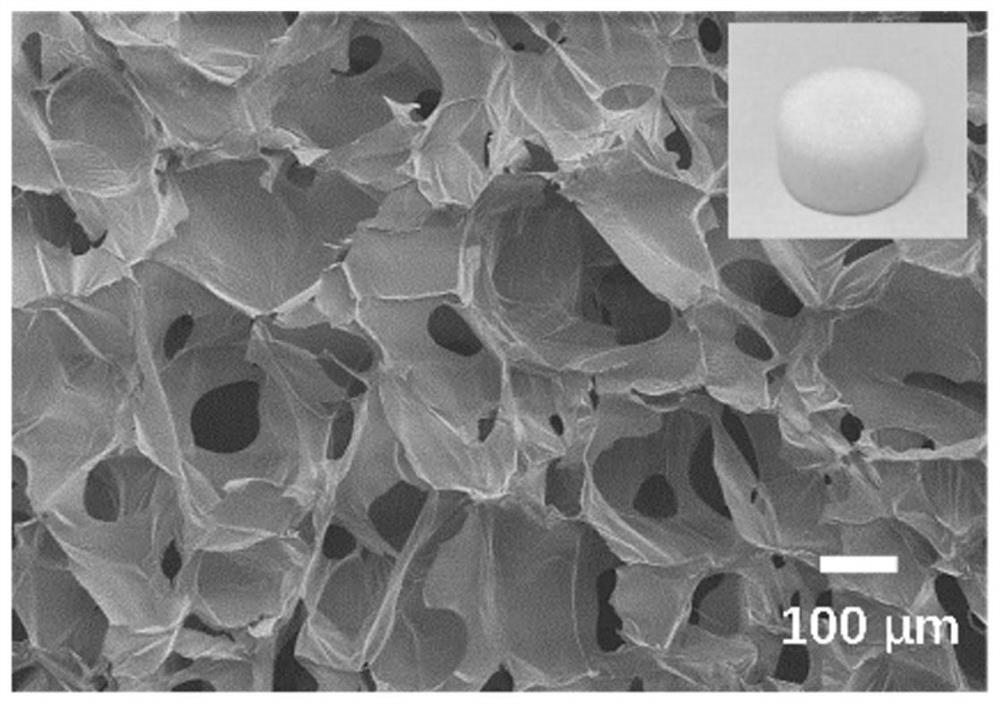

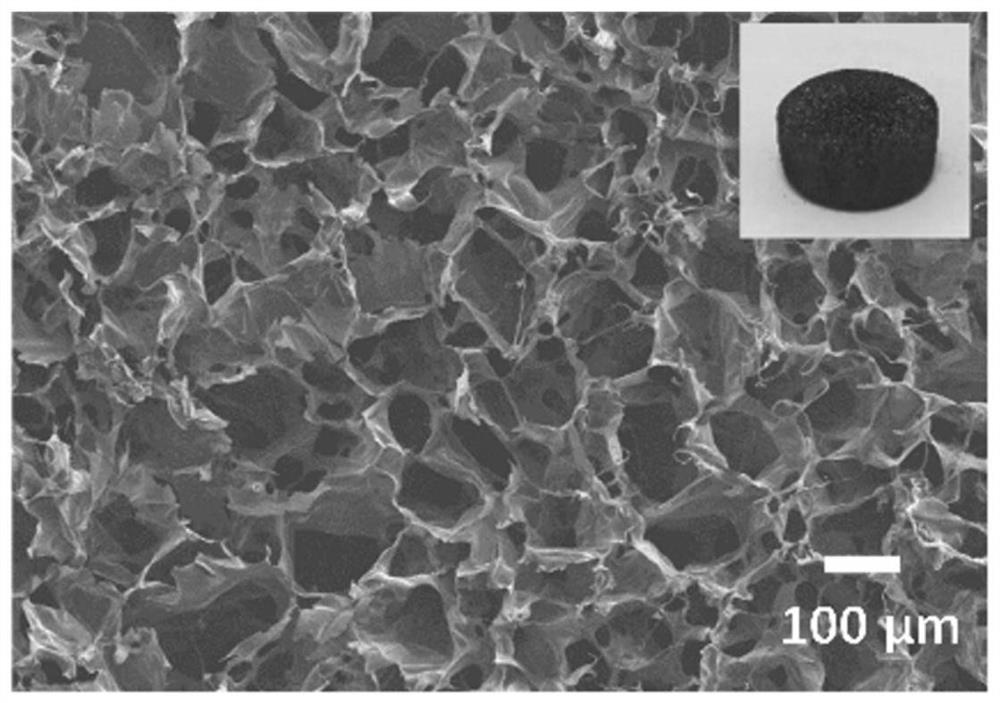

[0045] 1) Add chitosan powder in the acetic acid aqueous solution whose concentration is 0.3mol / L, prepare the chitosan-acetic acid solution that concentration is 10mg / mL. Pour this solution into a cylindrical glass beaker, freeze at -20°C for 24 hours, and dry it in a freeze dryer at -80°C to obtain a cylindrical chitosan foam and a shell prepared from chitosan-acetic acid solution. SEM images of glycan foam as figure 1 shown. The chitosan foam was placed in a tube furnace and calcined to 900°C at a heating rate of 5°C / min under an argon atmosphere and maintained for 2h. SEM images of chitosan-derived carbon foams prepared from chitosan-acetic acid solution as figure 2 shown.

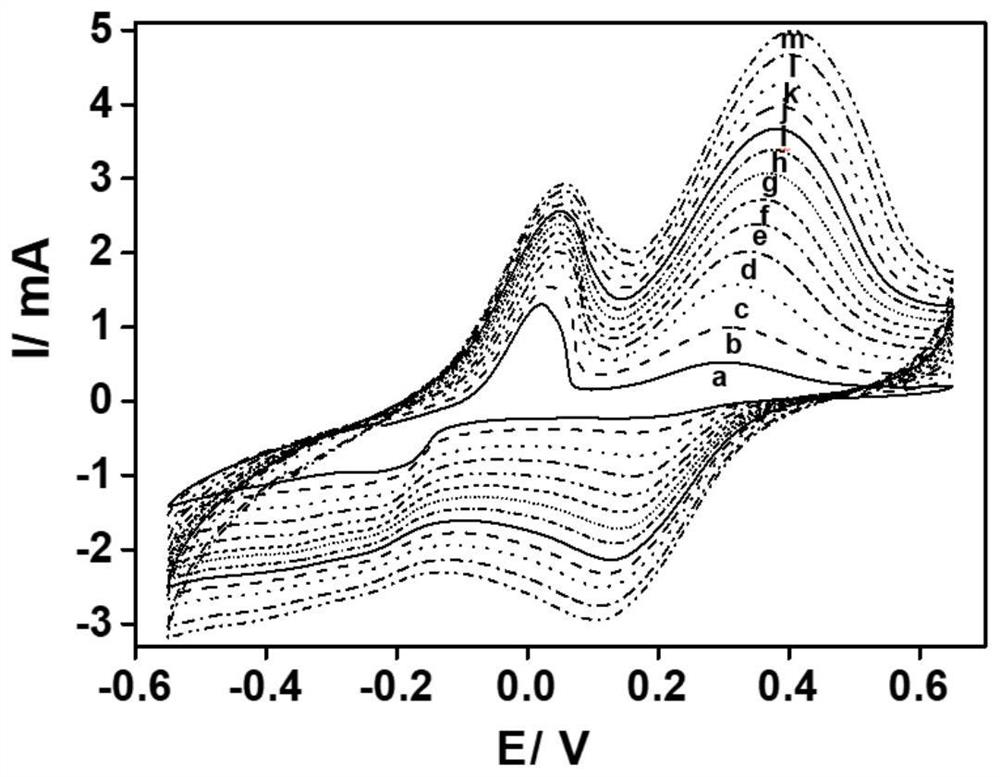

[0046] 2) The chitosan-derived porous carbon foam was cut into 1 mm circular slices, fixed on the gold sheet current collector with conductive carbon tape as the working electrode, the silver / silver chloride electrode was used as the reference electrode, and the platinum sheet electrode was used as...

Embodiment 2

[0057] 1) Add chitosan powder in the acetic acid aqueous solution whose concentration is 0.3mol / L, prepare the chitosan-acetic acid solution that concentration is 10mg / mL. Pour the solution into a cylindrical glass beaker, freeze at -20°C for 24 hours at a constant temperature, and dry in a freeze dryer at -80°C to obtain a cylindrical chitosan foam. The chitosan foam was placed in a tube furnace and calcined to 900°C at a heating rate of 5°C / min under an argon atmosphere and maintained for 2h.

[0058] 2) The chitosan-derived porous carbon foam was cut into 1 mm circular slices, fixed on the gold sheet current collector with conductive carbon tape as the working electrode, the silver / silver chloride electrode was used as the reference electrode, and the platinum sheet electrode was used as the counter electrode. electrodes to form a three-electrode system.

[0059] 3) Prepare 1.4mmol / L KH 2 PO 4 , 4.3mmol / L Na 2 HPO 4 , a mixed aqueous solution of 137mmol / L NaCl and 2.7m...

Embodiment 3

[0064] 1) Add chitosan powder in the acetic acid aqueous solution that concentration is 0.5mol / L, prepare the chitosan-acetic acid solution that concentration is 10mg / mL. Pour the solution into a cylindrical glass beaker, freeze at -20°C for 12 hours at a constant temperature, and dry in a freeze dryer at -80°C to obtain a cylindrical chitosan foam. The chitosan foam was placed in a tube furnace and calcined to 900°C at a heating rate of 10°C / min under an argon atmosphere and maintained for 3h.

[0065] 2) The chitosan-derived porous carbon foam was cut into 1 mm circular slices, fixed on the gold sheet current collector with conductive carbon tape as the working electrode, the silver / silver chloride electrode was used as the reference electrode, and the platinum sheet electrode was used as the counter electrode. electrodes to form a three-electrode system.

[0066] 3) Prepare 1.4mmol / L KH 2 PO 4 , 4.3mmol / L Na 2 HPO 4 , a mixed aqueous solution of 137mmol / L NaCl and 2.7m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com