Electrocatalyst for a fuel cell and the method of preparing thereof

A technology for electrode catalysts and fuel cells, applied in battery electrodes, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as poor durability, affecting performance, and affecting the efficiency of direct methanol fuel cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

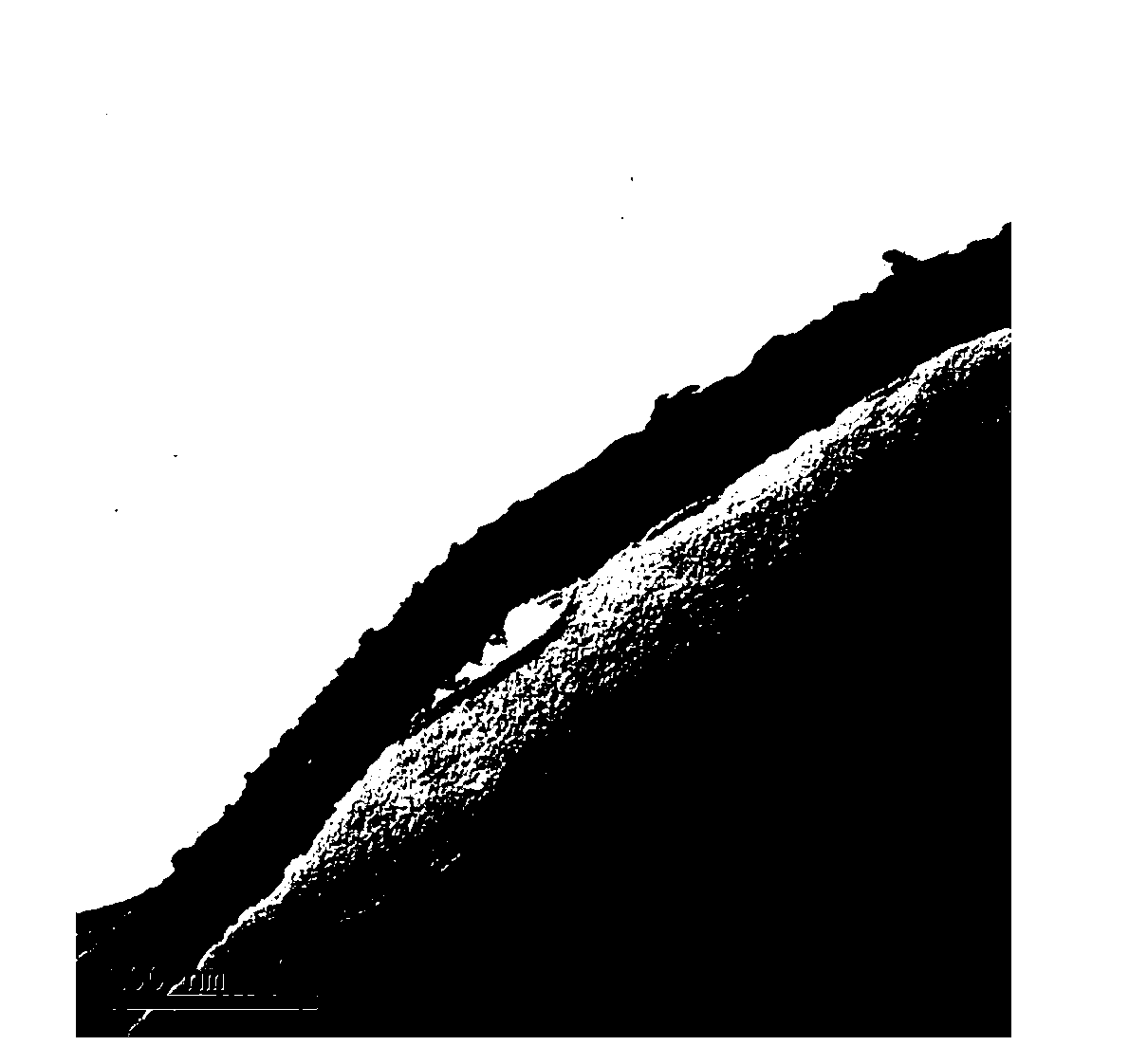

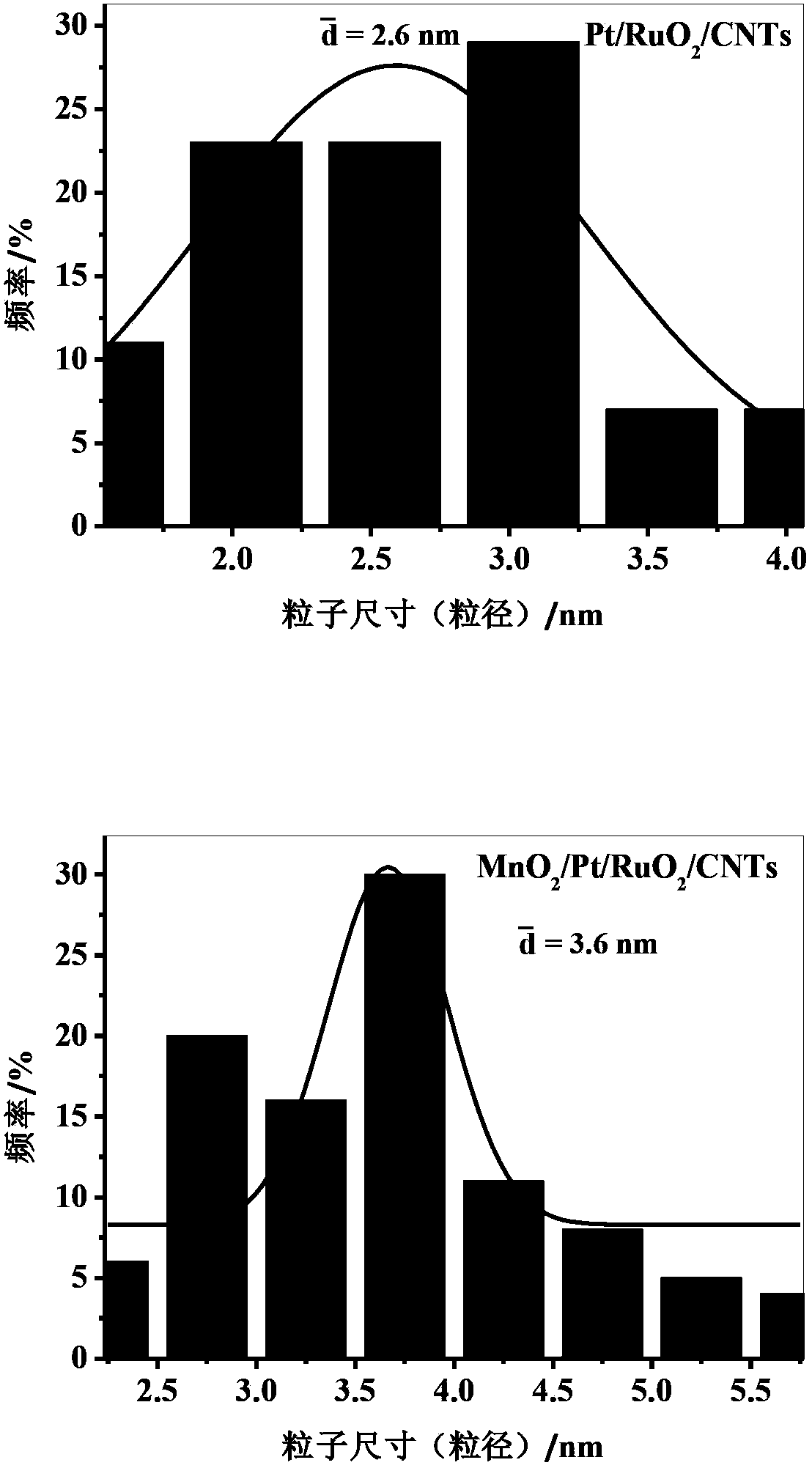

[0062] Step 1: Carbon nanotubes (CNTs) were dispersed in ruthenium trichloride aqueous solution by sonication, wherein the mass ratio of CNTs to ruthenium was in the range of 1:0.02, and the sonication time was 0.5 hours. Hydrogen peroxide (30% (volume)) was added dropwise at a rate of 9 mL / h, and the ratio of the volume of hydrogen peroxide (30% (volume)) to the mass of ruthenium was 1 ml: 1 mg. The suspension was refluxed for 3 hours at a temperature of 60°C. After filtering, washing and drying at a temperature of 90 °C, carbon nanotubes loaded with ruthenium dioxide (RuO 2 / CNTs complex).

[0063] Step 2: Incorporate the RuO 2 / CNTs were dispersed into ethylene glycol added with chloroplatinic acid, in which the mass ratio of ruthenium to platinum to ethylene glycol was 1:0.5:200. The pH value of the suspension was adjusted to 6.5, and then the suspension was heated and refluxed at a temperature of 90° C. for 1.5 hours. After filtering, washing and drying at a temperatu...

Embodiment 2

[0066] Step 1: Carbon nanotubes (CNTs) were dispersed in ruthenium trichloride aqueous solution by sonication, wherein the mass ratio of CNTs to ruthenium was in the range of 1:0.04, and the sonication time was 1 hour. Hydrogen peroxide (30% (volume)) was added dropwise at a rate of 12 ml / h, and the ratio of the volume of hydrogen peroxide (30% (volume)) to the mass of ruthenium was 1.3 ml: 1 mg. The suspension was refluxed for 4 hours at a temperature of 80°C.

[0067] After filtering, washing and drying at a temperature of 100 °C, carbon nanotubes loaded with ruthenium dioxide (RuO 2 / CNTs complex).

[0068] Step 2: RuO 2 / CNTs were dispersed into ethylene glycol added with chloroplatinic acid, in which the mass ratio of ruthenium to platinum to ethylene glycol was 1:1:250. The pH value of the suspension was adjusted to 8, and then the suspension was heated and refluxed at a temperature of 130° C. for 2 hours. After filtering, washing and drying at a temperature of 70 °C...

Embodiment 3

[0072] Step 1: Carbon nanotubes (CNTs) were dispersed in ruthenium trichloride aqueous solution by sonication, wherein the mass ratio of CNTs to ruthenium was in the range of 1:0.08, and the sonication time was 2 hours. Add hydrogen peroxide (30% (volume)) dropwise at a rate of 15 mL / h, and the ratio of the volume of hydrogen peroxide (30% (volume)) to the mass of ruthenium is 1.5 mL: 1 mg. The suspension was refluxed for 4.5 hours at a temperature of 85°C. After filtering, washing and drying at a temperature of 110 °C, carbon nanotubes loaded with ruthenium dioxide (RuO 2 / CNTs complex).

[0073] Step 2: RuO 2 / CNTs were dispersed into ethylene glycol added with chloroplatinic acid, in which the mass ratio of ruthenium to platinum to ethylene glycol was 1:1.2:270. The pH value of the suspension was adjusted to 8.5, and then the suspension was heated and refluxed at a temperature of 135° C. for 2.5 hours. After filtering, washing and drying at a temperature of 75 °C, the R...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com