High activity methanol-resistance direct methanol fuel cell cathode catalyst and production method thereof

A technology for methanol fuel cells and cathode catalysts, applied in battery electrodes, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. Difficulties and other problems, to achieve the effect of performance improvement, stability improvement, and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Ultrasonic dispersion of carbon nanotubes, ferric chloride, chloroplatinic acid aqueous solution in ethylene glycol analytical grade, wherein the mass ratio of platinum (Pt): iron (Fe): carbon nanotubes: ethylene glycol is 1:0.1:8.4 : 2800, the ultrasonic time is 1h, the pH value is adjusted to 7, the mixture is refluxed at 125°C for 2h, then filtered, washed 3 times, and vacuum-dried at 65°C to obtain PtFe / CNTs;

[0032]Disperse the PtFe / CNTs prepared in step (1) in ethylene glycol analytical grade, ultrasonically disperse, and add copper sulfate, wherein the mass ratio of platinum (Pt): copper (Cu): ethylene glycol is 1:0.1:2800 , adjusted the pH value to 7, refluxed at 125°C for 2h, then filtered, washed three times, and dried in vacuum at 65°C to obtain Cu / PtFe / CNTs.

Embodiment 2

[0034] Ultrasonic dispersion of carbon nanotubes, ferric chloride, and chloroplatinic acid aqueous solution in analytically pure ethylene glycol, wherein the mass ratio of platinum (Pt): iron (Fe): carbon nanotubes: ethylene glycol is 1:0.2:8.4 : 3000, the ultrasonic time is 2h, the pH value is adjusted to 7.5, the mixture is refluxed at 130°C for 2.5h, then filtered, washed 4 times, and vacuum-dried at 70°C to obtain PtFe / CNTs;

[0035] Disperse the PtFe / CNTs prepared in step (1) in ethylene glycol analytical grade, ultrasonically disperse, and add copper sulfate, wherein the mass ratio of platinum (Pt): copper (Cu): ethylene glycol is 1:0.2:3000 , adjusted the pH value to 7.5, refluxed at 130°C for 2.5h, then filtered, washed 4 times, and dried in vacuum at 70°C to obtain Cu / PtFe / CNTs.

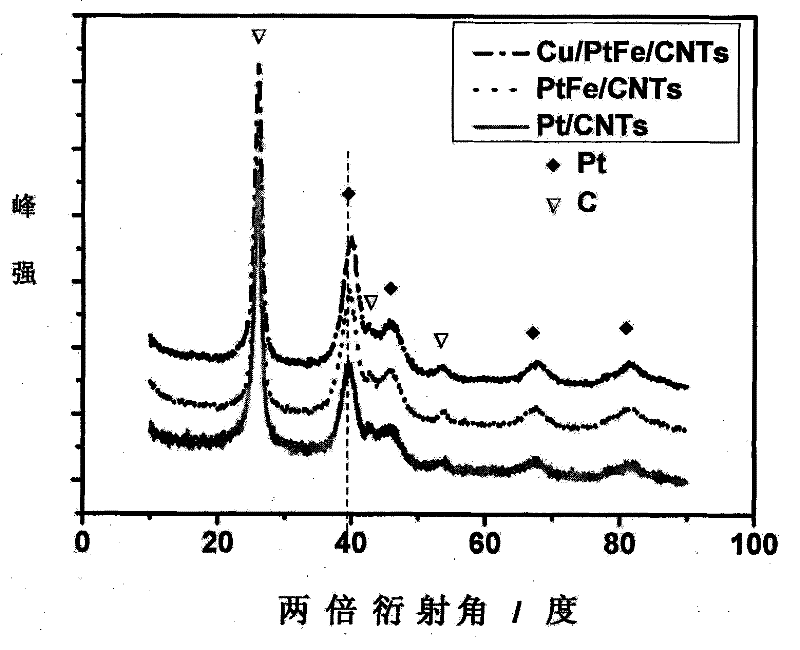

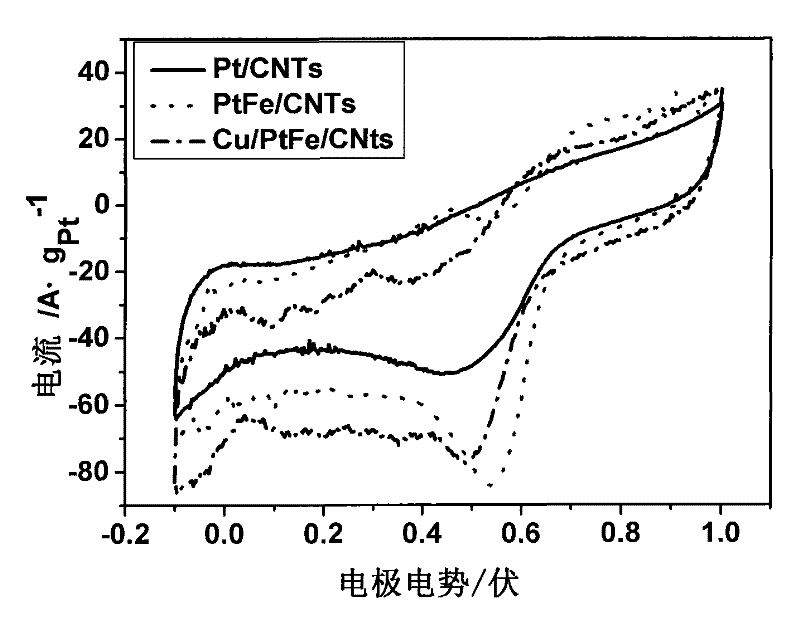

[0036] The XRD patterns of the thus prepared PtFe / CNTs, Cu / PtFe / CNTs catalysts and Pt / CNTs catalysts (for comparison) are shown in figure 2 As shown, it can be seen from the figure that Pt...

Embodiment 3

[0038] Ultrasonic dispersion of carbon nanotubes, ferric chloride, and chloroplatinic acid aqueous solution in ethylene glycol analytically pure, wherein the mass ratio of platinum (Pt): iron (Fe): carbon nanotubes: ethylene glycol is 1:0.29:8.4: 3500, the ultrasonic time is 3h, and the pH value is adjusted to 7.5. The mixture is refluxed at 140°C for 2h, then filtered, washed 5 times, and vacuum-dried at 70°C to obtain PtFe / CNTs;

[0039] Disperse the PtFe / CNTs prepared in step (1) in ethylene glycol of analytical grade, ultrasonically disperse, add copper sulfate, wherein the mass ratio of platinum (Pt): copper (Cu): ethylene glycol is 1:0.45:3500, Adjust the pH value to 7.5, reflux at 140°C for 3h, then filter, wash 5 times, and vacuum-dry at 70°C to prepare Cu / PtFe / CNTs.

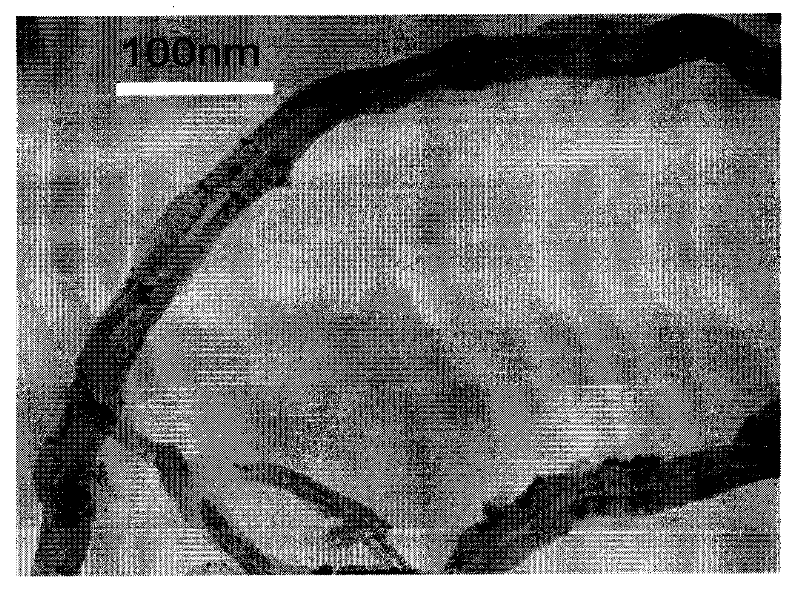

[0040] The transmission electron micrographs of the Cu / PtFe / CNTs catalyst thus prepared are as follows: figure 1 As shown, it can be seen from the figure that the supported catalyst prepared by the pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com