Triatomic-scale dispersed metal cluster loaded nitrogen-doped nano carbon fuel cell catalyst

A technology of nitrogen-doped nano-carbon and metal clusters, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of fuel cell catalysts that have not been reported publicly, and achieve excellent catalytic activity and stability of oxygen reduction reaction, The effect of good reproducibility and excellent oxygen reduction activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

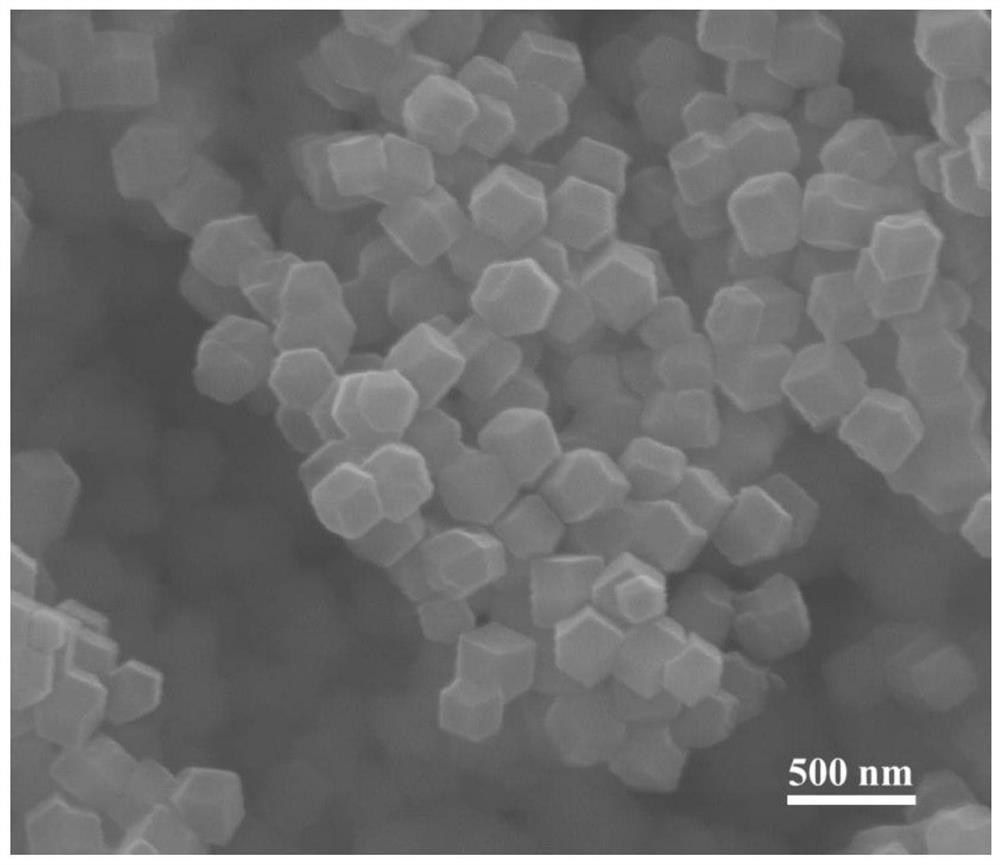

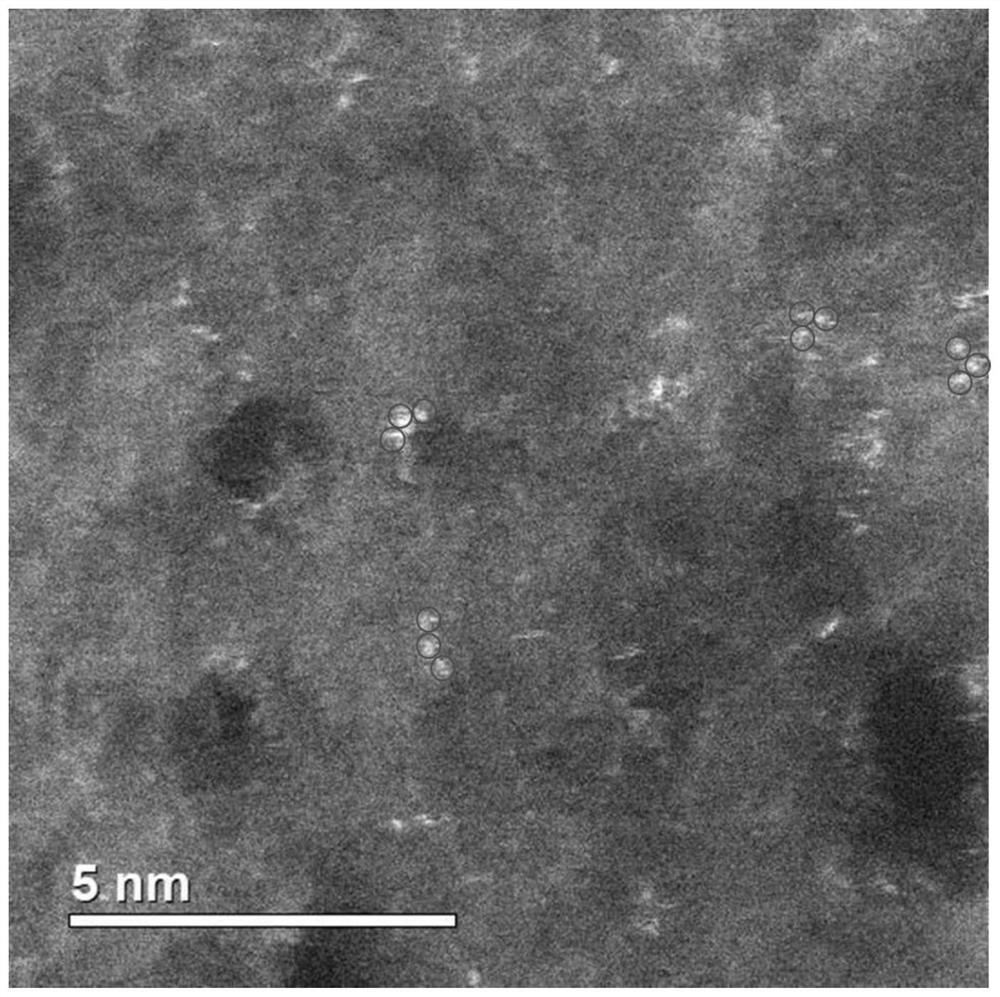

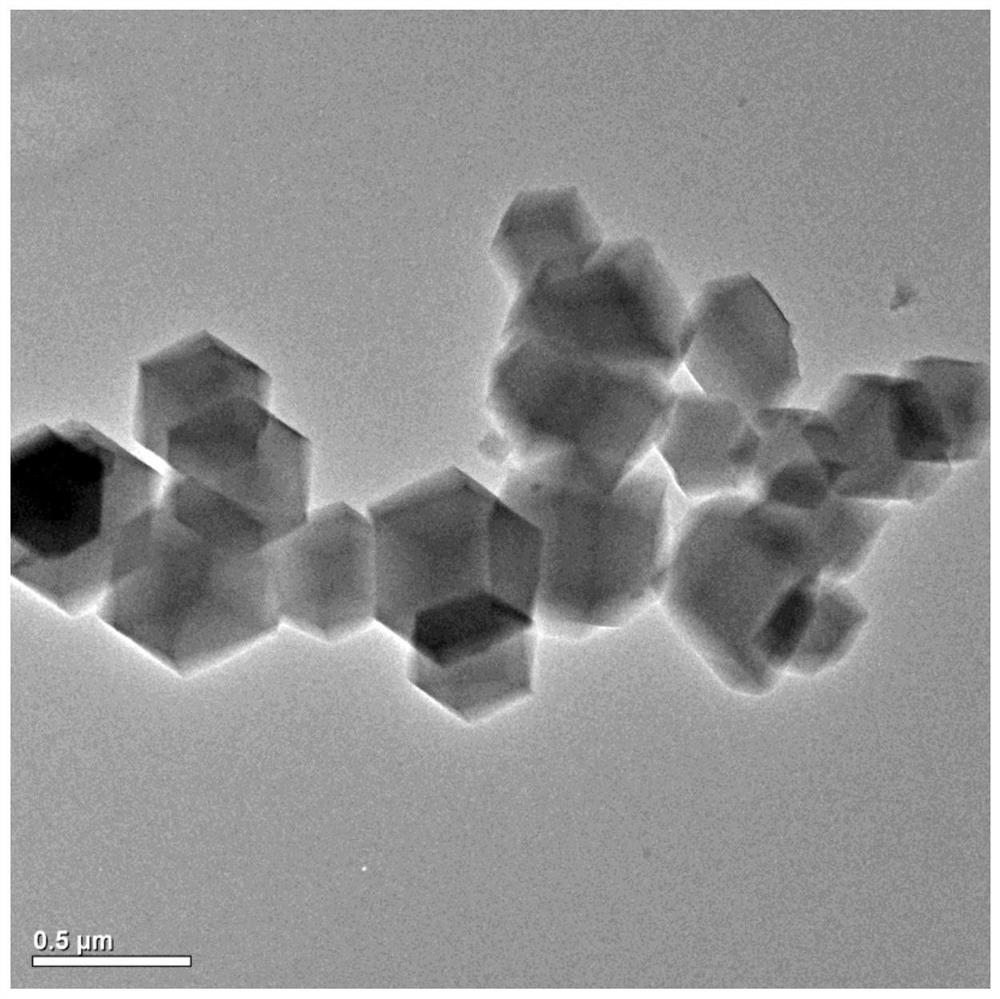

[0031] Measure tetrahydrofuran (THF) 2mL, methanol (CH 3 OH) 4mL and stir well. After that, weigh the iron dodecacarbonyl (Fe 3 (CO) 12 ) crystals (purchased from Alfa Aesar) 15.1mg, Zn(NO 3 ) 2 ·6H 2 O (purchased from Shanghai Xinping Fine Chemical Co., Ltd.) 238mg dissolved in the above THF+CH 3 OH in a mixed solvent, and sonicated at 60°C for 1 h to obtain a clear solution A. Measure 1.2 mL of N,N-dimethylformamide (DMF), methanol (CH 3 OH) 0.8mL and mix well. Weigh 263 mg of 2-methylimidazole and dissolve in the above DMF+CH 3 OH solvent, then added to solution A, and stirred evenly to obtain solution B. The solution B was transferred to a hydrothermal reactor and reacted at 120°C for 4 hours, the product was taken out and then centrifuged, and then separated in THF and CH 3Washed 3 times and 2 times in OH, dried and taken out to obtain Fe 3 (CO) 12 @ZIF-8. Then put it in a muffle furnace at 800°C under H 2 (5%) / Ar mixed atmosphere and calcined for 2 hours. ...

Embodiment 2

[0034] By the same operation as in Example 1, just adjust the metal type of the triatomic metal cluster in the catalyst, specifically as follows:

[0035] Measure tetrahydrofuran (THF) 2mL, methanol (CH 3 OH) 4mL and stir well. Then weigh nonacarbonyl carbon tricobalt Co 3 (CO) 9 C crystals (purchased from Alfa Aesar) 9.7mg, Zn(NO 3 ) 2 ·6H 2 O (purchased from Shanghai Xinping Fine Chemical Co., Ltd.) 238mg dissolved in the above THF+CH 3 OH in a mixed solvent, and sonicated at 60°C for 1 h to obtain a clear solution A. Measure 1.2 mL of N,N-dimethylformamide (DMF), methanol (CH 3 OH) 0.8mL and mix well. Weigh 263 mg of 2-methylimidazole and dissolve in the above DMF+CH 3 OH solvent, then added to solution A, and stirred evenly to obtain solution B. The solution B was transferred to a hydrothermal reactor and reacted at 120°C for 4 hours, the product was taken out and then centrifuged, and then separated in THF and CH 3 OH washed 3 times and 2 times, dried and taken...

Embodiment 3

[0038] According to the same operation as in Example 1, just adjust the type of MOFs in the metal cluster catalyst dispersed at the triatomic level and adjust the corresponding synthesis process, as follows:

[0039] Measure tetrahydrofuran (THF) 2mL, methanol (CH 3 OH) 4mL and stir well. After that, weigh the iron dodecacarbonyl (Fe 3 (CO) 12 ) crystals (purchased from Alfa Aesar) 15.1mg, Zn(NO 3 ) 2 ·6H 2 O (purchased from Shanghai Xinping Fine Chemicals Co., Ltd.) 238mg and terephthalic acid 32.4mg were dissolved in the above THF+CH 3 In a mixed solvent of OH, a clear solution A was obtained. Measure 50.0 mL of N,N-dimethylformamide (DMF) and 263 mg of 2-methylimidazole, mix them and add to solution A, then transfer to a hydrothermal reaction kettle and react at 130°C for 4 hours, take out The product is then centrifuged, washed 3 times in DMF, dried, and taken out to obtain Fe 3 (CO) 12 @MOF-5. Then put it in a muffle furnace at 800°C under H 2 (5%) / Ar mixed atm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com