Fuel cell electrocatalyst and preparation method and application thereof

An electrocatalyst and fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as the requirement for the amount of precursors and carriers used, the difficulty in controlling the particle size of alloy particles, and the complicated steps of the chemical reduction method, etc., to achieve excellent Oxygen Reduction Activity, Rapid Preparation, Ease of Handling Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

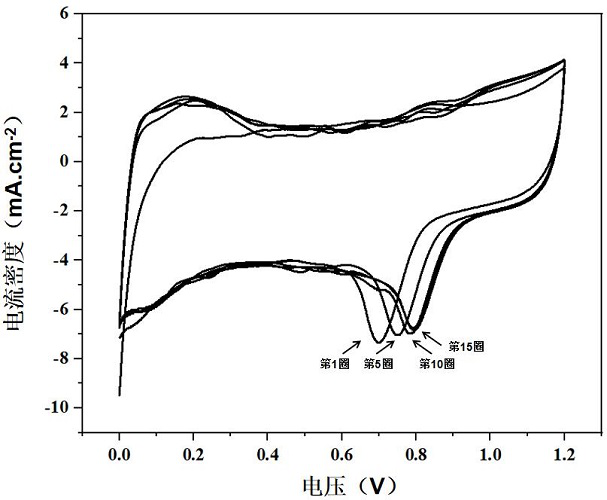

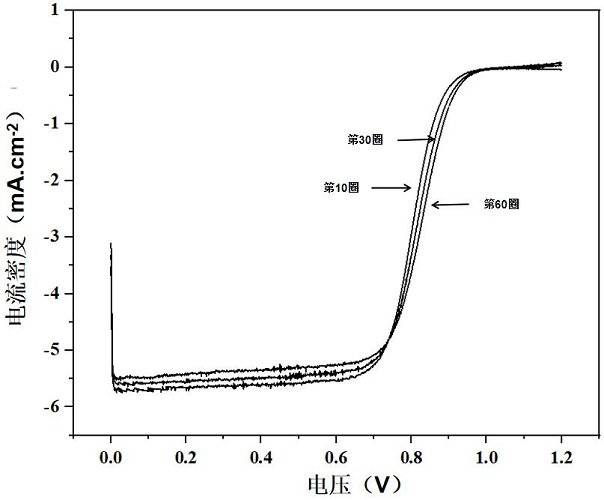

[0027] (1) Dissolve 1418mg of 2-methylimidazole in 180ml of methanol to obtain solution A, dissolve 1220mg of zinc nitrate hexahydrate and 30mg of ferric nitrate nonahydrate in 180ml of methanol to obtain solution B, and ultrasonicate solution A and solution B for half an hour respectively It is evenly dispersed; then pour solution A into solution B and sonicate for 3 minutes, then transfer the mixed solution to a hydrothermal kettle, and perform a hydrothermal reaction at 120°C in a blast oven for 6 hours; after the hydrothermal reaction, pour the solution into a centrifuge tube, Centrifuge and wash with methanol three times at 12000rpm for 5min. Put the obtained precipitate in a blast drying oven at 60°C for 12h. Pour the dried sample into a mortar and grind it thoroughly to obtain about 300mg of light yellow powder. Pour the powder into Porcelain boat, placed in the quartz tube of tube furnace, heat treated under nitrogen protection, raised to 1000°C at a rate of 5°C / min, an...

Embodiment 2

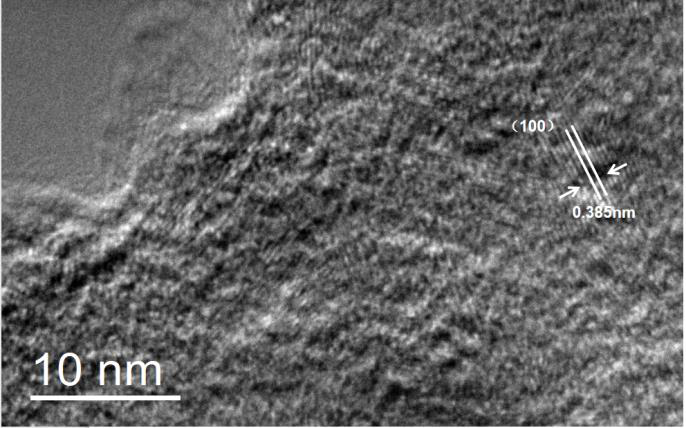

[0032] The difference between this embodiment and embodiment 1 is: the volume of adding chloroplatinic acid solution in step 2 is respectively 1.24ml, 2.48ml, 4.96ml, 9.92ml, from Figure 4 It can be seen from the TEM picture that the reduced Pt forms Pt with the transition metal Fe in the carrier. 3 Fe alloy.

Embodiment 3

[0034] The difference between this example and Example 1 is: Potassium chloroplatinate is used in step 2, the volume of potassium chloroplatinate is 6.42ml, and the concentration of Pt is 3.77mg / ml.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com