Preparation method and application of Zn/Co-N-C carbon nanotube oxygen reduction catalyst for autocatalytic growth

A carbon nanotube and catalyst technology, applied in the field of electrochemical energy, can solve the problems of high price, scarce reserves, poor cycle stability, etc., and achieve high power density, excellent oxygen reduction activity, and good cycle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

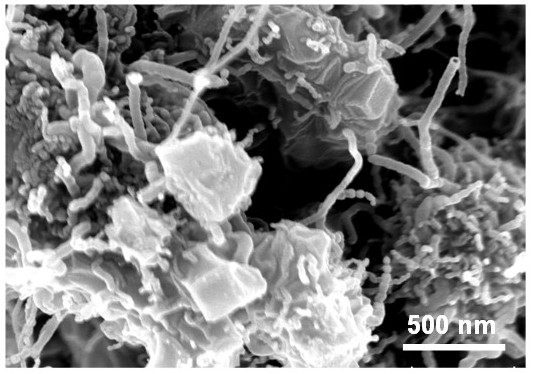

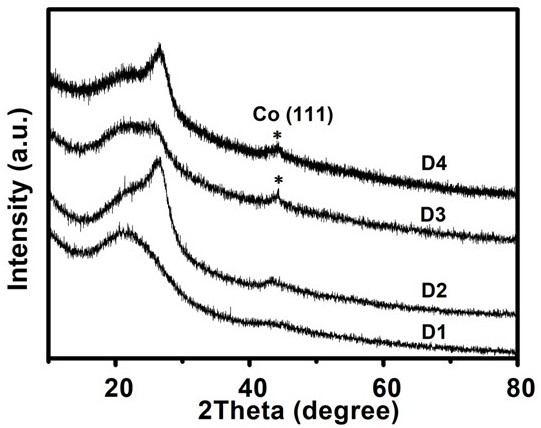

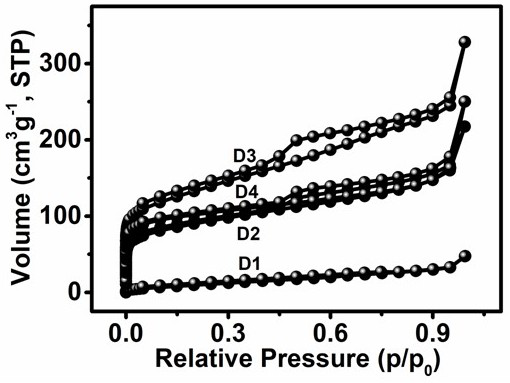

Image

Examples

Embodiment 1

[0033] Step S1: Disperse 6.5g of 2-methylimidazole into 100mL of methanol, ultrasonicate for 5min to obtain a uniform solution A, disperse 3g of zinc nitrate hexahydrate into 50mL of methanol, ultrasonically for 5min to obtain a uniform solution B, and then dissolve solution B quickly Pour into solution A and stir at room temperature for 24 hours to obtain material A1;

[0034] Step S2: Centrifuge material A1 at a rotational speed of 10000 r / min, wash with methanol three times, and then vacuum dry at 80° C. for 6 hours to obtain material B1;

[0035] Step S3: Transfer the material B2 to a corundum boat and place it in a tube furnace. In an inert gas atmosphere, first raise the temperature from room temperature to 300°C for 55 minutes and keep it for 60 minutes, then raise the temperature to 900°C at a rate of 5°C / min. Keep for 180min, then naturally cool to room temperature to obtain material C1;

[0036] Step S4: Transfer the material C1 into a hydrochloric acid solution wit...

Embodiment 2

[0038] Step S1: Disperse 6.5g of 2-methylimidazole in 100mL of methanol, ultrasonicate for 5min to obtain uniform solution A, disperse 3g of zinc nitrate hexahydrate and 0.2g of graphene oxide in 50mL of methanol, ultrasonicate for 5min to obtain uniform solution B , then quickly pour solution B into solution A and stir at room temperature for 24 hours to obtain material A2;

[0039] Step S2: Centrifuge the material A2 at a speed of 10,000 r / min, wash it three times with methanol, and then vacuum-dry it at 80° C. for 6 hours to obtain material B2;

[0040] Step S3: Transfer the material B2 to a corundum boat and place it in a tube furnace. In an inert gas atmosphere, first raise the temperature from room temperature to 300°C for 55 minutes and keep it for 60 minutes, then raise the temperature to 900°C at a rate of 5°C / min. Keep for 180min, then naturally cool to room temperature to obtain material C2;

[0041] Step S4: Transfer the material C2 to a 2M hydrochloric acid solut...

Embodiment 3

[0043] Step S1: Disperse 6.5g of 2-methylimidazole into 100mL of methanol, ultrasonicate for 5min to obtain a uniform solution A, disperse 3g of zinc nitrate hexahydrate and 0.514g of cobalt(III) acetylacetonate into 50mL of methanol, and ultrasonicate for 5min to obtain a uniform solution B, then quickly pour solution B into solution A and stir at room temperature for 24 hours to obtain material A3;

[0044] Step S2: Centrifuge the material A3 at a rotation speed of 10,000 r / min, wash with methanol three times, and then vacuum-dry at 80° C. for 6 hours to obtain material B3;

[0045] Step S3: Transfer material B3 to a corundum boat and place it in a tube furnace. In an inert gas atmosphere, first raise the temperature from room temperature to 300°C for 55 minutes and keep it for 60 minutes, then raise the temperature to 900°C at a heating rate of 5°C / min. Keep for 180min, then naturally cool to room temperature to obtain material C3;

[0046] Step S4: Transfer the material C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com