Preparation method of Co-N/CNTs catalytic material, catalytic material obtained through preparation method and application of Co-N/CNTs catalytic material

A catalytic material, co-n technology, applied in biochemical fuel cells, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of slow reaction kinetics, restricted MFC performance, insufficient ORR catalyst performance, etc., to achieve easy synthesis , Improve catalytic activity and stability, good oxygen reduction activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

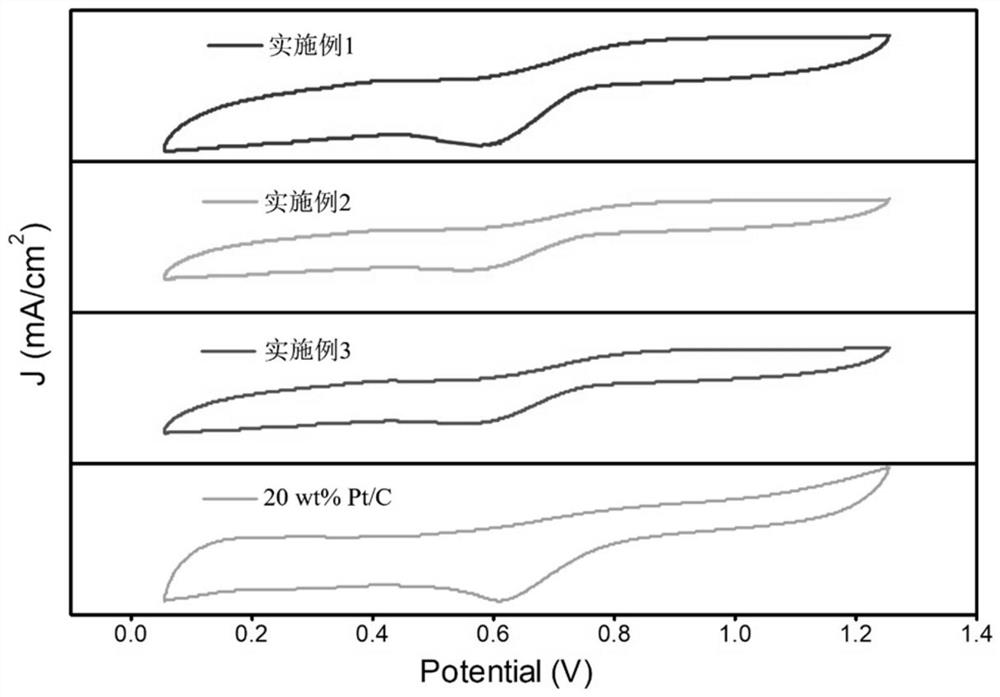

Embodiment 1

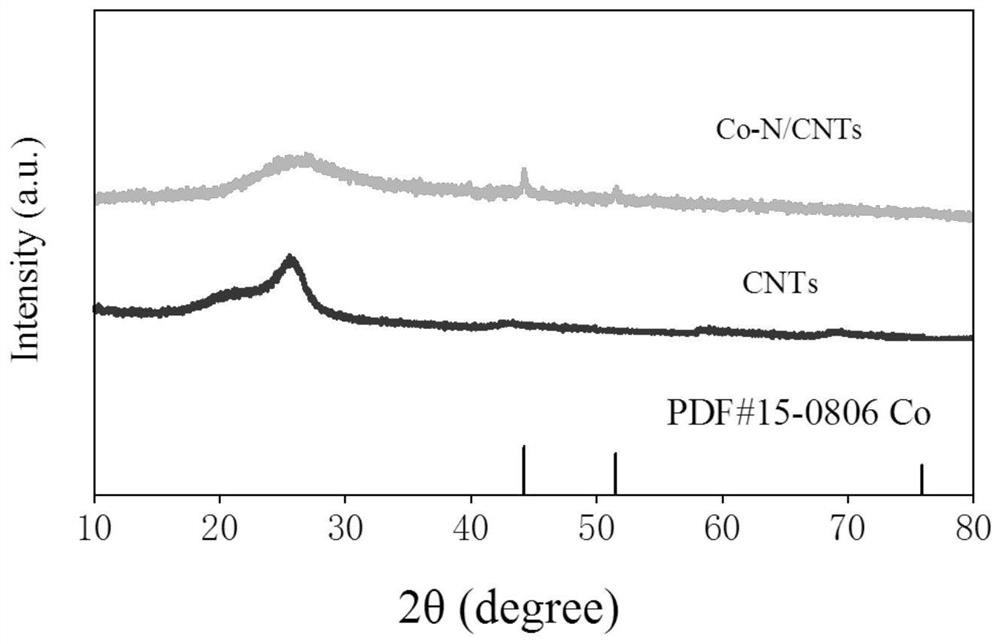

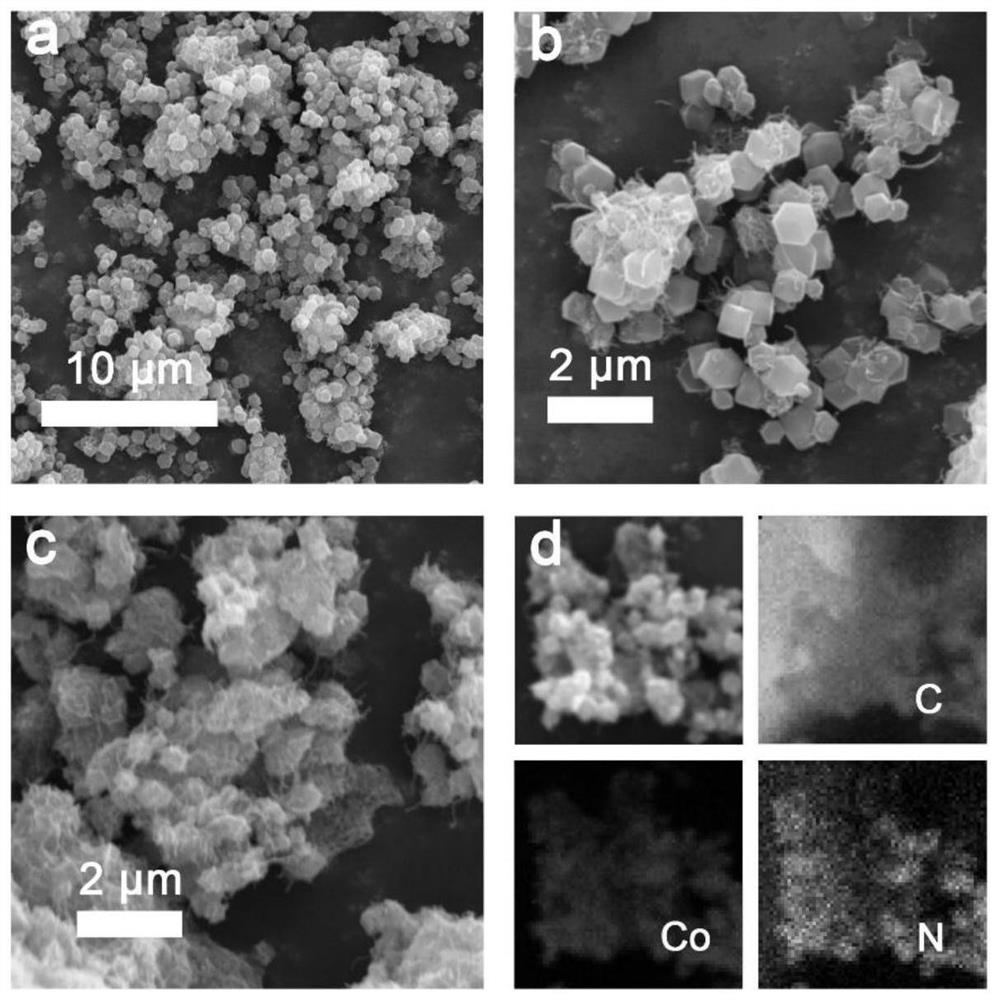

[0031] A kind of synthetic method of the catalytic material of Co-N / CNTs, comprises the following steps:

[0032] (1) Synthesis of ZIF-67 / CNT: 35 mg of carboxylated multi-walled carbon nanotubes and 175 mg of polyvinylpyrrolidone with a molecular weight of 10,000 were dissolved in 25 mL of methanol and ultrasonically oscillated for 0.5 h;

[0033] (2) Add 222 mg of cobalt chloride to the carbon nanotube dispersion obtained in step (1), and continue stirring for 1 hour;

[0034] (3) Dissolve 765mg of organic ligand 2-methylimidazole in 25mL of methanol solution, then add dropwise into the above mixed solution, then put it into a high-temperature reactor at 100°C, and react for 24h;

[0035] (4) The obtained product was filtered and washed several times with methanol and deionized water, then dried and ground to obtain a powder;

[0036] (5) The precursor powder prepared in step (4) was carbonized at 800°C for 2 hours under an inert atmosphere, and the heating rate was 5°C·min ...

Embodiment 2

[0041] A kind of synthetic method of the catalytic material of Co-N / CNTs, comprises the following steps:

[0042] (1) Synthesis of ZIF-67 / CNT: 35 mg of carboxylated multi-walled carbon nanotubes and 140 mg of polyvinylpyrrolidone with a molecular weight of 10,000 were dissolved in 35 mL of methanol and ultrasonically oscillated for 2.0 h;

[0043] (2) Add 222 mg of cobalt chloride to the carbon nanotube dispersion obtained in step (1), and continue stirring for 1 hour;

[0044] (3) Dissolve 560 mg of organic ligand 2-methylimidazole in 35 mL of methanol solution, then add it dropwise to the above mixed solution, and then put it in a high-temperature reactor at 100 ° C for 36 hours;

[0045] (4) The obtained product was filtered and washed several times with methanol and deionized water, then dried and ground to obtain a powder;

[0046] (5) The precursor powder prepared in step (4) was carbonized at 700 °C for 3 hours under an inert atmosphere, and the heating rate was 2.5 °C...

Embodiment 3

[0048] A kind of synthetic method of the catalytic material of Co-N / CNTs, comprises the following steps:

[0049] (1) Synthesis of ZIF-67 / CNT: 35 mg of carboxylated multi-walled carbon nanotubes and 105 mg of polyvinylpyrrolidone with a molecular weight of 10,000 were dissolved in 40 mL of ethanol and ultrasonically oscillated for 0.5 h;

[0050] (2) Add 222 mg of cobalt chloride to the carbon nanotube dispersion obtained in step (1), and continue stirring for 1 hour;

[0051] (3) Dissolve 315 mg of organic ligand 2-methylimidazole in 40 mL of methanol solution, then add it dropwise to the above mixed solution, and then put it in a high-temperature reactor at 110 ° C for 36 hours;

[0052] (4) The obtained product was filtered and washed several times with methanol and deionized water, then dried and ground to obtain a powder;

[0053] (5) The precursor powder prepared in step (4) was carbonized at 600°C for 4 hours under an inert atmosphere, and the heating rate was 1°C·min ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com