Preparation method of iron-phosphorus oxynitride applied to zinc-air battery and fuel battery

A technology for fuel cells and zinc-air batteries, applied in iron compounds, nitrogen compounds, battery electrodes, etc., can solve problems such as unstable performance, accelerate the promotion and application of fuel cells and zinc-air batteries, and expensive Pt catalysts. Low, conducive to large-scale development and utilization, excellent oxygen reduction activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

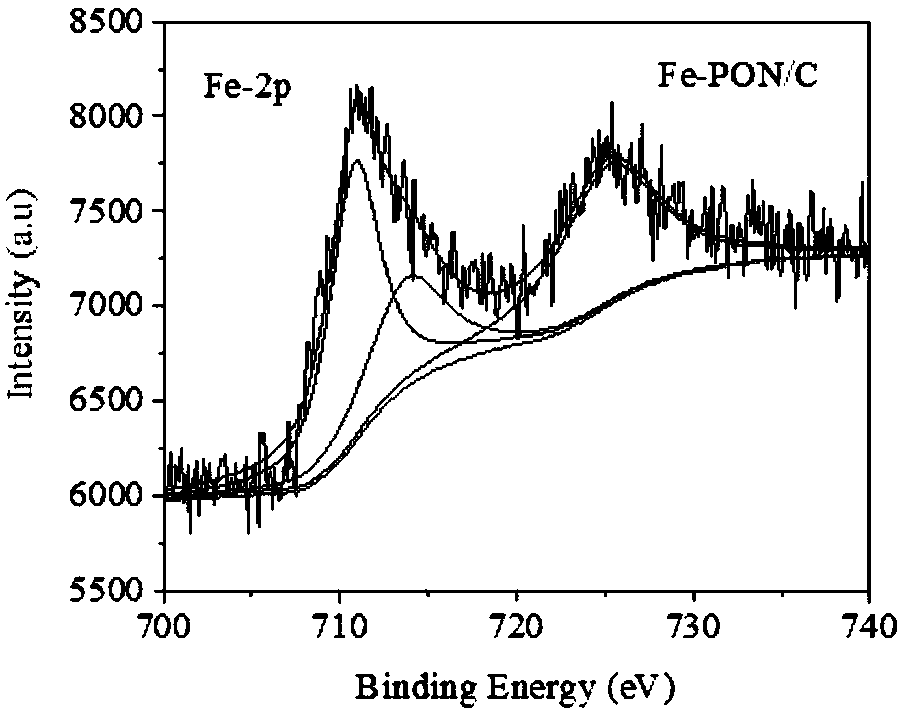

Image

Examples

Embodiment 1

[0034] Step 1: At room temperature, add 0.25g of ferric acetate to quantitative phytic acid and ultrasonically dissolve all the metal salts; then add excess acetone to the solution to produce metal colloid precipitation, finally pour out the solvent, and wash the metal colloid with acetone repeatedly for 3 times . In the second step, the metal glue obtained in the first step was transferred to the porcelain boat of the tube furnace, and the temperature was raised to 800°C in an argon atmosphere, then kept at a constant temperature for 2 hours, and finally cooled down to room temperature naturally. The third step is to fully grind the sample obtained in the previous step, transfer it to a single-necked flask, add excess hydrochloric acid, then sonicate until uniform, and then reflux for 24 hours. The solid was isolated by suction filtration and washed with a large amount of deionized water until neutral, and the solid was vacuum-dried at 80° C. for several hours. The fourth st...

Embodiment 2

[0041] The first step, at room temperature, add 0.1g of ferric acetate to quantitative phytic acid and ultrasonically dissolve all the metal salts; then add excess acetone to the solution to produce metal colloid precipitation, finally pour out the solvent, and wash the metal colloid with acetone repeatedly for 3 times . In the second step, the metal glue obtained in the first step was transferred to the porcelain boat of the tube furnace, and the temperature was raised to 700°C in an argon atmosphere, then kept at a constant temperature for 2 hours, and finally cooled down to room temperature naturally. The third step is to fully grind the sample obtained in the previous step, transfer it to a single-necked flask, add excess hydrochloric acid, then sonicate until uniform, and then reflux for 20 hours. The solid was isolated by suction filtration and washed with a large amount of deionized water until neutral, and the solid was vacuum-dried at 80° C. for several hours. The fi...

Embodiment 3

[0043] The first step, at room temperature, add 0.1g of ferric acetate to quantitative phytic acid and ultrasonically dissolve all the metal salts; then add excess acetone to the solution to produce metal colloid precipitation, finally pour out the solvent, and wash the metal colloid with acetone repeatedly for 3 times . In the second step, the metal glue obtained in the first step is transferred to the porcelain boat of the tube furnace, and the temperature is raised to 1000°C in an argon atmosphere, then kept at a constant temperature for 2 hours, and finally cooled down to room temperature naturally. The third step is to transfer the obtained solid to the porcelain boat in the tube furnace, raise the temperature to 1000°C at 5°C / min under an argon atmosphere, then pass through ammonia gas, keep the constant temperature for several hours, finally turn off the ammonia gas and The argon gas was adjusted back to the original flow rate, and the iron phosphorus oxynitride was obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Limiting current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com