Oxygen reduction catalyst and preparation method thereof

A catalyst and solvent technology, which is applied in the field of oxygen reduction catalyst and its preparation, can solve the problems of restricting the commercialization process of low-temperature fuel cells, high price, and shortage of resources, and achieve the effect of improving the catalytic performance of oxygen reduction and improving the half-wave point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a preparation method of an oxygen reduction catalyst, comprising the steps of:

[0026] Mixing the carbon carrier and the solvent to obtain a carbon carrier suspension;

[0027] After mixing uric acid, iron salt and the carbon carrier suspension, the solvent is removed to obtain a solid mixture;

[0028] Under an inert atmosphere, the solids are mixed and calcined to obtain an oxygen reduction catalyst.

[0029] The invention mixes the carbon carrier and the solvent to obtain the carbon carrier suspension. In the present invention, the carbon carrier is preferably one, two or three of conductive carbon black, carboxylated multi-walled carbon nanotubes (pioneer nano) and graphene oxide (ACS material); the conductive carbon The black is preferably one, two or three of the conductive carbon blacks whose product models are XC-72, KJ-600 and BP-2000. In the present invention, the solvent is preferably one or more of methanol, ethanol, acetone and wa...

Embodiment 1

[0038] Add 40mg of conductive carbon black whose product model is XC-72 to 20ml of methanol solvent, and disperse ultrasonically for 30 minutes with a power of 500W and a working frequency of 40KHz to obtain a carbon carrier suspension.

[0039] 200mg uric acid, 40mgFeCl 3 ·6H 2 O salt was added to the above-mentioned carbon carrier suspension, ultrasonically dispersed for 30 minutes with a power of 500 W and a working frequency of 40 KHz, and the solvent was evaporated to obtain a solid mixture.

[0040] Under the protection of argon, the obtained solid mixture was heat-treated at 800°C for 3 hours to obtain a black powdery product, that is, Fe-N-C oxygen reduction catalyst, and its XPS spectrum is as follows: Figure 5 shown.

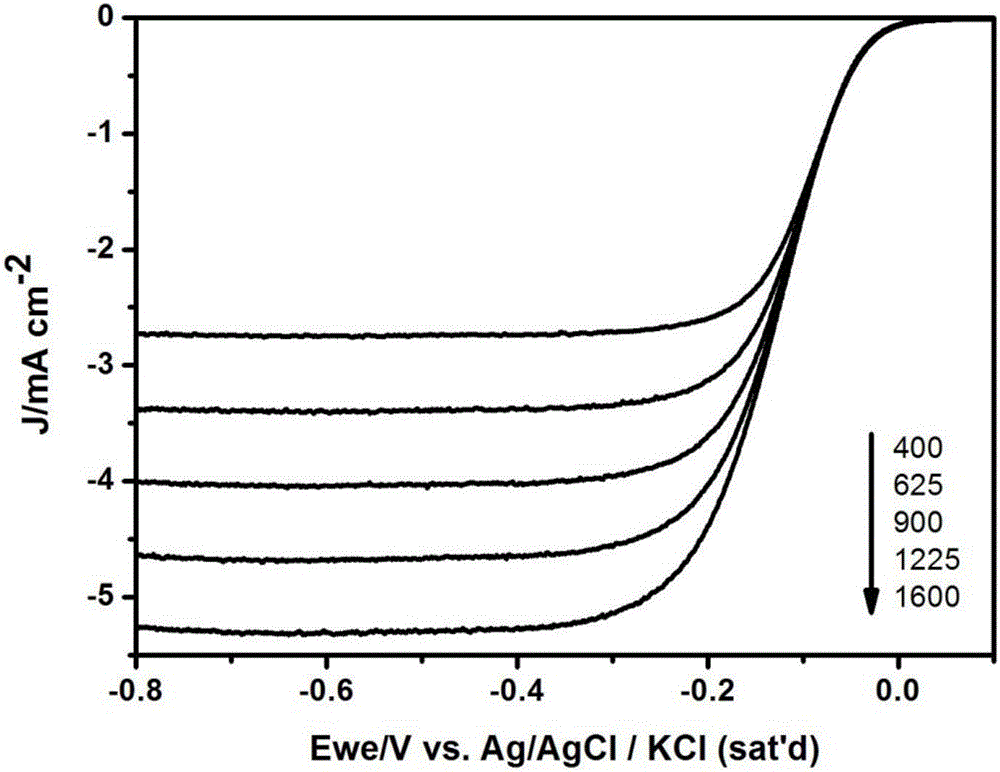

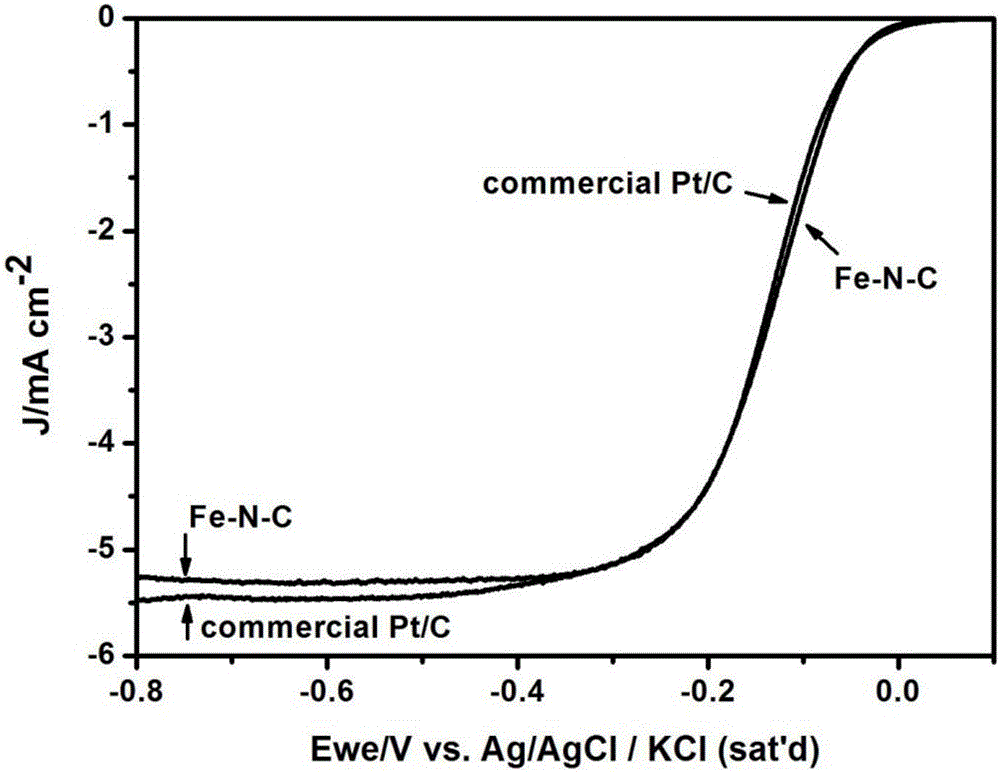

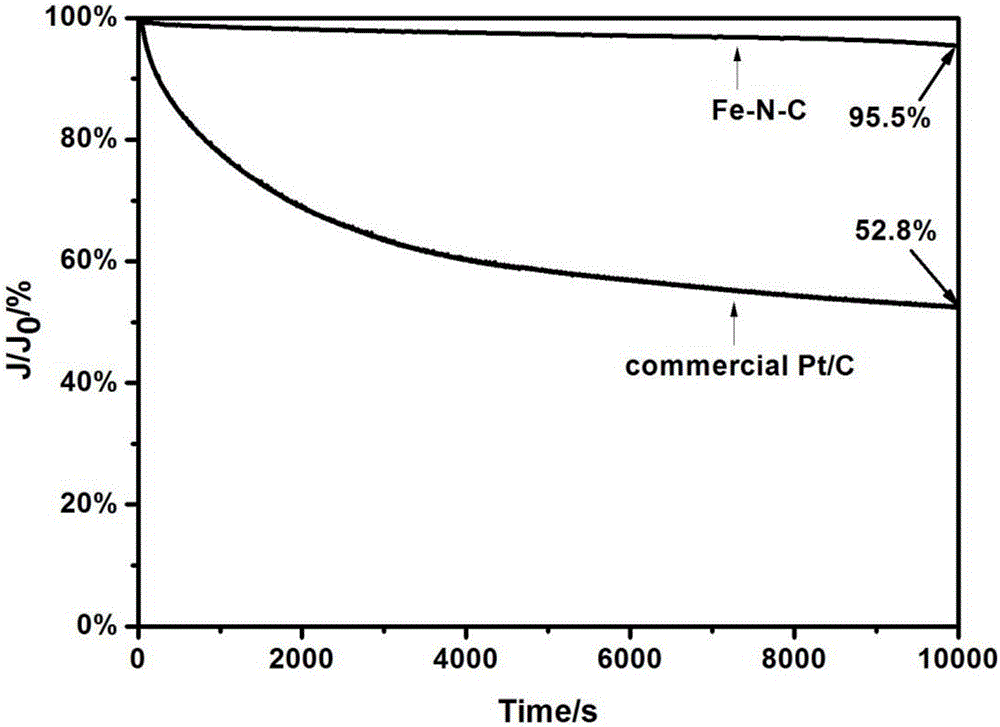

[0041] The present invention also tests the catalytic performance and stability of the Fe-N-C oxygen reduction catalyst obtained in this embodiment, and the test results are as follows Figure 1~3 shown.

[0042] figure 1 For the linear scanning ...

Embodiment 2

[0046] Add 60 mg of carboxylated multi-walled carbon nanotubes into 20 ml of ethanol solvent, and ultrasonically disperse for 20 minutes with a power of 400 W and a working frequency of 45 KHz to obtain a carbon carrier suspension.

[0047] 400mg uric acid, 40mgFeCl 2 The salt was added to the above-mentioned carbon carrier suspension, ultrasonically dispersed at a power of 400 W and a working frequency of 45 KHz for 20 minutes, and the solvent was evaporated to obtain a solid mixture.

[0048] The resulting solid mixture was heat-treated at 1000° C. for 1 h under the protection of nitrogen to obtain a black powdery product, namely Fe—N—C oxygen reduction catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com