A kind of triazine hyperbranched polyurea char-forming agent and preparation method thereof

A technology of hyperbranched polyurea char-forming agent, applied in the field of hyperbranched polyurea char-forming agent and its preparation, can solve the problems of difficult dispersion, harmful water resources, poor matrix compatibility, etc., and achieves good compatibility and char-forming. Good performance and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Take 20 parts of toluene diisocyanate and add 50 parts of acetone to dissolve it completely, then pour the solution into a three-necked flask, and at the same time add 30 parts of melamine into the three-necked flask. After fully stirring at a rotating speed of 20 min, 2 parts of triethylamine were added, and then the reaction was continued for 5 hours. Washing with 50 parts of N,N-dimethylformamide solvent for several times and then washing with water, drying the obtained solid at 100° C. for 8 hours to obtain a triazine hyperbranched polyurea char-forming agent.

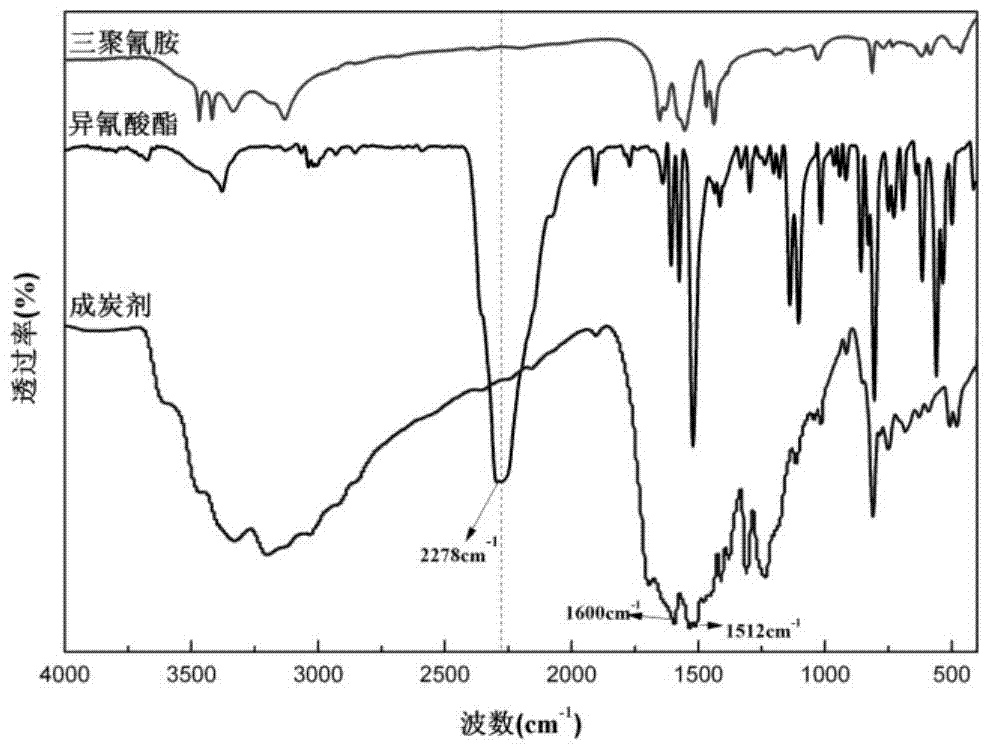

[0033] In the above-mentioned experimental process, the infrared spectrograms of the prepared triazine hyperbranched polyurea char-forming agent, melamine and isocyanate are as follows: figure 1 As shown, 1512cm -1 It is the vibration absorption peak of -NH-CO-NH-, 1600cm -1 It is the -C=O- vibration absorption peak in -NH-CO-NH-, and at 2278cm -1 The -NCO group vibration peak at 3300cm -1 -3500cm -1 -N...

Embodiment 2

[0035] Take 30 parts of 4,4'-diphenylmethane diisocyanate and add 50 parts of N,N-dimethylformyl to dissolve it completely, then pour the solution into a three-necked flask, and at the same time add 40 parts of melamine In the three-necked flask, under nitrogen atmosphere, after fully stirring at 80° C. at a speed of 150 r / min for 10 minutes, 3 parts of triethanolamine were added, and then the reaction was continued for 6 hours. Washing with water after washing with 70 parts of acetone solvent for several times, drying the obtained solid at 80° C. for 6 hours to obtain a triazine hyperbranched polyurea char-forming agent.

Embodiment 3

[0037] Take 35 parts of 2,4'-diphenylmethane diisocyanate and add 60 parts of N,N-diethylformamide to dissolve it completely, then pour the solution into a three-necked flask, and at the same time add 35 parts of melamine In the three-necked flask, under a nitrogen atmosphere, after fully stirring at 70° C. for 30 minutes at a speed of 120 r / min, 4 parts of triethanolamine were added, and then the reaction was continued for 7 hours. Washing with 60 parts of N,N-dimethylacetamide solvent for several times and then washing with water, drying the obtained solid at 70° C. for 6 hours to obtain a triazine hyperbranched polyurea char-forming agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com