Method for preparing ethylene carbonate from ethylene oxide and carbon dioxide

A technology of ethylene carbonate and ethylene oxide, which is used in the field of preparing ethylene carbonate from ethylene oxide and carbon dioxide, can solve the problems of low catalyst activity and easy loss of active components, and achieves the effect of high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Add 18.0 ml of 25% by weight concentrated ammonia water to a mixed solution of 80.0 ml of deionized water and 890.0 ml of ethanol (the molar ratio of ammonia to ethanol is 0.016, and the molar ratio of deionized water to ethanol is 0.29). In the presence of 40W ultrasonic waves, 41.6 g of tetraethyl orthosilicate (TEOS, the molar ratio of TEOS to ethanol is 0.013) was added dropwise to the mixed solution. After the dropwise addition, the ultrasonic treatment with the same power was continued for 3 hours, and then the precipitate was separated by centrifugation. After washing with deionized water, the resulting SiO 2 The nanospheres were re-dispersed ultrasonically in 200 ml of deionized water, and then 200 ml of an aqueous solution containing 3.3 g of polyethyleneimine (PEI, average molecular weight 1600) and 5.1 g of KCl (PEI and SiO 2 The weight ratio of nanospheres is 0.29, KCl and SiO 2 The weight ratio of nano-microspheres is 0.45). After stirring at 60°C for 4 ...

Embodiment 2

[0019] Add 285.0 ml of 25% by weight concentrated ammonia water to a mixed solution of 349.1 ml of deionized water and 81.0 ml of methanol (the molar ratio of ammonia to methanol is 1.9, and the molar ratio of deionized water to methanol is 9.7). In the presence of 400W ultrasonic waves, 30.4 g of methyl orthosilicate (TMOS, the molar ratio of TMOS to methanol is 0.1) was added dropwise to the mixed solution. After the dropwise addition, continue to use ultrasonic treatment with the same power for 3 hours, then centrifuge to separate the precipitate, wash with deionized water, and the obtained SiO 2 The nanospheres were re-dispersed ultrasonically in 200 ml of deionized water, and then 200 ml of an aqueous solution containing 0.13 g of polyethyleneimine (PEI, average molecular weight 16000) and 0.25 g of KCl (PEI and SiO 2 The weight ratio of nanospheres is 0.011, KCl and SiO 2 The weight ratio of nano-microspheres is 0.020). After stirring at 30°C for 0.5 hours, centrifugat...

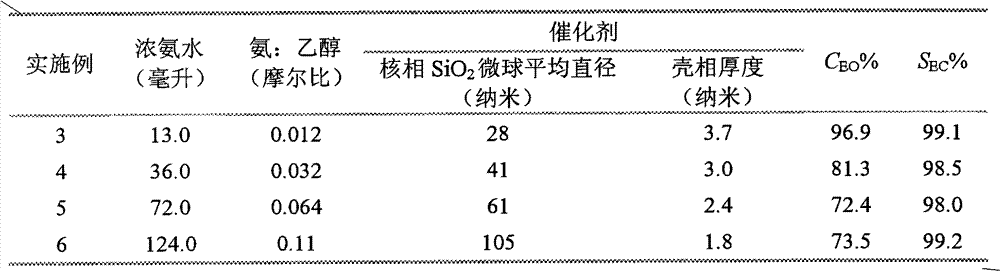

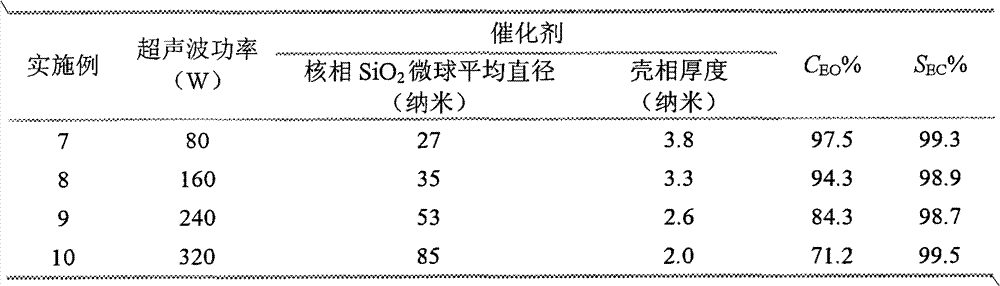

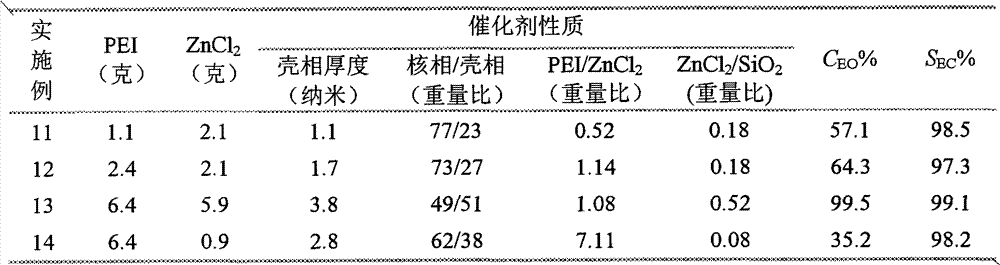

Embodiment 3~6

[0023] Change the amount of concentrated ammonia water used, the average molecular weight of the PEI used is 6600, all the other operating steps are the same as [Example 1], the core phase / shell phase weight ratio of the obtained core-shell catalyst, PEI and ZnCl 2 The weight ratio is consistent with [Example 1], the core phase SiO of the core-shell catalyst 2 The average diameter and thickness of the shell phase of the microspheres and the catalytic activity under the same conditions are listed in Table 1.

[0024] Table 1

[0025]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com